1. What Is Ni-WC Powder and Why It Matters in Industry

Ni-WC powder refers to a composite metal powder consisting of Nickel (Ni) and Tungsten Carbide (WC). This hybrid material is engineered for extreme wear resistance, corrosion resistance, and high strength, making it a preferred choice in industries such as mining, aerospace, oil & gas, and additive manufacturing.

Why Ni-WC is Important for B2B Buyers:

- High Performance: Combines the toughness of nickel with the hardness of tungsten carbide.

- Cost-Effective: Offers extended lifecycle of parts, reducing downtime and replacement costs.

- Versatile Applications: Suitable for coating, sintering, and additive manufacturing.

- Scalable Supply: Available for bulk orders, ideal for OEMs, distributors, and industrial manufacturers.

Industries Benefiting from Ni-WC Powder:

| Industry | Application Example |

|---|---|

| Oil & Gas | Drill bits, valve seats, nozzles |

| Aerospace | Turbine blades, wear-resistant coatings |

| Mining | Crushers, wear plates |

| Automotive | Brake components, cutting tools |

| Additive Manufacturing | 3D printed wear-resistant components |

As a leading powder metallurgy solution provider, Shanghai Truer Technology Co., Ltd offers high-quality Ni-WC powders tailored to these industries.

2. Applications of Nickel-Tungsten Carbide in Industrial Manufacturing

Ni-WC powder serves both as a base material and as a reinforcement component to enhance mechanical properties. It is widely used in:

a) Thermal Spray Coatings

- Ni-WC is applied via HVOF (High-Velocity Oxygen Fuel) or plasma spray.

- Used to protect parts from extreme wear and corrosion.

- Common in aerospace and petrochemical industries.

b) Hot Isostatic Pressing (HIP)

- Ni-WC powders are sintered under high pressure and temperature.

- Produces dense, high-strength components for tool and die production.

c) Additive Manufacturing (AM)

- Ni-WC blends are ideal for metal 3D printing.

- Used in producing custom, complex geometries with enhanced properties.

- Compatible with selective laser melting (SLM) and binder jetting.

d) Cemented Carbide Production

- Used as a matrix binder or reinforcement.

- Enhances fracture toughness and thermal shock resistance in tools.

Common Parts Made from Ni-WC Powder:

- Downhole tools

- Pump sleeves

- Cutting inserts

- Nozzles

- Engine components

3. Properties and Types of Ni-WC Powder for B2B Buyers

When sourcing Ni-WC powder, understanding the material properties and available variants is crucial for procurement teams, OEM engineers, and industrial buyers.

Key Properties

| Property | Value Range | Benefit |

|---|---|---|

| Hardness | 1100–1400 HV | Exceptional wear resistance |

| Density | 10.5–14.0 g/cm³ | High material integrity |

| Corrosion Resistance | Excellent in harsh chemicals | Long-term stability in tough environments |

| Thermal Stability | Up to 1400°C | Suitable for high-heat applications |

| Electrical Conductivity | Low | Ideal for non-conductive applications |

Types of Ni-WC Powder

| Type | Description | Best Use Case |

|---|---|---|

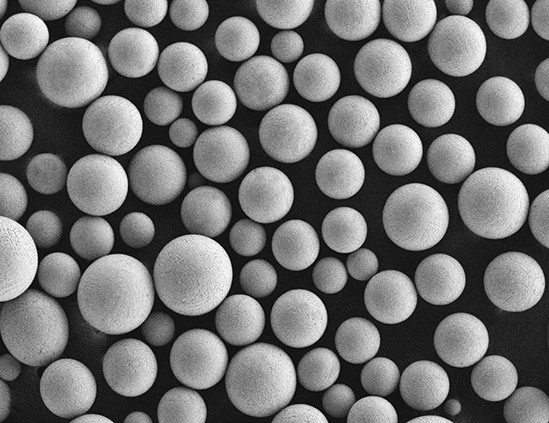

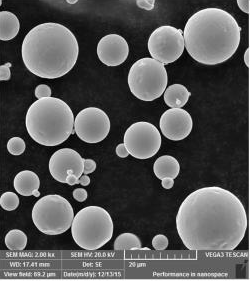

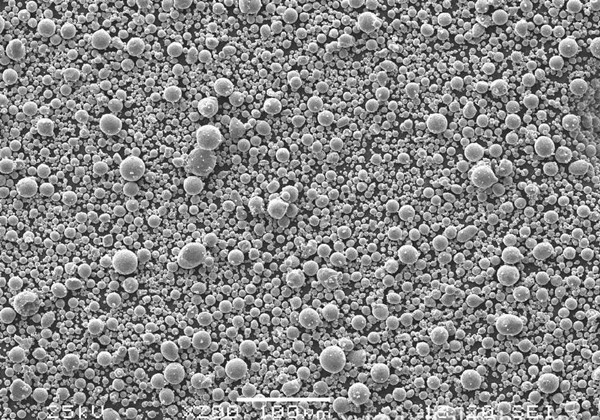

| Agglomerated & Sintered | Uniform grain size, high flowability | Thermal spray coatings |

| Mechanically Blended | Custom Ni:WC ratio, economical | General manufacturing |

| Pre-Alloyed | Homogeneous distribution of Ni and WC | Additive manufacturing, high-precision parts |

| Spherical Powder | Ideal for SLM and binder jetting | 3D printed components |

Shanghai Truer offers both water-atomized and gas-atomized Ni-WC powders. Their advanced production facilities can tailor particle size distribution, morphology, and chemical composition to meet specific B2B needs.

4. Current Market Trends & Future Potential of Ni-WC Powder

The global market for Ni-WC powder is experiencing rapid growth, driven by the rise of high-performance manufacturing, increased adoption of additive manufacturing (AM), and demand for wear-resistant materials across heavy industries.

📈 Market Trends Driving Ni-WC Powder Demand

- Additive Manufacturing Expansion:

Aerospace and defense sectors are increasing their reliance on metal 3D printing, often using Ni-WC for its strength and stability under stress. - Energy Sector Modernization:

Oil & gas companies are investing in high-durability components made from Ni-WC to reduce downtime and extend equipment life. - Green Manufacturing:

Ni-WC powder contributes to sustainability by prolonging part lifespan, reducing waste, and improving energy efficiency in manufacturing processes.

🌍 Global Market Forecast

| Year | Market Size (USD Million) | CAGR |

|---|---|---|

| 2023 | 280 | — |

| 2024 | 310 | 10.7% |

| 2026 | 420 | 11.2% |

| 2029 | 620+ | 12%+ |

🔍 Key Growth Opportunities for B2B Buyers

- Custom-grade Ni-WC powder for AM applications

- Nickel-WC coatings in renewable energy equipment

- Expansion into Southeast Asia and Eastern Europe markets

For forward-thinking wholesalers and industrial buyers, now is an ideal time to secure long-term supply contracts with reliable manufacturers like Shanghai Truer Technology.

5. Key Factors to Consider When Choosing a Ni-WC Powder Supplier

Selecting the right supplier for Ni-WC powder can affect everything from production efficiency to end-product performance. B2B buyers should evaluate suppliers based on the following criteria:

✅ Technical Specifications

- Particle Size Distribution (PSD)

- Flowability & Morphology

- Purity Levels & Contaminant Control

- Sintering Behavior

✅ Production Capabilities

| Capability | Why It Matters |

|---|---|

| Water & Gas Atomization Options | Tailored powder for specific applications |

| Custom Alloying & Blending | Meets unique B2B requirements |

| High-volume Production | Supports large OEM or distributor orders |

| Quality Certifications (ISO, SGS) | Ensures international compliance and reliability |

✅ Logistics & Delivery

- Global shipping and warehousing options

- Flexible MOQs for testing and large-scale procurement

- Real-time tracking and after-sales support

✅ Technical Support

- Application-specific powder recommendations

- Metallurgical consultation

- On-site or remote support for process integration

Shanghai Truer Technology stands out by offering water atomized, gas atomized, and combined atomization Ni-WC powders, giving buyers unparalleled flexibility in specification and performance needs.

6. Top Global Ni-WC Powder Suppliers for Distributors and OEMs

To assist industrial buyers in identifying trusted sources, here’s a comparative table of key Ni-WC powder suppliers globally.

| Company Name | Country | Strengths | MOQ Flexibility | Customization |

|---|---|---|---|---|

| Shanghai Truer Technology | China | Full in-house powder production and R&D | Yes | High |

| Höganäs AB | Sweden | Global leader in metal powders | Limited | Medium |

| GTP (Global Tungsten) | USA | Strong in tungsten-based applications | Moderate | Low |

| Oerlikon Metco | Switzerland | Advanced AM and thermal spray materials | Low | High |

| Sandvik Additive | Sweden | Focused on 3D printing applications | Low | High |

Shanghai Truer is especially suitable for B2B buyers looking for:

- Competitive pricing without compromising quality

- OEM services and private labeling

- A reliable partner for long-term supply chains

Want to learn more about Truer’s product line? Visit Truer’s Powder Metallurgy Page for detailed technical specs.

7. Why More Buyers Are Turning to Chinese Ni-WC Powder Manufacturers

Over the past decade, Chinese manufacturers have emerged as the backbone of the global powder metallurgy and additive manufacturing supply chain.

🏭 Competitive Advantages of Chinese Suppliers

- Advanced Production Technologies:

Many Chinese factories use cutting-edge water and gas atomization facilities capable of producing spherical and high-purity powders. - Massive Production Scale:

Lower cost due to bulk production capacity; ideal for high-MOQ distributors. - Integrated R&D and Manufacturing:

Enables faster prototyping and custom solutions. - Government Support:

Export-friendly policies and certifications align with global standards.

🇨🇳 Case Study: Shanghai Truer Technology

Since 2009, Shanghai Truer has built a reputation for excellence in powder metallurgy and additive manufacturing. Their Ni-WC powders are engineered specifically for:

- Wear-resistant coatings

- Binder jet and SLM-based 3D printing

- Sintered tools and automotive components

Their dedicated Additive Manufacturing Business Unit was launched in 2019 to better serve industrial clients with tailored solutions and fast delivery.

Capabilities at a Glance:

- Powder Grades: Customizable Ni-WC blends

- Manufacturing Methods: Water atomized, gas atomized, combined

- Specialty Products: PM bronze, PM brass, PM iron-nickel, CuSn diffusion powders

- Additives Division: Lubricants, cutting agents, graphite, soft magnetic additives

Looking for a trusted supplier who understands your industry? Learn more about Shanghai Truer Technology here.

8. How to Order Wholesale Ni-WC Powder from China

For B2B buyers — whether you’re a distributor, OEM, or materials procurement officer — sourcing Ni-WC powder in bulk requires a streamlined, transparent, and technically supported process. Shanghai Truer Technology Co., Ltd offers a flexible and efficient ordering system tailored to international buyers.

🛒 Step-by-Step Wholesale Ordering Process from Shanghai Truer

| Step | Description |

|---|---|

| 1 | Submit Inquiry via Contact Page with technical specs, quantity, and usage info |

| 2 | Technical Consultation — Truer’s engineers will suggest optimal Ni-WC blend & particle size |

| 3 | Receive Quotation with lead time, delivery options, and payment terms |

| 4 | Sample Testing (Optional) — Order 1–5 kg sample for compatibility testing |

| 5 | Bulk Order Confirmation — MOQ starts at 50 kg with volume discount tiers |

| 6 | Production & Quality Control — ISO-certified QA process, particle size & morphology reports provided |

| 7 | Shipping — Global delivery via air or sea, with real-time tracking supported |

| 8 | Post-Sales Support — Technical support for integration with your manufacturing process |

📦 Packaging & Delivery Options

- Standard Packaging: Sealed aluminum-lined bags within steel drums (25kg or 50kg net weight)

- Custom Labels: Company logo, batch number, and QR-coded traceability

- Lead Time: 7–14 days for standard grades, 14–21 days for customized powders

💲 Payment & Trade Terms

- Accepted Terms: T/T, L/C, Alibaba Trade Assurance

- FOB / CIF / DAP Available: Depending on buyer location

- Samples: Free samples available for qualified B2B clients

With a proven track record in delivering high-quality powder to over 30 countries, Shanghai Truer ensures your procurement process is smooth, timely, and technically verified.

9. FAQs: Buying Ni-WC Powder in Bulk for Industrial Use

Q1: What Ni:WC ratio is standard in the industry?

A: Common ratios include 60:40, 70:30, and 80:20 (Nickel:Tungsten Carbide), depending on application. Truer offers custom blending to match specific mechanical or thermal requirements.

Q2: Is your Ni-WC powder compatible with additive manufacturing?

A: Yes. Truer’s spherical and fine particle Ni-WC powders are optimized for processes like SLM, binder jetting, and DED. Visit our PM Powder Page for technical data sheets.

Q3: Can I request custom particle size distribution?

A: Absolutely. Truer can supply powders with PSD ranging from 15–53 μm, 45–105 μm, or as per your process requirements.

Q4: What is the minimum order quantity for international buyers?

A: The MOQ starts at 50 kg for industrial clients. Sample orders of 1–5 kg are also available for testing before committing to volume purchases.

Q5: What quality certifications do you provide?

A: All powders are produced under ISO 9001:2015 certified processes. Material certifications, SDS, and third-party test reports are available upon request.

Q6: What industries commonly purchase your Ni-WC powder?

A: Our clients come from oil & gas, aerospace, mining, and advanced manufacturing sectors. We also support R&D labs and universities for material development.

Q7: How do I reach your technical sales team?

A: Simply fill out our contact form or email us directly. Our team will respond within 24 hours with application-specific advice.

Ready to Upgrade Your Materials Supply Chain?

Shanghai Truer Technology Co., Ltd is not just a powder supplier — we are your engineering partner in performance materials. Whether you’re a distributor looking for long-term sourcing, an OEM needing high-precision powder, or a production engineer optimizing your AM workflow, we’re here to help.

Why Choose Truer?

✅ In-house production with advanced atomization

✅ Customizable Ni-WC formulations

✅ Fast lead times and global shipping

✅ Trusted by over 100 industrial clients worldwide

✅ Dedicated support from powder to part

To get started with your wholesale Ni-WC powder order, contact us today or explore more on our official site.

🔗 Internal Anchor Texts Used:

- Powder Metallurgy Page

- About Shanghai Truer Technology

- Contact Page

- Main Website

- PM Powder Technical Data

Stay ahead of your competition with high-performance Ni-WC powder solutions from Shanghai Truer — engineered for precision, built for industry.