Titanium Alloy Powders

Shanghai Truer Industrial Development Co., Ltd

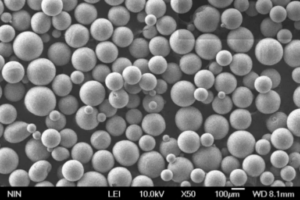

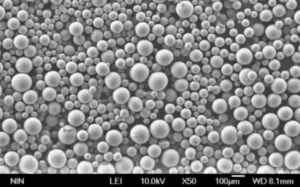

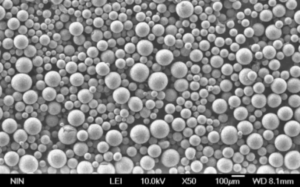

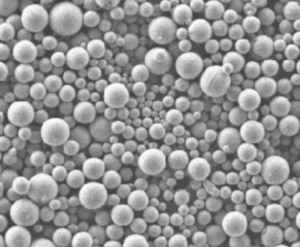

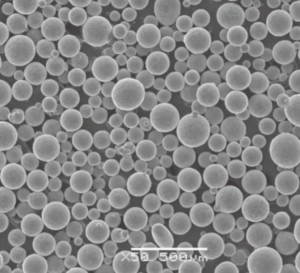

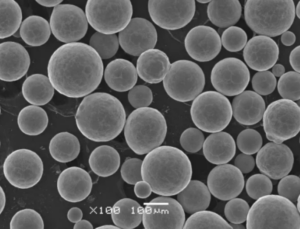

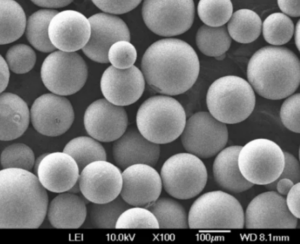

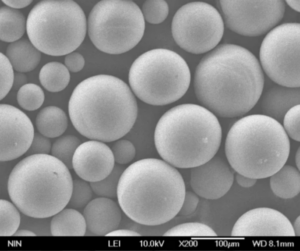

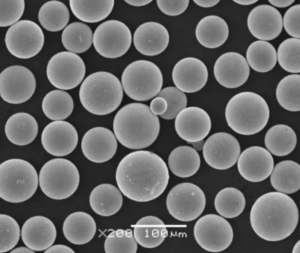

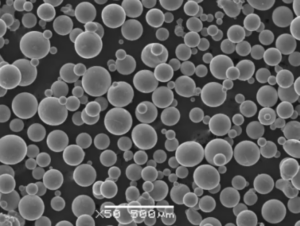

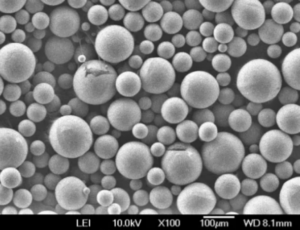

What is Titanium Alloy Powders

Titanium alloy powder is a metal which can be made into many different shapes, depending on what use it is for. It is an important metal for industry today because it has unique properties that not many other metals have.

Why Choose Titanium Alloy Powders?

Titanium alloy powders are becoming more and more popular for a variety of reasons. They offer a number of benefits that make them an attractive choice for certain applications. Here are some of the reasons why titanium alloy powders can be a great option for your next project:

– They’re strong: Titanium alloy powders are extremely strong, making them perfect for use in applications where strength is critical.

– They’re lightweight: Titanium alloy powders are lightweight, so they’re ideal for applications where weight is important.

– They’re corrosion resistant: Titanium alloy powders are resistant to corrosion, making them ideal for use in applications where protection from environmental factors is important.

11 PREP Titanium Alloy Powders:

Contact to get free solution!

Titanium Alloy Powders Chemical Composition

| Additive Manufacturing | ||||

| Titanium Alloy Powders | ||||

| Grades | Chemical Composition, wt% | Particle Size Grades | ASTM | |

| TA1 | Ti Bal. | Fe 0.20max | 15-53μm 53-106μm 53-150μm | B348 |

| C 0.08max | H 0.015max | |||

| O 0.18max | Other 0.40max | |||

| N 0.03max | ||||

| TA7 | Ti Bal. | Fe 0.20max | 15-53μm 53-106μm 53-150μm | B348 |

| C 0.08max | H 0.015max | |||

| O 0.18max | Pa 0.12-0.25 | |||

| N 0.03max | Other 0.40max | |||

| TA11 | Ti Bal. | Fe 0.20max | 15-53μm 53-106μm 53-150μm | B348 |

| C 0.08max | H 0.015max | |||

| O 0.18max | Pa 0.12-0.25 | |||

| N 0.03max | Other 0.40max | |||

| TA15 | Ti Bal. | Fe 0.30max | 15-53μm 53-106μm 53-150μm | B348 |

| C 0.08max | Ru 0.04-0.06 | |||

| O 0.25max | Ni 0.4-0.6 | |||

| N 0.05max | Other 0.40max | |||

| H 0.015max | ||||

| TC4 | Ti Bal. | N 0.05max | 15-53μm 53-106μm 53-150μm | B348 |

| Al 5.50-6.75 | H 0.015max | |||

| V 3.50-4.50 | Fe 0.40max | |||

| O 0.20max | Other 0.40max | |||

| C 0.08max | ||||

| TC4 ELI | Ti Bal. | N 0.03max | 15-53μm 53-106μm 53-150μm | B348 |

| Al 5.50-6.50 | H 0.0125max | |||

| V 3.50-4.50 | Fe 0.25max | |||

| O 0.13max | Other 0.40max | |||

| C 0.08max | ||||

| TC11 | Ti Bal. | Pa 0.12-0.25 | 15-53μm 53-106μm 53-150μm | B348 |

| C 0.08max | H 0.015max | |||

| O 0.18max | N 0.03max | |||

| Fe 0.20max | Other 0.40max | |||

| TC18 | Ti Bal. | V 2.0-3.0 | 15-53μm 53-106μm 53-150μm | B348 |

| C 0.08max | H 0.015max | |||

| O 0.15max | N 0.03max | |||

| Fe 0.25max | Pa 0.04-0.08 | |||

| Al 2.5-3.5 | Other 0.40max | |||

| Ti2AlNb | Ti Bal. | Y 0.005max | 15-53μm 53-106μm 53-150μm | |

| Al 11.1-11.5 | Si 0.002max | |||

| Nb 38.4-41.2 | V 1.9-3.8 | |||

| Ti45Al8Nb | Ti Bal. | C 0.025max | 15-53μm 53-106μm 53-150μm | |

| Al 28.0-29.5 | O 0.12max | |||

| Nb 17.0-17.8 | N 0.02max | |||

| Fe 0.10max | H 0.003max | |||

| Ti48Al2Cr2Nb | Ti Bal. | C 0.025max | 15-53μm 53-106μm 53-150μm | |

| Al 32.0-34.0 | O 0.12max | |||

| Cr 2.2-2.6 | N 0.02max | |||

| Nb 4.5-5.1 | H 0.003max | |||

| Fe 0.10max | ||||

| Customized: TA2, TA3, TA4, TA5, TA9, TB5, TC1,TC2, TC3,TC10, Ti-6Al-2Sn-4Zr-2Mo, Ti-5Al-5V-5Mo-3Cr, TiTaNbZr, etc | ||||

PREP Titanium Alloy Powders Applications

Titanium alloy powders can be found in various applications across many industries. They are used as a component in many products, such as aircraft and spacecraft, medical implants, and industrial equipment. Titanium alloy powders are also used in laser marking and etching systems because of their high machinability.

3D Printing

Mechanical Industry

Metallurgical Industry

Medical Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]