1. Introduction to Copper Tin Alloy Powder in Modern Manufacturing

Copper tin alloy powder, also known as bronze powder, plays a critical role in various powder metallurgy (PM) and additive manufacturing (AM) applications. These powders are composed primarily of copper and tin, offering a unique blend of mechanical strength, corrosion resistance, and thermal conductivity. In B2B markets, copper tin alloy powder is widely used by automotive part manufacturers, electrical equipment suppliers, and precision component producers.

For wholesale buyers, the demand for copper tin alloy powder is increasing due to:

- Growth in additive manufacturing and metal 3D printing

- Rising demand for sintered components in automotive and industrial sectors

- Expanding use in diamond tools and oil-impregnated bearings

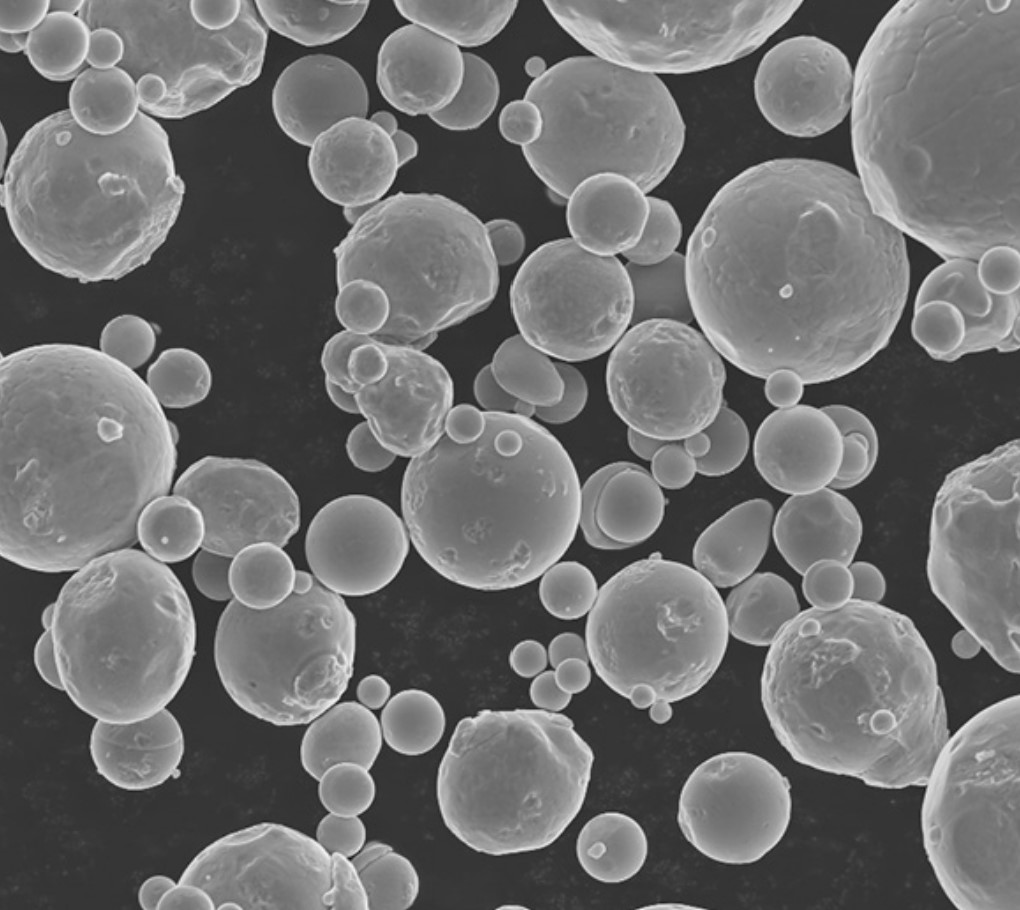

With advanced production technologies like water atomization and gas atomization, manufacturers now produce ultra-fine, high-purity powders suitable for both traditional and advanced manufacturing.

2. Industrial Applications of Copper Tin Alloy Powder

Copper tin alloy powder is a versatile material, especially for B2B buyers who supply to manufacturers across multiple industries. Below are the key sectors and their use cases:

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Sintered bushings, bearings, gears | High wear resistance and self-lubrication |

| Electrical | Conductive components and contact points | Excellent electrical conductivity |

| Aerospace | Lightweight structural parts | Corrosion resistance and strength |

| Diamond Tool Manufacturing | Matrix material for diamond tools | High bonding strength and wear resistance |

| Oil & Gas | Oil-impregnated bearings | Excellent porosity for lubrication retention |

| Consumer Electronics | EMI shielding components | High conductivity and aesthetic finish |

Additional Use Cases:

- Architectural hardware components (e.g., locks, hinges)

- Marine fittings and valves

- Decorative finishes for sculptures and furniture

These widespread applications make copper tin alloy powder a strategic material for wholesalers, distributors, and large-scale manufacturers.

3. Types & Properties of Copper Tin Alloy Powders

Copper tin alloy powders come in a variety of grades and compositions, each designed for specific manufacturing processes and performance requirements. Buyers must assess the right type based on application demands.

Common Types of Copper Tin Alloy Powders

| Powder Type | Composition | Atomization Method | Key Use |

|---|---|---|---|

| Diffusion CuSn | Pre-alloyed copper and tin | Water Atomized | Diamond tools, sintered bearings |

| Bronze PM Powder | Cu + Sn blend | Gas/Water Atomized | Bearings, bushings |

| Pre-alloyed Bronze | Homogeneous alloy | Carbonyl or Gas Atomized | High-precision parts |

Key Material Properties

- Melting Point: 900°C–1000°C depending on Sn content

- Density: 8.2–8.9 g/cm³

- Hardness: Varies by composition, typically 50–90 HB

- Electrical Conductivity: Moderate (15–30% IACS)

- Corrosion Resistance: Excellent, especially in marine environments

Why Pre-Alloyed Powders Are Preferred

- Uniform microstructure

- Better sintering performance

- Enhanced mechanical properties

Shanghai Truer Technology Co., Ltd specializes in diffusion CuSn powder, ideal for high-performance applications such as sintered oil-containing bearings and diamond tools. Their powder metallurgy product line includes a wide variety of metal powders manufactured through advanced atomization methods, ensuring consistency and quality.

4. Global Market Trends for Copper Tin Alloy Powder

The global copper tin alloy powder market is experiencing a surge in demand, driven by the growth of powder metallurgy (PM), additive manufacturing (AM), and sustainable production initiatives in automotive, electrical, and tooling industries. Distributors and B2B wholesale buyers are increasingly turning to advanced powder materials like bronze (Cu-Sn) due to their versatility and performance capabilities.

Key Market Drivers:

- Rise of Electric Vehicles (EVs): Copper tin alloy powders are used in conductive and thermal management parts, fueling demand from EV manufacturers.

- Growth in 3D Printing: The adoption of metal powders in additive manufacturing, especially for prototyping and small batch production, boosts demand for high-purity Cu-Sn powders.

- Sustainable Manufacturing: PM processes reduce waste and energy usage, aligning with global sustainability goals.

- Infrastructure Development: Increased construction and infrastructure projects drive demand for durable, corrosion-resistant bronze components.

Market Size & Forecast

| Year | Global Market Value (USD) | CAGR |

|---|---|---|

| 2022 | $650 Million | 5.8% |

| 2024 | $725 Million (Est.) | 6.2% |

| 2027 | $890 Million (Forecast) | 6.8% |

Regional Demand Highlights

- Asia-Pacific is the largest manufacturing hub, with China, Japan, and South Korea leading in powder metallurgy applications.

- Europe focuses on sustainability and high-performance automotive components.

- North America drives innovation in AM and aerospace applications.

Wholesale buyers looking to capitalize on this trend should secure reliable supplier partnerships, especially in Asia, where production capabilities continue to scale.

5. Key Criteria for Selecting a Reliable Powder Supplier

Choosing the right copper tin alloy powder supplier is crucial for manufacturers, distributors, and e-commerce sellers sourcing industrial materials. Here are essential factors to consider:

A. Powder Quality & Consistency

- Particle size distribution (PSD): Uniform PSD ensures consistent sintering and final part properties.

- Purity level: Low impurity content (e.g., sulfur, phosphorus) is critical for high-performance parts.

- Atomization method: Gas atomization produces spherical particles ideal for AM; water atomization is cost-effective for PM.

B. Production Capabilities

- Capacity to fulfill bulk orders

- Customizable alloy compositions

- In-house testing and quality assurance labs

C. Technical Support & Certifications

- ISO 9001 or other quality management certifications

- Material safety data sheets (MSDS) and technical datasheets

- Application-specific recommendations from R&D teams

D. Logistics & Lead Time

- Short lead times and stable supply chains

- Flexible shipping options (FOB, CIF, DDP)

- Strong packaging solutions to maintain powder integrity

E. Price & MOQ (Minimum Order Quantity)

- Competitive wholesale pricing with volume discounts

- Transparent pricing models

- Reasonable MOQs for distributors and small-batch buyers

Working with a supplier like Shanghai Truer Technology Co., Ltd, which combines manufacturing experience with technical expertise, ensures long-term reliability and performance in your production chain.

6. Top Wholesale Copper Tin Powder Suppliers in Asia

Asia is home to the world’s most advanced and cost-effective powder metallurgy ecosystems. Here are top players for B2B buyers seeking copper tin alloy powders:

| Company Name | Country | Strengths | Website |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Wide range of CuSn powders, custom blends, advanced atomization | am-material.com |

| Fukuda Metal Foil & Powder | Japan | High-purity powders for electronics | N/A |

| Hoganas AB (Asia Division) | China/Japan | Global brand, large distribution network | hoganas.com |

| CNPC Powder | China | Mass production, cost-effective options | cnpcpowder.com |

| Kymera International | South Korea | Alloy innovation and R&D | kymerainternational.com |

Why Shanghai Truer Stands Out:

- Offers diffusion CuSn powder specifically for PM bearings and diamond tools

- Provides both water atomized and gas atomized powder options

- Supplies hybrid low-alloy PM powders such as FD-0200, FN-5000, and more

- Known for comprehensive technical support and tailored additive solutions

Distributors and OEMs looking to source wholesale copper tin alloy powder can contact Truer directly for product catalogs, pricing, and sample requests.

7. Why Buyers Are Switching to Chinese Powder Manufacturers

In recent years, B2B buyers across North America, Europe, and Southeast Asia have increasingly shifted their sourcing strategies toward Chinese powder metallurgy manufacturers. This trend is especially strong in the copper tin alloy powder sector.

Here’s why more international buyers are choosing Chinese suppliers like Shanghai Truer Technology Co., Ltd:

A. Cost Competitiveness

- Lower production costs due to economies of scale and efficient labor markets

- Affordable pricing for both standard and customized alloy powders

- Volume discounts for distributors and long-term partners

B. Technological Advancements

- Chinese manufacturers, including Truer, use state-of-the-art atomization methods (water, gas, and hybrid atomization)

- Ability to produce high-purity and fine particle powders for advanced applications like additive manufacturing and sintered bearings

C. Flexibility and Customization

- Tailored powder compositions to meet unique application requirements

- Small-batch customization options for R&D and prototyping

- Wide range of grades such as FD-0208, FN-5000, and diffusion CuSn

D. Integrated Services

- In-house R&D and application support

- Packaging, logistics, and documentation tailored for international trade

- Responsive communication and multilingual support for global clients

Example: Shanghai Truer Technology Co., Ltd

- Supplies to over 20 countries worldwide

- Offers advanced CuSn powder for diamond tools, oil-impregnated bearings, and PM parts

- Recognized as one of China’s most professional additive solution providers for PM applications

For buyers seeking a strategic supply partner, Truer’s additive division offers reliability, scalability, and deep technical know-how.

8. Why Choose Shanghai Truer Technology as Your Supplier

Shanghai Truer Technology Co., Ltd is not just a manufacturer — it is a full-service powder metallurgy solution provider that has been serving the industry since 2009. Since launching its additive manufacturing division in 2019, Truer has quickly become a trusted supplier for copper tin alloy powders both in China and globally.

Truer’s Key Strengths for Wholesale Buyers:

| Feature | Benefit to B2B Customers |

|---|---|

| Over 14 Years of Experience | Proven expertise in metallurgy and powder production |

| Advanced Atomization Techniques | Water, gas, and combined methods for optimal powder quality |

| Broad Product Range | PM bronze, CuSn diffusion powder, low-alloy and hybrid steel powders |

| Custom Alloy Development | Tailored solutions for unique application needs |

| Additive Expertise | Strong support for 3D printing materials and sintered component production |

Product Portfolio Highlights:

- Diffusion CuSn Powder: Ideal for sintered bearings and diamond tools

- Prealloyed PM Steels: Including 4600, 4200, FD-0200, and more

- Lubricants and Additives: Lube-W, SUW-8000, SME-100 cutting agent

- Soft Magnetic Additives: QH-150, QHP-330 for motor core applications

As a recognized specialist in the Chinese market, Truer is committed to quality, innovation, and customer service, making it the perfect partner for OEMs, distributors, and large-scale manufacturers.

To explore Truer’s full product range, visit their official website.

9. FAQs: Buying Wholesale Copper Tin Alloy Powder

Q1: What is the minimum order quantity (MOQ) for copper tin alloy powder?

A: Shanghai Truer typically offers MOQs starting at 25 kg for standard grades. Custom MOQ terms can be discussed based on the application and destination.

Q2: Can I request a sample before placing a bulk order?

A: Yes. Truer provides free or low-cost samples for evaluation. Shipping charges may apply depending on location.

Q3: Which atomization method should I choose?

A:

- Water Atomized Powder: Cost-effective, ideal for conventional PM parts

- Gas Atomized Powder: Spherical particles, best for additive manufacturing

- Hybrid Atomization: Balances cost and performance for advanced applications

Truer’s technical team can help you select the appropriate method.

Q4: How does Truer ensure powder quality and consistency?

A: Truer utilizes in-house laboratories for quality control, including PSD analysis, chemical composition testing, sintering behavior, and flowability checks. All shipments include COA and relevant certifications.

Q5: How do I place a wholesale order?

A:

- Visit the contact page

- Submit your inquiry including quantity, grade, and specifications

- Receive a custom quote and delivery timeline within 24–48 hours

- Confirm your order and initiate production

Embedded Internal Links Recap

Here are the internal links embedded throughout the blog post:

- PM Powder Product Line – See full portfolio of CuSn and other PM powders

- About Truer Technology – Learn more about the company’s history and mission

- Contact Us – Submit RFQs and sample requests

- Official Website – Explore all products, services, and technical support

- PM Powder Division – Get in-depth technical details on available grades

🟢 Ready to source high-quality copper tin alloy powder?

💬 Contact Shanghai Truer Technology Co., Ltd today for samples, pricing, and customized solutions tailored to your manufacturing needs. Visit am-material.com to explore the full product catalog and get a quote.