Welcome to our comprehensive guide on Gás inerte para fusão por indução de eletrodos (EIMIG), a sophisticated technique used in the production of high-quality metal powders. Whether you’re a materials engineer, a researcher, or simply curious about advanced metallurgical processes, this article is designed to provide you with a detailed understanding of EIMIG. We’ll dive into its mechanics, explore specific metal powder models, and highlight its various applications. So, let’s get started!

Overview of Electrode Induction Melting Inert Gas

Electrode Induction Melting Inert Gas (EIMIG) is a cutting-edge metallurgical process that involves the melting of metals using an electric arc generated between electrodes in an inert gas environment. This method is particularly advantageous for producing high-purity metal powders, which are essential in industries ranging from aerospace to biomedical engineering.

What Makes EIMIG Special?

EIMIG stands out due to its ability to produce metal powders with superior purity and controlled particle sizes. By using an inert gas atmosphere, typically argon or helium, oxidation and contamination are minimized, ensuring the production of high-quality metal powders. The process is also highly versatile, allowing for the melting of a wide range of metals and alloys.

Core Components of EIMIG

- Electrodes: Usually made of graphite or tungsten, these generate the electric arc necessary for melting.

- Inert Gas Environment: Argon or helium is commonly used to prevent oxidation.

- Induction Heating System: Provides the necessary energy to sustain the melting process.

- Cadinho: Holds the metal as it melts and cools into powder form.

Types of Metal Powders Produced by EIMIG

EIMIG can produce a variety of metal powders, each with unique properties suitable for different applications. Here are ten specific models:

1. Liga de titânio (Ti-6Al-4V)

Composição: Titânio, alumínio, vanádio

Propriedades: Alta relação resistência/peso, excelente resistência à corrosão

Formulários: Aerospace components, medical implants

2. Nickel Superalloy (Inconel 718)

Composição: Nickel, Chromium, Iron, Niobium

Propriedades: High temperature resistance, excellent mechanical properties

Formulários: Turbine blades, jet engines

3. Stainless Steel (316L)

Composição: Ferro, cromo, níquel, molibdênio

Propriedades: High corrosion resistance, good formability

Formulários: Biomedical devices, food processing equipment

4. Cobalt-Chromium Alloy (Co-Cr-Mo)

Composição: Cobalto, cromo, molibdênio

Propriedades: Alta resistência ao desgaste, biocompatibilidade

Formulários: Dental implants, orthopedic implants

5. Aluminum Alloy (AlSi10Mg)

Composição: Alumínio, silício, magnésio

Propriedades: Lightweight, good thermal conductivity

Formulários: Automotive parts, aerospace structures

6. Copper Alloy (CuNi2SiCr)

Composição: Cobre, níquel, silício, cromo

Propriedades: High electrical conductivity, good mechanical strength

Formulários: Electrical connectors, heat exchangers

7. Aço ferramenta (H13)

Composição: Ferro, cromo, molibdênio, vanádio

Propriedades: High toughness, excellent heat resistance

Formulários: Molds for die casting, extrusion tools

8. Aço Maraging (18Ni300)

Composição: Iron, Nickel, Cobalt, Molybdenum

Propriedades: High strength, good toughness

Formulários: Aerospace components, tooling

9. Tungsten Carbide (WC-Co)

Composição: Tungsten, Cobalt

Propriedades: Extremely hard, high wear resistance

Formulários: Cutting tools, mining equipment

10. Zirconium Alloy (Zr702)

Composição: Zirconium, Hafnium, Iron

Propriedades: Excellent corrosion resistance, good mechanical properties

Formulários: Nuclear reactors, chemical processing equipment

Características de Gás inerte para fusão por indução de eletrodos

EIMIG is known for several key characteristics that make it an attractive option for producing metal powders.

Pureza

The inert gas environment significantly reduces contamination, resulting in metal powders with high purity levels.

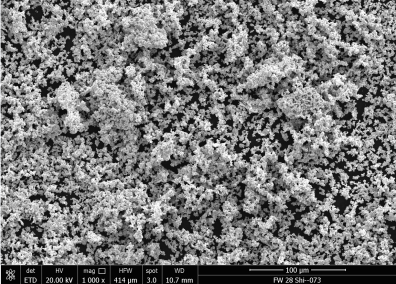

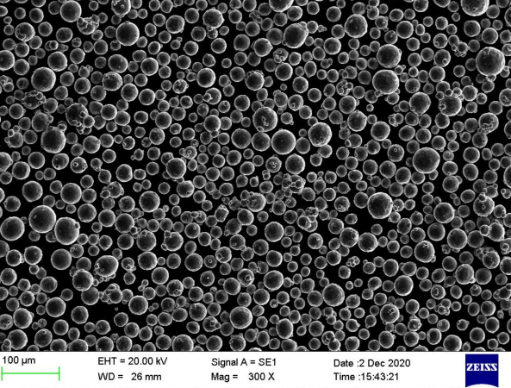

Controle de tamanho de partícula

EIMIG allows for precise control over particle size distribution, which is crucial for applications requiring specific powder characteristics.

Versatilidade

The process is adaptable to a wide range of metals and alloys, making it suitable for diverse industrial applications.

Eficiência

EIMIG is an energy-efficient process, capable of producing high yields of metal powder with minimal waste.

Applications of Electrode Induction Melting Inert Gas

EIMIG-produced metal powders find use in various high-tech industries due to their superior properties.

Indústria aeroespacial

High-strength, lightweight alloys like Ti-6Al-4V are crucial for aircraft components, where performance and reliability are paramount.

Biomedical Engineering

Biocompatible materials such as Co-Cr-Mo are used in medical implants and devices, ensuring safety and effectiveness for patients.

Setor automotivo

Aluminum alloys like AlSi10Mg are used in automotive parts to reduce weight and improve fuel efficiency.

Eletrônicos

Copper alloys with high electrical conductivity are essential for connectors and other electronic components.

Tooling and Manufacturing

Tool steels and tungsten carbide powders are used to create durable molds and cutting tools for various manufacturing processes.

Detailed Specifications of EIMIG Metal Powders

Propriedades e características

| Pó metálico | Densidade (g/cm³) | Ponto de fusão (°C) | Dureza (HV) | Resistência à tração (MPa) | Alongamento (%) |

|---|---|---|---|---|---|

| Ti-6Al-4V | 4.43 | 1660 | 349 | 895 | 10 |

| Inconel 718 | 8.19 | 1350 | 330 | 1240 | 12 |

| Aço inoxidável 316L | 7.99 | 1375 | 217 | 620 | 40 |

| Co-Cr-Mo | 8.29 | 1330 | 450 | 900 | 8 |

| AlSi10Mg | 2.68 | 570 | 85 | 310 | 7 |

| CuNi2SiCr | 8.78 | 1083 | 100 | 450 | 20 |

| Aço para ferramentas H13 | 7.80 | 1427 | 750 | 1450 | 12 |

| 18Ni300 Maraging Steel | 8.00 | 1413 | 340 | 2000 | 10 |

| WC-Co | 15.60 | 2870 | 1600 | – | – |

| Zr702 | 6.50 | 1855 | 250 | 550 | 30 |

Aplicações e usos

| Pó metálico | Aplicativos primários | Additional Uses |

|---|---|---|

| Ti-6Al-4V | Componentes aeroespaciais, implantes médicos | Sporting goods, marine applications |

| Inconel 718 | Turbine blades, jet engines | Nuclear reactors, space vehicles |

| Aço inoxidável 316L | Biomedical devices, food processing | Chemical processing, marine applications |

| Co-Cr-Mo | Implantes dentários, implantes ortopédicos | Watch components, industrial bearings |

| AlSi10Mg | Automotive parts, aerospace structures | Consumer electronics, bicycles |

| CuNi2SiCr | Conectores elétricos, trocadores de calor | Marine applications, coinage |

| Aço para ferramentas H13 | Molds for die casting, extrusion tools | Injection molds, forging dies |

| 18Ni300 Maraging Steel | Componentes aeroespaciais, ferramentas | High-performance gears, shafts |

| WC-Co | Cutting tools, mining equipment | Wear-resistant parts, drilling tools |

| Zr702 | Nuclear reactors, chemical processing | Medical devices, aerospace components |

Especificações, tamanhos, graus, padrões

| Pó metálico | Grau | Faixa de tamanho (µm) | Padrão |

|---|---|---|---|

| Ti-6Al-4V | Grau 5 | 15-45 | ASTM B348 |

| Inconel 718 | UNS N07718 | 15-53 | AMS 5662 |

| Aço inoxidável 316L | 316L | 10-45 | ASTM F138 |

| Co-Cr-Mo | ASTM F75 | 20-63 | ISO 5832-4 |

| AlSi10Mg | – | 15-45 | DIN EN 1706 |

| CuNi2SiCr | – | 20-50 | ASTM B422 |

| Aço para ferramentas H13 | H13 | 20-63 | ASTM A681 |

| 18Ni300 Maraging Steel | 18Ni300 | 10-45 | AMS 6514 |

| WC-Co | 1-20 | ISO 4499-1 | |

| Zr702 | R60702 | 15-45 | ASTM B551 |

Detalhes de fornecedores e preços

| Fornecedor | Pó metálico | Preço (por kg) | Disponibilidade |

|---|---|---|---|

| Advanced Powders Inc. | Ti-6Al-4V | $150 | Em estoque |

| Specialty Metals Co. | Inconel 718 | $200 | Estoque limitado |

| Medical Materials LLC | Aço inoxidável 316L | $120 | Em estoque |

| BioMetals Corp. | Co-Cr-Mo | $180 | Pre-order required |

| Light Metals Inc. | AlSi10Mg | $100 | Em estoque |

| Electrical Alloys Ltd. | CuNi2SiCr | $160 | Em estoque |

| Tool Steel Supply Co. | Aço para ferramentas H13 | $140 | Estoque limitado |

| High Strength Metals | 18Ni300 Maraging Steel | $220 | Em estoque |

| Hard Metals Group | WC-Co | $300 | Pre-order required |

| Nuclear Materials Inc. | Zr702 | $250 | Em estoque |

Comparing Pros and Cons, Advantages and Limitations

| Pó metálico | Vantagens | Limitações |

|---|---|---|

| Ti-6Al-4V | High strength, lightweight, corrosion resistant | Caro, difícil de usinar |

| Inconel 718 | Excellent high-temperature properties | High cost, complex processing |

| Aço inoxidável 316L | Corrosion resistant, biocompatible | Menor resistência em comparação com outras ligas |

| Co-Cr-Mo | Alta resistência ao desgaste, biocompatibilidade | Brittleness, expensive |

| AlSi10Mg | Leve, com boas propriedades térmicas | Menor resistência em comparação com as ligas de aço |

| CuNi2SiCr | High electrical conductivity, corrosion resistant | Expensive, limited mechanical strength |

| Aço para ferramentas H13 | High toughness, heat resistance | Susceptible to cracking under stress |

| 18Ni300 Maraging Steel | Alta resistência, boa tenacidade | Expensive, complex heat treatment required |

| WC-Co | Extremamente duro, com alta resistência ao desgaste | Brittleness, high cost |

| Zr702 | Excelente resistência à corrosão, boas propriedades mecânicas | Alto custo, disponibilidade limitada |

perguntas frequentes

O que é Gás inerte para fusão por indução de eletrodos (EIMIG)?

EIMIG is a process where metals are melted using an electric arc between electrodes in an inert gas atmosphere, producing high-purity metal powders.

Why use an inert gas in EIMIG?

Inert gases like argon or helium prevent oxidation and contamination during the melting process, ensuring high-quality metal powders.

What metals can be melted using EIMIG?

EIMIG is versatile and can melt a wide range of metals and alloys, including titanium, nickel, stainless steel, cobalt-chromium, and more.

What are the applications of EIMIG metal powders?

EIMIG metal powders are used in aerospace, biomedical engineering, automotive, electronics, and tooling industries due to their superior properties.

How does EIMIG control particle size?

The process parameters in EIMIG can be finely adjusted to control the particle size distribution, ensuring consistency and precision in the final product.

Are EIMIG metal powders expensive?

The cost of EIMIG metal powders varies based on the metal type and purity but generally tends to be higher due to the advanced nature of the process.

What are the main benefits of EIMIG?

EIMIG offers high purity, precise particle size control, versatility in metal types, and efficient production, making it highly beneficial for producing specialized metal powders.

How is EIMIG different from other melting techniques?

EIMIG uses an inert gas atmosphere and induction heating, which reduces contamination and allows for precise control over the melting process, setting it apart from other techniques like conventional arc melting.

Can EIMIG be used for large-scale production?

Yes, EIMIG can be scaled up for industrial production, making it suitable for both small-scale research and large-scale manufacturing.

Who are the leading suppliers of EIMIG metal powders?

Leading suppliers include Advanced Powders Inc., Specialty Metals Co., Medical Materials LLC, and BioMetals Corp., among others, offering a variety of metal powders for different applications.

Conclusão

Electrode Induction Melting Inert Gas (EIMIG) is a transformative technology in the field of metallurgy, offering unparalleled purity and precision in metal powder production. Its applications span across critical industries, ensuring high performance and reliability in demanding environments. Whether you’re looking into aerospace components, biomedical devices, or high-performance tooling, EIMIG provides the advanced materials needed to push the boundaries of innovation.