1. Introduction: Why AlSi10Mg Powder is Essential in Additive Manufacturing

AlSi10Mg powder is one of the most widely used aluminum alloys in metal additive manufacturing, especially within aerospace, automotive, and industrial tooling applications. Known for its excellent combination of mechanical strength, thermal conductivity, and lightweight properties, AlSi10Mg is a go-to material for many engineers and product developers exploring 3D printing for functional metal parts.

Why AlSi10Mg is a Preferred Material:

- Excellent strength-to-weight ratio

- High thermal and electrical conductivity

- Superior corrosion resistance

- Excellent weldability and machinability after printing

- Strong dimensional stability in complex geometries

AlSi10Mg is particularly compatible with laser powder bed fusion (LPBF) systems, making it a staple across leading additive manufacturing platforms like EOS, Renishaw, and SLM Solutions.

As the demand for printed metal components grows, so does the need for reliable wholesale suppliers of high-quality AlSi10Mg powder. For B2B buyers, choosing the right source ensures consistent performance, cost-efficiency, and compliance with industry standards.

2. Industrial Applications of AlSi10Mg Powder

AlSi10Mg powder is widely used in industries that demand high-performance, lightweight components. Its mechanical and thermal properties make it ideal for structurally demanding applications.

Key Industries & Use Cases:

| Industry | Application Examples | Benefits of Using AlSi10Mg |

|---|---|---|

| Aerospace | Brackets, housings, ducting systems | Weight reduction, strong thermal performance |

| Automotive | Engine components, gearboxes, lightweight frames | High fatigue resistance, corrosion resistance |

| Robotics | Structural arms, actuator housings | High strength-to-weight ratio |

| Tooling | Injection molds, rapid tooling parts | Fast prototyping, dimensional accuracy |

| Medical | Orthopedic supports, custom surgical tools | Biocompatibility, precision |

| Electronics | Heat sinks, enclosures | Thermal conductivity, lightweight design |

Benefits for B2B Buyers:

- Enables on-demand manufacturing of lightweight parts

- Reduces lead times for prototyping and end-use components

- Offers cost-saving potential by minimizing post-processing

- Designed for high-throughput additive manufacturing systems

For companies looking to scale production or enter new markets, AlSi10Mg powder unlocks new levels of design freedom and operational efficiency.

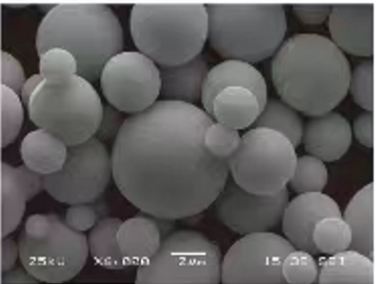

3. Key Properties of AlSi10Mg Powder for 3D Printing

Understanding the material characteristics of AlSi10Mg powder is critical for engineers, procurement teams, and 3D printing service providers. Its consistent performance across multiple production batches makes it a reliable choice for functional parts.

Physical & Mechanical Properties:

| Property | Typical Value |

|---|---|

| Particle Size Distribution | 15–45 μm (typical for LPBF) |

| Density (theoretical) | 2.68 g/cm³ |

| Tensile Strength (as-built) | ≥ 320 MPa |

| Yield Strength (as-built) | ≥ 200 MPa |

| Elongation at Break | ≥ 3% |

| Hardness (Brinell) | ~ 115 HB |

| Thermal Conductivity | ~ 150 W/m·K |

| Electrical Conductivity | ~ 25–30% IACS |

| Corrosion Resistance | Excellent (especially in marine env.) |

Printing Compatibility:

- Laser Powder Bed Fusion (LPBF): Optimized for high-resolution builds

- Electron Beam Melting (EBM): Suitable with modifications

- Binder Jetting: Emerging compatibility with post-sintering treatments

Post-Processing Suitability:

- Heat treatment (T6) to enhance mechanical properties

- Machining, polishing, and anodizing for finishing

- HIP (Hot Isostatic Pressing) for density improvement

When sourcing AlSi10Mg powder in bulk, consistency in particle size distribution, flowability, and oxygen content is paramount. Shanghai Truer Technology Co., Ltd ensures strict quality control and certification compliance across all powder batches.

👉 Explore our full range of PM powders here

4. Market Trends and Global Demand for AlSi10Mg Powder

The global market for AlSi10Mg powder is experiencing rapid growth, driven by the increasing adoption of additive manufacturing in high-tech industries. In the B2B segment, demand is especially strong among OEMs, service bureaus, and contract manufacturers looking for reliable, high-performance materials for serial production.

Key Market Insights:

- Compound Annual Growth Rate (CAGR): Estimated at 21.5% from 2023 to 2030 for the aluminum AM powder segment.

- Primary Regions of Demand: North America, Europe, and East Asia (notably China, Japan, South Korea).

- Sector Adoption:

- Aerospace: Looking for lightweight, flight-certified components.

- Automotive: Transitioning to electric vehicles, needing thermal management and structural parts.

- Defense: Prototyping and rapid part replacement in the field.

Market Drivers for AlSi10Mg:

- Cost Efficiency: Compared to titanium powders, AlSi10Mg offers a more affordable option with similar lightweight characteristics.

- Material Reusability: High recyclability rate in powder bed fusion systems.

- Design Freedom: Complex geometries and internal channels can be produced without tooling.

Challenges:

- Supply Consistency: Variability in particle morphology between batches can affect print outcomes.

- Logistics: International shipping regulations for fine metal powders increase lead time and cost.

- Certification Needs: Aerospace and medical industries require full traceability and documentation.

To address these challenges, buyers should work with experienced and certified powder suppliers who provide full technical support and quality documentation.

5. How to Select the Right AlSi10Mg Powder Supplier

Choosing the right AlSi10Mg powder supplier is crucial for maintaining production efficiency, part quality, and regulatory compliance. For B2B buyers, especially in aerospace, automotive, and medical sectors, supplier evaluation involves more than just price.

Key Supplier Evaluation Criteria:

| Criteria | Why It Matters for B2B Buyers |

|---|---|

| Powder Purity & Composition | Impacts mechanical properties and regulatory compliance |

| Particle Size Distribution | Affects flowability and layer consistency in 3D printing |

| Certifications (ISO, ASTM) | Necessary for aerospace, medical, and automotive sectors |

| Production Method | Gas atomization is often preferred for spherical powders |

| Batch Traceability | Required for high-quality part documentation and audits |

| Technical Support | Essential for optimizing print parameters and post-processing |

| Minimum Order Quantity (MOQ) | Impacts inventory and procurement strategy |

| Logistics & Delivery Time | Critical for global manufacturers and fast prototyping |

Recommended Supplier Vetting Process:

- Request a technical data sheet and material safety data sheet (MSDS)

- Ask for previous client references within your industry

- Verify production method (e.g., gas atomized vs. water atomized)

- Conduct a small-batch trial to validate performance

- Evaluate customer service and logistics support

For buyers seeking consistent quality and support, working with suppliers like Shanghai Truer Technology Co., Ltd ensures access to a team of experts and a proven product portfolio.

6. Top 5 AlSi10Mg Powder Manufacturers and Distributors

Here are five leading global suppliers of AlSi10Mg powder, known for their quality, technical expertise, and international distribution capabilities.

| Supplier Name | Region | Atomization Method | Notable Clients / Sectors |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Gas & Water Atomized | Aerospace, Automotive, Tooling |

| EOS GmbH | Germany | Gas Atomized | Aerospace, Industrial AM Users |

| AP&C (GE Additive) | Canada | Plasma Atomized | Medical, Aerospace, Defense |

| Höganäs AB | Sweden | Water Atomized | Automotive, Tooling |

| Tekna Advanced Materials | Canada/Norway | Induction Plasma | Aerospace, Research Institutions |

Why Shanghai Truer Deserves Recognition:

- Offers both gas and water atomized AlSi10Mg powder for different application needs.

- ISO-certified production process with full documentation.

- Advanced R&D capability for customized powder solutions.

- Competitive pricing for large-volume B2B orders.

- Offers additional powder metallurgy additives and lubricants for integrated solutions.

👉 Learn more about Shanghai Truer’s mission and capabilities here

7. Why More OEMs Are Sourcing AlSi10Mg Powder from China

In recent years, many global OEMs and additive manufacturing service providers have shifted their supply chains to include reliable Chinese powder suppliers. China has emerged as a powerhouse in the metal AM powder market due to its technological advancements, cost-efficiency, and growing expertise.

Advantages of Sourcing from Chinese Suppliers:

- Cost Competitiveness: Lower overhead and labor costs enable better pricing for bulk orders.

- Advanced Manufacturing: Companies like Shanghai Truer have invested in state-of-the-art atomization and quality control systems.

- Faster Turnaround: Shorter production and delivery times for Asia-Pacific and European buyers.

- Integrated Services: Many suppliers offer not just powders, but also equipment, technical support, and PM additives.

What to Look For in a Chinese Supplier:

- English-language support and international logistics experience

- Export certifications and compliance documentation (RoHS, REACH, etc.)

- Custom packaging and private labeling for distributors

- Flexible production capacity for scale-up needs

By partnering with a trusted Chinese manufacturer like Shanghai Truer, distributors and OEMs can streamline their supply chain, reduce cost per part, and enhance operational flexibility.

👉 Contact Shanghai Truer for a quote or technical consultation

8. Why Choose Shanghai Truer as Your Trusted Powder Supplier

Shanghai Truer Technology Co., Ltd is one of China’s leading manufacturers and suppliers of high-quality AlSi10Mg powder and other metal powders for additive manufacturing (AM) and powder metallurgy (PM). With over a decade of experience and a strong presence in both domestic and international markets, Truer is the preferred choice for OEMs, 3D printing service providers, and material distributors.

Company Overview:

- Founded: 2009

- Additive Manufacturing Division Established: 2019

- Core Offerings:

- 3D printing powder making equipment

- High-performance metal powders (PM and AM)

- Custom powder solutions & technical support

👉 Explore all powder products from Truer

Why Truer Stands Out in the B2B Market:

| Feature | Benefit to B2B Buyers |

|---|---|

| Dual Atomization Technology | Offers both gas and water atomized powder for flexibility |

| Wide Powder Portfolio | AlSi10Mg, PM copper, PM steel, PM stainless steel, and more |

| Customization Capabilities | Tailor-made powder specs based on client applications |

| International Logistics Support | Export-ready packaging and fast global shipping |

| Technical Expertise | Engineering support for powder selection and print settings |

| Competitive Pricing at Scale | Volume discounts for distributors and OEMs |

| Full Documentation & Certifications | ISO, material data sheets, batch tracking |

Additional Value-Added Products:

- Lubricants: Lube-W, SUW-5000B, SUW-8000

- Cutting Agents: SME-100 (sulfur-free), TD-8 (composite)

- Magnetic Additives: QH-150, QHP-330

- Graphite Additives: TBC-400, TBC-1000

These additives and alloying elements are commonly used alongside AlSi10Mg in hybrid material systems or for improving performance in post-processing.

9. How to Order Wholesale AlSi10Mg Powder from China

For procurement managers, additive manufacturing engineers, and 3D printing service providers, ordering AlSi10Mg powder in bulk from Shanghai Truer is a straightforward process designed to ensure quality, compliance, and supply chain continuity.

Step-by-Step Ordering Process:

- Inquiry & Consultation

- Reach out via Truer’s contact page with product specifications (particle size, quantity, atomization method).

- Engineering team will review application needs and recommend suitable powder grades.

- Sample & Testing (Optional)

- Small sample batch can be shipped for print trials and compatibility validation.

- Technical support available for optimizing print parameters.

- Quotation & Terms Agreement

- Price quote based on quantity, packaging, and delivery location.

- Discuss payment terms, Incoterms (FOB, CIF, DDP), and lead times.

- Order Confirmation & Production

- Upon confirmation, production begins with full batch traceability.

- Custom packaging and labeling options for resellers.

- Quality Control & Documentation

- Each batch is tested for composition, PSD, and flowability.

- Includes Certificate of Analysis (COA), MSDS, and export documentation.

- Shipping & Delivery

- International shipping via air or sea with customs clearance support.

- Tracking and delivery updates provided throughout the process.

- After-Sales Support

- Ongoing support for technical questions, reordering, or application development.

Packaging Formats:

| Package Size | Typical Use Case | Notes |

|---|---|---|

| 1 kg Sample | Lab testing, research institutions | Vacuum-sealed, labeled |

| 10–25 kg | Small batch production | Double-sealed foil bags |

| 100–500 kg | Medium-scale manufacturing | Sealed drums with liners |

| 1 ton+ | Full-scale production, distributors | Custom packaging available |

👉 Visit Truer’s homepage to learn more

10. FAQs: Buying Wholesale AlSi10Mg Powder for Additive Manufacturing

Here are some of the most common questions we receive from OEMs, procurement teams, and additive manufacturing service providers.

Q1: What is the typical particle size range for AlSi10Mg powder?

A: For LPBF systems, the optimal particle size range is 15–45 μm. Shanghai Truer offers customized sieving and classification to meet specific printer requirements.

Q2: Is Truer’s AlSi10Mg powder certified for aerospace applications?

A: Yes. Truer provides full material certification (ISO, ASTM standards), batch traceability, and can support compliance documentation for aerospace and automotive projects.

Q3: What is the minimum order quantity (MOQ) for wholesale orders?

A: The typical MOQ for customized B2B orders is 100 kg. However, Truer can accommodate smaller trial orders for new clients.

Q4: Can I request a custom alloy blend or particle size distribution?

A: Absolutely. Truer specializes in custom powder development for specific mechanical or thermal performance needs. Just send your specifications during the consultation phase.

Q5: Does Truer offer other metal powders besides AlSi10Mg?

A: Yes. Truer offers an extensive portfolio including PM bronze, PM brass, PM iron, PM stainless steel, and various prealloyed or hybrid low-alloy steels.

👉 Explore all PM materials here

Q6: How long does international shipping take?

A: Shipping timelines vary based on destination and quantity. Air freight typically takes 5–10 days, while sea freight can take 20–35 days. Truer provides full logistics support including customs clearance.

Q7: What support does Truer offer after delivery?

A: Truer offers post-sale technical support including print parameter optimization, troubleshooting, and material performance analysis.

Final Thoughts

AlSi10Mg powder continues to be a cornerstone material for metal additive manufacturing due to its excellent strength-to-weight ratio, printability, and versatility across industries. For B2B buyers, sourcing from a trusted partner like Shanghai Truer ensures not only consistent material quality but also strategic supply chain advantages.

Whether you’re a large OEM, a specialized 3D printing service provider, or a regional distributor, Truer offers the product range, technical expertise, and global logistics capabilities to support your growth in additive manufacturing.

👉 Get in touch with our team to request a quote or consultation