When it comes to material science and engineering, one of the most critical aspects is the preparation of high purity powders. These powders are essential in various applications, ranging from aerospace to electronics, due to their enhanced properties and performance. In this extensive guide, we will delve into the nuances of preparing high purity powders, exploring specific metal powder models, their properties, applications, and more. We’ll also tackle the pros and cons, supplier details, and answer some frequently asked questions. Let’s dive in!

Overview

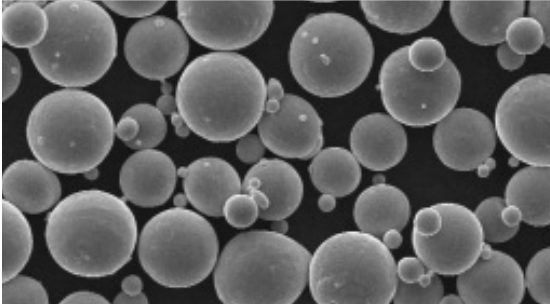

High purity powders are finely ground particles of metals or alloys that boast extremely low levels of impurities. These powders are pivotal in advanced manufacturing processes, including additive manufacturing, metal injection molding, and more. The primary goal in preparing these powders is to achieve a uniform particle size distribution and high chemical purity to ensure optimal performance in their respective applications.

Key Details of High Purity Powders

- Purity Level: Typically above 99.9%

- Particle Size: Can range from nanometers to micrometers

- Applications: Aerospace, medical devices, electronics, energy storage, etc.

- Preparation Methods: Chemical vapor deposition, electrolysis, atomization, and mechanical alloying

Types of High Purity Metal Powders

1. Titanium (Ti) Powder

Titanium powders are known for their high strength-to-weight ratio and excellent corrosion resistance. They are widely used in aerospace, medical implants, and high-performance automotive components.

2. Aluminum (Al) Powder

Aluminum powders are lightweight and possess good electrical conductivity. They are commonly used in electronics, additive manufacturing, and as a catalyst in chemical reactions.

3. Nickel (Ni) Powder

Nickel powders are valued for their high melting point and excellent corrosion resistance. They find applications in battery electrodes, superalloys, and coatings.

4. Copper (Cu) Powder

Copper powders offer excellent thermal and electrical conductivity. They are used in electrical contacts, conductive inks, and heat sinks.

5. Iron (Fe) Powder

Iron powders are cost-effective and have good magnetic properties. They are utilized in magnetic materials, automotive parts, and as a catalyst in various reactions.

6. Cobalt (Co) Powder

Cobalt powders are known for their wear resistance and high-temperature stability. They are used in superalloys, cutting tools, and battery cathodes.

7. Silver (Ag) Powder

Silver powders exhibit the highest electrical conductivity among metals. They are used in conductive adhesives, inks, and photovoltaic cells.

8. Gold (Au) Powder

Gold powders have excellent corrosion resistance and electrical conductivity. They are used in electronics, medical devices, and as a catalyst.

9. Platinum (Pt) Powder

Platinum powders are highly stable and resistant to oxidation. They are used in catalytic converters, fuel cells, and sensors.

10. Tungsten (W) Powder

Tungsten powders have the highest melting point among metals. They are used in high-temperature applications, electrical contacts, and radiation shielding.

Composition, Properties, and Characteristics

Below is a table summarizing the key properties of these high purity metal powders.

| Metal Powder | Composition | Key Properties | Characteristics |

|---|---|---|---|

| Titanium (Ti) | 99.9% Ti | High strength, corrosion resistance | Lightweight, biocompatible |

| Aluminum (Al) | 99.9% Al | Lightweight, good conductivity | High ductility, reflective |

| Nickel (Ni) | 99.9% Ni | High melting point, corrosion resistance | Magnetic, good mechanical strength |

| Copper (Cu) | 99.9% Cu | Excellent conductivity | Ductile, high thermal conductivity |

| Iron (Fe) | 99.9% Fe | Cost-effective, magnetic | High strength, easy to alloy |

| Cobalt (Co) | 99.9% Co | Wear resistance, high-temperature stability | Magnetic, high hardness |

| Silver (Ag) | 99.9% Ag | Highest electrical conductivity | Ductile, reflective |

| Gold (Au) | 99.9% Au | Excellent conductivity, corrosion resistance | Malleable, biocompatible |

| Platinum (Pt) | 99.9% Pt | High stability, oxidation resistance | Dense, high melting point |

| Tungsten (W) | 99.9% W | Highest melting point | Dense, very hard |

Applications of High Purity Powders

High purity powders are utilized across various industries for their exceptional properties. Here’s a detailed table showing their applications.

| Metal Powder | Applications |

|---|---|

| Titanium (Ti) | Aerospace components, medical implants, automotive parts |

| Aluminum (Al) | Electronics, additive manufacturing, chemical catalysts |

| Nickel (Ni) | Battery electrodes, superalloys, coatings |

| Copper (Cu) | Electrical contacts, conductive inks, heat sinks |

| Iron (Fe) | Magnetic materials, automotive parts, catalysts |

| Cobalt (Co) | Superalloys, cutting tools, battery cathodes |

| Silver (Ag) | Conductive adhesives, inks, photovoltaic cells |

| Gold (Au) | Electronics, medical devices, catalysts |

| Platinum (Pt) | Catalytic converters, fuel cells, sensors |

| Tungsten (W) | High-temperature applications, electrical contacts, radiation shielding |

Specifications, Sizes, Grades, and Standards

When selecting high purity powders, it’s crucial to understand their specifications, sizes, grades, and standards. The following table provides this information.

| Metal Powder | Specifications | Sizes | Grades | Standards |

|---|---|---|---|---|

| Titanium (Ti) | ASTM B348, AMS 4902 | 1-100 micrometers | Grade 1, Grade 2 | ASTM, AMS |

| Aluminum (Al) | ASTM B221, AMS 4068 | 1-200 micrometers | 1100, 2024 | ASTM, AMS |

| Nickel (Ni) | ASTM B160, AMS 5564 | 1-150 micrometers | Nickel 200, Nickel 201 | ASTM, AMS |

| Copper (Cu) | ASTM B187, AMS 4500 | 1-120 micrometers | C10100, C11000 | ASTM, AMS |

| Iron (Fe) | ASTM A848, AMS 5030 | 1-180 micrometers | Fe 99.9, Fe 99.95 | ASTM, AMS |

| Cobalt (Co) | ASTM F75, AMS 4778 | 1-160 micrometers | Co 99.9, Co 99.95 | ASTM, AMS |

| Silver (Ag) | ASTM B700, AMS 4764 | 1-100 micrometers | Ag 99.9, Ag 99.95 | ASTM, AMS |

| Gold (Au) | ASTM B488, AMS 4787 | 1-50 micrometers | Au 99.9, Au 99.95 | ASTM, AMS |

| Platinum (Pt) | ASTM B493, AMS 4897 | 1-100 micrometers | Pt 99.9, Pt 99.95 | ASTM, AMS |

| Tungsten (W) | ASTM B777, AMS 7875 | 1-150 micrometers | W 99.9, W 99.95 | ASTM, AMS |

Suppliers and Pricing Details

Finding the right supplier for high purity powders is essential for ensuring quality and cost-effectiveness. Here’s a table of notable suppliers and their pricing details.

| Metal Powder | Supplier | Price (per kg) | Comments |

|---|---|---|---|

| Titanium (Ti) | American Elements | $300 | Customizable particle size |

| Aluminum (Al) | Alfa Aesar | $150 | High purity, various sizes |

| Nickel (Ni) | Goodfellow | $250 | Available in different grades |

| Copper (Cu) | Sigma-Aldrich | $100 | High purity, fine powders |

| Iron (Fe) | Höganäs | $50 | Bulk availability |

| Cobalt (Co) | Materion | $400 | Premium quality, consistent supply |

| Silver (Ag) | Ames Goldsmith | $1000 | High conductivity, various sizes |

| Gold (Au) | Tanaka Kikinzoku | $5000 | Ultra-high purity, customizable |

| Platinum (Pt) | Johnson Matthey | $3000 | High stability, various sizes |

| Tungsten (W) | Buffalo Tungsten | $500 | High melting point, bulk availability |

Advantages and Disadvantages of High Purity Powders

Understanding the benefits and drawbacks of high purity powders helps in making informed decisions. The following table compares the pros and cons.

| Metal Powder | Advantages | Disadvantages |

|---|---|---|

| Titanium (Ti) | High strength, corrosion resistance | Expensive, challenging to process |

| Aluminum (Al) | Lightweight, good conductivity | Prone to oxidation, lower strength |

| Nickel (Ni) | High melting point, corrosion resistance | Expensive, limited suppliers |

| Copper (Cu) | Excellent conductivity, ductile | Prone to oxidation, not as strong |

| Iron (Fe) | Cost-effective, magnetic properties | Prone to rust, lower corrosion resistance |

| Cobalt (Co) | Wear resistance, high-temperature stability | Expensive, limited suppliers |

| Silver (Ag) | Highest electrical conductivity, ductile | Very expensive, prone to tarnishing |

| Gold (Au) | Excellent conductivity, corrosion resistance | Extremely expensive, soft metal |

| Platinum (Pt) | High stability, oxidation resistance | Extremely expensive, dense |

| Tungsten (W) | Highest melting point, very hard | Difficult to process, expensive |

Preparation Methods for High Purity Powders

Several methods are used to prepare high purity powders, each with its advantages and limitations. Here’s a detailed look at the common preparation methods.

1. Chemical Vapor Deposition (CVD)

Chemical vapor deposition involves the chemical reaction of gaseous precursors to form a solid material. This method is ideal for producing high purity powders with uniform particle sizes.

Advantages:

- High purity levels

- Uniform particle size distribution

- Can produce complex shapes

Disadvantages:

- Expensive equipment

- Requires precise control of reaction conditions

2. Electrolysis

Electrolysis involves passing an electric current through a solution containing the metal, causing the metal to deposit as a powder. This method is commonly used for metals like copper and nickel.

Advantages:

- High purity

- Simple setup

- Cost-effective for certain metals

Disadvantages:

- Limited to conductive materials

- Slower production rate

3. Atomization

Atomization involves breaking up a molten metal stream into fine droplets that solidify into powders. This method is used for metals like aluminum, titanium, and steel.

Advantages:

- Can produce large quantities

- Good control over particle size

- Suitable for a wide range of metals

Disadvantages:

- Requires high-energy input

- Potential contamination from the environment

4. Mechanical Alloying

Mechanical alloying involves repeatedly fracturing and welding metal powders in a high-energy ball mill. This method is used to produce complex alloys and composite powders.

Advantages:

- Can produce unique alloys

- High energy efficiency

- Good control over composition

Disadvantages:

- Long processing time

- Potential contamination from milling media

Application-Specific Preparation Methods

Different applications may require specific preparation methods to achieve the desired powder properties. Here’s a look at some application-specific methods.

Aerospace

For aerospace applications, high purity powders like titanium and nickel are prepared using atomization and CVD to ensure high strength and corrosion resistance.

Medical Devices

Medical devices often use titanium and cobalt powders prepared through electrolysis and mechanical alloying to achieve biocompatibility and wear resistance.

Electronics

In electronics, aluminum and copper powders are typically prepared using electrolysis and atomization to ensure high electrical conductivity and fine particle size.

Energy Storage

Energy storage applications, such as batteries, use nickel and cobalt powders prepared through mechanical alloying and electrolysis for high performance and stability.

Comparing Preparation Methods

To help you decide which preparation method to use, here’s a comparison of the methods based on key parameters.

| Preparation Method | Purity | Particle Size Control | Cost | Speed | Suitable Metals |

|---|---|---|---|---|---|

| CVD | High | Excellent | High | Moderate | Titanium, tungsten, platinum |

| Electrolysis | High | Good | Moderate | Slow | Copper, nickel, silver |

| Atomization | Moderate | Excellent | Moderate | Fast | Aluminum, titanium, steel |

| Mechanical Alloying | High | Good | Low | Slow | Complex alloys, composites |

Conclusion

Preparing high purity powders involves selecting the right metal, understanding the properties and applications, choosing the appropriate preparation method, and finding reliable suppliers. Whether you’re working in aerospace, electronics, medical devices, or energy storage, the quality of your powders will significantly impact your final product. By considering the detailed comparisons and insights provided in this guide, you can make informed decisions that will enhance your manufacturing processes and product performance.

know more 3D printing processes

FAQ

1. What is the importance of high purity in metal powders?

High purity in metal powders is crucial because it ensures optimal performance in applications requiring precise chemical compositions and superior physical properties. Impurities can significantly affect the material’s strength, conductivity, and corrosion resistance.

2. How do I choose the right metal powder for my application?

Choosing the right metal powder depends on your specific application requirements, such as desired properties (e.g., strength, conductivity), preparation method compatibility, and cost considerations. Refer to the detailed properties and applications tables in this guide to help make an informed decision.

3. What are the most common methods for preparing high purity powders?

The most common methods include chemical vapor deposition (CVD), electrolysis, atomization, and mechanical alloying. Each method has its advantages and limitations, as discussed in the preparation methods section.

4. Can high purity powders be customized?

Yes, high purity powders can be customized in terms of particle size, composition, and shape to meet specific application requirements. It’s essential to work with reputable suppliers who offer customization options.

5. Are there any safety concerns when handling high purity powders?

Handling high purity powders requires appropriate safety measures to avoid inhalation, ingestion, and skin contact. Always follow the manufacturer’s safety guidelines, use protective equipment, and work in a well-ventilated area.

6. How does the preparation method affect the final properties of the powder?

The preparation method affects the powder’s purity, particle size distribution, morphology, and potential contamination levels. Each method has its strengths and is suited for different applications, as detailed in the preparation methods comparison table.

7. Where can I purchase high purity metal powders?

High purity metal powders can be purchased from specialized suppliers like American Elements, Alfa Aesar, Goodfellow, and Sigma-Aldrich. The supplier table in this guide provides more details on suppliers and pricing.

8. What are the advantages of using high purity powders in manufacturing?

Using high purity powders in manufacturing enhances the performance, reliability, and longevity of the final products. They offer better control over material properties and reduce the risk of defects caused by impurities.

9. Can high purity powders be used in additive manufacturing?

Yes, high purity powders are widely used in additive manufacturing to produce high-performance components with excellent mechanical properties and fine feature resolution. Metals like titanium and aluminum are commonly used in this process.

10. What factors should I consider when storing high purity powders?

When storing high purity powders, consider factors like moisture control, temperature, and contamination prevention. Use airtight containers, store in a dry environment, and handle with clean tools to maintain powder quality.