1. Introduction: The Role of Soft Magnetic Powder in Modern Industry

Soft magnetic powders are increasingly critical in the development of high-efficiency electrical and electronic components. These powders, primarily made from iron or iron alloys, are known for their ability to magnetize and demagnetize easily, making them ideal for use in high-frequency and low-loss electromagnetic applications.

Why Soft Magnetic Powder Matters in B2B Manufacturing:

- Enables miniaturization of electronic components

- Reduces energy losses in transformers and inductors

- Supports innovations in electric vehicles (EVs), renewable energy, and consumer electronics

- Essential for powder metallurgy (PM) parts and soft magnetic composites (SMCs)

Soft magnetic materials are a key component in the shift towards energy-efficient, compact, and high-performance devices, making them a high-intent search topic for OEMs, e-mobility developers, and industrial component manufacturers.

2. Key Applications of Soft Magnetic Powder in Manufacturing

Soft magnetic powders are the foundation of countless components in industrial and consumer electronics. Their ability to reduce core losses and improve magnetic permeability makes them invaluable to manufacturers across multiple sectors.

Major B2B Applications:

| Industry Sector | Application Area | Benefits |

|---|---|---|

| Automotive | Electric motors, sensors, magnetic clutches | High torque density, reduced weight |

| Renewable Energy | Wind turbine generators, solar inverters | High efficiency, low power loss |

| Consumer Electronics | Inductors, transformers, EMI shielding | Miniaturization, high performance |

| Industrial Automation | Relays, actuators, magnetic field sensors | High durability, rapid response |

| Power Tools | Brushless DC motors, control units | Lower energy consumption, compact design |

Typical Usage Scenarios:

- Electromagnetic shielding for sensitive electronics

- High-frequency inductors in power supplies

- Magnetic cores in transformers and chokes

- Stator and rotor components in electric motors

- Smart grid components needing high magnetic permeability

For OEMs, sourcing high-quality soft magnetic powders ensures product reliability and performance, especially in competitive sectors like EV manufacturing and power electronics.

3. Properties and Classifications of Soft Magnetic Powders

Soft magnetic powders are classified based on composition, production method, and magnetic properties. Understanding these classifications is critical for buyers and engineers selecting materials for specific applications.

Key Magnetic Properties:

- High permeability (μ)

- Low coercivity (Hc)

- High saturation magnetization (Ms)

- Low core loss (especially under AC conditions)

Common Types of Soft Magnetic Powders:

| Type | Composition | Characteristics | Applications |

|---|---|---|---|

| Iron Powder | Pure iron | High saturation, cost-effective | Inductors, cores, sensors |

| Iron-Phosphorus (Fe-P) | Iron with phosphorus additive | Lower loss, good compaction | Magnetic cores, PM parts |

| Iron-Silicon (Fe-Si) | Iron alloyed with silicon | Improved resistivity, lower eddy current loss | Transformers, chokes |

| Iron-Nickel (Permalloy) | 45–80% nickel | Excellent permeability, low Hc | Shielding, precision sensors |

| Soft Magnetic Composites | Insulated iron particles | Low eddy current loss, 3D magnetic paths | Rotors, stators, axial flux motors |

Shanghai Truer Technology Co., Ltd offers a comprehensive range of soft magnetic powders under its PM Powder product line, such as QH-150 and QHP-330. These are tailored for high-frequency performance and compatibility with automated pressing and sintering processes.

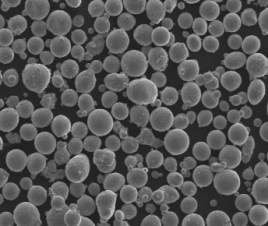

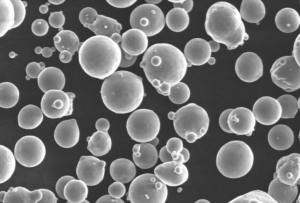

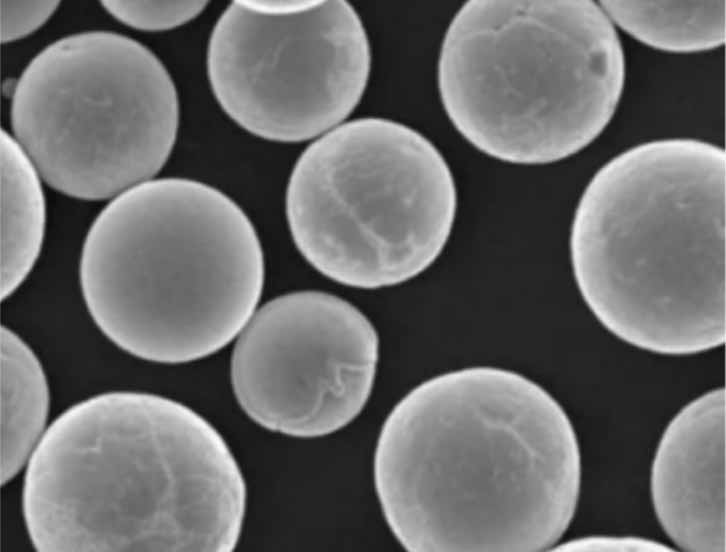

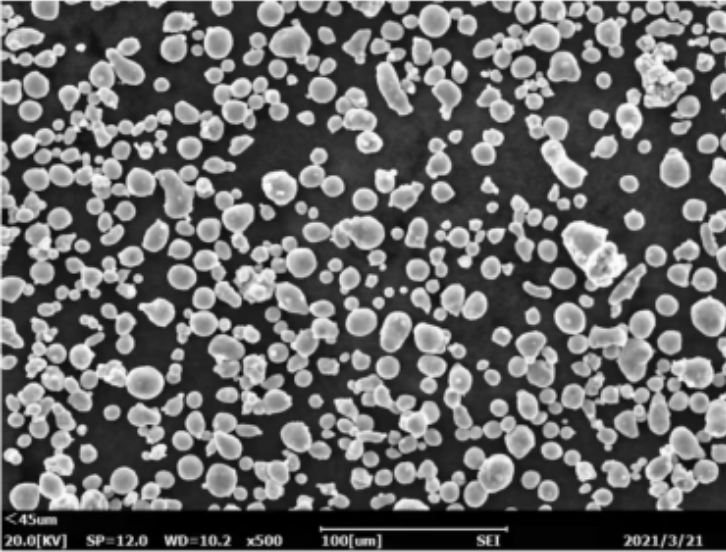

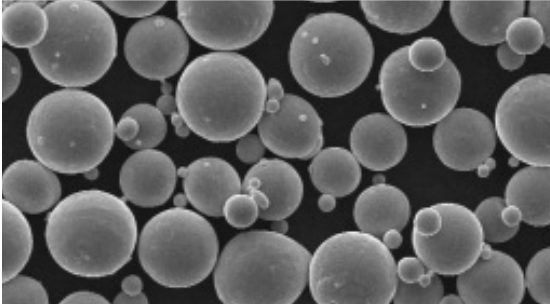

Production Methods Used:

- Water Atomization

- Gas Atomization

- Carbonyl Process

- Reduction Method

Each method affects the powder’s particle shape, size distribution, and purity—factors critical to magnetic performance and compaction behavior.

4. Market Demand and Trends for Soft Magnetic Materials

The global market for soft magnetic materials is witnessing rapid growth, driven by the rising adoption of electric vehicles, renewable energy systems, and industrial automation. For B2B buyers, understanding these trends can inform bulk procurement strategies and long-term supply planning.

Global Market Insights

- 📈 The global soft magnetic materials market was valued at over USD 20 billion in 2023 and is expected to reach USD 35+ billion by 2030.

- 🌍 Asia-Pacific accounts for the largest market share due to high demand from China, Japan, and South Korea.

- 🚗 EV motor applications are projected to be the fastest-growing segment.

- 🔋 Magnetic materials for inductors and transformers are in high demand for renewable energy integration.

Key Growth Drivers

- Surge in electric motor production for electric vehicles (EVs)

- Focus on energy efficiency and miniaturization of components

- Increased adoption of smart grids and industrial IoT solutions

- Expansion of 5G infrastructure and consumer electronics

Table: Top Industries Driving Demand

| Industry | Usage of Soft Magnetic Powder | Future Growth Potential |

|---|---|---|

| Automotive (EVs) | Traction motors, onboard chargers | Very High |

| Renewable Energy | Inverters, transformers, generator cores | High |

| Electronics | Inductors, wireless charging modules | High |

| Industrial Equipment | Sensors, actuators, power conversion units | Medium |

For wholesale buyers and procurement managers, aligning with suppliers who can meet future demand with scalable production is vital. Shanghai Truer Technology Co., Ltd anticipates these shifts and offers tailored additive solutions for next-gen manufacturing.

5. How to Select the Right Soft Magnetic Powder Supplier

Choosing the right B2B supplier for soft magnetic powder is more than just comparing prices—it involves assessing technical capabilities, product consistency, and supply chain reliability.

Key Qualities to Look for in a Supplier

- ✅ Consistent particle morphology and size distribution

- ✅ Stable and scalable production capacity

- ✅ Technical support and customization

- ✅ Compliance with international quality standards (ISO, RoHS, REACH)

- ✅ Transparent logistics and delivery timelines

Supplier Evaluation Checklist

| Criteria | Importance for B2B Buyers | Shanghai Truer’s Offering |

|---|---|---|

| Product Customization | High | Offers proprietary grades like QH-150, QHP-330 |

| Production Technology | Very High | Water/gas atomization, carbonyl, reduction |

| Quality Assurance | Very High | In-house lab testing, traceability |

| Technical Consultation | High | Engineering team support for PM applications |

| Lead Times & Logistics | Medium | Global shipping, strong domestic logistics |

| Industry Reputation | High | Trusted supplier to China’s PM industry |

For a deeper understanding of Truer’s capabilities, explore the About Us page that highlights its 15+ years in powder technology and additive manufacturing.

6. Top 5 Global Suppliers of Soft Magnetic Powder

To support B2B procurement strategies, here’s a comparison of the top global suppliers of soft magnetic powder by market presence, product portfolio, and regional accessibility.

Leading Global Suppliers

| Supplier Name | Country | Key Offerings | Strengths |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Wide range of PM powders and additives | Flexible customization, advanced atomization tech |

| Höganäs AB | Sweden | Iron-based powders, soft magnetic composites | Global leader, large-scale production |

| Rio Tinto Metal Powders | Canada | Iron powders for automotive and industrial uses | Extensive mining-to-manufacturing integration |

| GKN Hoeganaes | USA | Magnetic and structural powders | Focused on North American automotive sector |

| JFE Steel | Japan | Fe-Si, Fe-Ni based magnetic powders | High-quality production, precision materials |

Shanghai Truer stands out for its ability to deliver both standard and custom blends, such as QH-150 and QHP-330, with consistent performance across batches. Its vertical integration of powder production and application support makes it a preferred partner for many Asian manufacturers.

🔗 You can explore Truer’s full range of PM powder solutions here.

7. Why More Buyers Are Sourcing Soft Magnetic Powder from China

In the global powder metallurgy supply chain, China has emerged as a dominant force in the production and innovation of soft magnetic powders. For wholesale buyers, distributors, and OEM manufacturers, sourcing from Chinese suppliers offers significant cost-efficiency, scalability, and access to advanced materials.

Key Advantages of Sourcing from China

- 🏭 Cost Competitiveness: Lower production and labor costs lead to more competitive pricing without compromising quality.

- ⚙️ Advanced Manufacturing Technology: Chinese suppliers like Shanghai Truer are investing in state-of-the-art atomization and reduction technologies.

- 🧪 Material Innovation: Custom powder blends and additives are widely available, including high-performance grades like QH-150 and QHP-330.

- 🚢 Efficient Export Infrastructure: China’s integrated logistics and shipping systems allow for reliable, global order fulfillment.

- 📈 Rapid Response to Market Trends: Suppliers are agile in developing new grades for EVs, renewable energy, and smart manufacturing.

B2B Insight: Why Distributors Prefer Chinese Manufacturers

| Factor | Benefit to Distributors & OEMs |

|---|---|

| Volume Scalability | Supports mass production and bulk orders |

| Custom Formulations | Tailored to specific magnetic and mechanical needs |

| Technical Support | Localized engineering assistance |

| Shorter Lead Times | Faster turnaround for urgent projects |

Shanghai Truer Technology Co., Ltd exemplifies these advantages by offering full-spectrum powder metallurgy solutions, from base iron powders to high-performance additives. As a trusted name in the Chinese PM industry, Truer is recognized for its reliability and technical depth.

To learn more about the company’s international presence and capabilities, visit the Shanghai Truer homepage.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Supplier

Shanghai Truer stands out as a leading B2B supplier of soft magnetic powders for several reasons. With a legacy of innovation since 2009 and dedicated additive manufacturing services launched in 2019, Truer combines deep materials expertise with a client-centric approach.

Comprehensive Product Portfolio

Truer offers a wide range of soft magnetic and structural powders manufactured via:

- ✅ Water Atomization

- ✅ Gas Atomization

- ✅ Carbonyl Process

- ✅ Reduction Method

These methods yield powders suitable for:

- High-frequency inductors

- Magnetic cores

- SMC components

- EV motor assemblies

Flagship Soft Magnetic Products

| Product Code | Description | Application Area |

|---|---|---|

| QH-150 | Soft magnetic additive with high purity | Excellent for sintered magnetic parts |

| QHP-330 | High-performance magnetic composite | Ideal for soft magnetic composites (SMCs) |

| TBC-400 | Graphite-based additive | Enhances magnetic loss control |

Truer’s powders are compatible with both conventional powder metallurgy and additive manufacturing techniques, enabling more flexible part geometries and reduced post-processing.

Value-Added Services

- 🧬 Custom powder formulation for unique applications

- 🧪 In-house R&D and material testing

- 🔧 Engineering support for part design and optimization

- 🌍 Global shipping and export documentation

For more information on how Truer can support your projects, visit the Contact Us page to speak with a technical consultant.

9. FAQs: Common Questions About Buying Soft Magnetic Powder

Q1: What is the minimum order quantity (MOQ) for soft magnetic powders?

Most soft magnetic powders from Shanghai Truer have an MOQ of 25 kg, but this can vary depending on the product type and customization level. Bulk discounts are available for orders over 500 kg.

Q2: Can I request custom compositions or particle size distributions?

Yes. Truer specializes in custom formulations and can adjust chemical composition, grain size, and surface treatments according to your technical requirements.

Q3: What quality certifications does Shanghai Truer hold?

Truer complies with ISO 9001 standards for quality management. All powders undergo rigorous lab testing for consistency, purity, and magnetic performance.

Q4: How do I place a wholesale order?

To place a wholesale order, visit the PM Powder product page and select your desired grade. You can also reach out directly via the Contact Us page for a personalized quote and technical consultation.

Q5: Which industries commonly use Truer’s soft magnetic powders?

Truer supplies soft magnetic powders to industries such as:

- EV motor manufacturing

- Renewable energy systems

- Industrial automation

- Consumer electronics

- Powder metallurgy parts manufacturing

🔗 Internal Anchor Links Summary

Here are the five internal anchor links included in this article for optimal SEO and user navigation:

By choosing Shanghai Truer Technology Co., Ltd as your soft magnetic powder supplier, you’re not just buying a material—you’re gaining a trusted partner dedicated to your success in the powder metallurgy and additive manufacturing industries.