Günümüzün gelişmiş imalat ortamında, 3D baskıdan metalurjiye kadar çeşitli uygulamalar için yüksek kaliteli metal tozlarının üretimi esastır. Bu metal tozlarını üretmenin en verimli ve etkili yöntemlerinden biri gaz atomizasyonudur. A gaz atomizör makinesi bu süreçte kritik bir ekipmandır. Bu kapsamlı kılavuz, gaz atomizör makinelerinin inceliklerini, türlerini, bileşimlerini, özelliklerini, uygulamalarını ve daha fazlasını inceleyecektir.

Gaz Atomizör Makinelerine Genel Bakış

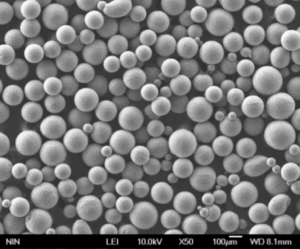

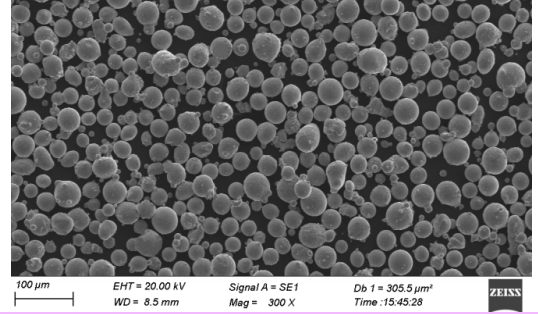

Bir gaz atomizör makinesi, erimiş metali yüksek hızlı bir gaz akımı kullanarak küçük damlacıklara ayırarak ince metal tozları üretmek üzere tasarlanmıştır. Bu damlacıklar daha sonra ince parçacıklara katılaşır ve çeşitli endüstriyel uygulamalar için uygun hale gelir. Bu yöntem, özellikle homojen bir boyut dağılımına, yüksek saflığa ve mükemmel küreselliğe sahip tozlar üretme yeteneği nedeniyle tercih edilmektedir.

Türleri ve Modelleri Gaz Atomizör Makineleri

Spesifik Metal Tozu Modelleri

İşte gaz atomizör makineleri kullanılarak üretilen, her biri benzersiz özelliklere ve uygulamalara sahip bazı özel metal tozu modelleri:

- 316L Paslanmaz Çelik Toz: Korozyon direnci ve mukavemeti ile bilinir, tıp ve havacılık endüstrilerinde yaygın olarak kullanılır.

- 17-4 PH Paslanmaz Çelik Toz: Yüksek mukavemet ve sertlik sunar, havacılık, kimya ve petrokimya endüstrileri için uygundur.

- Titanyum Alaşımlı Toz (Ti-6Al-4V): Hafif ve güçlü, havacılık, tıbbi implantlar ve otomotiv sektörlerinde kullanılır.

- Inconel 718 Toz: Nikel bazlı süper alaşım tozu, havacılık ve enerji sektörlerinde yüksek sıcaklık uygulamaları için mükemmeldir.

- Alüminyum Alaşımlı Toz (AlSi10Mg): İyi termal özelliklere sahip hafif, otomotiv ve havacılık uygulamaları için idealdir.

- Bakır Tozu: Yüksek termal ve elektriksel iletkenlik, elektronik ve ısı eşanjörlerinde kullanılır.

- Kobalt-Krom Alaşımlı Toz: Yüksek aşınma ve korozyon direnci, tıbbi implantlar ve diş uygulamalarında kullanılır.

- Takım Çeliği Tozu (H13): Yüksek sertlik ve termal direnç, takımlama ve kalıplama endüstrilerinde kullanılır.

- Nikel Alaşımlı Toz (NiCrMo): Yüksek sıcaklık ve korozyon direnci, türbin motorları ve kimyasal işleme için uygundur.

- Bronz Tozu: İyi işlenebilirlik ve aşınma direnci, yataklarda, burçlarda ve heykellerde kullanılır.

Gaz Atomizör Makinelerinin Bileşimi ve Özellikleri

Gaz Atomizör Makinelerinin Bileşimi

Gaz atomizör makineleri, ince metal tozları üretmek için birlikte çalışan çeşitli temel bileşenlerden oluşur:

| Bileşen | Açıklama |

|---|---|

| Pota | Metalin eritildiği kap. |

| Gaz Nozülü | Eriyik metale yüksek hızlı gazı yönlendirerek atomize eder. |

| Atomizasyon Odası | Atomizasyonun gerçekleştiği ve partiküllerin katılaştığı kapalı alan. |

| Siklon Ayırıcı | Tozu gaz akışından ayırır. |

| Toz Toplayıcı | Atomizasyondan sonra ince metal tozlarını toplar. |

| Kontrol Sistemi | Tutarlı üretim kalitesini sağlayarak proses parametrelerini yönetir. |

Gaz Atomizer Makinelerinin Özellikleri

Gaz atomizer makineleri, yüksek kaliteli metal tozları üretmeleri için onları uygun kılan çeşitli özelliklere sahiptir:

| Karakteristik | Açıklama |

|---|---|

| Yüksek Saflık | Minimum kontaminasyonlu tozlar üretir. |

| Üniform Boyut | Tutarlı partikül boyutu dağılımına sahip tozlar üretebilir. |

| Küresellik | Akışkanlığı ve paketleme yoğunluğunu iyileştiren küresel tozlar üretir. |

| Ölçeklenebilirlik | Hem küçük ölçekli hem de büyük ölçekli üretim için uygundur. |

| Çok Yönlülük | Çok çeşitli metal ve alaşımları atomize edebilir. |

| Verimlilik | Enerji tüketimi ve üretim hızı açısından verimlidir. |

Uygulamaları Gaz Atomizasyon Makinesi Ürünler

Gaz atomizer makineleri kullanılarak üretilen metal tozları, çeşitli endüstrilerde geniş bir uygulama yelpazesine sahiptir:

| Uygulama | Açıklama |

|---|---|

| Katmanlı Üretim | Karmaşık ve hassas bileşenler oluşturmak için 3D baskıda kullanılır. |

| Havacılık ve Uzay | Yüksek mukavemet ve hafiflik özellikleri gerektiren yüksek performanslı parçaların imalatı. |

| Tıbbi İmplantlar | İmplantlar ve protezler için biyouyumlu malzemelerin üretimi. |

| Otomotiv | Yüksek mukavemet ve hafiflik özellikleri gerektiren bileşenler oluşturma. |

| Takımlama | Dayanıklı ve yüksek mukavemetli takımların ve kalıpların imalatı. |

| Elektronik | Elektrik uygulamaları için iletken bileşenlerin üretimi. |

| Enerji Sektörü | Yüksek sıcaklıklara ve aşındırıcı ortamlara dayanabilen bileşenler oluşturma. |

| Takı | Değerli metallerde yüksek kaliteli ve karmaşık tasarımlar üretme. |

Spesifikasyonlar, Boyutlar, Kaliteler ve Standartlar

Bir gaz atomizer makinesi veya ürettiği metal tozlarını seçerken, spesifikasyonları, boyutları, kaliteleri ve standartları dikkate almak önemlidir:

| Parametre | Detaylar |

|---|---|

| Parçacık Boyutu | Uygulamaya bağlı olarak tipik olarak 10 ila 150 mikron arasında değişir. |

| Saflık | Genellikle ,9'u aşan yüksek saflık seviyeleri. |

| Notlar | Alaşım bileşimine ve amaçlanan kullanıma bağlı olarak çeşitli kaliteler mevcuttur. |

| Standartlar | ASTM, ISO ve AMS gibi endüstri standartlarına uygundur. |

| Üretim Hacmi | Birkaç kilogramdan birkaç tona kadar üretim yapabilir. |

| Erime Kapasitesi | Küçük ölçekli 10 kg sistemlerden büyük ölçekli 1000 kg sistemlere kadar değişir. |

Tedarikçiler ve Fiyatlandırma Detayları

Birçok tedarikçi, gaz atomizer makineleri ve ilgili metal tozlarını sağlar ve fiyatlar spesifikasyonlara ve miktarlara göre değişir:

| Tedarikçi | Ürün | Fiyat Aralığı |

|---|---|---|

| LPW Teknoloji | AM için metal tozları | kg başına 50 - 500 ABD Doları |

| Höganäs AB | Yüksek kaliteli metal tozları | kg başına 100 - 600 ABD Doları |

| Sandvik Osprey | Çeşitli alaşım tozları | kg başına 150 - 700 ABD Doları |

| Marangoz Teknolojisi | Özel alaşımlı tozlar | kg başına 200 - 800 ABD Doları |

| GKN Katkı Maddesi | 3D baskı için metal tozları | Kilogram başına 120 - 650 ABD doları |

| AP&C | Titanyum ve alüminyum alaşımlı tozlar | Kilogram başına 250 - 900 ABD doları |

| Praxair | Yüksek performanslı metal tozları | Kilogram başına 180 - 750 ABD doları |

| Erasteel | Takım çeliği ve yüksek hız çeliği tozları | Kilogram başına 140 - 680 ABD doları |

| Arcam AB | EBM sistemleri için metal tozları | Kilogram başına 220 - 850 ABD doları |

| VBN Bileşenleri | Özel alaşım tozları | Kilogram başına 300 - 1000 ABD doları |

Artıları ve Eksileri Karşılaştırmak

Seçim yaparken gaz atomizör makinesi veya metal tozları, avantajlarını ve sınırlamalarını tartmak önemlidir:

| Artıları | Eksiler |

|---|---|

| Yüksek Saflık | Yüksek Başlangıç Maliyeti |

| Tekdüze Parçacık Boyutu Dağılımı | Karmaşık Bakım Gereksinimleri |

| Çok Yönlü Malzeme Seçenekleri | Yetenekli Operatörler Gerektirir |

| Büyük Üretim Hacimleri İçin Ölçeklenebilirlik | Yüksek Enerji Tüketimi |

| Geliştirilmiş Toz Akışkanlığı | Gaz Kirlenme Potansiyeli |

| Verimli Üretim Süreci | Belirli Metaller ve Alaşımlarla Sınırlıdır |

Bileşimi Gaz Atomizasyon Makinesi Ürünler

Yaygın Tozların Ayrıntılı Bileşimi

| Toz Modeli | Birincil Unsurlar | İkincil Unsurlar |

|---|---|---|

| 316L Paslanmaz Çelik | Fe, Cr, Ni, Mo | Mn, Si, P, S |

| 17-4 PH Paslanmaz Çelik | Fe, Cr, Ni, Cu | C, Mn, Si, P, S, Nb |

| Ti-6Al-4V | Ti, Al, V | O, N, C, H, Fe |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo, Ti, Al | C, Mn, Si, Cu |

| AlSi10Mg | Al, Si, Mg | Fe, Cu, Mn, Zn |

| Bakır | Cu | Pb, Fe, Ni, Zn |

| Kobalt-Krom | Co, Cr | Mo, Ni, Fe, Si |

| Takım Çeliği H13 | Fe, Cr, Mo, Si, V | C, Mn, P, S |

| NiCrMo | Ni, Cr, Mo | Fe, C, Mn, Si, Cu |

| Bronz | Cu, Sn | Zn, Pb, Ni |

SSS

| Soru | Cevap |

|---|---|

| Gaz atomizasyon makinesi nedir? | Ergitilmiş metali yüksek hızlı bir gaz kullanarak atomize ederek ince metal tozları üretmek için kullanılan bir makine. |

| Hangi metaller atomize edilebilir? | Paslanmaz çelikler, titanyum, nikel alaşımları, alüminyum ve daha fazlası dahil olmak üzere çeşitli metaller. |

| Metal tozlarının kullanım alanları nelerdir? | Uygulamalar arasında 3D baskı, havacılık, tıbbi implantlar, otomotiv, takımlama ve elektronik yer alır. |

| Gaz atomize tozların faydaları nelerdir? | Faydaları arasında yüksek saflık, tekdüze boyut, küresellik ve mükemmel akışkanlık yer alır. |

| Bu tozların tipik parçacık boyutu nedir? | Parçacık boyutları tipik olarak 10 ila 150 mikron arasında değişir. |

| Gaz atomizasyonunun herhangi bir sınırlaması var mı? | Sınırlamalar arasında yüksek ilk maliyetler ve yetenekli operatörlere duyulan ihtiyaç yer alır. |

| Doğru gaz atomizasyon makinesini nasıl seçerim? | Üretim hacmi, metal türü ve istenen toz özellikleri gibi faktörleri göz önünde bulundurun. |

| Bu makinelerin önde gelen tedarikçilerinden bazıları kimlerdir? | Tedarikçiler arasında LPW Technology, Höganäs AB, Sandvik Osprey, Carpenter Technology ve daha fazlası yer alır. |

| Gaz atomize tozların temel özellikleri nelerdir? | Temel özellikler yüksek saflık, tekdüze boyut, küresellik ve iyi akışkanlıktır. |

| Gaz atomizasyonu diğer yöntemlerle nasıl karşılaştırılır? | Gaz atomizasyonu, genellikle tutarlı özelliklere sahip yüksek kaliteli tozlar üretme yeteneği nedeniyle tercih edilir. |

Sonuç olarak, gaz atomizasyon makineleri modern imalatta vazgeçilmezdir ve çok çeşitli uygulamalar için yüksek kaliteli metal tozlarının üretilmesini sağlar. Bu makinelerin ve tozların çeşitli türlerini, bileşimlerini, özelliklerini ve uygulamalarını anlayarak, ihtiyaçlarınıza en uygun bilinçli kararlar verebilirsiniz.