Overview of High-Temperature Build Bed Assembly

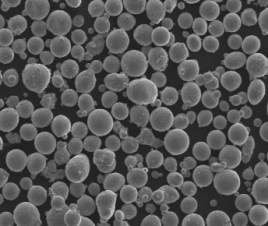

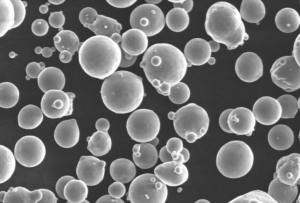

In the world of additive manufacturing and 3D printing, the build bed, also known as the build plate, is a critical component. But when you’re dealing with high-temperature printing materials like PEEK, Ultem, or metals, a regular build bed won’t cut it. That’s where high-temperature build bed assemblies come in. These specialized beds are designed to withstand extreme temperatures, ensuring that your prints adhere correctly and don’t warp, even under the most demanding conditions.

High-temperature build beds are crucial for industrial applications where precision, durability, and consistency are non-negotiable. They are engineered from advanced materials that can endure temperatures beyond 200°C, often integrated with heaters, temperature sensors, and other components that help maintain the perfect environment for your specific material.

Composition of High-Temperature Build Bed Assembly

Understanding the composition of a high-temperature build bed assembly is key to choosing the right one for your application. These assemblies are typically made from a combination of metals, ceramics, and composites, each chosen for their ability to handle high heat while maintaining structural integrity.

| Material | Composition | Properties | Examples of Use |

|---|---|---|---|

| Aluminum Alloys | Aluminum with additives (e.g., 6061, 7075) | High thermal conductivity, lightweight, moderate strength | Widely used in general-purpose high-temp beds |

| Stainless Steel | Iron, carbon, chromium, nickel | High strength, corrosion resistance, lower thermal conductivity | Ideal for environments where durability is key |

| Inconel | Nickel-chromium superalloys | Exceptional heat resistance, oxidation-resistant | Used in aerospace and high-precision industrial applications |

| Tool Steel | Carbon, tungsten, molybdenum | Extremely hard, wear-resistant, retains strength at high temperatures | Suitable for heavy-duty applications |

| Ceramic Coatings | Silicon carbide, aluminum oxide | High-temperature resistance, non-conductive, wear-resistant | Often used as a top coating on metal beds |

| Graphite Composites | Graphite with resin binders | High thermal stability, excellent thermal conductivity, lightweight | Used for extremely high-temperature processes |

| Copper Alloys | Copper with additives like chromium | Excellent thermal conductivity, high electrical conductivity | Suitable for applications needing fast thermal response |

| PEEK | Polyether ether ketone | High strength-to-weight ratio, excellent chemical resistance | Common in specialized plastic printing processes |

| Ultem | Polyetherimide (PEI) | High thermal stability, flame retardant | Used in aerospace and automotive industries |

| Carbon Fiber Reinforced Polymers | Carbon fibers in a polymer matrix | High strength-to-weight ratio, stiff, resistant to deformation at high temperatures | Used in lightweight, high-temp applications |

Characteristics of High-Temperature Build Bed Assembly

When evaluating high-temperature build beds, it’s important to consider their key characteristics, which will directly affect the quality of your prints and the longevity of the build bed itself.

Thermal Conductivity

Thermal conductivity is crucial for even heat distribution across the bed. Metals like aluminum and copper excel in this area, ensuring consistent temperature, which is vital for preventing warping and ensuring even adhesion across the print.

Temperature Stability

Materials like Inconel and ceramic coatings are designed for stability at extreme temperatures. This characteristic is essential for high-precision industries like aerospace and automotive, where even slight temperature fluctuations can lead to defects.

Durability and Wear Resistance

Stainless steel and tool steel are known for their durability, especially in environments where the build bed might be subject to physical stress, such as heavy-duty industrial printing.

Adhesion Properties

The surface of the build bed needs to provide sufficient adhesion to keep the print in place during the process, but also allow for easy removal once the print is complete. Coatings like PEI or specially treated aluminum surfaces are often used for this purpose.

| Characteristic | Best Material Options | Importance |

|---|---|---|

| Thermal Conductivity | Aluminum, Copper Alloys | Ensures even heating and reduces warping |

| Temperature Stability | Inconel, Ceramic Coatings | Prevents deformation and defects in high-temp processes |

| Durability | Stainless Steel, Tool Steel | Ensures longevity and withstands physical stress |

| Adhesion Properties | PEI Coatings, Textured Aluminum | Improves print adherence, reducing failed prints |

Advantages of High-Temperature Build Bed Assembly

So, why invest in a high-temperature build bed assembly? Here are the key benefits:

Precision and Quality

High-temperature build beds allow for the printing of high-performance materials, resulting in parts that have better mechanical properties, heat resistance, and overall performance. This precision is crucial for industries like aerospace, where part failure is not an option.

Versatility

These build beds can handle a wide range of materials, from high-temperature thermoplastics like PEEK and Ultem to metal powders used in direct metal laser sintering (DMLS). This versatility makes them indispensable in a multi-material printing environment.

Longevity

Materials like Inconel and stainless steel are incredibly durable, meaning your build bed will last through many print cycles without degrading, even under continuous high-temperature conditions.

Consistent Results

With excellent thermal conductivity and stability, these beds provide consistent results, which is particularly important for batch production where each part needs to meet strict specifications.

| Advantage | Description |

|---|---|

| Precision and Quality | Enables high-accuracy printing with top-tier materials, critical for precision parts |

| Versatility | Compatible with a wide range of high-temp materials, enhancing printer capability |

| Longevity | Durable materials ensure the build bed lasts longer, reducing replacement costs |

| Consistent Results | Reliable thermal properties provide uniform print quality, crucial for production |

Applications of High-Temperature Build Bed Assembly

High-temperature build beds are used across a variety of industries, each with unique demands and standards. Here are some of the most common applications:

| Industry | Application | Material Used | Benefits |

|---|---|---|---|

| Aerospace | Manufacturing of lightweight, high-strength components | Inconel, Carbon Fiber, PEEK | High precision, temperature resistance, durability |

| Automotive | Production of high-performance parts like engine components and heat shields | Stainless Steel, Ultem | High thermal stability, mechanical strength, corrosion resistance |

| Medical Devices | Custom implants and surgical tools | Titanium, PEEK | Biocompatibility, precision, sterilizability |

| Electronics | Prototyping and small-batch production of circuit boards and heat sinks | Copper Alloys, Ceramic | Excellent thermal conductivity, electrical insulation |

| Oil & Gas | Components for high-temperature, high-pressure environments | Inconel, Stainless Steel | Corrosion resistance, high strength at elevated temperatures |

| Defense | Production of weapons components and other high-stress parts | Tool Steel, Inconel | Extreme durability, heat resistance, wear resistance |

| Energy | Parts for turbines, reactors, and other energy production equipment | Inconel, Stainless Steel | High-temperature performance, resistance to thermal cycling |

| Consumer Goods | Specialized items like custom jewelry, eyewear frames | Stainless Steel, PEI | Aesthetic appeal, precision, durability |

| Architecture | Custom metalwork for structural and decorative applications | Aluminum, Stainless Steel | Structural integrity, weather resistance, aesthetic flexibility |

| Robotics | Components for high-performance robotic systems | Carbon Fiber, Tool Steel | Lightweight, strong, thermally stable |

Specifications, Sizes, Grades, and Standards for High-Temperature Build Bed Assemblies

Choosing the right high-temperature build bed assembly requires attention to specific details like size, grade, and adherence to industry standards. Here’s a breakdown of the most common specifications:

| Specification | Details | Typical Materials |

|---|---|---|

| Size | Customizable, common sizes include 300x300mm, 400x400mm, 500x500mm | Aluminum, Stainless Steel |

| Thickness | Ranges from 5mm to 20mm, depending on the application | Inconel, Tool Steel |

| Grade | Material grades include 6061 (Aluminum), 304 (Stainless Steel), 718 (Inconel) | Aluminum, Stainless Steel, Inconel |

| Surface Finish | Textured, coated, or polished, depending on the adhesion needs | PEI, Ceramic, Aluminum |

| Heating Capabilities | Integrated heaters can range from 100°C to 400°C | PEEK, Ultem, Stainless Steel |

| Compliance Standards | ASTM, ISO, or specific industry standards like ASME, FDA for medical use | Varies by industry |

Suppliers and Pricing Details for High-Temperature Build Bed Assemblies

Here’s a snapshot of some of the top suppliers in the industry, along with pricing details to help you make an informed decision.

| Supplier | Material Offered | Price Range | Notes |

|---|---|---|---|

| McMaster-Carr | Stainless Steel, Aluminum Alloys | $100 – $500 per sheet | Good for general-purpose high-temp beds |

| Protolabs | Inconel, Tool Steel | $500 – $2000 per assembly | Custom builds with high precision |

| Grainger | Aluminum, Stainless Steel | $200 – $800 per sheet | Offers a wide range of sizes and thicknesses |

| 3D Systems | PEEK, Ultem | $1000 – $5000 per assembly | Specializes in high-performance thermoplastic beds |

| EOS | Inconel, Carbon Fiber | $3000 – $10000 per assembly | High-end options for industrial applications |

| Markforged | Carbon Fiber, Stainless Steel | $1500 – $7000 per assembly | Known for their carbon fiber build beds |

| Stratasys | Ultem, PEEK | $2000 – $6000 per assembly | Focuses on thermoplastic and composite materials |

| Arcam | Titanium, Stainless Steel | $4000 – $12000 per assembly | Specializes in metal additive manufacturing |

| Materialise | Aluminum, Stainless Steel | $500 – $3000 per assembly | Custom manufacturing with a focus on detail |

| Renishaw | Inconel, Stainless Steel | $3000 – $10000 per assembly | High-end metal printing applications |

Comparing High-Temperature Build Bed Assembly Options

With so many options on the market, how do you choose? Here’s a comparison to help you weigh the pros and cons:

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Aluminum Alloys | Lightweight, good thermal conductivity | Less durable at very high temperatures | General-purpose printing |

| Stainless Steel | Durable, corrosion-resistant, stable | Lower thermal conductivity compared to aluminum | High-stress environments |

| Inconel | Exceptional heat resistance, strong, oxidation-resistant | Expensive, heavier than aluminum or steel | Aerospace, high-precision manufacturing |

| Tool Steel | Extremely hard, wear-resistant | Can be brittle, especially at very high temperatures | Heavy-duty industrial applications |

| Ceramic Coatings | High-temp resistance, non-conductive | Can be fragile, expensive | Coatings for metal beds in high-temp printing |

| Graphite Composites | High thermal stability, excellent thermal conductivity | Can be expensive, fragile in some configurations | Extreme high-temperature processes |

| Copper Alloys | Excellent thermal conductivity, electrically conductive | Can corrode if not properly protected | Applications requiring fast thermal response |

| PEEK | High strength-to-weight ratio, chemical resistance | Expensive, limited to high-end printers | Specialized plastic printing |

| Ultem | High thermal stability, flame retardant | Expensive, limited to specific industrial applications | Aerospace, automotive applications |

| Carbon Fiber Reinforced Polymers | Lightweight, strong, resistant to deformation | Can be expensive, limited print size | High-temp, lightweight applications |

FAQ

Here’s a quick FAQ section to address some common questions:

| Question | Answer |

|---|---|

| What is the maximum temperature these build beds can handle? | It depends on the material, but generally, high-temperature build beds can handle temperatures up to 400°C or more. |

| Can I use a high-temperature build bed for standard 3D printing? | Yes, but it might be overkill unless you’re printing with high-temp materials like PEEK, Ultem, or metals. |

| How do I maintain my high-temperature build bed? | Regular cleaning and inspection for wear or damage are crucial. For metal beds, occasional resurfacing might be needed. |

| Is there a significant difference in print quality? | Absolutely! The right build bed can dramatically improve print adhesion, reduce warping, and result in smoother, more precise prints. |

| Are high-temperature build beds worth the investment? | If you’re working with high-temp materials or require precision in industrial applications, the investment is definitely worth it. |

| Can I retrofit a standard printer with a high-temperature build bed? | Yes, but make sure your printer’s firmware and hardware can support the increased thermal load. |

| Do these beds require special adhesives? | Some materials might require specific adhesives, while others rely on the surface texture or coating for adhesion. |

| How long do these build beds last? | With proper maintenance, high-temperature build beds can last for years, but this depends on the material and the frequency of use. |

Conclusion

High-temperature build bed assemblies are a vital component for anyone involved in high-performance or industrial 3D printing. Whether you’re printing with PEEK, Ultem, metals, or other demanding materials, these beds offer the thermal stability, durability, and precision needed to achieve top-notch results. Investing in the right high-temperature build bed assembly not only ensures better print quality but also extends the life of your printer and reduces the frequency of failed prints. With the wide range of materials and configurations available, there’s a high-temperature build bed assembly suited to every application, making it a crucial consideration for any serious 3D printing setup.