1. Introduction to Steel Powder in Modern Manufacturing

Steel powder is a cornerstone material in powder metallurgy (PM) and additive manufacturing (AM), playing a vital role in producing high-performance components across industries such as automotive, aerospace, medical, and industrial tooling. As global manufacturing pivots toward lightweight, precision-engineered parts, steel powder offers unmatched versatility and performance.

Why Steel Powder Matters in B2B Manufacturing

- High Strength-to-Weight Ratio: Ideal for structural components.

- Excellent Formability: Suitable for complex geometries in AM and PM.

- Cost Efficiency: Reduces material waste through near-net-shape production.

- Scalability: Bulk manufacturing capabilities for OEMs and suppliers.

Steel powders are commonly used in sintered parts, magnetic components, and wear-resistant applications. With growing demand for sustainable and precision-engineered components, wholesale buyers and industrial distributors are increasingly sourcing steel powder in bulk to remain competitive.

2. Industrial Applications of Steel Powder

Steel powder’s versatility allows it to serve a wide range of sectors. Below are major industrial applications:

| Industry | Application Examples | Benefits of Steel Powder |

|---|---|---|

| Automotive | Gears, bearings, bushings, brake pads | High wear resistance, mass production scalability |

| Aerospace | Turbine components, structural parts | High strength, lightweight |

| Medical | Surgical tools, orthopedic implants | Biocompatibility, precision fabrication |

| Tooling & Machining | Dies, cutting tools, wear-resistant inserts | Hardness, machinability |

| Consumer Goods | Appliance components, locks, and fasteners | Cost-effective, corrosion resistance |

Common Use Cases in Manufacturing

- Additive Manufacturing (3D Printing): Gas atomized stainless steel powders enable precise, durable prototypes and end-use parts.

- Powder Metallurgy (PM): Water atomized and diffusion-alloyed steel powders are used for mass production of mechanical components.

- Sintered Products: High-density structural parts used in automotive and industrial machinery.

Shanghai Truer Technology Co., Ltd plays a vital role in supporting these applications by offering steel powders tailored for both powder metallurgy and additive manufacturing.

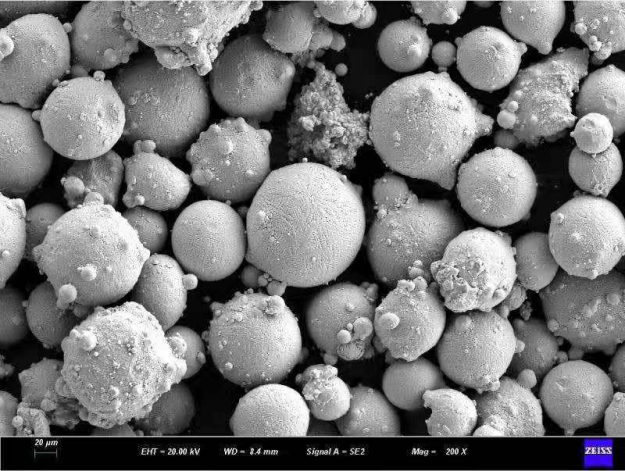

3. Types of Steel Powder and Their Properties

Steel powders differ in alloy composition, particle size, production method, and mechanical properties. Choosing the right type depends on the end-use application and required performance.

Major Categories of Steel Powder

| Steel Powder Type | Alloy Composition | Production Method | Key Properties | Common Grades |

|---|---|---|---|---|

| Prealloyed Steel Powder | Iron + alloying elements | Water or gas atomization | Consistent properties, high strength | FL-4605, FX-2008 |

| Hybrid Low-Alloy Powder | Iron + pre-mixed additives | Diffusion alloying | Cost-effective, good machinability | FD-0208, FD-0200 |

| Stainless Steel Powder | Fe-Cr-Ni alloys | Water/gas atomized | Corrosion-resistant, AM-compatible | SBF2218 |

| Iron-Copper Powder | Iron + Copper | Reduction or atomization | Enhanced wear resistance | FD-20Cu, FC-0208 |

| Iron-Nickel Powder | Iron + Nickel | Carbonyl or reduction | Improved magnetic performance | FN-0205, FN-5000 |

Choosing the Right Steel Powder

- For tooling applications: Choose high-hardness prealloyed powders like FL-4605.

- For automotive PM parts: Opt for hybrid low-alloy grades such as FD-0208.

- For 3D printing: Gas atomized stainless steel powders ensure uniformity and precision.

Shanghai Truer offers a comprehensive range of steel powders manufactured via water, gas, and combined atomization techniques to meet varying demands. For example, their diffusion alloyed steel grades like FD-0208 are widely used in sintered structural parts due to their high compressibility and strength.

🔗 Learn more about the types of PM steel powders offered by Shanghai Truer.

4. Market Trends and Global Demand for Steel Powder

The global steel powder market has witnessed significant growth driven by the expansion of automotive, aerospace, and additive manufacturing industries. As sustainability, precision engineering, and lightweight materials become top priorities, steel powder continues to gain traction among OEMs and industrial buyers.

Global Market Overview

According to market research:

- The global steel powder market size exceeded $4.5 billion in 2022.

- It’s projected to grow at a CAGR of 6.8% from 2023 to 2030.

- Asia-Pacific dominates the market with over 45% share, led by China, Japan, and India.

Key Trends Shaping the Market

- 🔩 Growth of Additive Manufacturing: Increasing use of stainless and tool steel powders in 3D printing.

- 🚗 Automotive Electrification: Demand for lightweight, high-performance components.

- 🛠️ Customization & Miniaturization: Complex part designs requiring high-purity steel powders.

- 🌱 Sustainability Focus: Powder metallurgy reduces material waste and energy use.

Demand by Region (2023)

| Region | Key Drivers | Demand Share |

|---|---|---|

| Asia-Pacific | Large manufacturing base, cost-effective production | 45% |

| North America | Aerospace, defense, and automotive innovation | 25% |

| Europe | Adoption of green technologies and powder metallurgy | 20% |

| Others | Emerging economies in South America and Middle East | 10% |

Steel powder demand is expected to increase notably among wholesale distributors and parts manufacturers looking to integrate AM and PM technologies. This opens sourcing opportunities for reliable suppliers like Shanghai Truer Technology Co., Ltd.

5. Key Factors to Consider When Choosing a Steel Powder Supplier

Choosing the right supplier is critical for maintaining the integrity and performance of your products. For B2B buyers, especially in automotive or aerospace sectors, the decision goes beyond price.

Essential Criteria for Supplier Selection

| Evaluation Criteria | What to Look For |

|---|---|

| Product Range | Variety of steel powder types and grades |

| Production Capabilities | Modern atomization methods (gas, water, hybrid) |

| Quality Certifications | ISO, REACH, RoHS, IATF 16949 |

| Technical Support | Application guidance, sample testing, R&D partnership |

| Lead Times & Logistics | Fast turnaround, global delivery network |

| Customization Options | Tailored particle size, alloy composition, packaging |

Red Flags to Avoid

- Inconsistent particle size distribution

- Low purity or contamination

- Lack of transparency in sourcing and production

- No technical data sheets or COAs (Certificates of Analysis)

A reliable supplier like Shanghai Truer not only provides high-quality steel powders but also supports B2B clients with engineering consultation, custom blends, and additive formulations.

🔗 Learn more about how to contact Shanghai Truer for wholesale orders.

6. Top 5 Steel Powder Suppliers in Asia

Asia is home to several globally recognized steel powder manufacturers. Let’s compare the top five based on quality, range, and service capabilities.

| Supplier | Country | Strengths | Product Offerings |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Comprehensive grades, tailored solutions, expert consultation | PM & AM steel powders, additives, lubricants |

| Hoganas AB (Asia Division) | Sweden/China | Global footprint, high R&D investment | Prealloyed powders, soft magnetic powders |

| GKN Hoeganaes | USA/India | Advanced metallurgy, strong global support | Hybrid and prealloyed steel powders |

| JFE Steel | Japan | High-quality stainless and tool steel powders | Gas atomized stainless steel powders |

| CNPC Powder | China | Competitive pricing, large-scale production | Water atomized iron and steel powders |

Why Shanghai Truer Stands Out

Shanghai Truer Technology Co., Ltd offers a rare combination of:

- 🌐 Local production with global quality standards

- 🧪 In-house R&D and powder formulation services

- 📦 Bulk packaging for wholesale buyers

- ⚙️ Support for both powder metallurgy and additive manufacturing applications

In addition to steel powders, Truer provides essential PM additives like SUW-8000 lubricants, SME-100 cutting agents, and diffusion CuSn powder for sintered bearings and diamond tools — making it a one-stop sourcing partner.

🔗 Visit Truer’s homepage to explore their full steel powder and additive product line.

7. Why More Manufacturers Are Choosing Chinese Steel Powder Suppliers

In recent years, there has been a marked shift in sourcing strategies among global manufacturers, particularly in the powder metallurgy and additive manufacturing sectors. Increasingly, OEMs, distributors, and e-commerce sellers are turning to Chinese steel powder suppliers for their wholesale needs. This is not just a cost-driven decision—Chinese suppliers now offer competitive advantages in quality, innovation, and supply chain reliability.

Key Advantages of Chinese Steel Powder Suppliers

| Benefits | Description |

|---|---|

| 🏭 Cost Efficiency | Lower production costs without compromising on quality |

| ⚙️ Advanced Manufacturing | Adoption of water/gas atomization, diffusion alloying, and hybrid methods |

| 🧪 R&D Capabilities | Custom powder solutions, application-specific development |

| 🚚 Scalable Logistics | High-volume production and efficient global shipping |

| 📄 Regulatory Compliance | ISO-certified facilities with global export experience |

Case Example: Shanghai Truer Technology Co., Ltd

Shanghai Truer exemplifies the evolution of Chinese suppliers. With over a decade of powder metallurgy experience and a dedicated additive manufacturing division launched in 2019, Truer delivers high-purity steel powders that meet the demands of B2B clients worldwide.

What sets Truer apart:

- Offers a wide range of steel powder grades (e.g., FL-4605, FD-0208, SBF2218)

- Utilizes advanced atomization techniques (gas, water, hybrid)

- Provides comprehensive PM additives and lubricants

- Delivers technical support and custom formulations for OEMs and wholesalers

🔗 Discover Truer’s company background and expertise.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Steel Powder Partner

If you’re a manufacturer, distributor, or industrial buyer looking for a long-term steel powder sourcing partner, Shanghai Truer Technology Co., Ltd is a trusted choice in China’s powder metallurgy industry. Here’s why:

Comprehensive Product Portfolio

- PM steel powders: FD-0200, FD-0208, FL-4605, FN-0205, FN-5000

- Stainless steel powders: SBF2218, gas/water atomized grades

- Diffusion alloyed steel powders: FX-2008, FX1005

- Additional PM materials: CuSn diffusion powder, iron-copper, and iron-nickel blends

PM Additives for Performance Optimization

Truer is more than just a powder producer—it offers full additive packages for PM processes:

| Additive Type | Product Name | Use Case |

|---|---|---|

| Lubricants | Lube-W, SUW-5000B, SUW-8000 | Improves compaction and sintering efficiency |

| Cutting Agents | Manganese Sulfide, SME-100 | Enhances machinability |

| Soft Magnetic Additives | QH-150, QHP-330 | Used in magnetic PM components |

| Graphite Additives | TBC-400, TBC-1000 | Carbon control in sintered parts |

End-to-End Support for B2B Buyers

- 📦 Flexible order volumes: from small-batch to full-container loads

- 🧾 Technical documentation: COAs, SDS, TDS provided

- 🧑🔬 Engineering consultation: help with product development and testing

- 🌍 Global shipping: on-time delivery to North America, Europe, and Asia

🔗 View steel powder products and request samples via Truer’s product listing page.

9. FAQs: Common Questions About Buying Wholesale Steel Powder

Here are answers to some of the most frequently asked questions by B2B buyers, distributors, and OEMs.

Q1: What is the minimum order quantity (MOQ) for wholesale steel powder?

- Shanghai Truer offers flexible MOQs depending on the powder type. Standard MOQ is 500 kg, but custom arrangements can be made for sample lots or pilot projects.

Q2: What particle sizes are available?

- Particle sizes typically range from 15μm to 300μm, depending on the production method (gas vs. water atomized). Custom sieving is available upon request.

Q3: Can I request a custom steel powder formulation?

- Yes. Truer’s R&D team can formulate custom steel powder blends tailored to your mechanical property or sintering requirements.

Q4: Do you offer technical support during application development?

- Absolutely. Truer provides full technical support, including powder selection, sintering guidance, and additive optimization for various industries.

Q5: How do I get a quote and sample?

- You can request a quote and technical datasheets via the Contact Us page. Sample requests are typically processed within 3–5 working days.

By offering a wide variety of steel powder grades, technical support, and global delivery, Shanghai Truer Technology Co., Ltd stands out as a reliable partner for manufacturers, distributors, and industrial buyers.

🔗 Ready to take the next step? Visit the homepage to explore all steel powder solutions and get in touch with the Truer team.