1. What Is Inconel Powder and Why It Matters in Modern Manufacturing

Inconel powder is a high-performance, nickel-based alloy powder known for its exceptional resistance to heat, oxidation, and corrosion. It is used extensively in industries such as aerospace, power generation, chemical processing, and additive manufacturing (AM).

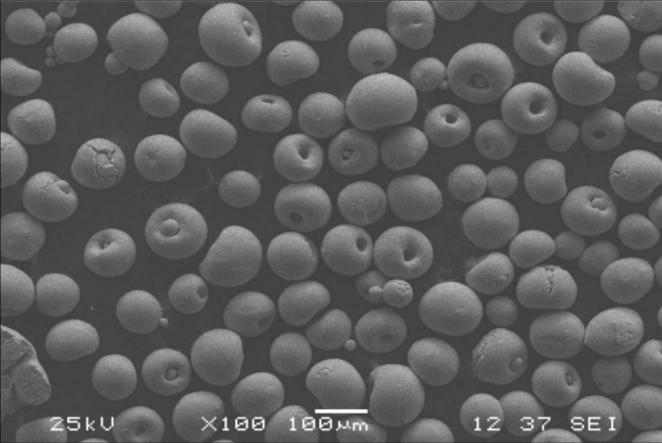

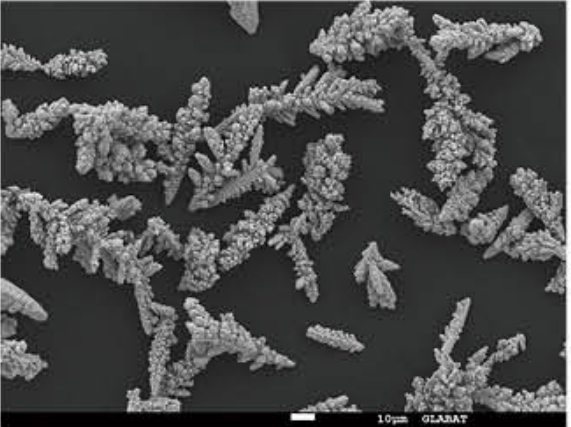

Inconel powders are produced through various atomization techniques such as gas atomization, which ensures a spherical morphology ideal for 3D printing and powder metallurgy (PM) applications. Inconel’s unique composition enables it to retain mechanical integrity even in extreme environments.

Key Characteristics

| Property | Description |

|---|---|

| High-temperature stability | Retains strength and integrity up to 982°C (1800°F) |

| Corrosion resistance | Resistant to oxidation, acids, and seawater |

| Mechanical strength | Excellent tensile strength and fatigue resistance |

| AM compatibility | Spherical powder shape ideal for laser sintering, binder jetting, and DMLM |

Common Inconel Grades Used in Powder Form

- Inconel 625: High corrosion resistance and weldability

- Inconel 718: High strength and creep resistance, widely used in aerospace

- Inconel 738: Designed for turbine blades and high-stress environments

2. Industrial Applications of Inconel Powder

Inconel powder is in high demand across industries that require materials to perform under extreme conditions. Below are the major sectors using Inconel powder:

Aerospace Industry

- Turbine blades: Inconel 718 and 738 are used due to their high creep resistance

- Combustion chambers: Withstands high heat and pressure

- Fuel nozzles: 3D printed using Inconel 625 for precision and durability

Energy Sector

- Gas turbines: Inconel powders are used to produce hot-section components

- Nuclear reactors: Corrosion-resistant parts with long service life

- Heat exchangers: Ideal for thermal cycling environments

Chemical Processing

- Pressure vessels: Withstand corrosive chemicals and high pressure

- Pipelines: Corrosion-resistant inner linings

- Valves and pumps: High reliability in corrosive environments

Additive Manufacturing and 3D Printing

- Prototyping: Rapid prototyping of complex, high-performance components

- Tooling: High-wear resistance molds and dies

- Functional parts: Lightweight, strong components with intricate geometries

Medical Applications

- Implants: Biocompatible and corrosion-resistant components

- Surgical tools: Precision and high sterilization resistance

Summary of Industry Use

| Industry | Application | Inconel Grade |

|---|---|---|

| Aerospace | Turbine blades, nozzles | Inconel 718, 625 |

| Energy | Turbines, exchangers, reactors | Inconel 738, 625 |

| Chemical Processing | Valves, vessels, pipelines | Inconel 625 |

| Additive Mfg. | Prototypes, tooling, production | Inconel 625, 718 |

| Medical | Implants, surgical instruments | Inconel 625 |

3. Key Properties and Grades of Inconel Powder

Understanding the properties and available grades of Inconel powder is essential for sourcing the right material for industrial applications.

Mechanical Properties

| Property | Inconel 625 | Inconel 718 |

|---|---|---|

| Tensile Strength | ~827 MPa | ~1375 MPa |

| Yield Strength | ~414 MPa | ~1034 MPa |

| Elongation | ~30% | ~12-18% |

| Hardness (HRB) | ~94 | ~130-140 (HRC) |

Thermal and Chemical Properties

- Melting Point: 1290–1350°C

- Thermal Conductivity: Low (~9.8 W/m-K)

- Corrosion Resistance: Excellent in marine and chemical environments

- Oxidation Resistance: Retains properties even at high operating temperatures

Particle Size Distribution

Depending on manufacturing needs, Inconel powders are available in various mesh sizes:

- 15–45 µm: Ideal for Selective Laser Melting (SLM)

- 45–105 µm: Suitable for Electron Beam Melting (EBM)

- 105–150 µm: Used in Binder Jetting and traditional PM

Inconel Grades Comparison Table

| Grade | Key Feature | Typical Use Case |

|---|---|---|

| Inconel 625 | Superior corrosion resistance | Chemical, marine, and nuclear |

| Inconel 718 | High strength, weldable, creep-resistant | Aerospace and energy components |

| Inconel 738 | High-temperature oxidation resistance | Turbine blades, jet engines |

Why Choose High-Quality Inconel Powder?

- Reduced porosity in AM parts

- Improved mechanical properties

- Greater process consistency

- Minimized contamination risk

Shanghai Truer Technology Co., Ltd, an expert in powder metallurgy and additive manufacturing materials, offers reliable Inconel powder solutions. Their advanced atomization technology ensures spherical particles, clean surfaces, and consistent quality. Learn more about their wide selection of PM powders here.

4. Global Market Trends and Growth of Inconel Powder

The global Inconel powder market is experiencing robust growth, driven by advancements in additive manufacturing, increased demand from aerospace and energy sectors, and rapid industrialization in emerging economies.

Key Market Drivers

- Additive Manufacturing Boom: 3D printing of aerospace and medical parts is increasing the demand for high-performance powders like Inconel 625 and 718.

- Aerospace Expansion: Commercial and military aviation programs are investing in components made from high-temperature-resistant alloys.

- Energy Sector Growth: The need for efficiency in turbines and reactors is pushing demand for reliable nickel alloy powders.

- Corrosion-Resistant Materials: Chemical and marine industries are shifting toward nickel-based alloys for long-term durability.

Market Size Forecast

| Year | Global Inconel Powder Market Size (USD Billion) |

|---|---|

| 2022 | 1.12 |

| 2023 | 1.32 |

| 2024 | 1.56 (est.) |

| 2027 | 2.35 (projected) |

Regional Demand Breakdown

- North America: Aerospace and defense are major contributors.

- Europe: Strong demand from automotive and energy sectors.

- Asia-Pacific: Fastest-growing region due to manufacturing expansions in China and India.

Emerging Trends

- Increased use of Inconel powder in binder jetting and DMLS (Direct Metal Laser Sintering)

- Development of hybrid atomization technologies for better particle morphology

- Growing preference for sustainable production and recycling of superalloy powders

5. How to Choose the Right Inconel Powder Supplier

Choosing the right Inconel powder supplier is critical to ensure product performance, consistency, and cost-efficiency. Here are the key factors to consider:

1. Powder Quality and Consistency

- Particle Size Distribution: Uniformity ensures smoother printing and compaction

- Sphericity: High sphericity improves flowability and packing density

- Purity: Low oxygen and impurity levels reduce the risk of defects

- Mechanical Properties: Must meet application-specific standards

2. Production Capabilities

- Does the supplier offer multiple atomization methods (e.g., gas, water, hybrid)?

- Can they customize particle sizes for specific AM or PM applications?

3. Certification and Compliance

- ISO 9001, AS9100D, or equivalent quality management systems

- Material certifications (e.g., ASTM B243, AMS 5662/5663)

- Third-party chemical composition analysis

4. Logistics and Supply Chain

- Lead times and production capacity

- Shipping reliability and global distribution networks

- Inventory availability for bulk or recurring orders

5. Technical Support and Customization

- On-site or remote engineering consultation

- R&D collaboration for custom alloy development

- Post-sales support and troubleshooting

Supplier Evaluation Checklist

| Criteria | Importance Level | ✓/✗ |

|---|---|---|

| Consistent PSD and morphology | Critical | |

| Certification (ISO, ASTM, etc.) | Essential | |

| Customization options | High | |

| Lead time and stock availability | Medium | |

| Competitive pricing for bulk orders | High |

Shanghai Truer Technology Co., Ltd excels in all these areas, offering both standardized and custom Inconel powders tailored to your manufacturing needs. Their multiple atomization technologies provide flexibility in particle size and sphericity, ensuring compatibility with your equipment and application.

6. Top 5 Inconel Powder Suppliers in Asia

Asia is home to several reputable Inconel powder manufacturers that support the region’s growing aerospace, energy, and additive manufacturing industries. Here are the top suppliers:

1. Shanghai Truer Technology Co., Ltd (China)

Overview:

- Founded in 2009, entered the additive manufacturing market in 2019

- Offers high-quality Inconel powders produced through gas, water, and hybrid atomization

- Known for consistent quality, reliable supply chain, and technical expertise

Key Products:

- Inconel 625 powder

- Inconel 718 powder

- Custom superalloy powders for AM and PM

Why Choose Truer:

- Offers full support from powder development to post-sale services

- Extensive range of powder metallurgy solutions

- One of the most professional additive suppliers in China

2. JG Precision Powder (China)

Overview:

- Specializes in gas-atomized metal powders

- Supplies aerospace-grade Inconel powders

- Focused on SLM and EBM applications

3. Sandvik Additive Manufacturing (India)

Overview:

- Global leader with AM facilities in India

- Offers proprietary nickel alloy powders including Inconel variants

- Strong presence in energy and aerospace sectors

4. CNPC Powder (China)

Overview:

- Major supplier of metal powders for AM and PM

- Offers wide distribution in Asia and Europe

- Supplies Inconel powders with high sphericity and low oxygen content

5. GKN Hoeganaes (Japan)

Overview:

- Well-known for PM materials, including Inconel alloys

- Supplies custom powder solutions for automotive and aerospace

- Holds multiple quality certifications for critical applications

Supplier Comparison Table

| Supplier Name | Country | Atomization Method | Inconel Grades | Customization | Lead Time |

|---|---|---|---|---|---|

| Shanghai Truer | China | Gas/Water/Hybrid | 625, 718 | Yes | Fast |

| JG Precision Powder | China | Gas | 718 | Yes | Medium |

| Sandvik AM | India | Gas | 625, 718 | Yes | Medium |

| CNPC Powder | China | Gas | 625 | Limited | Medium |

| GKN Hoeganaes | Japan | Water/Gas | 718 | Yes | Slow |

For more information about Shanghai Truer’s product line and company background, visit their About Us page.

7. Why More Manufacturers Are Choosing Chinese Inconel Powder Sources

China’s powder metallurgy and additive manufacturing sectors have rapidly advanced in recent years, and global manufacturers are increasingly turning to Chinese sources for Inconel powder due to several strategic advantages.

Economic Advantages

- Cost Efficiency: Lower production and labor costs

- Bulk Pricing: Competitive rates for high-volume orders

- Government Incentives: Export subsidies and tax benefits for high-tech materials

Technological Advancements

- Modern Atomization Facilities: Many suppliers now operate gas and hybrid atomizers with tight process controls

- Advanced QA Systems: Increasing adoption of ISO and ASTM standards

- R&D Investment: Focus on developing new alloys and improving powder morphology

Logistics and Scalability

- Fast Turnaround: Shorter lead times compared to European or American suppliers

- Global Reach: Strategic export hubs in Shanghai, Shenzhen, and Tianjin

- Flexible MOQ: Many suppliers accept small to large batch orders

Case in Point: Shanghai Truer

Shanghai Truer is a leading example of China’s rise in the global Inconel powder market:

- Offers both standard and custom Inconel grades

- Utilizes advanced gas atomization and hybrid atomization methods

- Supplies to clients in aerospace, automotive, and energy sectors

- Provides reliable support across R&D, production, and logistics

To explore product details or request a quote, you can contact Shanghai Truer here.

8. How to Order Wholesale Inconel Powder from Shanghai Truer

Ordering Inconel powder in bulk requires careful coordination between technical, procurement, and logistics teams. Shanghai Truer Technology Co., Ltd simplifies the process for B2B customers by offering a streamlined, consultative wholesale ordering experience tailored to your project requirements.

Step-By-Step: Ordering Inconel Powder from Shanghai Truer

Step 1: Initial Consultation

- Submit Inquiry: Contact via the official website or email to initiate the process.

- Technical Requirements: Share application details (e.g. AM method, desired particle size, alloy grade).

- Volume Estimate: Indicate estimated tonnage or kilograms required monthly or annually.

Step 2: Sample & Specification Confirmation

- Sample Powder: Truer can send a small sample (e.g. 500g or 1kg) for in-house testing.

- Material Certification: Full chemical composition and particle size analysis provided.

- Specification Sheet: Confirm alloy grade, PSD, morphology, and atomization type.

Step 3: Quotation & Commercial Agreement

- Custom Quotation: Based on alloy, MOQ, and delivery terms (EXW, FOB, CIF).

- Payment Terms: Flexible options for long-term B2B partners (T/T, L/C, or Net30).

- Contract Signing: NDA and supply agreements for long-term cooperation.

Step 4: Production & Quality Control

- Batch Manufacturing: Production begins per agreed lead time (typically 2–4 weeks).

- Quality Control: Particle shape, flowability, and purity tested per lot.

- Packaging: Secure, moisture-resistant drums or vacuum-sealed bags.

Step 5: Logistics & Delivery

- Shipping Options: Airfreight for urgent orders, sea freight for bulk.

- Export Documentation: Includes MSDS, CoA, RoHS/REACH certificates if required.

- Delivery Time: Typically 7–21 days depending on region and quantity.

Available Packaging Formats

| Quantity | Packaging Type | Applications |

|---|---|---|

| 1–10 kg | Vacuum-sealed bags | Lab use, R&D, prototyping |

| 20–50 kg | Plastic drums | Small-batch production |

| 100–500 kg | Steel drums | Medium-scale manufacturing |

| ≥1 metric ton | Palletized drum sets | High-volume industrial production |

Shanghai Truer offers full documentation and traceability for every batch of Inconel powder, ensuring procurement compliance and quality assurance for critical industry sectors.

9. FAQs: Common Questions About Buying Wholesale Inconel Powder

Q1: What is the minimum order quantity (MOQ) for wholesale Inconel powder?

A: The MOQ typically starts at 20–50 kg, but Truer can accommodate smaller trial orders for new clients and R&D purposes.

Q2: Which Inconel alloys are available from Shanghai Truer?

A: Major Inconel grades include:

- Inconel 625

- Inconel 718

- Inconel 738 (upon request)

Custom compositions can be developed for specialized applications.

Q3: What atomization methods are offered?

A: Shanghai Truer uses:

- Gas atomization (for spherical, high-purity powders)

- Water atomization (for cost-effective PM applications)

- Hybrid gas-water atomization (for balanced performance and price)

Q4: Can I request custom particle size distributions?

A: Yes. Truer offers PSD customization options such as:

- 15–45 μm (SLM, DMLS)

- 45–105 μm (EBM, DED)

- 105–150 μm (Binder Jetting, PM pressing)

Q5: Are the powders certified?

A: All powders are supplied with:

- Certificate of Analysis (CoA)

- Material Safety Data Sheet (MSDS)

- Third-party lab reports (upon request)

- Compliance with ASTM, AMS, and ISO standards

Q6: What is the lead time for large orders?

A: Standard lead time is 2–4 weeks. For urgent orders, expedited production and airfreight options are available.

Q7: Can I visit the manufacturing facility?

A: Yes. Shanghai Truer welcomes plant visits and audits. Contact the team via this form to schedule a visit or virtual tour.

Q8: Does Shanghai Truer export globally?

A: Absolutely. The company has shipped to North America, Europe, Southeast Asia, and the Middle East. Export documentation and logistics support are fully managed in-house.

Internal Anchor Links Recap

Here are 5 internal links strategically embedded for SEO and user navigation:

- Learn more about Shanghai Truer’s powder metallurgy solutions

- Visit the company’s About Us page to explore its history and capabilities

- Contact the sales and technical team using this form

- Browse the full AM material catalog on the homepage

- Navigate to the PM powder section for a complete list of alloys and grades

By following this comprehensive guide, industrial buyers, distributors, and sourcing managers can make confident, data-driven decisions when purchasing Inconel powder in bulk. Shanghai Truer Technology Co., Ltd stands out as a trusted partner with turnkey capabilities, technical expertise, and global distribution capacity.

Ready to source high-quality Inconel powder? Get in touch with Truer’s team to request a quote, sample, or technical consultation.