Overview of FeCoNiCrMo-1 Powder

The FeCoNiCrMo-1 powder is a high-entropy alloy (HEA) gaining traction in advanced manufacturing and materials science due to its exceptional mechanical properties, corrosion resistance, and structural stability. HEAs like FeCoNiCrMo-1 are characterized by the nearly equimolar proportions of their constituent elements, giving them unique traits compared to traditional alloys.

Why is this powder significant? Think of it as the superhero of metal powders, offering a combination of toughness, flexibility, and resistance. Whether you’re exploring advanced manufacturing or looking to improve structural performance under extreme conditions, FeCoNiCrMo-1 powder might be your go-to solution.

Composition of FeCoNiCrMo-1 Powder

The composition of FeCoNiCrMo-1 powder sets it apart from traditional metal alloys. The five core elements—iron (Fe), cobalt (Co), nickel (Ni), chromium (Cr), and molybdenum (Mo)—are mixed in approximately equal ratios, ensuring superior performance.

| Element | Composition (Approximate %) | Role in Alloy |

|---|---|---|

| Iron (Fe) | ~20% | Strengthens the alloy matrix. |

| Cobalt (Co) | ~20% | Enhances wear resistance. |

| Nickel (Ni) | ~20% | Improves ductility and toughness. |

| Chromium (Cr) | ~20% | Increases corrosion resistance. |

| Molybdenum (Mo) | ~20% | Provides excellent hardness and creep resistance. |

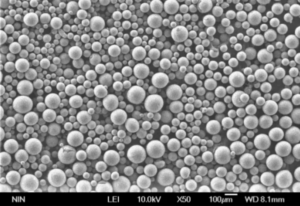

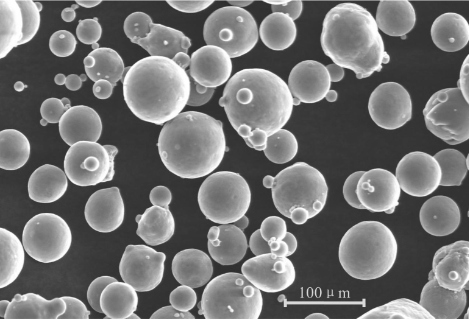

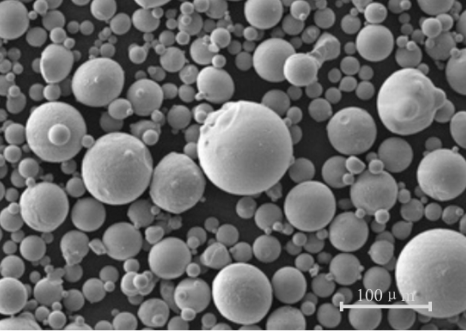

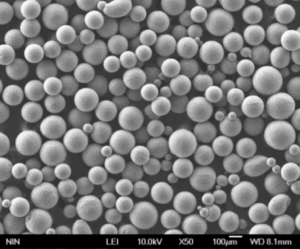

Characteristics of FeCoNiCrMo-1 Powder

FeCoNiCrMo-1 powder boasts a set of characteristics that make it a versatile choice for various applications:

- Exceptional Strength and Toughness: With its multi-elemental design, the powder exhibits a remarkable strength-to-weight ratio, suitable for aerospace and defense applications.

- Corrosion Resistance: Chromium and molybdenum contribute to resistance in highly corrosive environments.

- Thermal Stability: Its composition ensures stability at both high and low temperatures.

- Wear Resistance: Cobalt strengthens its ability to withstand mechanical wear over time.

- Customizable Microstructure: Suitable for 3D printing and other additive manufacturing techniques.

Applications of FeCoNiCrMo-1 Powder

Thanks to its impressive properties, FeCoNiCrMo-1 powder is used in numerous industries. Here’s a quick look:

| Industry | Applications |

|---|---|

| Aerospace | Turbine blades, structural components, heat shields |

| Automotive | High-performance engine parts, wear-resistant gears |

| Medical | Prosthetics, dental implants, surgical tools |

| Defense | Armor plating, missile components |

| Energy | Nuclear reactor components, offshore drilling rigs |

| Additive Manufacturing | 3D-printed parts requiring high precision |

Specific Models of FeCoNiCrMo-Based Powders

Here are some notable FeCoNiCrMo-based powder models with their unique features:

1. FeCoNiCrMo-1 Standard

- Description: The baseline powder offering a balance of strength, corrosion resistance, and thermal stability.

- Best For: General industrial applications and research purposes.

2. FeCoNiCrMo-1 HTP

- Description: High-temperature performance variant optimized for use in extreme heat conditions.

- Best For: Aerospace and energy industries.

3. FeCoNiCrMo-1 XR

- Description: Extra resistant to wear and corrosion, thanks to enhanced molybdenum content.

- Best For: Marine and offshore applications.

4. FeCoNiCrMo-1 Flex

- Description: Focused on flexibility and ductility without compromising strength.

- Best For: Medical implants and prosthetics.

5. FeCoNiCrMo-1 Nano

- Description: Nanoscale powder particles for advanced 3D printing precision.

- Best For: Additive manufacturing in electronics and aerospace.

6. FeCoNiCrMo-1 AM

- Description: Specially designed for additive manufacturing, offering superior printability.

- Best For: Rapid prototyping.

7. FeCoNiCrMo-1 Ultra

- Description: Features ultra-high corrosion resistance.

- Best For: Chemical processing equipment.

8. FeCoNiCrMo-1 HP

- Description: High-performance variant with increased cobalt content for improved wear resistance.

- Best For: High-stress mechanical components.

9. FeCoNiCrMo-1 Lite

- Description: A lightweight version with reduced density.

- Best For: Aerospace and automotive weight-sensitive components.

10. FeCoNiCrMo-1 Bio

- Description: Biocompatible powder designed for medical use.

- Best For: Surgical implants and dental applications.

Specifications of FeCoNiCrMo-1 Powder

| Specification | Details |

|---|---|

| Particle Size | 10-45 μm (customizable) |

| Density | ~7.8 g/cm³ |

| Melting Point | ~1300-1400°C |

| Hardness | 300-400 HV |

| Standards | ASTM B212, ISO 9001 |

| Packaging Options | 1 kg, 5 kg, 10 kg |

Suppliers and Pricing Information

| Supplier | Region | Price (USD/kg) | Notes |

|---|---|---|---|

| Advanced Alloys Inc. | North America | $150-$180 | Offers bulk discounts. |

| MetalWorks Co. | Europe | $140-$170 | Custom compositions available. |

| Asia Alloys Pvt Ltd. | Asia-Pacific | $120-$160 | Competitive pricing. |

| Global Metal Traders | Worldwide | $130-$175 | Fast shipping worldwide. |

Advantages and Disadvantages of FeCoNiCrMo-1 Powder

| Advantages | Disadvantages |

|---|---|

| Exceptional corrosion and wear resistance. | Higher initial cost compared to traditional alloys. |

| Excellent performance at extreme temperatures. | Limited availability in some regions. |

| Versatile for multiple applications. | Requires specialized equipment for processing. |

| High stability and durability. | Complex recycling process due to multi-elements. |

FAQs

| Question | Answer |

|---|---|

| What is FeCoNiCrMo-1 powder used for? | Aerospace, automotive, medical, energy, and 3D printing. |

| How is FeCoNiCrMo-1 better than steel? | It offers better corrosion resistance, wear resistance, and temperature stability. |

| Can it be 3D printed? | Yes, many models are optimized for additive manufacturing. |

| Is it expensive? | It’s pricier than traditional alloys but offers superior properties. |

| Who are the leading suppliers? | Advanced Alloys Inc., MetalWorks Co., and Global Metal Traders. |