1. Introduction: Why Iron Powder is Vital in Modern Manufacturing

Iron powder plays a critical role in today’s manufacturing and metallurgy industries, especially in applications related to powder metallurgy (PM), additive manufacturing (AM), magnetic materials, and surface coating. With the shift towards lightweight, cost-effective, and high-performance components, iron powder has become a go-to material for B2B customers ranging from automotive OEMs to industrial equipment manufacturers.

Why Iron Powder is Important for B2B Buyers:

- Cost Efficiency: Lower production costs due to near-net-shape manufacturing.

- Material Versatility: Suitable for various industrial applications.

- Sustainability: Enables waste reduction and energy-efficient production.

- Customization: Available in multiple grades and particle sizes for targeted applications.

Whether you’re a supplier of automotive components or a manufacturer of sintered structural parts, sourcing high-quality iron powder can significantly improve your product performance and operational efficiency.

2. Key Industrial Applications of Iron Powder

Iron powder is used across a broad range of industries, especially where strength, wear resistance, and thermal conductivity are required. Below are core B2B industrial sectors that heavily rely on iron powder:

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Gears, bearings, bushings, camshaft pulleys | High strength, precision, mass production |

| Aerospace | Magnetic components, filters | Lightweight, corrosion resistance |

| Electronics | Magnetic cores, inductors | High permeability, stable magnetic properties |

| Construction | Welding electrodes, heavy machinery components | Durability, cost-effective production |

| Additive Manufacturing | 3D printed parts, prototyping | Complex geometries, rapid production |

Common Use Cases:

- Powder metallurgy components

- Magnetic materials

- Soft magnetic composites

- Friction materials

- Diamond tools and sintered bearings

For instance, Shanghai Truer Technology’s PM iron and steel powders are widely used in the automotive and manufacturing sectors to create high-precision, high-density parts. Their powders are produced through water atomization, reduction, or carbonyl methods to meet various customer needs.

3. Types of Iron Powder and Their Properties

There are several classifications of iron powder depending on manufacturing methods and chemical composition. Choosing the right type is essential for industrial buyers aiming to optimize performance.

Main Iron Powder Types:

| Type | Production Method | Key Features | Applications |

|---|---|---|---|

| Reduced Iron Powder | Hydrogen or CO reduction | High purity, irregular shape | Soft magnetic parts, friction materials |

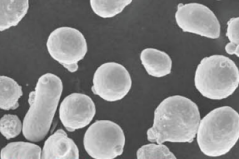

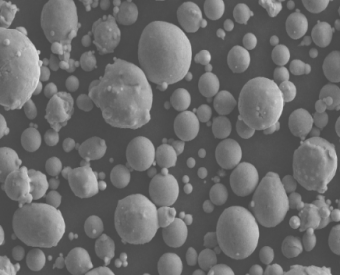

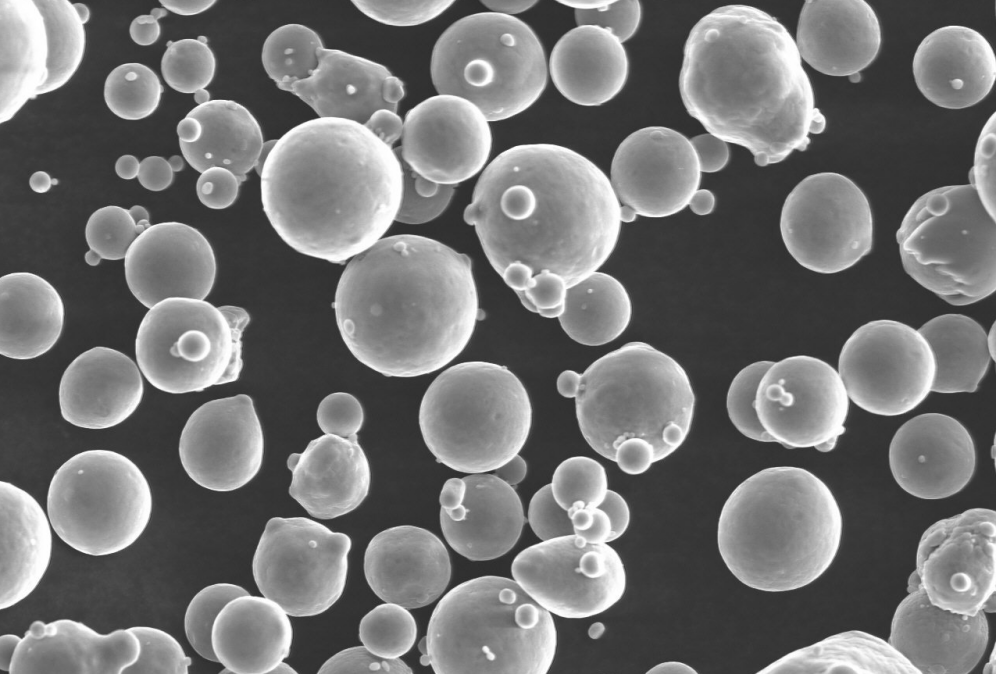

| Atomized Iron Powder | Water or gas atomization | Spherical particles, good flowability | PM parts, AM applications |

| Carbonyl Iron Powder | Carbonyl decomposition | Ultra-fine, high purity | Magnetic materials, electronics |

| Electrolytic Iron Powder | Electrochemical process | High density, low carbon | Welding, food fortification |

Popular Grades by Shanghai Truer:

- CT-1000, F-0000, F0008: General-purpose reduced iron powders.

- FC-0208, FL-4605: Alloyed powders for stronger mechanical properties.

- FD-0200, FD-0208: Diffusion alloyed powders for PM structural parts.

These PM iron powders are ideal for industries seeking consistent performance, and Truer’s extensive product list provides detailed specifications for each grade and application.

Advantages of Using Shanghai Truer’s Iron Powders:

- Multiple production methods (water atomized, carbonyl, reduction)

- Customizable particle sizes and distributions

- Competitive pricing and consistent quality

- Compliance with international standards

4. Global Market Trends and Growth Opportunities

The global iron powder market is experiencing significant growth, driven by increased demand across the automotive, additive manufacturing, and electronics sectors. For B2B buyers, understanding these trends is essential for strategic sourcing and supply chain planning.

Key Market Insights:

- Market Size: The global iron powder market was valued at over USD 5 billion in 2023 and is projected to grow at a CAGR of 4.5% through 2030.

- Regional Demand: Asia-Pacific dominates the market due to its robust manufacturing infrastructure, with China and India being the leading consumers.

- Technology Adoption: The rise of additive manufacturing and powder metallurgy is fueling demand for high-purity and functionalized iron powders.

- Sustainability Focus: Manufacturers are shifting to eco-friendly processes, increasing demand for recycled and low-emission powders.

Growth Opportunities for Distributors and Wholesalers:

- Expand product portfolio by including specialty grades like diffusion-alloyed or pre-alloyed iron powders.

- Partner with manufacturers that offer both powder and equipment—like Shanghai Truer Technology—to provide turnkey PM solutions.

- Leverage the booming e-commerce market by offering customizable packaging and shipping options for smaller B2B buyers.

Trending Applications:

| Growth Sector | Iron Powder Use | Future Outlook |

|---|---|---|

| Electric Vehicles | Magnetic cores, structural parts | Strong demand growth expected |

| 3D Printing | High-precision prototyping and tooling | Increasing adoption in aerospace and medical |

| Smart Manufacturing | Magnetic sensors, IoT components | Integration with Industry 4.0 systems |

5. How to Choose the Right Iron Powder Supplier

Sourcing iron powder for industrial and metallurgical applications requires more than just comparing prices. B2B procurement professionals must assess a range of factors to ensure quality, consistency, and long-term partnership value.

Key Selection Criteria:

- Powder Consistency and Quality Control:

- Particle size uniformity

- Chemical purity and composition

- Flowability and compressibility

- Production Capabilities:

- In-house atomization, reduction, or carbonyl production

- Certification (ISO 9001, REACH, RoHS compliant)

- Customization and Support:

- Technical support for application-specific needs

- Custom blending or particle size distribution

- Logistics and Scalability:

- Reliable lead times and global fulfillment

- Capability to scale with your production demands

Supplier Comparison Table:

| Supplier Attribute | Importance | Shanghai Truer Technology |

|---|---|---|

| Multiple production technologies | High | ✓ Water, gas, carbonyl, reduction |

| Range of PM grades | High | ✓ CT-1000, F-0000, FC-0208, etc. |

| Customization options | Medium | ✓ Blends, sizes, packaging |

| Global shipping capabilities | High | ✓ Export-ready support |

| Technical support | High | ✓ Dedicated PM additive division |

By choosing a supplier like Shanghai Truer Technology, buyers gain access to both high-quality powders and expert consultation, making it easier to optimize their production processes and reduce material waste.

6. Top 5 Reliable Iron Powder Suppliers in Asia

Asia is home to a variety of high-quality iron powder manufacturers, each with unique strengths to offer. Below are five of the most reliable suppliers, including Shanghai Truer Technology, trusted by B2B buyers across the globe.

1. Shanghai Truer Technology Co., Ltd (China)

- Founded: 2009

- Specialization: PM powders, additive manufacturing powders, 3D printing powder-making equipment

- Notable Grades: FC-0208, FD-0200, FN-0205, FL-4605

- Advantages:

- Full in-house production

- R&D-backed customization

- Complete PM additive solutions

2. Hoganas AB (Sweden/India/China operations)

- Founded: 1797

- Specialization: Reduced and atomized iron powders

- Advantages:

- Global presence

- Premium quality, wide product range

3. JFE Steel Corporation (Japan)

- Founded: 2003

- Specialization: Water atomized iron powders

- Advantages:

- High-quality standards

- Trusted in automotive and industrial sectors

4. Industrial Metal Powders (India)

- Founded: 1974

- Specialization: Electrolytic and reduced iron powders

- Advantages:

- Competitive pricing

- Strong presence in pharmaceutical and food industries

5. CNPC Powder Group (China)

- Founded: 1993

- Specialization: Metal and alloy powders

- Advantages:

- Gas and water atomized powders

- Custom metal powder blends

Why Shanghai Truer Stands Out:

- Dual capability in powder production and equipment manufacturing

- Dedicated support for powder metallurgy and 3D printing industries

- Contact their team for custom inquiries or bulk pricing

7. Why More Buyers Are Sourcing Iron Powder from China

In recent years, China has become a global hub for metal powder manufacturing. B2B buyers across industries—from automotive to additive manufacturing—are increasingly turning to Chinese suppliers due to competitive pricing, technological advancements, and expansive production capacities.

Key Reasons for the Shift to Chinese Iron Powder Suppliers:

- Cost Efficiency

Chinese manufacturers offer high-quality iron powder at competitive prices due to economies of scale and vertically integrated supply chains. - Advanced Manufacturing Technology

Suppliers like Shanghai Truer Technology have invested heavily in proprietary powder-making equipment, using atomization, reduction, and hybrid techniques to produce a wide variety of powder grades. - Customization and Flexibility

- Custom blending and particle size distribution

- Tailored packaging for bulk and small-volume orders

- Technical consulting for application-specific solutions

- Export-Oriented Logistics

Many Chinese companies have streamlined their export processes to cater specifically to international B2B customers.

Comparative Table: Sourcing Iron Powder from China vs. Western Markets

| Criteria | China | Western Markets |

|---|---|---|

| Price per kg | Lower | Higher |

| MOQ (Minimum Order Quantity) | Flexible | Often higher |

| Lead Time | Short to medium | Medium |

| Customization | High | Medium |

| Technical Support | Available | Available |

| Supply Chain Control | Strong | Moderate |

With a growing focus on quality assurance and global certifications, Chinese suppliers are not just an affordable alternative—they are becoming strategic partners for businesses seeking to scale efficiently.

8. Why Choose Shanghai Truer Technology as Your Iron Powder Partner

Shanghai Truer Technology Co., Ltd is recognized as one of the most trusted and innovative manufacturers in the Chinese powder metallurgy industry. Since launching its additive manufacturing division in 2019, Truer has expanded its product portfolio to serve a wide range of industrial clients.

Core Advantages of Working with Shanghai Truer:

- Extensive Product Range

- PM Iron Powders: CT-1000, F-0000, FC-0208, FD-0208, etc.

- Hybrid & Diffusion-Alloyed Grades: FL-4605, FN-5000, FD-20Cu

- Stainless Steel PM Powders: Water and gas atomized options

- Comprehensive Manufacturing Capability

- Water atomization

- Gas atomization

- Carbonyl iron powder production

- Reduction process for high-purity applications

- Integrated Support Services

- Powder metallurgy additives: lubricants, cutting agents, graphite

- Equipment for powder production and 3D printing

- Technical consultation and R&D support

- Global Reach with Local Support

Truer supports international clients with export documentation, logistics coordination, and regulatory compliance assistance. Learn more about their products and capabilities.

Truer’s Iron Powder Applications:

| Application | Recommended Powder Grades |

|---|---|

| Automotive Components | FC-0208, FD-0200, FL-4605 |

| Magnetic Parts | F-0000, FN-0205 |

| Diamond Tools | Diffusion CuSn, FD-20Cu |

| Sintered Bearings | PM Phosphorus Iron, FD-0208 |

| Additive Manufacturing | Custom blends, fine atomized powders |

By choosing Shanghai Truer, suppliers, distributors, and manufacturers gain a responsive, innovative partner dedicated to delivering both quality and value.

9. FAQs: Buying Wholesale Iron Powder for Industrial Use

Below are answers to common questions from B2B buyers looking to source iron powder in bulk.

Q1. What is the minimum order quantity (MOQ) for iron powder?

- MOQ generally starts at 100 kg for standard grades but can be customized based on application and blend requirements.

Q2. Can I request custom particle sizes or blends?

- Yes. Shanghai Truer offers custom sieving and blending services to meet specific application needs, such as magnetic properties or compressibility.

Q3. Do you provide international shipping?

- Yes. Truer ships globally with full export documentation and supports shipping via sea, air, and express courier depending on urgency.

Q4. Are the powders compliant with international standards?

- Absolutely. Most grades comply with ISO standards and are REACH and RoHS-compliant. Technical data sheets are available upon request.

Q5. How do I place a wholesale order?

- You can start by contacting the Truer sales team with your specifications, volume, and application. They will provide a quote, lead time, and shipping options.

Q6. Is technical support available post-purchase?

- Yes. Truer offers ongoing consultation for optimizing powder use in your production process, including sintering, compacting, and additive manufacturing support.

Internal Link Anchors Used:

- About Shanghai Truer Technology

- PM Powder Product Portfolio

- Contact Us for Wholesale Orders

- Truer’s Complete Additive Solutions

- Truer’s Product Capabilities

By partnering with a versatile and globally trusted manufacturer like Shanghai Truer Technology, B2B buyers can secure high-quality, application-specific iron powders that give them a competitive edge in their market.

👉 Ready to get a quote or request a sample? Contact us today and discover how Truer can support your manufacturing goals.