Monel K500 powder is one of the most fascinating and versatile alloys out there. Known for its exceptional corrosion resistance, high strength, and magnetic properties, it’s no wonder that Monel K500 is widely used in industries such as aerospace, marine, and oil and gas. But there’s more to this material than meets the eye.

In this article, we’ll dive deep into the world of Monel K500 powder, exploring everything from its composition, properties, and uses, to specific models, specifications, and suppliers. Whether you’re a seasoned engineer, a materials scientist, or just curious about this impressive alloy, you’re in the right place. Let’s unravel the mystery behind Monel K500 powder and see how it stacks up against other metals.

Overview of Monel K500 Powder

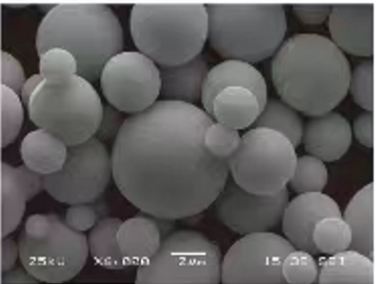

Monel K500 is a nickel-copper alloy, also known as a nickel-based superalloy. What makes it special? It combines the corrosion resistance of Monel 400 with greater strength and hardness due to the inclusion of titanium and aluminum. It’s often used in powder form to create intricate parts through powder metallurgy (PM) and additive manufacturing (AM).

The K500 variant stands out due to its superior toughness, resistance to seawater corrosion, and high-temperature performance, making it ideal for challenging environments.

| Feature | Details |

|---|---|

| Main Elements | Nickel (63-70%), Copper (27-33%), Aluminum (2.3-3.15%), Titanium (0.35-0.85%) |

| Tensile Strength | 110,000 psi (minimum) |

| Corrosion Resistance | Excellent in seawater and acidic conditions |

| Hardness | Rockwell C32-40 |

| Density | 8.44 g/cm³ |

| Melting Point | 1350°C (2460°F) |

| Applications | Marine, oil and gas, chemical processing, aerospace |

Composition of Monel K500 Powder

Monel K500 powder is primarily composed of nickel and copper, but it also includes small amounts of other elements such as aluminum, titanium, carbon, and iron. These additional elements play a crucial role in enhancing the mechanical properties of the alloy.

| Element | Percentage Composition |

|---|---|

| Nickel (Ni) | 63-70% |

| Copper (Cu) | 27-33% |

| Aluminum (Al) | 2.3-3.15% |

| Titanium (Ti) | 0.35-0.85% |

| Carbon (C) | 0.25% (max) |

| Iron (Fe) | 2.0% (max) |

Why Does Composition Matter?

The balance between nickel and copper gives Monel K500 its renowned corrosion resistance, especially in seawater and harsh chemical environments. The addition of aluminum and titanium enables age-hardening, which significantly increases the material’s strength and hardness without compromising its corrosion resistance.

Characteristics of Monel K500 Powder

Monel K500 powder boasts a unique set of properties that make it one of the go-to materials for industries that demand durability, toughness, and resistance to extreme conditions. Let’s break down its most important characteristics.

1. High Strength

Monel K500’s strength is one of its defining features. Thanks to the alloying elements, it has a tensile strength that can reach over 160,000 psi when heat-treated. This is significantly stronger than its predecessor, Monel 400.

2. Superior Corrosion Resistance

This alloy’s excellent corrosion resistance in both acidic and alkaline environments makes it invaluable for marine and chemical applications. Whether it’s resisting pitting in seawater or holding up against harsh chemicals, Monel K500 delivers.

3. Magnetic Properties

A fun fact? Monel K500 is slightly magnetic at room temperature, which is unusual for nickel-based alloys. This property can come in handy in certain specialized applications.

4. Hardness and Wear Resistance

The age-hardening process increases the hardness of the material, making it resistant to wear, even in abrasive environments. Its hardness can be measured at Rockwell C32-40, depending on treatment.

5. Excellent Fatigue and Creep Resistance

Monel K500 performs remarkably well under stress, making it ideal for parts subjected to repeated loading and high temperatures.

| Characteristic | Performance |

|---|---|

| Strength | Very High (Tensile strength of 110,000 psi) |

| Corrosion Resistance | Excellent, especially in seawater and chemicals |

| Hardness | Rockwell C32-40 |

| Magnetic Properties | Slightly magnetic |

| Wear Resistance | Excellent |

| Fatigue Resistance | Outstanding |

Advantages of Monel K500 Powder

So, what makes Monel K500 powder better compared to other metal powders like Inconel or Hastelloy? Let’s break it down.

1. Corrosion Resistance Up Against Inconel

Compared to Inconel, Monel K500 is better suited for environments where seawater and saltwater exposure are a constant challenge. If you’re working in marine engineering or shipbuilding, Monel K500 is your best bet.

2. Strength Compared to Hastelloy

While Hastelloy is known for its high-temperature resistance, Monel K500 takes the cake in terms of strength, especially after age-hardening. It’s toug3. Cost Considerations

Monel K500 can be more expensive than some stainless steels or lower-grade nickel alloys. However, its exceptional longevity in extreme environments often offsets the initial costs over time.

| Material | Advantages | Disadvantages |

|---|---|---|

| Monel K500 | Superior corrosion resistance, excellent strength | Higher initial cost, slightly magnetic |

| Inconel | Exceptional heat resistance | Less suited for marine environments |

| Hastelloy | Great at high temperatures, resists chemical corrosion | Not as strong as Monel K500 after hardening |

| Stainless Steel | Affordable, good general corrosion resistance | Weaker in extreme environments |

Applications of Monel K500 Powder

Monel K500 powder finds its way into numerous industries thanks to its impressive properties. From marine equipment to oil extraction tools, this alloy is indispensable in the following sectors:

| Industry | Common Applications |

|---|---|

| Marine | Propeller shafts, seawater valves, underwater fasteners |

| Oil & Gas | Drilling tools, pump shafts, valve components |

| Aerospace | Landing gear, springs, fasteners, instrumentation components |

| Chemical Processing | Valves, fittings, and other parts exposed to corrosive environments |

| Defense | Torpedo parts, sonar components, underwater weaponry |

Specific Monel K500 Powder Models

When it comes to Monel K500 powder, there are various forms and grades available, each tailored for specific applications:

- LPW Technology – Monel K500 Powder

- High-quality atomized powder for additive manufacturing.

- Advanced Powder Solutions – K500

- Used for metal injection molding (MIM) and 3D printing applications.

- Sandvik – K500

- Suited for specialized marine applications.

- Carpenter Technology – Monel K500

- Focuses on aerospace components and offers high-purity variants.

- Kennametal – K500 Powder

- Powder for cutting tools in oil and gas industries.

- Ametek Specialty Metal Products – Monel K500

- Provides high-performance powder for thermal spray coating.

- Erasteel – K500

- Suitable for both hot and cold isostatic pressing (HIP & CIP).

- Powder Alloy Corporation – K500

- Offers nickel-based superalloys in powder form for welding.

- Oerlikon Metco – Monel K500

- Known for its high corrosion resistance in thermal applications.

- Renishaw – K500 Additive Manufacturing Powder

- Specializes in powder for precision parts using 3D printing.

Specifications and Standards for Monel K500 Powder

When working with Monel K500, it’s important to adhere to specific standards to ensure material quality and performance.

| Specification | Details |

|---|---|

| ASTM B865 | Standard for age-hardenable nickel-copper alloys |

| AMS 4676 | Aerospace material specification for nickel alloy rods |

| ISO 15156 | Materials for use in H₂S-containing environments |

| DIN 2.4375 | European material number for Monel K500 |

Suppliers and Pricing for Monel K500 Powder

Pricing for Monel K500 powder can vary based on supplier, location, and the specific powder grade. Here’s a snapshot of some key suppliers and their price ranges:

| Supplier | Price Range (per kg) | Notes |

|---|---|---|

| LPW Technology | $100 – $150 | For additive manufacturing |

| Advanced Powder Solutions | $90 – $140 | Metal injection molding applications |

| Sandvik | $130 – $200 | Specialized marine-grade powder |

| Ametek | $110 – $160 | Thermal spray coating powder |

| Carpenter Technology | $120 – $180 | High-purity powder for aerospace |

Comparison of Monel K500 Powder to Other Alloys

Here’s a quick comparison of how Monel K500 stacks up against other popular metal powders:

| Alloy | Corrosion Resistance | Strength | Cost | Temperature Tolerance |

|---|---|---|---|---|

| Monel K500 | Excellent (seawater, acid) | Very High | Moderate | High |

| Inconel 625 | Good (oxidation resistance) | High | High | Very High |

| Hastelloy C276 | Excellent (chemical environments) | Moderate | High | Moderate |

| Stainless 316 | Good (general purpose) | Moderate | Low | Moderate |

Pros and Cons of Monel K500 Powder

Let’s summarize the key advantages and limitations of Monel K500 powder:

| Pros | Cons |

|---|---|

| Outstanding corrosion resistance | Higher cost compared to standard stainless steel |

| Superior strength and hardness | Limited availability in certain regions |

| Good magnetic properties | Slightly magnetic, which may be undesirable in some cases |

| Excellent fatigue and creep resistance | Requires heat treatment to reach full potential |

FAQ

| Question | Answer |

|---|---|

| What is Monel K500 powder used for? | It is used in marine, oil & gas, aerospace, and chemical industries for parts like propeller shafts, pumps, valves, and springs. |

| How does Monel K500 differ from Monel 400? | Monel K500 has added aluminum and titanium, which increase its strength and hardness through age-hardening. |

| Can Monel K500 powder be 3D printed? | Yes, Monel K500 powder is commonly used in additive manufacturing and 3D printing for producing high-strength parts. |

| Is Monel K500 magnetic? | It has slight magnetic properties at room temperature, which can vary depending on its heat treatment. |

| What are the temperature limits of Monel K500? | It can operate effectively at temperatures up to 480°C (896°F), making it suitable for high-temperature environments. |

Conclusion

Monel K500 powder is an engineering marvel, combining the best of corrosion resistance, strength, and hardness into a single material. Whether you’re dealing with the salty seas or the harsh conditions of a chemical plant, this alloy holds its own against the toughest of environments.

For engineers, manufacturers, and material scientists, Monel K500 offers a solution that’s both powerful and versatile. With options for powder metallurgy and additive manufacturing, it’s a material that’s here to stay.