Laser-DED Process of Inconel 718 Alloy Powder

Compared with wire-based materials, Inconel 718 alloy powder feed offers higher material utilization and greater cost efficiency. The feeding process is faster, and when combined with the high energy concentration of the laser, it significantly enhances deposition efficiency. Layer-by-layer deposition enables the flexible fabrication of complex metal components, overcoming the geometric limitations of conventional manufacturing.

By adjusting the laser power in real time and integrating a coaxial infrared pyrometer, closed-loop monitoring of melt pool temperature can be achieved, offering strong potential for dynamic thermal control.

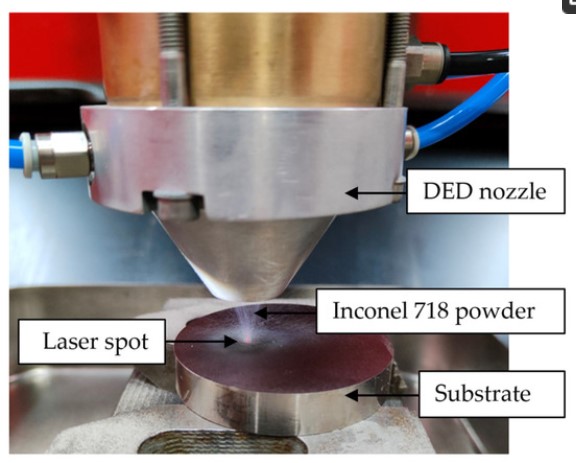

Experimental Setup:

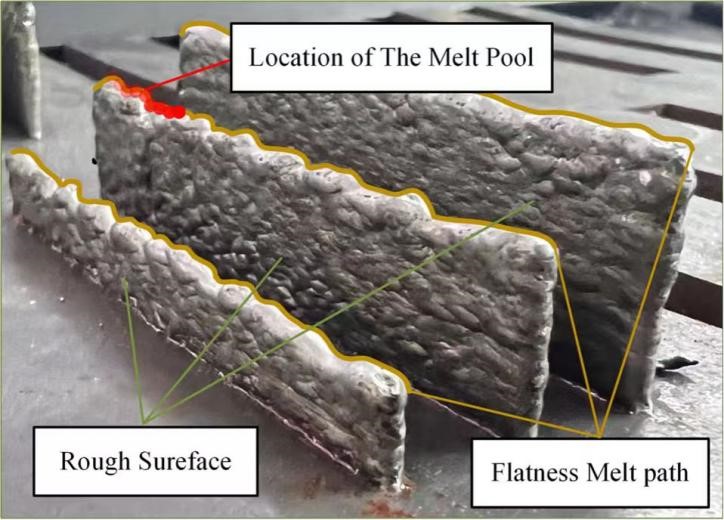

However, this technology also faces notable challenges in practice. Multi-layer deposition tends to cause heat accumulation, which can enlarge the melt pool, increase vertical dimensional deviation, porosity, and grain coarsening.

The repetitive scanning paths further amplify thermal gradient fluctuations, resulting in spattering and balling, thus reducing structural uniformity.

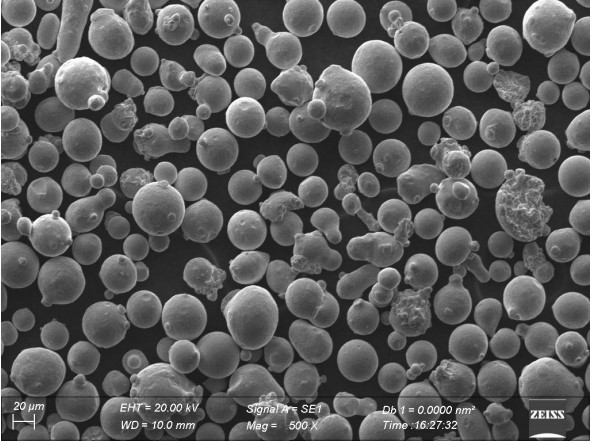

Morphology of gas atomized Inconel 718 powder:

It can be observed that there are some Satellite and agglomerated particles from gas atomized Inconel 718 powder.

Irregular melt paths and rough surface morphology deposited by gas atomized Inconel 718 powder:

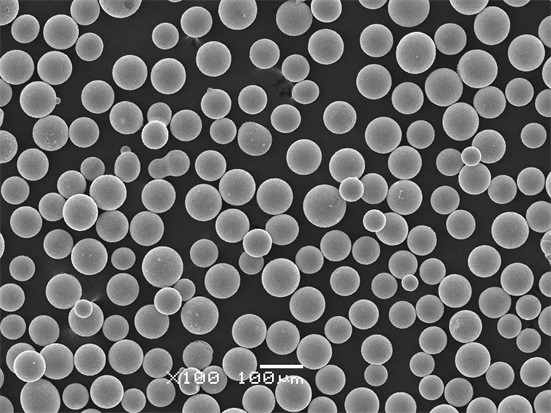

Morphology of PREP Inconel 718 powder:

It can be observed that there are not any Satellite and agglomerated particles from PREP Inconel 718 powder.

By changing the Inconel 718 powder from gas atomized type to PREP type, the vertical dimensional deviation was reduced greatly by 85% and improved structural uniformity by 98% due to more uniform particle size and more sphericity of PREP powder to stabilize the melt pool dynamics.

And the DED parts by PREP Inconel 718 powders have least defects and discontinuities due to almost zero hollow and satellite powders of PREP powder.

Surface morphology deposited by PREP Inconel 718 powder: