Surface Repair of 7075 Aluminum Alloy by AFSD

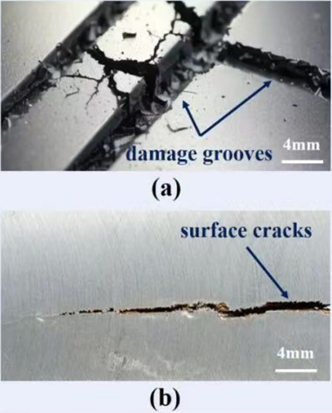

7075 aluminum alloys are widely used in aerospace and transportation due to their high strength and excellent corrosion resistance. However, under extreme service conditions, these aluminum alloy components are prone to surface damage such as wear, impact, and corrosion.

Traditional repair methods often deteriorate the material’s properties, resulting in large heat-affected zones and elemental segregation. Additive Friction Stir Deposition (AFSD), an emerging solid-state additive manufacturing technique, offers distinct advantages in alloy component repair, including significant grain refinement, low energy consumption, and high deposition rates. It effectively avoids problems such as hot cracking, large deformation, and high residual stress.

TRUER R&D team did some investigations on how the interface step design affects on the repair performance of 7075 aluminum alloys through different repair structure configurations which can provide some insights for the design and optimization of aluminum alloy repair processes.

Surface Damage of 7075 aluminum alloy part:

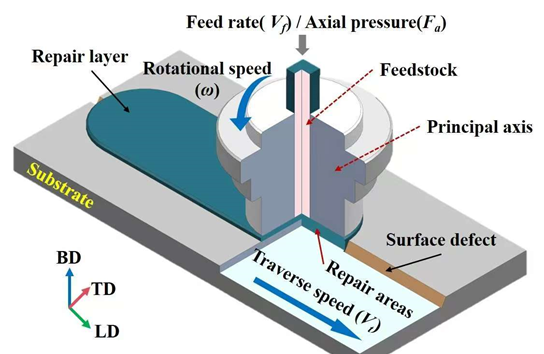

We use our self-developed AFSD system to do some repair experiments systematically to find how different repair structure designs affect the repair performance of 7075 aluminum alloys. And our study aslo reveals the microstructural and performance evolution mechanisms associated with step-structured repair interfaces.

Repair equipment:

Repair Process:

Optimization of Repair Parameters:

By analyzing the ideal and actual material volume variations during the repair process, a coordination equation between feed rate (Vf) and traverse rate (Vt) was derived. Given a specific repair layer thickness (Hr), an appropriate Vf/Vt ratio can be determined to ensure process stability and completeness.

Based on this principle, different combinations of repair parameters—including tool rotation speed, feed rate, and traverse rate—were evaluated.

The results showed a nonlinear relationship between rotation speed and heat generation. A peak repair temperature of around 390-410 °C combined with moderate heat input yielded optimal material plastic flow. The optimal AFSD parameters were determined as: rotation speed ω = 440 rpm, traverse rate Vt = 129.1 mm/min, and feed rate Vf = 50.9 mm/min, ensuring the best balance of heat generation, material flow, and repair quality.

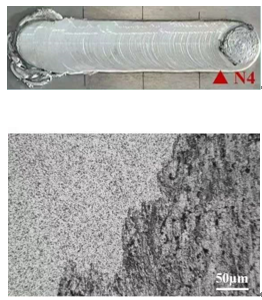

Interface Bonding after Repair under Optimal AFSD:

Under optimal process parameters, the repair exhibited better fill quality, repair depth and bonding. The surface exhibits a smooth morphology with better bonding quality, metallurgical bonding between the repair and base materials evident, indicating superior repair quality.

During AFSD, frictional heat generated by the tool and substrate is the primary heat source influencing material softening and filling. When the repair groove is too deep, insufficient heat limits effective material mixing. But under TRUER AFSD design, the stepped interface increases contact area, promotes material mixing, and enhances bonding.

Microstructural Evolution during the Repair of 7075:

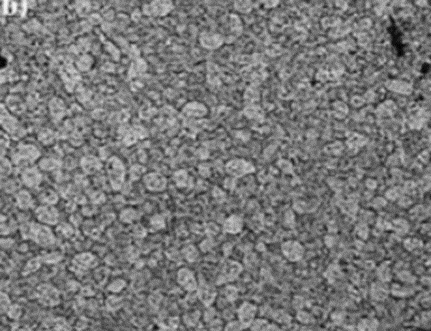

The repaired regions exhibited fine equiaxed grains, with more pronounced refinement in the stepped groove designs. The average grain size is between 3-8um.

Property Analysis after Repair:

Microhardness measurements showed that the repaired zones generally exhibited lower hardness than the base material. The low-hardness areas corresponded closely to the cross-sectional shape of the repair structure with a distinct softened zone and transition layer at the interface. Transmission electron microscopy (TEM) images confirmed the reduced MgZn₂ phase density in the repaired zones, consistent with the observed hardness decrease.

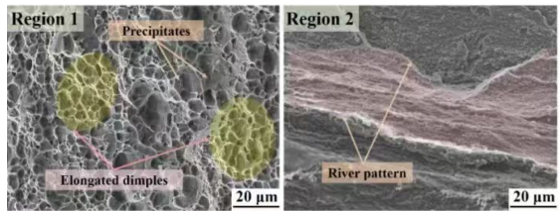

Fractographic examination of tensile specimens revealed both ductile and brittle features, with microvoid coalescence and small dimples typical of ductile failure, and also with river-like patterns indicating mixed fracture modes.

This study highlights the great potential and engineering applicability of AFSD technology in repairing Al-Zn-Mg-Cu Series alloys (7075 or 7050). Further research is needed to optimize heat input control, interface structural design, and the precise matching between repaired and base materials.