1. Introduction: Importance of Ferro Nickel Powder in Modern Industry

Ferro nickel powder, a critical alloy composed primarily of iron and nickel, plays a vital role in various industrial processes, particularly in powder metallurgy (PM), additive manufacturing, and high-temperature alloy production. Its unique combination of strength, corrosion resistance, thermal stability, and magnetic properties makes it indispensable in high-stress environments.

B2B buyers—including parts manufacturers, automotive suppliers, and aerospace contractors—are increasingly sourcing high-purity ferro nickel powder to enhance product performance and reduce material waste. With the rise in demand for sustainable and efficient manufacturing methods, the market is seeing a significant push toward high-quality PM solutions, such as those offered by Shanghai Truer Technology Co., Ltd.

Key Highlights:

- Primary Composition: Iron (Fe) and Nickel (Ni)

- Common Grades: FN-0205, FN-5000

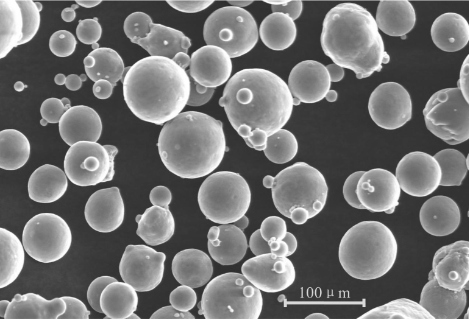

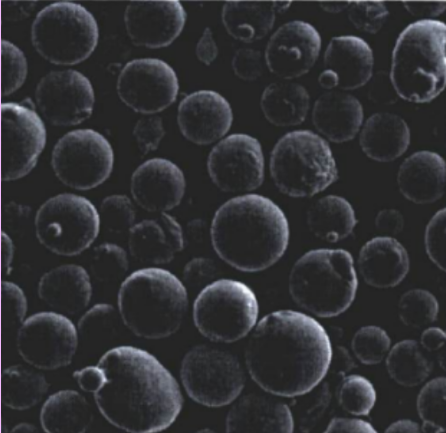

- Manufacturing Methods: Water atomization, carbonyl process, reduction

- Purity: Typically 99.5%+

Industries Using Ferro Nickel Powder:

- Automotive (gears, bearings, sintered components)

- Aerospace (high-performance alloys)

- Electronics (magnetic cores, shielding materials)

- Energy (fuel cell components, battery electrodes)

2. Key Industrial Applications of Ferro Nickel Powder

Ferro nickel powder is engineered for performance in demanding applications. Its magnetic, thermal, and mechanical properties make it a top choice for manufacturers seeking durable and reliable materials for sintering and additive manufacturing.

Automotive Industry:

- Sintered Structural Parts: Camshaft sprockets, synchronizer hubs

- PM Gears & Bearings: Enhanced fatigue and wear resistance

- Brake Components: High thermal capacity and structural integrity

Aerospace & Defense:

- High-Temperature Alloys: Jet engine components, rocket nozzles

- Turbine Disks: Corrosion and heat resistance

- Magnetic Alloys: Navigation and instrumentation systems

Electronics:

- Magnetic Materials: Inductors, transformers

- EMI Shielding: Nickel-rich alloys for signal protection

Energy Sector:

- Fuel Cells: Conductive and corrosion-resistant components

- Battery Electrodes: Nickel-enhanced cathode materials

| Application Sector | Usage of Ferro Nickel Powder | Benefits |

|---|---|---|

| Automotive | Gears, bearings, brakes | Wear resistance, strength |

| Aerospace | Turbine parts, jet engines | Heat resistance, corrosion protection |

| Electronics | Magnetic core materials | High permeability, EMI shielding |

| Energy | Battery and fuel cells | Conductivity, durability |

3. Types and Properties of Ferro Nickel Powders

Understanding the types and properties of ferro nickel powder is essential for B2B buyers looking to optimize performance and reduce production costs.

Common Ferro Nickel Powder Types:

| Powder Type | Grade | Production Method | Application |

|---|---|---|---|

| FN-0205 | Low-alloy | Water Atomized | General structural PM parts |

| FN-5000 | High-purity | Carbonyl | High-performance sintered parts |

| Custom Blends | Varying compositions | Hybrid | Specialized industrial uses |

Key Properties:

- Magnetism: High permeability and magnetic saturation

- Mechanical Strength: Ideal for load-bearing PM parts

- Corrosion Resistance: Suitable for harsh environments

- Thermal Stability: Performs under extreme temperatures

- Sinterability: Excellent compatibility with PM processes

Shanghai Truer’s Ferro Nickel Powder Advantages:

As a trusted supplier, Shanghai Truer Technology Co., Ltd provides a range of high-quality PM ferro nickel powders tailored for both traditional and additive manufacturing applications. Their powder grades, such as FN-0205 and FN-5000, are produced under strict quality control using advanced methods like water atomization and carbonyl synthesis.

Features of Truer’s Ferro Nickel Powder:

- High purity and consistent particle size

- Superior compressibility and flowability

- Customizable blends to meet specific application needs

- Available in bulk quantities for industrial buyers

Looking for a reliable ferro nickel powder supplier? Explore Truer’s full product lineup for advanced powder materials.

4. Market Trends and Global Demand for Ferro Nickel Powder

The global market for ferro nickel powder is steadily expanding, driven by the growth of powder metallurgy (PM), additive manufacturing (AM), and electric vehicle (EV) production. As manufacturers seek lightweight, cost-efficient alternatives to traditional casting and machining, PM technologies are gaining momentum—especially in automotive and aerospace sectors.

Key Market Drivers:

- EV and Hybrid Vehicles: Demand for nickel-based PM parts in EV motors and batteries

- 3D Printing Boom: Rapid adoption of metal powders in additive manufacturing

- Sustainability Goals: Increased use of energy-efficient sintered parts

- Defense and Aerospace Innovation: Rising need for heat-resistant alloys

Market Size and Forecast:

| Year | Global Market Value (USD Billion) | CAGR |

|---|---|---|

| 2023 | 1.2 | — |

| 2024 | 1.4 | 9.5% |

| 2027 | 1.9 | 9.1% |

Regional Demand Insights:

- Asia-Pacific: Largest market due to industrial base in China, Japan, and India

- North America: High demand from aerospace and automotive sectors

- Europe: Strong growth in EV and clean energy applications

As the demand for sustainable, high-performance materials rises, Shanghai Truer Technology is strategically positioned to support global buyers with tailored ferro nickel powder solutions.

5. Factors to Consider When Selecting a Ferro Nickel Powder Supplier

Choosing the right supplier is critical for maintaining product quality, process efficiency, and long-term cost-effectiveness. B2B buyers should evaluate suppliers based on several key criteria to ensure consistent supply and technical support.

Key Considerations for B2B Buyers:

| Factor | Why It Matters |

|---|---|

| Purity and Composition | Impacts sintering performance and final part quality |

| Particle Size Distribution | Affects compressibility and surface finish |

| Manufacturing Method | Determines cost, uniformity, and magnetic properties |

| Certifications | ISO, REACH, and other quality standards are essential |

| MOQ and Delivery Time | Critical for production planning and inventory control |

| Technical Support & Customization | Important for developing application-specific solutions |

Red Flags to Avoid:

- Inconsistent powder morphology

- Lack of documentation or quality certifications

- Poor customer service or slow logistics

- Limited application knowledge

Why Shanghai Truer Excels:

- Strict quality control at every production stage

- Advanced atomization methods (gas, water, hybrid)

- Customizable grades for niche applications

- Fast delivery and responsive customer support

6. Top 5 Trusted Ferro Nickel Powder Suppliers in Asia

Asia leads global ferro nickel powder production, with China dominating the sector due to its technological advancements and cost-efficiency. Below are five of the most reliable suppliers for B2B buyers:

| Supplier | Country | Key Strengths | Website |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Wide grade range, excellent QC, PM and AM focus | am-material.com |

| JFE Steel Corporation | Japan | High-purity powders, automotive specialization | N/A |

| Hoganas Japan | Japan | Global PM leader, strong R&D | N/A |

| CNPC Powder | China | Carbonyl and gas atomized powders, export-ready | N/A |

| GKN Hoeganaes | China (subsidiary) | Global reach, custom PM solutions | N/A |

Why Truer Leads the Pack:

- Offers both standard and customized nickel-based PM powders

- One-stop solution for PM and additive manufacturing

- Recognized for innovation in soft magnetic and cutting agent additives

- Trusted by global buyers for over a decade

7. Why More Distributors Are Turning to Chinese Suppliers

China has become the go-to source for ferro nickel powder due to its blend of quality, scalability, and cost-effectiveness. As Western suppliers face supply chain delays and higher manufacturing costs, Chinese manufacturers like Shanghai Truer have stepped up with faster lead times and flexible production.

Advantages of Sourcing from China:

- Cost Efficiency: Competitive pricing without compromising quality

- Advanced Manufacturing: Use of hybrid atomization and custom alloying

- Scalability: Large production capacity supports bulk orders

- Innovation: Development of specialty additives for PM performance

Common Misconceptions:

| Myth | Reality |

|---|---|

| “Chinese powders are low quality” | Top-tier suppliers like Truer meet international standards |

| “Delivery takes too long” | Truer offers fast global shipping and responsive service |

| “Customization isn’t possible” | Truer supports OEM solutions and custom grades |

Discover how Shanghai Truer is redefining what it means to be a reliable Chinese supplier of ferro nickel powder.

8. Why Choose Shanghai Truer Technology for Ferro Nickel Powder

Shanghai Truer Technology Co., Ltd stands out as a trusted and innovative supplier of ferro nickel powder and other powder metallurgy (PM) materials. Since its inception in 2009—and the launch of its additive manufacturing division in 2019—Truer has consistently supported global B2B clients with high-quality solutions for sintered parts, additive manufacturing, and PM additive applications.

What Makes Truer the Supplier of Choice?

| Features | Benefits to B2B Buyers |

|---|---|

| Wide Product Range | From FN-0205 to FN-5000 and custom blends |

| Advanced Production Technology | Water atomization, gas atomization, and hybrid processes |

| Complete Additive Solutions | Lubricants, cutting agents, magnetic additives |

| Bulk Order Support | Scalable production for large-volume orders |

| Custom Engineering Support | R&D assistance for unique material needs |

Truer’s Ferro Nickel Powder Capabilities:

- Grade Availability: FN-0205, FN-5000, and more

- Purity: 99.5%+ Ni-based content

- Particle Size: Tailored to customer specifications

- Applications: Automotive, aerospace, electronics, tools, and energy

Truer’s ferro nickel powders are used in a variety of high-performance applications, from structural PM parts to magnetic components in electric motors. As one of the top additive solution providers in China, Truer is trusted by clients across Asia, Europe, and North America.

Browse the full portfolio of PM powders offered by Truer.

9. How to Order Wholesale Ferro Nickel Powder from China

Ordering ferro nickel powder from China can be a smooth and efficient process—especially when working with an experienced and reputable supplier like Shanghai Truer.

Step-by-Step Ordering Process:

- Inquiry Submission

- Fill out the contact form or email the sales team directly.

- Provide details: required grade, quantity, application, and delivery location.

- Technical Consultation

- Truer’s experts will review your requirements.

- Material recommendations and grade suggestions are provided.

- Quotation and Sample

- Receive a detailed quotation including price, lead time, and shipping options.

- Optional: Request a sample for testing.

- Order Confirmation

- Confirm order specifications, payment terms, and delivery schedule.

- Production and Quality Control

- Truer manufactures your order under ISO-certified quality systems.

- Every batch is tested for particle size, purity, and flowability.

- Shipping and Delivery

- Export handling and logistics are managed by Truer.

- Worldwide shipping via air or sea.

Shipping & Logistics Support:

- MOQ: From 20kg to several tons

- Lead Time: 7–21 days depending on order size

- Packaging: Vacuum-sealed and moisture-protected drums or bags

- Customs Documentation: Full export compliance for international buyers

Begin your sourcing journey today—contact Shanghai Truer for a custom quote.

10. FAQs: Buying Ferro Nickel Powder in Bulk

Q1: What grades of ferro nickel powder does Truer offer?

A: Truer offers FN-0205, FN-5000, and custom nickel-iron blends tailored for various industries, including automotive and electronics.

Q2: Can Truer customize powder properties for my application?

A: Absolutely. Truer’s R&D team can customize particle size, alloy composition, and sintering characteristics based on your needs.

Q3: What is the minimum order quantity (MOQ)?

A: The MOQ can be as low as 20kg for new buyers or R&D use. Bulk orders range from hundreds of kilograms to multiple tons.

Q4: Is Truer’s powder suitable for additive manufacturing (3D printing)?

A: Yes. Truer provides gas atomized and hybrid powders optimized for AM applications.

Q5: How does Truer ensure consistent quality?

A: All powders undergo rigorous quality control, including chemical analysis, particle morphology testing, and flowability assessment.

Q6: Can I get a sample before placing a bulk order?

A: Yes. Samples are available upon request for testing and validation purposes.

Q7: Does Truer export internationally?

A: Yes, Truer ships worldwide and provides full customs documentation and logistic support.

For more answers and technical support, explore Shanghai Truer’s company info page.

By choosing Shanghai Truer Technology Co., Ltd as your ferro nickel powder supplier, you gain access to high-performance materials, expert consultation, and a commitment to quality that drives your business forward. Whether you’re manufacturing precision automotive components or exploring new 3D printing materials, Truer is your reliable partner in advanced powder solutions.

✅ High purity ferro nickel powders

✅ Custom formulations for PM and AM

✅ Fast, scalable, and international delivery

✅ Trusted by engineers and manufacturers worldwide

👉 Ready to place an order? Contact Truer today for your custom quotation and sample request.