1. Introduction: Why Copper Alloy Powder is Critical in Modern Manufacturing

Copper alloy powders play a vital role in numerous industries due to their excellent electrical conductivity, thermal conductivity, corrosion resistance, and malleability. These powders are used in powder metallurgy (PM), additive manufacturing (3D printing), electronics, automotive, and aerospace sectors.

From electrical contacts to structural components, copper alloy powders offer high-performance characteristics in compact, customizable forms. As global manufacturing shifts toward more sustainable and cost-effective production methods, demand for high-quality copper-based powders continues to surge.

Key Benefits of Copper Alloy Powders in B2B Manufacturing:

- ✅ High electrical and thermal conductivity

- ✅ Excellent corrosion resistance

- ✅ Superior mechanical strength when alloyed

- ✅ Compatibility with PM and additive manufacturing processes

- ✅ Customizable for specific industrial applications

Copper Alloy Powder for B2B Segments:

| Industry | Application Example |

|---|---|

| Automotive | Brake pads, bearings, gears |

| Electronics | Electrical contacts, heat sinks |

| Aerospace | Structural components, bushings |

| Additive Manufacturing | Custom 3D printed parts |

| Industrial Machinery | Heavy-duty wear-resistant parts |

As a result, copper alloy powders are in high demand among bulk buyers, manufacturers, and global distributors seeking reliable, high-performance materials.

2. Industrial Applications of Copper Alloy Powders

Copper alloy powders are integral to many industrial applications where strength, conductivity, and resistance to wear or corrosion are necessary. Their flexibility in shaping, sintering, and alloying makes them ideal for various sectors.

Key B2B Applications of Copper Alloy Powders:

1. Powder Metallurgy (PM) Parts

Copper alloys are pressed and sintered into complex shapes for automotive, electrical, and industrial components. These parts are cost-effective and require minimal machining.

2. Electrical Components

Due to copper’s excellent conductivity, copper alloy powders are widely used in electrical contacts, connectors, and terminals.

3. Additive Manufacturing (3D Printing)

Copper alloy powders are used in laser sintering and binder jetting to create lightweight, conductive 3D printed components for electronics and aerospace.

4. Diamond Tools and Bearings

Diffusion copper-tin (CuSn) alloy powders are commonly used in diamond tools and sintered bearings due to their excellent bonding and lubrication properties.

5. Heat Exchangers and Heat Sinks

Copper’s thermal conductivity makes it essential for manufacturing heat-dissipating components.

Advantages in B2B Context:

- Reduced scrap and material waste

- Lower production cost for high-volume manufacturing

- Efficient supply chain integration with PM and AM processes

- High reliability in end-use applications

Table: Sector-wise Use of Copper Alloy Powders

| Industry | Copper Alloy Used | Typical Products |

|---|---|---|

| Automotive | Brass, Bronze | Brake pads, gears, bushings |

| Electronics | Copper-tin, CuNi | Connectors, switches, contacts |

| Aerospace | CuCrZr, Bronze | Heat exchangers, structural parts |

| Tools & Bearings | CuSn | Diamond tools, self-lubricating bearings |

3. Types of Copper Alloy Powders and Their Properties

Copper alloy powders vary based on their metal composition, production method, and intended application. Understanding the types available helps wholesale buyers and engineers select the right powder for specific use cases.

Common Types of Copper Alloy Powders

| Alloy Type | Composition | Key Properties | Applications |

|---|---|---|---|

| PM Bronze | Copper + Tin | High wear resistance, good lubrication | Bearings, bushings, diamond tools |

| PM Brass | Copper + Zinc | Corrosion resistance, machinability | Electrical parts, decorative components |

| PM Nickel Silver | Copper + Nickel + Zinc | Non-magnetic, corrosion-resistant | Musical instruments, electrical devices |

| PM Copper Steel | Copper + Iron | High strength, good conductivity | Structural parts, automotive components |

| PM Phosphorus Iron | Iron + Phosphorus + Copper | Enhanced strength, good sinterability | Gears, sprockets, heavy-duty PM parts |

Production Methods

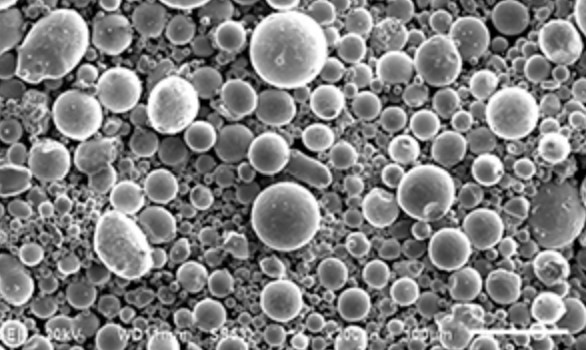

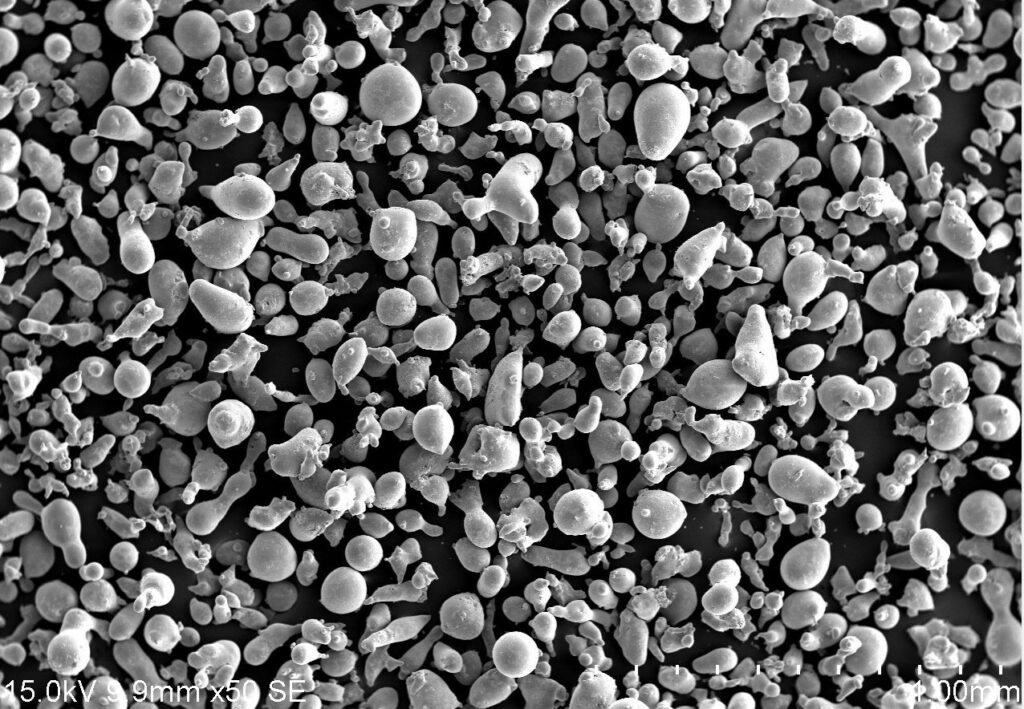

- Water Atomization

- High production volume

- Economical for large-scale PM applications

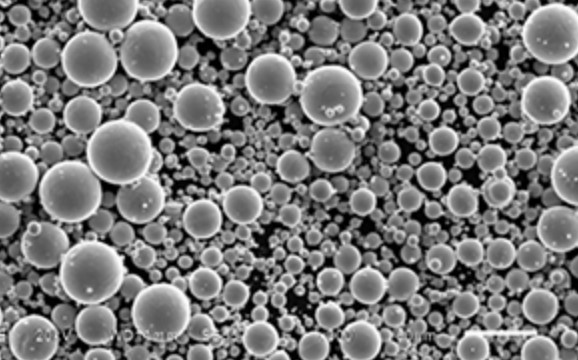

- Gas Atomization

- Finer particles, high purity

- Ideal for additive manufacturing

- Carbonyl Process

- Ultra-fine powder, high surface area

- Used in high-performance sintered parts

- Reduction Method

- Cost-effective for basic copper powders

- Used in general industrial applications

Why Properties Matter for B2B Buyers

- Grain size affects sintering behavior and part density

- Alloy composition influences mechanical strength and wear resistance

- Purity impacts conductivity and corrosion resistance

Shanghai Truer Technology Co., Ltd offers a comprehensive range of Copper Alloy Powders suitable for all major industrial applications. These powders are produced using advanced atomization techniques to ensure consistency, purity, and performance.

4. Market Trends and Demand Forecast for Copper Alloy Powders

The global market for copper alloy powders has experienced steady growth driven by increasing demand from manufacturing sectors such as automotive, electronics, and additive manufacturing. As sustainability, energy efficiency, and high-performance materials become more important, copper alloys are poised to remain a key material in industrial applications.

Global Market Overview

According to market research reports, the copper powder market is expected to grow at a CAGR of over 4.5% from 2024 to 2030. This growth is fueled by:

- Rising adoption of powder metallurgy in automotive parts

- Expansion of electric vehicle (EV) production

- Growth in 3D printing applications across aerospace and healthcare

- Increased demand for thermal and electrical components in electronics

Regional Demand Insights

| Region | Key Drivers |

|---|---|

| North America | Advanced manufacturing, aerospace, EVs |

| Europe | Green energy systems, high-end electronics |

| Asia-Pacific | Mass production, low-cost manufacturing, infrastructure |

| Middle East/Africa | Mining, heavy machinery |

Asia-Pacific remains the fastest-growing region due to its expansive manufacturing base, especially in China and India. This is also where many global buyers are now sourcing their copper alloy powders for cost and scale advantages.

Demand by Industry (2024–2030 Forecast)

| Industry | Market Share (%) | Growth Trend |

|---|---|---|

| Automotive | 30% | High – due to lightweight and durable parts |

| Electronics | 25% | Stable – increased use in smart devices |

| Additive Manufacturing | 15% | Rapid – expanding applications |

| Aerospace | 10% | Moderate – focus on high-performance alloys |

| Others (tools, bearings) | 20% | Moderate – steady industrial demand |

As the market expands, B2B buyers are increasingly looking for qualified and scalable suppliers that can offer consistent quality, competitive pricing, and global logistics support.

5. Key Factors to Consider When Choosing a Copper Alloy Powder Supplier

Selecting the right copper alloy powder supplier is critical for manufacturers and B2B buyers who rely on high-performance materials for precision applications. Here are the top considerations when evaluating potential suppliers:

1. Powder Quality and Customization

- Is the supplier capable of producing alloy powders with consistent particle size and composition?

- Can they provide tailored powders for specific applications (e.g., 3D printing, PM parts)?

2. Production Capacity and Scalability

- Does the supplier have the infrastructure to handle bulk orders?

- Can they scale production based on seasonal or project-based demand?

3. Certification and Compliance

- ISO 9001 or industry-specific certifications (automotive, aerospace)

- Compliance with REACH, RoHS, and other environmental standards

4. Technology and Innovation

- Does the supplier use advanced atomization methods (gas, water, carbonyl)?

- Are they investing in R&D for new alloy development?

5. Logistics and Global Support

- Can they ship efficiently to your region?

- Do they offer warehousing or inventory management for regular buyers?

Supplier Comparison Matrix

| Criteria | Ideal Supplier Profile |

|---|---|

| Powder Quality | Consistent alloy composition; fine particle size |

| Customization | Available for various applications |

| Certifications | ISO, REACH, RoHS |

| Logistics | Global shipping and tracking |

| Technical Support | Engineering consultation and material guidance |

Shanghai Truer Technology Co., Ltd checks all these boxes. With multiple production methods (water atomized, gas atomized, carbonyl), Truer delivers a wide range of copper alloy powders with consistent quality and global shipping capabilities. Learn more about Truer’s capabilities here.

6. Top Global Suppliers and Distributors of Copper Alloy Powders

There are many global players in the copper alloy powder supply chain. Here are some of the most trusted B2B suppliers recognized for quality, capacity, and customer service.

Leading Copper Alloy Powder Manufacturers

| Supplier Name | Region | Key Strengths |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Wide range of PM and AM powders, custom grades |

| GKN Powder Metallurgy | Europe/Global | Automotive PM parts, strong R&D |

| Höganäs AB | Sweden | High-end PM materials, sustainability focus |

| SCM Metal Products | USA | Copper-based powders for metallurgy |

| Mitsui Mining & Smelting | Japan | High-purity copper and alloy powders |

Shanghai Truer stands out in the Chinese market for its comprehensive offering of copper alloy powders, including PM Bronze, Nickel Silver, Brass, and CuSn diffusion powders used in a wide range of industries. With over a decade of experience and a strong focus on additive manufacturing since 2019, Truer is a preferred partner for many global manufacturers.

Advantages of Working with Truer

- ✅ Full range of copper alloy powders for PM and 3D printing

- ✅ Multiple manufacturing methods (gas, water, carbonyl, reduction)

- ✅ Certified quality control and R&D capability

- ✅ Reliable bulk supply and competitive pricing

- ✅ Professional B2B support and technical consulting

To explore Truer’s complete product range, visit their PM powder portfolio.

7. Why More Buyers Are Sourcing Copper Alloy Powders from China

In recent years, China has emerged as a dominant force in the global copper alloy powder market. For B2B buyers, distributors, and OEM manufacturers, sourcing from China offers a compelling mix of cost efficiency, advanced production capabilities, and a diverse supplier base.

Key Reasons for the Shift to Chinese Suppliers

1. Competitive Pricing Without Compromising Quality

- Lower labor and operational costs allow Chinese suppliers to offer more attractive pricing.

- High-volume manufacturing enables economies of scale for wholesale buyers.

- Many Chinese suppliers, including Shanghai Truer, match or exceed international quality standards.

2. Comprehensive Product Range

Chinese manufacturers typically offer a broader variety of copper alloy powders, tailored for both powder metallurgy (PM) and additive manufacturing (AM). This includes:

- PM Bronze, PM Brass, PM Nickel Silver

- Iron-Copper and Iron-Nickel alloys

- CuSn diffusion powders for diamond tools and sintered bearings

3. Advanced Manufacturing Technologies

Top-tier Chinese suppliers like Shanghai Truer use:

- Water atomization

- Gas atomization

- Carbonyl and reduction methods

- Hybrid atomization for specialized applications

These methods ensure high purity, consistent particle morphology, and application-specific performance.

4. Strengthening Supply Chain Resilience

- Flexible MOQs (Minimum Order Quantities) for small to large enterprises

- Faster production and delivery timelines

- Integrated logistics and global shipping support

5. Strong Focus on Export and B2B Services

Suppliers such as Shanghai Truer have built robust B2B export teams, providing services like:

- Technical consultation

- Custom product development

- After-sales support

- Documentation for compliance and import/export regulations

Chart: Benefits of Sourcing from China vs. Other Regions

| Parameter | China | Europe / North America |

|---|---|---|

| Price Competitiveness | ★★★★★ | ★★☆☆☆ |

| Product Variety | ★★★★★ | ★★★☆☆ |

| Custom Alloy Development | ★★★★☆ | ★★★☆☆ |

| Production Lead Time | ★★★★☆ | ★★☆☆☆ |

| Export Support Services | ★★★★☆ | ★★☆☆☆ |

As more B2B buyers reevaluate their sourcing strategies, China—and particularly companies like Shanghai Truer Technology Co., Ltd—has become the go-to choice for high-quality copper alloy powders at globally competitive pricing.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Supplier

Shanghai Truer Technology Co., Ltd stands out as one of China’s most professional and reliable manufacturers of copper alloy powder. Established in 2009 and launching its additive manufacturing division in 2019, Truer has rapidly become a trusted source for powder metallurgy and 3D printing materials.

Truer’s Competitive Advantages for B2B Buyers

🔧 Wide Product Range

Truer offers a full portfolio of copper alloy powders, including:

- PM Bronze

- PM Nickel Silver

- PM Brass

- PM Copper Steel (Iron-Copper)

- PM Phosphorus Iron

- PM Infiltrated Iron and Steel

- CuSn diffusion powders for diamond tools

These powders are available in grades such as CT-1000, F-0000, FD-0208, FN-5000, FX-2008, FD-20Cu, and more.

🏭 Advanced Production Technology

- Water and gas atomization

- Carbonyl and reduction processes

- Combined atomization for specialized applications

- Certified quality control systems

Truer’s flexible manufacturing setup allows it to meet custom specifications and volume requirements for global B2B clients.

🌐 International Export Expertise

- Professional export team fluent in international trade

- Full support for certifications, customs, and logistics

- Global shipping and timely delivery

📈 Customer-Focused R&D and Innovation

Truer’s in-house R&D team works closely with clients to co-develop new alloy powders and improve performance parameters for specialized applications like:

- Powder-based electric vehicle parts

- AM-fabricated aerospace components

- Heat sinks and electrical terminals

🤝 Trusted by Industry Professionals

Truer is recognized as a leading additive supplier in China’s powder metallurgy industry, with a reputation for delivering complete additive solutions and unmatched technical support.

Table: Why B2B Buyers Prefer Shanghai Truer

| Feature | Truer Advantage |

|---|---|

| Product Variety | Full range of copper and hybrid alloy powders |

| Quality Assurance | Consistent particle size, purity, and composition |

| Customization | Tailored solutions for PM and AM applications |

| Export Capability | Proven logistics and documentation support |

| Technical Partnership | Engineering consulting and collaborative R&D |

For more information or to request a quote, visit Truer’s official website.

9. FAQs: Common Questions About Buying Copper Alloy Powder in Bulk

Q1: What is the minimum order quantity (MOQ) for copper alloy powders from Truer?

A: MOQ depends on the specific alloy and granularity, but Truer offers flexible MOQ options to accommodate small and large buyers.

Q2: Can Truer customize copper alloy powders for specific applications?

A: Yes. Truer provides custom alloy development and particle sizing to meet precise B2B application needs like 3D printing or sintered parts.

Q3: What quality standards does Truer follow?

A: Truer adheres to ISO quality management systems and provides full documentation, including COA, TDS, and MSDS.

Q4: Does Truer ship internationally?

A: Yes. Truer has extensive experience in exporting to North America, Europe, Southeast Asia, and the Middle East with reliable logistics support.

Q5: Can I get technical support when selecting the right powder?

A: Absolutely. Truer’s engineering team assists clients in material selection, process compatibility, and performance optimization.

Q6: What are the most popular copper alloy powders for 3D printing?

A: Gas atomized bronze and CuSn alloys are among the most widely used in additive manufacturing for their conductivity and printability.

Q7: Where can I find detailed specifications of Truer’s copper alloy powders?

A: You can explore the full product catalog and technical specifications on their PM powder product page.

By choosing Shanghai Truer Technology Co., Ltd, you are partnering with a reliable, innovative, and globally trusted supplier of copper alloy powders. For product inquiries or custom solutions, connect with the team through their contact page.