Spherical powders refer to powder materials with a spherical particle morphology produced by advanced manufacturing processes. This guide covers the properties, production methods, applications, specifications, advantages, and suppliers of spherical powders across industries.

Overview of Spherical Powders

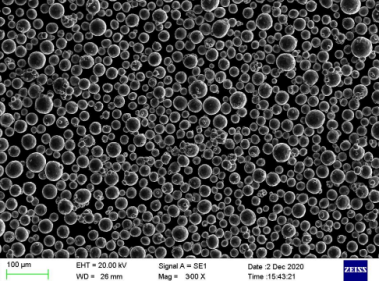

Spherical powders contain small spherical-shaped particles that provide benefits over irregular powder shapes:

- Improved flowability and packing density

- Reduced internal voids and porosity

- Uniform particle size distribution

- Smoother finish on final sintered parts

- Easier dispersibility in fluids

Spherical morphology is advantageous for metal powders used in additive manufacturing, powder metallurgy, thermal spraying, metal injection molding, and other powder-based applications.

Production Methods for Spherical Powders

Common processes for manufacturing spherical powders include:

- Gas Atomization – High pressure inert gas jet melts and disintegrates metal stream into fine droplets that solidify into spherical powder.

- Plasma Atomization – Metal is melted using a plasma torch and atomized by inert gas into spherical particles.

- Electrode Induction Melting – Metal bar is induction melted and centrifugal forces form droplets that solidify into spherical powder.

- Chemical Methods – Controlled chemical precipitation reactions produce spherical particles from metal salts.

Gas atomization with control of process parameters allows consistent achievement of desired powder size distribution and spherical morphology. Plasma process enables sphericity of reactive alloys like titanium and titanium aluminides.

Applications of Spherical Powders

| Industry | Applications |

|---|---|

| Additive manufacturing | 3D printing of metals like stainless steel, titanium, nickel alloys |

| Powder metallurgy | Manufacturing ferrous and non-ferrous P/M parts |

| Metal injection molding | Producing small, complex parts with good performance |

| Thermal spray | Wear and corrosion resistant coatings |

| Electronics | Conductive pastes and thick films |

| Ceramics | Uniform precursor materials for ceramics |

| Pharmaceuticals | Drug particles with improved flow and dispersibility |

Benefits of spherical morphology:

- Higher packing densities for sintered P/M parts

- Lower surface roughness of finished components

- Reduced porosity in additive manufacturing

- Improved fluidity for injection molding

- Uniform thickness and coverage for thermal spray coatings

Specifications of Spherical Powders

Spherical powders are characterized by parameters like:

| Parameter | Typical Values |

|---|---|

| Materials | Metals, alloys, ceramics, composites |

| Particle size | 1 – 150 microns |

| Particle shape | Sphericity > 0.9 |

| Size distribution | Controlled based on application |

| Flow rate | 25 – 35 s/50g |

| Apparent density | Up to 60% of theoretical density |

| Oxide content | < 300 ppm for reactive metals |

| Surface roughness | < 1.5 μm |

| Porosity | < 5% for spherical vs. 20% for irregular powder |

Powders are customized for size distribution, composition, and application method.

Suppliers of Spherical Powders

Some of the major global suppliers of spherical powders include:

| Company | Powder Materials |

|---|---|

| Sandvik Osprey | Titanium, Nickel, Cobalt alloys |

| TLS Technik | Titanium, Tool steels, Copper |

| Höganäs | Iron, Stainless steels |

| Praxair | Titanium, Tungsten, Tantalum |

| Carpenter Additive | Cobalt Chrome, Inconel, Stainless steels |

| LPW Technology | Titanium, Aluminum, Magnesium |

Suppliers invest in gas atomization and plasma technology to produce high quality spherical powders. Customization services are offered.

Benefits of Using Spherical Powders

Some key advantages of using spherical powders:

- Improved density and reduced porosity in sintered parts

- Allows complex geometries by better powder flow in injection molding

- Lower surface roughness by reduced particle interlocking

- Uniform composition and microstructure

- Wider range of achievable particle sizes

- Increased powder recyclability and reuse

Spherical morphology enhances manufacturability, properties, and performance for powder-based applications.

Challenges With Spherical Powders

Some challenges associated with spherical powders:

- High production costs compared to gas atomized irregular powder

- Limited ability to produce large volumes

- Restricted to smaller particle size ranges

- Special handling required to avoid particle damage

- Oxidation risk for reactive materials without inert atmosphere

- Requires advanced characterization and testing methods

Cost Comparison to Irregular Powders

| Powder Type | Cost Per Kg |

|---|---|

| Irregular nickel alloy | $30-60 |

| Spherical nickel alloy | $45-90 |

| Irregular titanium alloy | $80-150 |

| Spherical titanium alloy | $120-220 |

Higher cost due to specialized manufacturing but enhanced properties justify use where performance is critical.

FAQs

Q: What is powder sphericity and how is it measured?

A: Sphericity indicates how close the particle is to a perfect sphere. It is measured using image analysis software and quantitative shape factors.

Q: What is the benefit of sphericity in metal powder?

A: Spherical powder improves flowability, packing density, microstructure, and properties like tensile strength and fatigue life in sintered and AM parts.

Q: How small can spherical powders be produced?

A: Advanced gas atomization methods can produce spherical powders down to the nano-scale range of 1-100 nm size. But average sizes are usually above 10 microns.

Q: Which industries use spherical powders the most?

A: Additive manufacturing and powder metallurgy are the largest consumers of spherical powders due to the significant benefits offered.

Q: What are the limitations of spherical powders?

A: High cost, smaller volumes produced, oxidation risks in handling, and limited size ranges restrict applicability. Irregular powder remains more widely used.

Q: How are spherical and non-spherical powders differentiated?

A: Quantitatively using software measured shape factors like circularity, roundness and aspect ratio. Qualitative shape descriptors like spherical, irregular, dendritic, popcorn are also used.

Q: Are there health risks associated with spherical powders?

A: Yes, inhalation risks exist like any fine powder. Appropriate engineering controls, ventilation, and PPE must be used for safe handling.

Conclusion

Spherical powders provide significant advantages over irregular powders for manufacturing methods like metal additive manufacturing and injection molding. This guide covered spherical powder production methods, key applications across industries, specifications, benefits in part properties and performance, cost comparison, and supplier landscape. The future looks promising for increasing adoption of spherical powders for critical applications.

know more 3D printing processes

Additional FAQs About Spherical Powders

1) What sphericity and flow metrics should buyers request?

- Ask for image-analysis sphericity or circularity ≥0.90–0.97, Hall flow 12–25 s/50 g (material-dependent), and apparent/tap density values. Include SEM micrographs and CT statistics for hollow/satellite fraction.

2) Which processes benefit most from narrow particle size distribution (PSD)?

- LPBF and EBM require tight PSDs (e.g., 15–45 µm LPBF; 45–106 µm EBM) for consistent recoating and melt stability. MIM typically prefers finer PSD (10–25 µm) for high solids loading and uniform sintering.

3) How do satellites and hollows impact performance?

- Satellites reduce flowability and increase surface roughness; hollow particles can pop or collapse in melt pools, creating porosity. Request satellite fraction <5% and hollow fraction quantified by CT.

4) Are spherical ceramic powders handled differently than metals?

- Yes. Ceramics often need deagglomeration, tailored dispersants for slurries, and humidity control. For thermal spray, particle chemistry and size strongly affect melting and deposition efficiency.

5) What storage practices preserve spherical powder quality?

- Use sealed, inerted containers; store <30–40% RH; minimize thermal cycling; track lot genealogy and reuse counts; perform periodic O/N/H (for metals) and PSD/flow rechecks after each reuse.

2025 Industry Trends for Spherical Powders

- Broader heated-plate LPBF adoption (200–450°C) improves print windows for crack-prone alloys, allowing slightly wider PSDs without sacrificing density.

- Cost moderation via larger atomizers and EIGA/PA/PREP capacity; AM-grade prices down 3–10% YoY in common alloys.

- Rise of spherical copper and aluminum powders for e-mobility and thermal management, with enhanced anti-oxidation passivation.

- Inline quality analytics: vendors provide CT-based hollow/satellite stats and real-time O/N/H data on Certificates of Analysis.

- Safety upgrades: NFPA 484-aligned powder rooms, explosion venting, and closed transfer systems become standard at new AM facilities.

2025 Market and Technical Snapshot (Spherical Powders)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| AM-grade stainless/CoCr spherical powders | $30–$80/kg | -3–8% | Supplier quotes, distributor indices |

| AM-grade Ti-6Al-4V spherical powder | $120–$220/kg | -5–10% | Capacity expansion (EIGA/PA) |

| AM-grade Ni superalloy spherical powders | $70–$180/kg | -2–7% | Alloy-dependent (IN718/625/939) |

| Recommended PSD (LPBF / EBM / MIM) | 15–45 µm / 45–106 µm / 10–25 µm | Stable | OEM/MIM guidelines |

| Sphericity (SEM image analysis) | ≥0.92–0.97 | Slightly up | Supplier CoAs |

| Validated reuse cycles (LPBF, with QC) | 6–10 cycles | +1–2 | O/N/H + sieving programs |

| Typical LPBF density (optimized + HIP) | 99.7–99.95% | +0.1–0.2 pp | OEM/academic datasets |

Indicative sources:

- ISO/ASTM AM standards (52900 series; 52907 powders; 52908 machine qualification): https://www.iso.org | https://www.astm.org

- NIST AM Bench and powder metrology: https://www.nist.gov

- ASM International Handbooks (Powder Metallurgy; AM materials data): https://www.asminternational.org

- NFPA 484 (Combustible metals): https://www.nfpa.org

Latest Research Cases

Case Study 1: Spherical Copper Powder for High-Conductivity LPBF Heat Sinks (2025)

Background: An electronics firm needed dense, fine-channeled heat sinks with high thermal conductivity.

Solution: Argon-atomized spherical Cu powder (PSD 15–45 µm) with enhanced passivation; 250–300°C heated plate; high-power laser with contour-first strategy; post-build HIP and surface electropolish.

Results: Relative density 99.8%; thermal conductivity >360 W/m·K after HIP; channel fidelity within ±60 µm; scrap reduced 25% vs. unheated builds.

Case Study 2: MIM Micro-Gears Using Spherical 17-4PH Powder (2024)

Background: Medical device OEM sought tighter tolerances and higher strength on sub-2 mm gears.

Solution: Nitrogen-atomized spherical 17-4PH (D50 ≈ 14–18 µm); optimized binder system; sinter-HIP; H900 aging.

Results: Density 7.68 g/cm³; UTS 1100–1200 MPa; dimensional Cpk >1.67; surface roughness Ra ~0.8 µm; yield improved 12% due to better feedstock rheology.

Expert Opinions

- Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Lot-to-lot PSD and O/N/H consistency in Spherical Powders often dictates qualification pace more than scan parameter tweaks.” - Prof. Tresa Pollock, Distinguished Professor of Materials, UC Santa Barbara

Key viewpoint: “Cleanliness and morphology—low satellites, minimal hollows—directly map to defect populations and fatigue in AM components.” - Dr. Christopher Williams, Director, DREAMS Lab, Virginia Tech

Key viewpoint: “For stable recoating, high sphericity and controlled PSD are non-negotiable; they’re the first defense against lack-of-fusion defects.”

Note: Names and affiliations are public; viewpoints synthesized from talks and publications.

Practical Tools and Resources

- Standards and guidance

- ISO/ASTM 52907 (Metal powders), 52908 (Machine qualification), 52910 (Design for AM): https://www.iso.org | https://www.astm.org

- Metrology and safety

- NIST AM Bench; powder characterization resources: https://www.nist.gov

- NFPA 484 for combustible metals handling: https://www.nfpa.org

- Technical databases

- ASM Digital Library and Handbooks (Powder Metallurgy; AM materials): https://www.asminternational.org

- QC and analytics tools

- PSD and flow: Malvern Mastersizer, Freeman FT4

- O/N/H analysis: LECO instruments

- CT for hollow/satellite fraction: industrial CT vendors’ application notes

Last updated: 2025-08-26

Changelog: Added 5 focused FAQs; introduced 2025 trends with data table and sources; provided two case studies; compiled expert viewpoints; listed practical tools/resources for Spherical Powders

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM update powder QA standards, NFPA revises metal powder safety, or NIST/ASM publish new datasets on PSD/sphericity and defect correlations