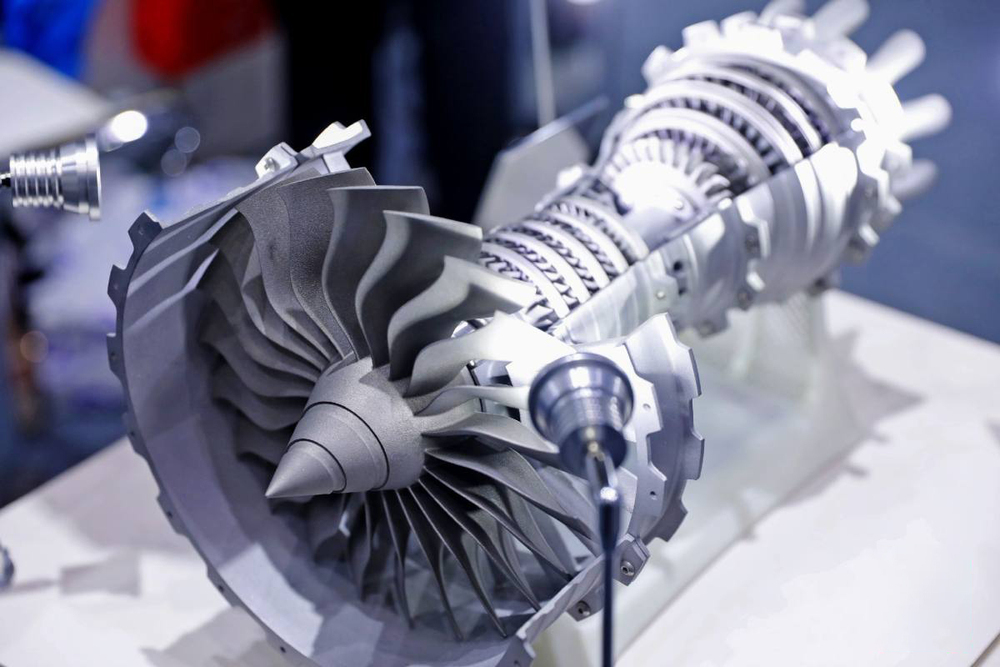

3D Printing Metal Powder Applications in the Aerospace Industry

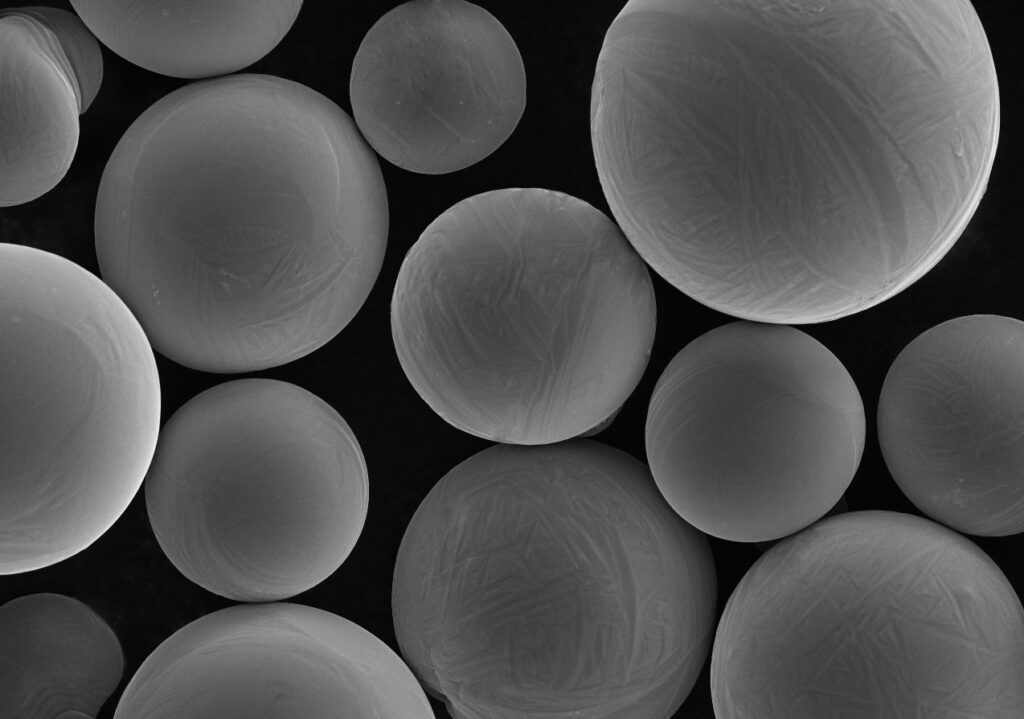

In recent years, the aerospace industry has witnessed remarkable advancements in manufacturing technology. One such technology that has revolutionized the industry is 3D printing, also known as additive manufacturing. 3D printing has opened up a whole new realm of possibilities, enabling the production of complex and intricate designs that were once deemed impossible. In particular, […]

3D Printing Metal Powder Applications in the Aerospace Industry Read More »