Steel Powder in Manufacturing: Applications and Sourcing Guide

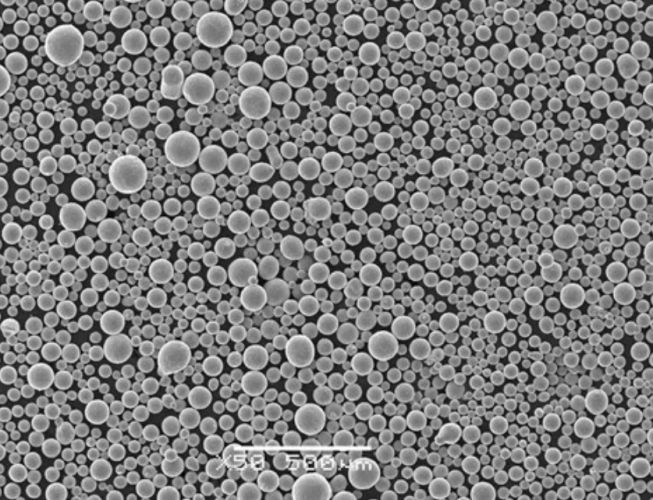

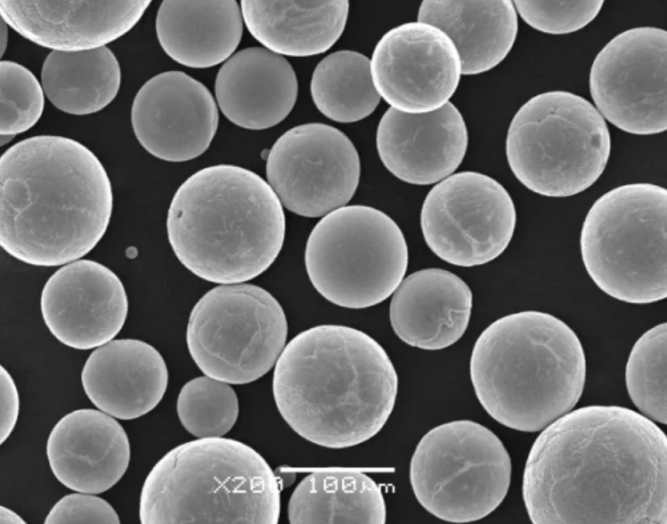

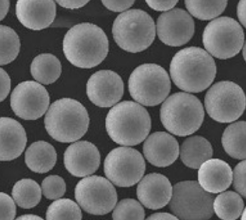

1. Introduction to Steel Powder in Modern Manufacturing Steel powder is a cornerstone material in powder metallurgy (PM) and additive manufacturing (AM), playing a vital role in producing high-performance components across industries such as automotive, aerospace, medical, and industrial tooling. As global manufacturing pivots toward lightweight, precision-engineered parts, steel powder offers unmatched versatility and performance. […]

Steel Powder in Manufacturing: Applications and Sourcing Guide Read More »