1. What is 15-5PH Powder and Why It Matters in Manufacturing

15-5PH stainless steel is a precipitation hardening martensitic alloy that offers excellent mechanical properties and corrosion resistance. The “15-5” denotes 15% chromium and 5% nickel, with added copper to enable age hardening. In powder form, 15-5PH is highly valued in additive manufacturing (AM), metal injection molding (MIM), and powder metallurgy (PM) due to its ease of processing and predictable properties.

Why 15-5PH Powder is Critical in B2B Manufacturing:

| Özellik | Fayda |

|---|---|

| Yüksek mukavemetli | Yapısal bileşenler için ideal |

| İyi korozyon direnci | Performs well in marine and chemical environments |

| Mükemmel mekanik özellikler | Suitable for aerospace, automotive, and defense |

| Tutarlı mikroyapı | Ensures reliability in 3D printed and PM parts |

| Machinability & weldability | Cost-efficient for high-volume production |

15-5PH powder is essential for OEMs, aerospace component manufacturers, and defense contractors looking to streamline production with advanced materials.

2. Industrial Applications of 15-5PH Stainless Steel Powder

B2B buyers and wholesale distributors are increasingly interested in 15-5PH powder due to its broad industrial use. This material is often used in sectors that demand performance under extreme conditions.

Major Industries Using 15-5PH Powder

- Havacılık ve Savunma

- Turbine blades

- Yapısal çerçeveler

- Fuselage components

- Otomotiv

- Yüksek performanslı motor parçaları

- Egzoz sistemleri

- Gear components

- Medical & Dental

- Cerrahi aletler

- Ortopedik implantlar

- Dental brackets

- Petrol & Gaz

- Valve components

- Pump parts

- Matkap uçları

- Endüstriyel Aletler

- Injection molds

- Die-casting dies

- High-pressure fittings

Application Methods

| Teknoloji | Uygulama |

|---|---|

| Katmanlı Üretim (AM) | Complex 3D printed parts with internal channels |

| Metal Enjeksiyon Kalıplama (MIM) | Small, intricate designs in mass quantities |

| Toz Metalurjisi (PM) | Structural components with predictable density |

3. Properties and Variants of 15-5PH Powder

When selecting 15-5PH powder for industrial applications, it’s critical to understand its mechanical, thermal, and chemical properties. Buyers must also evaluate powder morphology, particle size distribution, and atomization method.

Core Properties of 15-5PH Powder

| Mülkiyet | Değer |

|---|---|

| Kompozisyon | Fe-Cr-Ni-Cu |

| Sertlik | Up to 40 HRC after aging |

| Yoğunluk | ~7.7 g/cm³ |

| Çekme Dayanımı | 1380 MPa |

| Akma Dayanımı | 1170 MPa |

| Uzama | ~10–15% |

| Korozyon Direnci | Comparable to 304 stainless steel |

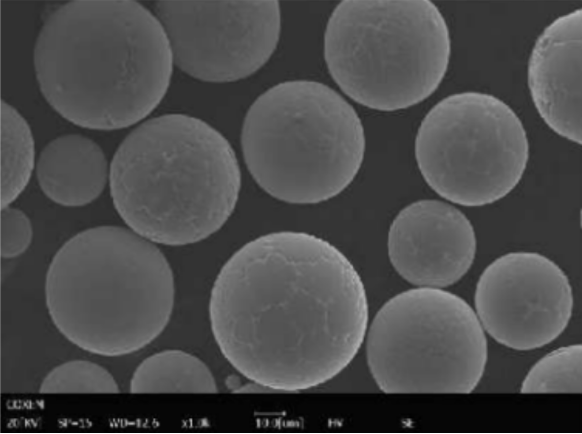

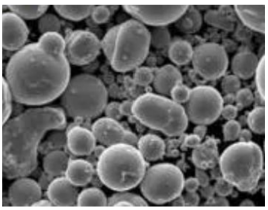

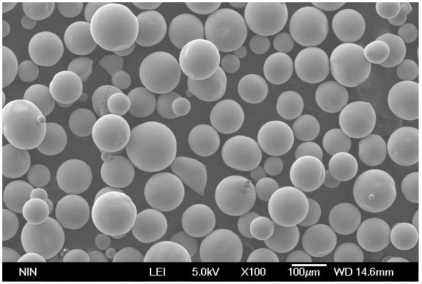

Powder Morphology Types

- Küresel Toz (Gas Atomized): Ideal for additive manufacturing due to flowability.

- Irregular Powder (Water Atomized): Cost-effective for MIM and PM.

Boyut Aralığı (µm)

| Uygulama | Parçacık Boyutu |

|---|---|

| AM (SLM, EBAM) | 15–45 µm |

| MIM | 5–25 µm |

| BAŞBAKAN | 45-150 µm |

Shanghai Truer Technology Co., Ltd. offers both gas and water atomized 15-5PH powders tailored for industrial applications. Their powders meet strict quality standards and are available in various size distributions and morphologies, making them ideal for sourcing wholesale 15-5PH powder.

Be sure to check out their ürün sayfası ayrıntılı özellikler için.

4. Global Market Trends and Growth Potential of 15-5PH Powder

The global powder metallurgy market is witnessing accelerated growth, with 15-5PH powder playing a key role due to its high strength, corrosion resistance, and compatibility with additive manufacturing. As industries shift towards lightweight, high-performance materials, 15-5PH is becoming a strategic material for aerospace, medical, and high-precision manufacturing.

Market Growth Drivers

- Rise in Additive Manufacturing

The demand for metal powders like 15-5PH has surged with the growth of 3D baskı in aerospace and medical sectors. - Increased Adoption in Defense and Aerospace

Governments across the globe are investing in defense modernization, boosting demand for advanced stainless steel powders. - Shift Toward Sustainable Manufacturing

Powder metallurgy and AM with 15-5PH reduce material waste and energy consumption.

Global Market Size Forecast

| Yıl | Global PM Market Value | 15-5PH Powder Segment Share |

|---|---|---|

| 2021 | $23.5 Billion | 3.8% |

| 2023 | $27.1 Billion | 4.6% |

| 2026 (Projected) | $34.8 Billion | 6.1% |

According to market insights, Asia-Pacific is emerging as the fastest-growing region for stainless steel powder production, thanks to competitive pricing, advanced facilities, and growing local demand.

5. Key Criteria for Choosing a 15-5PH Powder Supplier

For B2B buyers, choosing the right 15-5PH powder supplier impacts not only product performance but also supply chain efficiency, regulatory compliance, and cost management.

Key Factors to Evaluate:

| Kriterler | B2B Alıcıları için Önemi |

|---|---|

| Toz Kıvamı | Uniform particle size and morphology ensure process stability |

| Certification & Quality Control | ISO 9001, material traceability, and batch testing |

| Üretim Yöntemi | Gas atomized for AM; water atomized for MIM/PM |

| Özelleştirme | Ability to tailor particle size distribution or blend with additives |

| Pricing & MOQ | Competitive wholesale pricing and flexible minimum order quantities |

| Teslim Süresi & Lojistik | Reliable delivery schedules and international shipping capabilities |

Choosing a reputable supplier like Shanghai Truer Technology Co, Ltd. ensures that your business receives high-quality, consistent powders with technical support and reliable logistics.

6. Top 5 15-5PH Powder Suppliers in Asia

Asia has become a global hub for high-performance metal powders, and these five companies lead the charge in 15-5PH production for B2B applications:

| Tedarikçi | Ülke | Temel Güçlü Yönler | Uygulama Odağı |

|---|---|---|---|

| Shanghai Truer Technology Co, Ltd. | Çin | Wide range of PM and AM powders, custom sizing, advanced atomization | Havacılık, otomotiv, endüstriyel |

| Sandvik Katmanlı Üretim | India/Sweden | High-purity gas atomized powders | Medical, aerospace |

| CNPC Toz Grubu | Çin | Large-scale production, export-ready | Industrial, energy |

| Pometon S.p.A | Taiwan/Italy | Specialty steels and copper-based PM powders | Genel mühendislik |

| Marangoz Katkısı | Singapur | Aerospace-grade stainless steel powders | Havacılık ve uzay, medikal |

Bunlar arasında, Şangay Truer Teknoloji stands out for its blend of affordability, technical expertise, and product range. Their additive manufacturing division has gained a strong reputation for quality and innovation in China and abroad.

7. Why Manufacturers are Shifting to Chinese 15-5PH Powder Sources

China’s rapid development in powder metallurgy manufacturing has made it a leading exporter of metal powders. More B2B buyers are choosing Chinese suppliers for 15-5PH powder due to:

Strategic Advantages:

- Maliyet Verimliliği: Chinese suppliers offer competitive wholesale pricing without sacrificing quality.

- Advanced Atomization Equipment: Use of gas and water atomization processes to cater to various industries.

- Ölçeklenebilir Üretim: Facilities capable of producing large volumes with consistent quality.

- Elverişli Ticaret Politikaları: Export incentives and streamlined logistics support bulk international orders.

Örnek Vaka: Shanghai Truer Technology

Shanghai Truer has invested significantly in additive manufacturing capabilities since 2019. With their proprietary powder production lines and tight quality control, they deliver both small-batch and large-volume orders with reliability. Their diverse offerings include water-atomized, gas-atomized, and hybrid powders suitable for AM, MIM, and traditional PM processes.

Their website offers a detailed overview of their capabilities and company background, which assures B2B clients of their technical capacity and commitment to quality.

8. Why Choose Shanghai Truer Technology as Your 15-5PH Powder Supplier

Shanghai Truer Technology Co., Ltd. has emerged as a trusted name in the powder metallurgy industry for several reasons:

Temel Güçlü Yönler:

- ✅ Yerleşik Uzmanlık: Founded in 2009, with a dedicated additive manufacturing division launched in 2019.

- ✅ Kapsamlı Ürün Hattı: Offers a broad range of PM powders including 15-5PH, 420 stainless steel, 17-4PH, and custom blends.

- ✅ Multiple Atomization Methods: Ability to produce powders using gas atomization, water atomization, or hybrid techniques.

- ✅ Industry Certifications: Strict quality control aligned with ISO standards; full batch traceability.

- ✅ Teknik Destek: Application-specific consultation for AM, PM, and MIM customers.

Sample Product Offerings

| Ürün | Atomizasyon Tipi | Kullanım Örneği |

|---|---|---|

| 15-5PH Powder (15–45µm) | Gaz Atomize | Additive Manufacturing (SLM, L-PBF) |

| 15-5PH Powder (45–150µm) | Atomize Su | Powder Metallurgy & Press/Sinter |

| Özel Karışımlar | Hibrit | Tooling, MIM, Sintered Parts |

You can explore their detailed product catalog on the PM tozu ürün sayfası, which helps buyers find the exact powder specification needed for their applications.

Additionally, Truer offers complete additive solutions, from powder supply to lubricants, soft magnetic additives, and graphite. Learn more about their full product ecosystem by visiting their anasayfa.

9. How to Order Wholesale 15-5PH Powder from Shanghai Truer

Ordering 15-5PH stainless steel powder in bulk for your business needs is a straightforward process when working with a professional supplier like Shanghai Truer Technology Co., Ltd. Their streamlined B2B order system ensures efficiency, prompt delivery, and technical support.

Step-by-Step Wholesale Ordering Process:

1. Request a Quote

- Ziyaret edin Bize Ulaşın sayfası.

- Provide information about:

- Required powder type (e.g., gas atomized 15-5PH)

- Parçacık boyutu aralığı

- Quantity (MOQ available for trial orders)

- Intended application (AM, MIM, PM)

2. Teknik Danışmanlık Alın

- Truer’s technical team will evaluate your application needs.

- You’ll receive:

- Material datasheets

- Sample analysis (PSD, morphology, chemical composition)

- Packaging and shipping details

3. Confirm Specifications & Place Order

- Finalize:

- Toz derecesi

- Atomization method (gas / water / hybrid)

- Packaging type (vacuum-sealed drums, moisture-proof bags)

4. Üretim & Kalite Güvence

- Every batch undergoes:

- Particle size analysis (laser diffraction)

- SEM imaging for morphology

- Chemical composition verification (ICP, OES)

- Flowability and apparent density testing

5. Logistics & Delivery

- International shipping via air or sea.

- Truer handles export documentation, customs clearance, and tracking.

6. Satış Sonrası Destek

- Technical follow-up for:

- Printing parameters

- Sintering profiles

- Sorun Giderme

Available Packaging Options:

| Ambalaj Türü | Hacim | Recommended For |

|---|---|---|

| Aluminum Pouch | 5 kg | Sampling/testing |

| Vacuum Drum | 25 kg | Small batch production |

| Orta ila büyük ölçekli üretim | 50–100 kg | Bulk industrial use |

Shanghai Truer offers quick turnaround and flexible MOQs, making it ideal for both startups and large-scale manufacturers. Their responsive sales and support team ensures your procurement is smooth from inquiry to delivery.

10. FAQs: Buying Wholesale 15-5PH Stainless Steel Powder

Q1: What is the minimum order quantity (MOQ) for wholesale 15-5PH powder?

A: Shanghai Truer offers flexible MOQs, starting from 5 kg for sampling. Bulk discounts apply for orders over 100 kg.

Q2: What particle size should I choose for 3D printing?

A: For laser powder bed fusion (LPBF), a gas-atomized 15-5PH powder with a size range of 15–45µm is ideal due to excellent flowability and packing density.

Q3: What is the shelf life of 15-5PH powder?

A: Properly stored in vacuum-sealed packaging, 15-5PH powder has a shelf life of 12–24 months. Avoid humidity and direct sunlight.

Q4: Can I get customized particle size distribution?

A: Yes, Shanghai Truer provides custom sieving and blending services to meet specific particle size distribution (PSD) requirements.

Q5: Does Shanghai Truer offer technical support for additive manufacturing?

A: Absolutely. Truer’s AM division provides technical consultation, including print parameter optimization and post-processing recommendations. Visit their AM division page for more info.

Q6: What testing certifications are provided with each batch?

A: Each batch includes a Certificate of Analysis (CoA) with:

- Kimyasal bileşim

- Parçacık boyutu dağılımı

- Morphology (SEM report)

- Flowability and density

Additional testing like oxygen/nitrogen content or magnetic permeability can be arranged upon request.

Q7: Is 15-5PH powder suitable for sintered structural parts?

A: Yes. Water-atomized 15-5PH powder is ideal for press and sinter applications in structural components, offering high strength and corrosion resistance.

Q8: How do I know the powder is compatible with my equipment?

A: Provide Truer with equipment details (e.g., EOS M290, Renishaw AM400, or MIM press tonnage), and they will recommend the right powder specification.

Q9: Are there discounts for long-term supply agreements?

A: Yes, Shanghai Truer offers contract manufacturing and long-term pricing models for enterprise clients and OEMs.

Q10: Can I request a sample before placing a bulk order?

A: Definitely. Sample orders (5–20 kg) are available for testing, with fast global shipping. Contact Truer’s sales team to request a sample.

Internal Anchor Text Summary (5 Embedded Links)

Here are the internal anchor text links used in this blog post:

- Wholesale 15-5PH powder

- Product page

- Capabilities and company background

- Anasayfa

- Sales and support team

This comprehensive guide is designed to help B2B buyers, sourcing managers, and industrial engineers make informed purchasing decisions about 15-5PH stainless steel powders. With Shanghai Truer Technology as your trusted partner, you gain access to high-quality materials, technical expertise, and reliable global logistics.

👉 Ready to place a wholesale order or need a technical consultation? Contact Shanghai Truer Technology to get started today.