1. Introduction: What is FeCu Powder and Why It Matters for PM

FeCu powder, also known as iron-copper powder, is a key raw material used in the production of sintered parts through powder metallurgy (PM). In B2B manufacturing, especially in automotive, appliance, and industrial machinery sectors, FeCu powder offers a balance of strength, cost-efficiency, and machinability.

For buyers in the powder metallurgy supply chain—including wholesale distributors, OEMs, and PM component manufacturers—FeCu powder is a dependable choice for producing high-volume, precision-engineered components.

Why FeCu Powder is Crucial for B2B Manufacturing:

- Cost-Efficient Production: Enables near-net-shape manufacturing with minimal waste.

- High Machinability: Copper improves thermal conductivity and machining performance.

- Custom Alloying: Can be blended with other additives for specific performance needs.

- Scalable for Mass Production: Popular in automotive and machinery part production.

Shanghai Truer Technology Co., Ltd is a trusted provider of FeCu powders and other PM materials, specializing in customized blends and technical support for industrial buyers. Learn more about Truer’s powder metallurgy expertise here.

2. Industrial Applications of FeCu Powder

FeCu powder finds widespread applications across several industries due to its mechanical performance, thermal conductivity, and compatibility with various sintering processes.

Key Sectors Using FeCu Powder:

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Gears, bushings, connecting rods | Wear resistance, cost efficiency |

| Electrical | Switch parts, connectors | High conductivity |

| Industrial Machinery | Structural components, bearings | Dimensional stability |

| Home Appliances | Compressor parts, brackets | Noise dampening, corrosion resistance |

Why OEMs and Tier-1 Suppliers Prefer FeCu:

- Versatility in Design – Suitable for both structural and mechanical parts.

- Improved Density – Copper enhances the sintered density of parts.

- Reliable Performance – Enables consistent mechanical properties across batches.

Common FeCu Powder Grades Available:

- FC-0208 (Iron-copper blend)

- FD-0208 (Diffusion alloyed FeCu)

- FD-20Cu (High copper content for enhanced conductivity)

These grades are produced using water atomized or diffusion alloying methods, depending on the desired material characteristics.

3. Properties and Use Cases of FeCu Powder

FeCu powders are engineered to meet specific performance criteria that are essential in high-volume manufacturing. Whether you are a distributor looking to supply to PM factories or an OEM sourcing raw materials, understanding the material properties helps in making informed purchasing decisions.

Key Properties of FeCu Powder:

| Property | Description |

|---|---|

| Density | Typically 6.5–7.2 g/cm³ after sintering |

| Hardness | HB 60–90 depending on sintering conditions |

| Tensile Strength | Up to 480 MPa |

| Elongation | 1–3% |

| Machinability | Improved due to copper content |

| Thermal Conductivity | High, making it suitable for heat-sensitive applications |

Use Cases for FeCu Powder:

- Sintered Bearings: Copper offers self-lubricating characteristics.

- Electrical Contacts: High conductivity and wear resistance.

- Automotive Brake Pads: Enhances thermal stability and friction performance.

- Structural Parts: Reliable for producing complex geometries via PM.

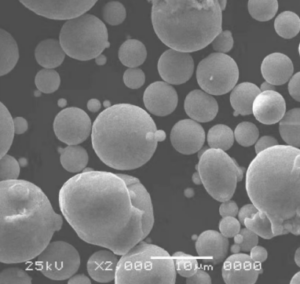

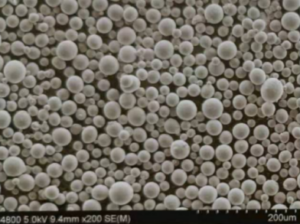

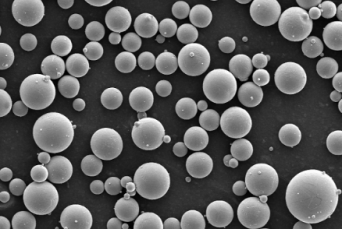

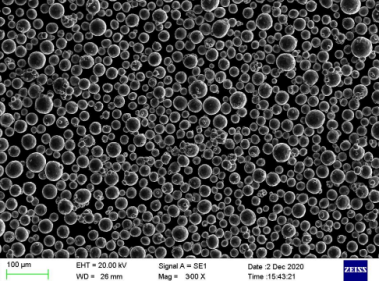

Available Manufacturing Techniques:

- Water Atomized FeCu

- Diffusion Alloyed FeCu

- Blended Fe + Cu Powders

Truer offers a wide range of PM powders including FeCu that are ideal for structural and functional components. These are available in various grades like FD-0208, FD-20Cu, and custom blends.

4. Top Global Suppliers of FeCu Powder

For B2B buyers, selecting a reliable FeCu powder supplier is critical to ensure consistent quality, timely delivery, and technical support. Below is a list of some of the top global suppliers known for their capabilities in powder metallurgy and iron-copper blends.

Leading FeCu Powder Suppliers in the Global Market

| Supplier | Region | Key Strengths | PM Powder Grades |

|---|---|---|---|

| Höganäs AB | Sweden | Global distribution, advanced R&D | FC-0208, FD-0208, custom alloys |

| Rio Tinto Metal Powders | Canada | Large-scale production, sustainability focus | High-purity water atomized FeCu |

| GKN Hoeganaes | USA | Automotive-grade PM powders | FC series, diffusion alloyed FeCu |

| Shanghai Truer Technology Co., Ltd | China | Competitive pricing, diversified grades, customization | FD-0208, FD-20Cu, blended and diffusion FeCu |

| Kobelco | Japan | High-quality PM for electronics & auto parts | Standardized FeCu blends |

Each of these companies brings unique advantages, but buyers increasingly value suppliers who offer flexibility in batch sizes, technical support, and cost-efficiency—areas where Asian manufacturers are gaining ground.

5. Why More Buyers Are Choosing Asian Suppliers for FeCu Powder

In the current global supply chain landscape, more B2B buyers are turning to Asia—especially China—for sourcing FeCu powder. This shift is driven by a combination of cost advantages, product diversity, and improvements in product quality and compliance.

Key Reasons for the Shift to Asian Suppliers:

- Cost-Effectiveness: Lower manufacturing and labor costs offer competitive pricing for bulk buyers.

- Customization Capability: Asian suppliers like Truer can provide tailored FeCu blends for specific applications.

- Shorter Lead Times: Regional shipping advantages within Asia-Pacific and growing logistics networks.

- Technical Innovation: Continuous development of new powder grades and additives.

- Flexible MOQs: Ideal for both large-scale manufacturers and mid-sized PM producers.

Want to explore cost-effective and high-quality FeCu powder options? Check out Truer’s product range and manufacturing capabilities.

Comparison Table: Western vs. Asian FeCu Suppliers

| Feature | Western Suppliers | Asian Suppliers |

|---|---|---|

| Unit Cost | Higher (due to labor & energy costs) | Lower (cost-efficient production) |

| Customization | Medium | High |

| MOQ Flexibility | Rigid | Flexible |

| Lead Times | Longer (especially for overseas buyers) | Shorter (regional proximity) |

| Technical Support | Strong | Strong (especially with English-speaking staff) |

As the demand for localized and just-in-time manufacturing grows, many industrial buyers are finding better alignment with Asian suppliers.

6. Why Choose Shanghai Truer Technology as Your FeCu Powder Supplier

Shanghai Truer Technology Co., Ltd is becoming a go-to choice for enterprises seeking high-performance FeCu powder and PM additives. Here’s why distributors, OEMs, and PM part manufacturers around the world trust Truer.

Company Overview

- Established: 2009

- PM Division Launched: 2019

- Core Focus: Additive manufacturing, 3D printing powders, and PM materials

- Production Methods: Water atomized, gas atomized, diffusion alloyed, carbonyl reduction

What Sets Truer Apart:

| Attribute | Details |

|---|---|

| Comprehensive Product Line | Offers FeCu, FeNi, FeSn, stainless, and hybrid alloy PM powders |

| Advanced Technology | Uses combined atomization (water + gas) for enhanced purity and flowability |

| Custom Blending | Tailors FeCu content and particle size to customer specs |

| Industry Expertise | One of China’s most professional PM additive suppliers |

| Additive Solutions | Supplies lubricants, soft magnetic materials, cutting agents, graphite additives |

Popular FeCu Powder Grades from Truer:

- FD-0208 – Diffusion alloyed iron-copper powder for high-density structural parts

- FD-20Cu – High-copper FeCu blend for electrical and thermal applications

- FC-0208 – Standard FeCu blend for general-purpose sintered components

Learn more about why Truer is a trusted leader in the Chinese PM industry by visiting the About Us page.

Client Industries Served:

- Automotive Tier-1 Suppliers

- Industrial Machinery OEMs

- Electrical Equipment Manufacturers

- Powder Metallurgy Component Distributors

Whether you’re sourcing for high-volume production or specialized PM components, Truer offers scalability, pricing flexibility, and technical support to match your manufacturing goals.

7. How to Order Wholesale FeCu Powder from Truer

For B2B buyers—especially those working with tight production timelines and quality standards—ordering FeCu powder from a reliable supplier like Shanghai Truer Technology is streamlined and customer-oriented.

Step-by-Step Ordering Process for Wholesale FeCu Powder:

| Step | Description |

|---|---|

| 1. Product Selection | Choose from standard grades like FD-0208, FC-0208, or request a custom FeCu blend. |

| 2. Technical Consultation | Truer’s engineers provide tailored advice on powder composition, sintering behavior, and additive recommendations. |

| 3. Sample Request | Request small-quantity samples for lab testing, prototyping, or validation. |

| 4. Quotation & Lead Time Confirmation | Receive a detailed quotation including pricing per kg/ton, logistics options, and estimated delivery times. |

| 5. Bulk Order Placement | Submit your purchase order with defined specifications and delivery schedule. |

| 6. Quality Assurance | Truer conducts strict QA using morphology analysis, flow rate testing, and chemical composition verification. |

| 7. Logistics & Export | FOB/CIF/DDU terms available. Truer works with international freight forwarders to ensure smooth customs clearance. |

Ready to request your quote or technical consultation? Contact Truer’s PM division directly to begin your order process.

Key Benefits for Distributors and OEMs:

- Minimum Order Quantity (MOQ): Flexible starting from 500kg

- Packaging Options: Vacuum-sealed bags, drums, or custom bulk solutions

- Delivery Time: 2–4 weeks depending on order size and customization

- Support: Multilingual customer service (Mandarin, English)

8. FAQs: Common Questions About Buying FeCu Powder in Bulk

Below are some of the most frequently asked questions from wholesale buyers, procurement managers, and product engineers.

❓ What is the standard composition of FeCu powder supplied by Truer?

Truer supplies several formulations, but common grades include:

- FC-0208: ~2% Cu and balance Fe

- FD-0208: Diffusion-alloyed grade with enhanced uniformity

- FD-20Cu: High Cu content for thermal/electrical use

❓ What particle size distribution (PSD) does Truer offer?

Truer can tailor PSD based on your application. Common ranges include:

- D50 = 60–100 µm (for structural parts)

- Finer grades available for precision sintering or diamond tool applications.

❓ What is the sintering temperature range for FeCu powder?

Typical sintering temperature for FeCu powder is between 1120°C–1150°C in a reducing atmosphere (usually endothermic gas or hydrogen).

❓ Can Truer provide technical documentation and MSDS?

Yes. All shipments include:

- Technical Data Sheets (TDS)

- Material Safety Data Sheets (MSDS)

- Batch-specific COA (Certificate of Analysis)

❓ What are the payment and shipping terms?

- Payment Terms: T/T, L/C for bulk orders

- Shipping Terms: FOB Shanghai, CIF, or delivered duty unpaid (DDU)

- Lead Time: 2–4 weeks after order confirmation

For detailed product specifications and safety documentation, explore the PM powder product catalog.

9. Conclusion & Next Steps to Source Quality FeCu Powder

FeCu powder remains a cornerstone material in the global powder metallurgy supply chain. With its versatility, machinability, and cost-efficiency, it’s a top choice for automotive, electrical, and industrial applications.

For purchasing managers, distributors, and OEMs looking to optimize their supply chains, choosing the right supplier is crucial. Shanghai Truer Technology Co., Ltd stands out with its:

- Comprehensive FeCu powder offerings (FC-0208, FD-0208, FD-20Cu)

- Custom powder blending and technical consultation

- Advanced atomization technologies ensuring purity and consistency

- Dedicated B2B support from inquiry to post-sales service

✅ Whether you’re preparing your next quarterly procurement or exploring new suppliers for long-term collaboration, Truer is ready to help.

Learn more about our product capabilities and start your sourcing journey with Truer by visiting our main website.