1. Introduction: What Is 4130 Powder and Why It Matters in B2B Manufacturing

4130 powder is a low-alloy steel powder primarily composed of chromium (Cr) and molybdenum (Mo) as strengthening agents. It is commonly used in powder metallurgy (PM), additive manufacturing (AM), and metal injection molding (MIM) due to its high strength-to-weight ratio, excellent hardenability, and weldability.

Why 4130 Powder is Crucial in B2B Industries:

- Versatile Alloy Composition: Suitable for aerospace, automotive, and tooling components.

- High-Strength Performance: Ideal for parts requiring high fatigue resistance.

- Adaptable to Multiple Manufacturing Techniques: Compatible with water atomization, gas atomization, and hybrid techniques.

4130 alloy powder is widely used by OEMs, tier-1 automotive suppliers, and industrial part manufacturers. For B2B buyers, sourcing high-quality 4130 powder ensures precision, repeatability, and cost-effectiveness in large-scale component production.

2. Key Industrial Applications of 4130 Powder

4130 powder is highly sought after across several industrial sectors due to its superior mechanical characteristics and processability. Below is a breakdown of its primary applications:

| Industry | Application Example | Benefits of 4130 Powder Use |

|---|---|---|

| Aerospace | Landing gear, engine mounts | High strength-to-weight ratio |

| Automotive | Transmission gears, suspension parts | Excellent fatigue and impact resistance |

| Oil & Gas | Drill collars, tubing, valves | Corrosion resistance under high pressure |

| Tooling | Dies, cutting tools | Wear resistance and machinability |

| Defense | Armor components, structural assemblies | High tensile strength and reliability |

Benefits for B2B Buyers:

- Reduced Machining Time: Near-net-shape capability reduces post-processing.

- Cost Efficiency: Bulk purchasing reduces cost-per-unit for large volume manufacturers.

- Scalability: Easily integrated into automated sintering and additive manufacturing lines.

3. Mechanical Properties and Use Cases of 4130 Alloy Powder

Understanding the material properties of 4130 powder is crucial for engineers, procurement teams, and production managers. Here’s a technical overview:

Composition of 4130 Alloy Powder:

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.28–0.33 |

| Chromium (Cr) | 0.80–1.10 |

| Molybdenum(Mo) | 0.15–0.25 |

| Manganese(Mn) | 0.40–0.60 |

| Iron (Fe) | Balance |

Mechanical Characteristics (after heat treatment):

- Ultimate Tensile Strength: 850–1000 MPa

- Yield Strength: 700–800 MPa

- Elongation at Break: 20–25%

- Hardness (HRC): 24–32 (adjustable via quenching and tempering)

Use Cases in Powder Metallurgy:

- Additive Manufacturing (AM): Compatible with laser and electron beam melting

- Metal Injection Molding (MIM): High flowability and sintering performance

- Hot Isostatic Pressing (HIP): Improved material density and isotropy

By using high-grade 4130 powder from trusted suppliers like Shanghai Truer Technology Co., Ltd, manufacturers can ensure consistent performance and reduce defect rates in critical components.

4. Market Trends for 4130 Powder in Powder Metallurgy

The market demand for 4130 alloy powder is growing rapidly, driven by advancements in additive manufacturing, automotive light-weighting, and aerospace innovation. B2B buyers, procurement managers, and OEMs are increasingly turning to powder metallurgy (PM) and 3D printing solutions using 4130 powder due to its cost-performance advantages.

Key Market Drivers:

- Additive Manufacturing Boom

The global 3D printing market is projected to reach $60 billion by 2030, with 4130 powder being a preferred material for structural parts. - Automotive Lightweighting

OEMs are using 4130 powder in metal injection molding (MIM) to reduce vehicle weight while maintaining strength. - Sustainable Manufacturing

Powder metallurgy and AM processes using 4130 significantly reduce material waste, supporting ESG objectives.

Market Size and Growth Forecast:

| Year | Global 4130 Alloy Powder Market Size (USD Million) |

|---|---|

| 2022 | 210 |

| 2023 | 240 |

| 2024 (Est.) | 275 |

| 2027 (Est.) | 400+ |

Regional Insights:

- North America: Aerospace and defense sectors drive demand.

- Europe: Emphasis on automotive innovation and green manufacturing.

- Asia-Pacific: Rapid industrialization and local sourcing trends.

5. Criteria for Selecting a Reliable 4130 Powder Supplier

When selecting a 4130 powder supplier for B2B needs, quality, scalability, and technical support are essential. Here are the key factors that procurement teams should evaluate:

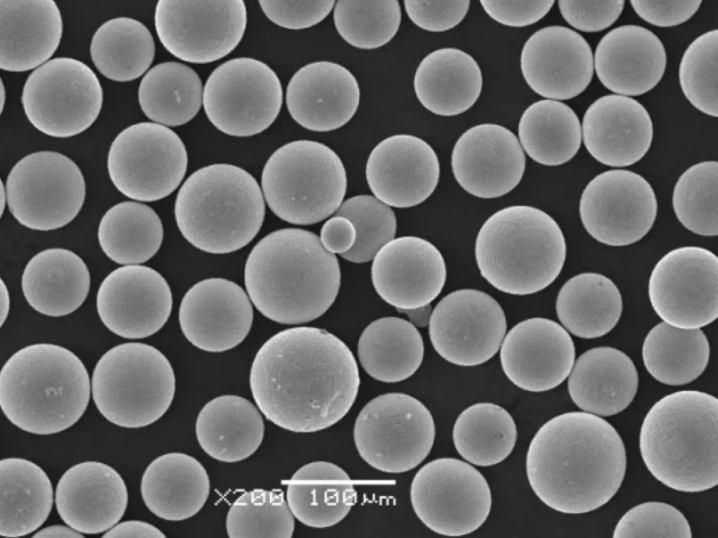

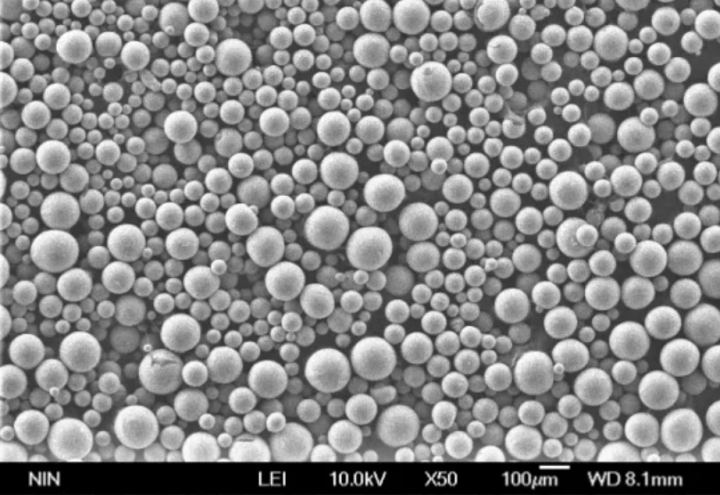

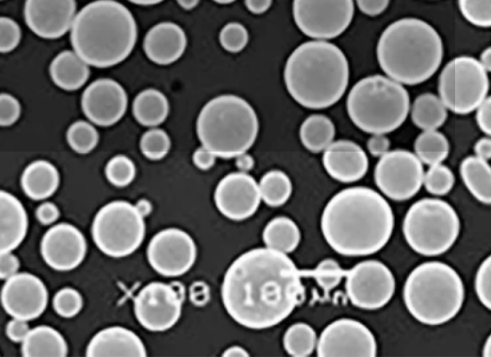

1. Powder Quality and Consistency

- Particle size distribution (PSD)

- Purity levels and contamination control

- Atomization method (water, gas, or hybrid)

2. Production Capacity

- Can the supplier meet your monthly or annual volume requirements?

- Do they offer just-in-time (JIT) delivery or warehousing options?

3. Certifications and Quality Assurance

- ISO 9001, AS9100 for aerospace

- Material Test Reports (MTRs) and batch traceability

4. Customization and Technical Support

- Ability to tailor PSD or composition for specific applications

- Technical consulting and application support

5. Logistics and Lead Times

- Global shipping capabilities

- Average lead time for bulk orders

6. Top 5 Global and Chinese 4130 Powder Suppliers

Here’s a curated list of leading suppliers known for offering high-quality 4130 alloy powder for B2B buyers:

| Supplier Name | Region | Key Strengths |

|---|---|---|

| Höganäs AB | Sweden | Global leader in PM powders, wide product range |

| Sandvik Additive Manufacturing | Global | Advanced atomization, AM focus |

| Shanghai Truer Technology Co., Ltd | China | Customizable powders, excellent price/performance |

| CNPC Powder | China | Large volume production, automotive sector focus |

| GKN Hoeganaes | USA | Strong in automotive-grade PM solutions |

Spotlight: Shanghai Truer Technology Co., Ltd

Shanghai Truer, established in 2009, has become a preferred choice for sourcing PM and AM powders in China. Since launching its additive manufacturing division in 2019, Truer has rapidly innovated in powder development and customization.

Why Truer stands out:

- Offers both water-atomized and gas-atomized 4130 powder

- Supports hybrid atomization for specialized applications

- Provides custom alloys and size ranges based on customer needs

- In-house testing, including PSD analysis and flowability checks

- Full traceability and batch certification

Truer’s 4130 powder is widely used in automotive, aerospace, and industrial tooling sectors, making it a top-tier choice for bulk powder sourcing in Asia and beyond.

7. Why Buyers Are Shifting to Chinese 4130 Powder Manufacturers

In recent years, a significant number of global B2B buyers—especially from Europe, North America, and Southeast Asia—have begun sourcing 4130 powder from China. This shift is not solely driven by cost, but by a combination of quality advancements, supply chain efficiency, and customization capabilities.

Key Reasons for the Shift:

- Competitive Pricing

Chinese suppliers like Shanghai Truer offer high-quality 4130 powder at 20–40% lower cost than Western counterparts. - Shorter Lead Times

Localized production and direct factory-to-buyer logistics reduce delivery times, especially for bulk orders. - Customization Expertise

Chinese manufacturers often provide tailored particle size distribution (PSD), atomization methods, and alloy blends per client request. - Advanced Manufacturing Capabilities

Companies like Truer have invested in hybrid atomization, automated sieving, and high-purity environments to meet global PM standards. - End-to-End Support

Truer’s team offers application consultation, powder selection guidance, and after-sales support, making sourcing easier for first-time buyers.

Testimonials from B2B Buyers:

“Working with Truer helped us reduce our material costs for MIM parts by 25% without compromising on quality.” – Procurement Manager, Auto Parts OEM

“Their ability to custom-tailor 4130 powder for our sintering line gave us complete process control.” – Senior Engineer, Aerospace Supplier

If you’re sourcing 4130 powder in large volumes, considering a proven Chinese partner like Shanghai Truer Technology Co., Ltd can significantly improve your cost-efficiency and delivery timelines.

8. Why Choose Shanghai Truer as Your 4130 Powder Supplier

Shanghai Truer Technology Co., Ltd is recognized as one of China’s most advanced and trustworthy manufacturers of powder metallurgy materials. With over a decade of metallurgical expertise and a dedicated additive manufacturing division launched in 2019, Truer offers unmatched value for global B2B buyers.

Truer’s Capabilities at a Glance:

| Feature | Details |

|---|---|

| Founded | 2009 |

| Additive Manufacturing Division | Since 2019 |

| Production Methods | Water-atomized, gas-atomized, hybrid |

| Powder Grades | FL-4605, FD-0200, FD-0208, FX-2008, FN-5000, and custom 4130 variants |

| Industries Served | Automotive, Aerospace, Tooling, Oil & Gas |

| Certification & Testing | ISO Certified, in-house PSD, flowability, and composition testing |

Key Advantages for B2B Buyers:

- ✔️ Custom 4130 alloy formulations to meet specific application needs

- ✔️ High flowability and sinterability for AM and PM processes

- ✔️ Bulk order support and global shipping logistics

- ✔️ Full documentation including MTRs, COAs, and batch traceability

- ✔️ Responsive technical support and material consultation

Truer also offers a wide range of related PM powders, lubricants, and cutting agents—enabling clients to source complete additive and PM solutions from a single trusted partner. Learn more about Truer’s capabilities here.

9. FAQs: Common Questions About Purchasing 4130 Powder Wholesale

Below are answers to frequently asked questions from B2B buyers interested in purchasing 4130 alloy powder in bulk.

Q1: What particle size distribution (PSD) is available for 4130 powder?

A: Truer offers a variety of PSD ranges, including -325 mesh, 45–105 µm, and customized sizes depending on the application (AM, MIM, HIP, etc.).

Q2: Is the 4130 powder suitable for both additive manufacturing and PM?

A: Yes. Truer’s 4130 powder can be produced using both gas and water atomization methods, making it suitable for 3D printing and conventional powder metallurgy.

Q3: What is the minimum order quantity (MOQ)?

A: The MOQ typically starts at 100 kg for custom orders, but standard stock powders may be available in smaller batches. Contact Truer’s sales team for specifics.

Q4: Can Truer provide technical support for integrating 4130 powder into our production process?

A: Absolutely. Truer has a team of engineers that provides expert consultation on alloy selection, sintering parameters, and AM compatibility.

Q5: How is the powder packaged and shipped?

A: Powder is vacuum-sealed in moisture-proof bags and packed in steel drums or fiber containers. Truer also supports export documentation and global freight forwarding.

Final Thoughts: Empower Your Manufacturing with Truer’s 4130 Powder

For B2B buyers, sourcing high-quality 4130 powder is a strategic decision that affects product performance, production cost, and long-term reliability. With decades of metallurgical expertise, state-of-the-art production facilities, and a customer-first approach, Shanghai Truer Technology Co., Ltd is your ideal supply partner for 4130 alloy powder and beyond.

Whether you’re in aerospace, automotive, or industrial engineering, Truer offers the materials, customization, and support to help you scale efficiently.

🛒 Ready to order or want to request a free sample? Contact us today and let our experts help you find the perfect 4130 powder solution for your needs.