Overview

Post-atomization treatment of metal powders is crucial in the manufacturing process for a variety of industries, from aerospace to medical devices. This process enhances the properties of metal powders, making them more suitable for specific applications. The treatment typically involves processes like annealing, sieving, and surface modification to improve particle size distribution, morphology, and chemical composition.

What is Post-Atomization Treatment?

Post-atomization treatment refers to the various methods applied to metal powders after they have been produced through atomization. Atomization is the process where molten metal is broken into fine droplets which then solidify into powder particles. The post-atomization treatments are essential for enhancing the powder’s properties, ensuring consistency, and improving performance in end-use applications.

Types of Metal Powders and Their Composition

Metal powders come in various types, each with unique compositions and properties tailored to specific applications. Here are some of the most commonly used metal powders and their compositions:

| Metal Powder | Composition | Properties |

|---|---|---|

| Stainless Steel 316L | Fe, Cr, Ni, Mo | Corrosion resistance, high tensile strength |

| Titanium Ti6Al4V | Ti, Al, V | High strength-to-weight ratio, corrosion resistance |

| Aluminum 6061 | Al, Mg, Si | Lightweight, good mechanical properties |

| Cobalt-Chromium Alloy | Co, Cr, Mo | High wear resistance, excellent biocompatibility |

| Nickel Alloy 625 | Ni, Cr, Mo, Nb | High strength, excellent corrosion resistance |

| Maraging Steel 18Ni300 | Fe, Ni, Co, Mo | High strength, good toughness |

| Copper Alloy C18150 | Cu, Cr, Zr | High conductivity, excellent wear resistance |

| Tungsten Carbide | WC, Co | Extreme hardness, wear resistance |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | High strength, good oxidation resistance |

| Bronze Alloy CuSn12 | Cu, Sn | Good corrosion resistance, excellent machinability |

Characteristics of Powder for Post-Atomization Treatment

Post-atomization treatments are designed to enhance various characteristics of metal powders. Here’s a look at some key properties:

| Characteristic | Description |

|---|---|

| Particle Size Distribution | Ensures uniformity, affecting flowability and packing density |

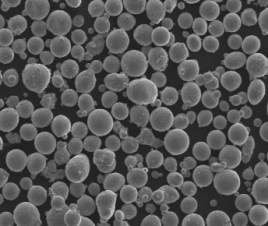

| Morphology | Spherical or irregular shapes affecting flow and packing |

| Surface Area | Influences reactivity and sintering behavior |

| Purity | High purity levels reduce contamination risk |

| Flowability | Affects ease of handling and processing |

| Apparent Density | Impacts packing and sintering efficiency |

| Oxidation Levels | Lower oxidation enhances performance in high-temperature applications |

Applications of Powder for Post-Atomization Treatment

The enhanced properties of post-atomized metal powders make them suitable for a wide range of applications:

| Application | Description |

|---|---|

| Aerospace | High-strength, lightweight components |

| Automotive | Engine parts, transmission components |

| Medical Devices | Implants, surgical instruments |

| Energy Sector | Turbine blades, fuel cells |

| Electronics | Conductive inks, thermal management |

| Tooling | Cutting tools, dies |

| Additive Manufacturing (3D Printing) | Custom, complex geometries, prototyping |

Specifications, Sizes, Grades, and Standards

When selecting metal powders for post-atomization treatment, it’s important to consider specifications, sizes, grades, and standards. Here’s a detailed table for reference:

| Powder Type | Size Range (µm) | Grade | Standards |

|---|---|---|---|

| Stainless Steel 316L | 15-45, 45-105 | AISI 316L | ASTM A276, AMS 5653 |

| Titanium Ti6Al4V | 15-45, 45-90 | Grade 5 | ASTM B348, AMS 4928 |

| Aluminum 6061 | 20-63, 63-125 | AA 6061 | ASTM B209, AMS 4027 |

| Cobalt-Chromium Alloy | 10-45, 45-90 | ASTM F75 | ISO 5832-4 |

| Nickel Alloy 625 | 15-53, 53-150 | UNS N06625 | ASTM B446, AMS 5666 |

| Maraging Steel 18Ni300 | 10-45, 45-105 | Grade 300 | AMS 6514, ASTM A538 |

| Copper Alloy C18150 | 20-53, 53-150 | UNS C18150 | ASTM B606, RWMA Class 2 |

| Tungsten Carbide | 5-15, 15-45 | ISO 9001 certified | ISO 9001, ASTM B777 |

| Inconel 718 | 15-45, 45-105 | UNS N07718 | ASTM B637, AMS 5662 |

| Bronze Alloy CuSn12 | 20-63, 63-150 | UNS C90700 | ASTM B505, AMS 4880 |

Suppliers and Pricing Details

Choosing the right supplier is crucial for obtaining high-quality metal powders. Here’s a look at some suppliers and their pricing details:

| Supplier | Location | Metal Powder | Price (USD/kg) |

|---|---|---|---|

| Höganäs AB | Sweden | Stainless Steel 316L | $50 – $70 |

| LPW Technology | UK | Titanium Ti6Al4V | $300 – $400 |

| Carpenter Technology | USA | Aluminum 6061 | $25 – $40 |

| Arcam AB (GE Additive) | Sweden | Cobalt-Chromium Alloy | $250 – $350 |

| Sandvik | Sweden | Nickel Alloy 625 | $100 – $150 |

| GKN Hoeganaes | USA | Maraging Steel 18Ni300 | $150 – $200 |

| AMETEK Specialty Metal | USA | Copper Alloy C18150 | $30 – $50 |

| Kennametal | USA | Tungsten Carbide | $70 – $90 |

| Metal Powder and Process | USA | Inconel 718 | $200 – $250 |

| Makin Metal Powders | UK | Bronze Alloy CuSn12 | $20 – $35 |

Pros and Cons of Powder for Post-Atomization Treatment

Every metal powder has its own set of advantages and limitations. Here’s a comparative look:

| Metal Powder | Advantages | Limitations |

|---|---|---|

| Stainless Steel 316L | Corrosion resistant, high strength | Higher cost compared to other steels |

| Titanium Ti6Al4V | Lightweight, high strength | Expensive, challenging to process |

| Aluminum 6061 | Lightweight, good mechanical properties | Lower strength compared to steel |

| Cobalt-Chromium Alloy | High wear resistance, biocompatible | Expensive, hard to machine |

| Nickel Alloy 625 | Excellent corrosion resistance, high strength | Expensive, high density |

| Maraging Steel 18Ni300 | High strength, good toughness | Expensive, requires heat treatment |

| Copper Alloy C18150 | High conductivity, wear resistance | Prone to oxidation, less strength than steel |

| Tungsten Carbide | Extremely hard, wear resistant | Brittle, expensive |

| Inconel 718 | High strength, good oxidation resistance | Expensive, difficult to machine |

| Bronze Alloy CuSn12 | Good corrosion resistance, machinable | Lower strength compared to other alloys |

Advantages of Powder for Post-Atomization Treatment

Post-atomization treatment offers numerous benefits that improve the quality and performance of metal powders. Here’s a detailed look at the advantages:

Enhanced Particle Size Distribution

Post-atomization treatments like sieving and classification help achieve a uniform particle size distribution, which is crucial for consistent performance in applications such as additive manufacturing and powder metallurgy.

Improved Morphology

Treatments such as annealing and heat treatment can improve the morphology of the powder particles, making them more spherical. Spherical particles flow better, pack more efficiently, and result in higher-quality finished products.

Reduced Contamination

High-purity powders with minimal contamination are essential for applications like medical devices and aerospace components. Post-atomization treatments ensure that powders meet stringent purity requirements.

Optimized Flowability

Good flowability is critical for processes like 3D printing and metal injection molding.

Post-atomization treatments enhance the flow characteristics of powders, ensuring smooth and reliable processing.

Controlled Oxidation Levels

Controlling the oxidation levels of metal powders is essential for high-temperature applications. Post-atomization treatments help in reducing oxidation, thereby improving the performance and lifespan of the end products.

Specifications, Sizes, Grades, and Standards for Powder for Post-Atomization Treatment

Selecting the right metal powder involves considering various specifications, sizes, grades, and standards. Here’s a detailed breakdown:

| Metal Powder | Size Range (µm) | Grade | Standards |

|---|---|---|---|

| Stainless Steel 316L | 15-45, 45-105 | AISI 316L | ASTM A276, AMS 5653 |

| Titanium Ti6Al4V | 15-45, 45-90 | Grade 5 | ASTM B348, AMS 4928 |

| Aluminum 6061 | 20-63, 63-125 | AA 6061 | ASTM B209, AMS 4027 |

| Cobalt-Chromium Alloy | 10-45, 45-90 | ASTM F75 | ISO 5832-4 |

| Nickel Alloy 625 | 15-53, 53-150 | UNS N06625 | ASTM B446, AMS 5666 |

| Maraging Steel 18Ni300 | 10-45, 45-105 | Grade 300 | AMS 6514, ASTM A538 |

| Copper Alloy C18150 | 20-53, 53-150 | UNS C18150 | ASTM B606, RWMA Class 2 |

| Tungsten Carbide | 5-15, 15-45 | ISO 9001 certified | ISO 9001, ASTM B777 |

| Inconel 718 | 15-45, 45-105 | UNS N07718 | ASTM B637, AMS 5662 |

| Bronze Alloy CuSn12 | 20-63, 63-150 | UNS C90700 | ASTM B505, AMS 4880 |

Comparative Analysis: Powder Types for Post-Atomization Treatment

Let’s delve into a detailed comparison of various metal powders:

Stainless Steel 316L vs. Titanium Ti6Al4V

Stainless Steel 316L is known for its corrosion resistance and strength. However, Titanium Ti6Al4V is lighter and has a higher strength-to-weight ratio, making it ideal for aerospace and medical applications where weight is a critical factor.

Aluminum 6061 vs. Cobalt-Chromium Alloy

Aluminum 6061 offers good mechanical properties and is lightweight, but it doesn’t match the wear resistance and biocompatibility of Cobalt-Chromium Alloy, which is preferred for medical implants and dental applications.

Nickel Alloy 625 vs. Maraging Steel 18Ni300

Nickel Alloy 625 is excellent for high-temperature and corrosive environments due to its superior oxidation resistance. On the other hand, Maraging Steel 18Ni300 provides exceptional strength and toughness, making it suitable for tooling and structural applications.

Copper Alloy C18150 vs. Tungsten Carbide

Copper Alloy C18150 excels in electrical conductivity and wear resistance, making it perfect for electrical contacts. In contrast, Tungsten Carbide is unparalleled in hardness and wear resistance, ideal for cutting tools and wear parts.

Inconel 718 vs. Bronze Alloy CuSn12

Inconel 718 is preferred for its high strength and good oxidation resistance in extreme environments. Bronze Alloy CuSn12, with its excellent machinability and corrosion resistance, is commonly used in bearings and bushings.

Expert Opinions and Studies

Studies and expert opinions reinforce the importance of post-atomization treatment in achieving the desired properties of metal powders. Research indicates that optimized particle size distribution and morphology significantly impact the performance of powders in additive manufacturing and other applications.

For instance, a study by the American Society for Testing and Materials (ASTM) highlights the role of post-atomization treatments in reducing porosity and enhancing the mechanical properties of 3D printed parts. Similarly, experts from the Metal Powder Industries Federation (MPIF) emphasize the need for high-purity powders in critical applications such as aerospace and medical devices.

FAQs

| Question | Answer |

|---|---|

| What is post-atomization treatment? | Post-atomization treatment refers to processes like annealing, sieving, and surface modification applied to metal powders after atomization to enhance their properties. |

| Why is particle size distribution important? | Uniform particle size distribution ensures consistent flowability, packing density, and overall performance in various applications like 3D printing and powder metallurgy. |

| What are the benefits of spherical powder morphology? | Spherical powders flow better, pack more efficiently, and result in higher-quality finished products compared to irregularly shaped powders. |

| How does post-atomization treatment reduce contamination? | Treatments like sieving and heat treatment help remove impurities and contaminants, ensuring high-purity powders suitable for critical applications. |

| Which metal powder is best for aerospace applications? | Titanium Ti6Al4V is preferred for its high strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace components. |

| What are the main advantages of using Nickel Alloy 625? | Nickel Alloy 625 offers high strength and excellent corrosion resistance, particularly in high-temperature and corrosive environments. |

| How is flowability of metal powders enhanced? | Post-atomization treatments like sieving and annealing improve the flow characteristics of powders, making them easier to handle and process. |

| What is the significance of oxidation levels in metal powders? | Low oxidation levels are crucial for high-temperature applications, as they improve the performance and lifespan of the end products. |

| Can post-atomization treatments improve the mechanical properties? | Yes, treatments like annealing and heat treatment can enhance the mechanical properties of metal powders, making them more suitable for specific applications. |

| Which metal powder is best for medical implants? | Cobalt-Chromium Alloy is commonly used for medical implants due to its high wear resistance and excellent biocompatibility. |