Tungsten Genel endüstriyel uygulamalar ve araştırma amaçları. 2. FeCoNiCrMo-1 HTPAşırı ısı koşullarında kullanım için optimize edilmiş yüksek sıcaklık performansı varyantı.

Havacılık ve enerji endüstrileri.

Geliştirilmiş molibden içeriği sayesinde aşınma ve korozyona karşı ekstra dirençli.

Denizcilik ve açık deniz uygulamaları.

Mukavemetten ödün vermeden esneklik ve sünekliğe odaklanmıştır.

Tıbbi implantlar ve protezler.

5. FeCoNiCrMo-1 Nano

Frequently Asked Questions (FAQ)

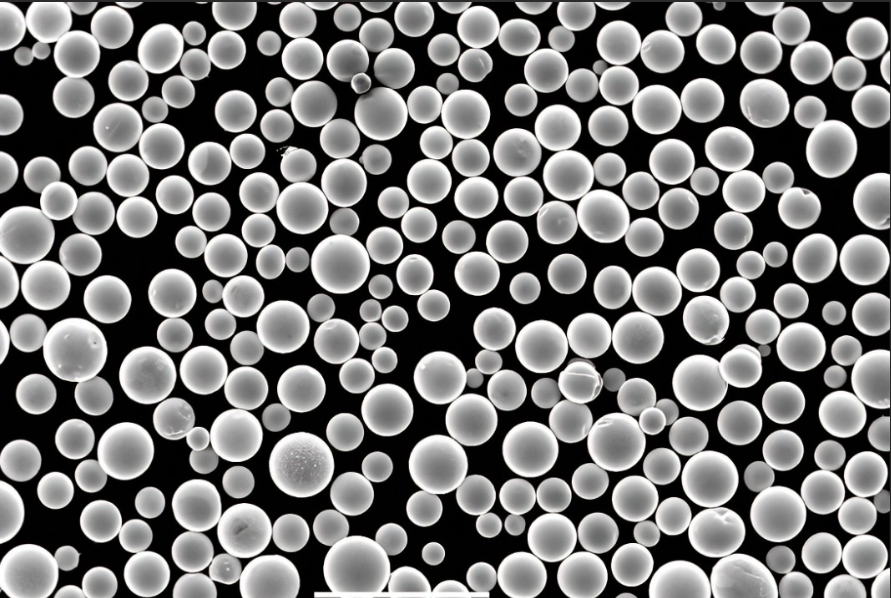

1) Why choose spherical tungsten powder over irregular tungsten powder?

- Spherical tungsten powder offers superior flowability, higher apparent/tap density, and more uniform packing—key for LPBF, DED, MIM, and thermal spraying. It improves layer quality, reduces lack‑of‑fusion defects, and enables tighter dimensional control.

2) What particle-size distribution (PSD) works best for AM with tungsten?

- LPBF commonly uses 15–45 μm (or 20–53 μm) cuts; DED prefers 45–90 μm or 75–150 μm. Narrow PSDs improve flow and packing; ultra-fines increase oxygen pickup and spatter.

3) How does RF plasma spheroidization compare to other routes?

- RF plasma yields highly spherical, dense tungsten powder with low contamination and controllable PSD, but at higher energy/gas cost. Alternatives (halogenation, re‑oxidation/reduction, microwave) have lower yields or poorer consistency for AM-grade needs.

4) How critical is oxygen content in tungsten powder?

- Very. Elevated oxygen increases brittleness and can cause porosity and cracking in sintering/AM. For AM-grade tungsten powder, aim for O < 0.05–0.10 wt% depending on application; verify via ASTM E1019.

5) Can spherical tungsten powder be reused in LPBF?

- Yes, with inert handling, sieving, and cycle-by-cycle QA (PSD, flow, O/N/H, density). Many workflows allow 4–8 reuse cycles before blending with virgin powder; establish limits based on oxygen drift and PSD changes.

2025 Industry Trends: Spherical Tungsten Powder

- Cost and energy optimization: Argon/nitrogen recovery systems and torch efficiency mapping cut RF plasma gas/energy use by 20–35% vs 2023 benchmarks.

- Quality stabilization: Inline optical/AI detection of satellites/hollows improves lot consistency; more suppliers publish digital material passports tied to ISO/ASTM 52907.

- Application growth: Higher demand for radiation shielding lattices, high‑heat flux components, and directed energy system parts drives AM-grade tungsten powder adoption.

- Hybrid processing: Water‑atomized W pre-cursor upgraded via RF plasma spheroidization balances cost with AM flow performance.

- Safer operations: Wider adoption of ATEX/DSEAR-compliant powder stations and closed-loop inert handling for dense, high‑Z powders.

2025 KPI Snapshot for Tungsten Powder Routes (indicative AM-grade ranges)

| Metrik | RF Plasma Spheroidized W | Gas Atomized W (where applicable) | Re-oxidation/Reduction + Spheroidize | Microwave Spheroidization |

|---|---|---|---|---|

| Sphericity (aspect ratio) | 0.95–0.98 | 0.90–0.94 | 0.92–0.96 | 0.88–0.93 |

| Oxygen (wt%) | 0.03–0.08 | 0.05–0.12 | 0.05–0.10 | 0.08–0.15 |

| Hall flow (s/50 g) | 15–19 | 18–24 | 17–22 | 20–28 |

| Fine fraction yield (<53 μm) | Orta düzeyde | Orta düzeyde | Low–Moderate | Düşük |

| Relative cost | Yüksek | Medium–High | Orta | Orta |

| AM suitability (LPBF/DED) | Mükemmel | Good (limited suppliers) | Good after tight QA | Variable/lot‑dependent |

References: ISO/ASTM 52907:2023; ASTM B212/B213/B703; ASTM E1019; NIST AM‑Bench datasets; HSE ATEX/DSEAR guidance

Latest Research Cases

Case Study 1: RF Plasma Spheroidization of WA Tungsten for LPBF Heat-Flux Panels (2025)

Background: An aerospace thermal systems supplier needed LPBF-grade tungsten with improved flow and low oxygen for thin-wall, high‑density panels.

Solution: Upgraded water‑atomized W via RF plasma; optimized torch power and carrier gas; tight classification to 20–45 μm; closed-loop inert handling; ISO/ASTM 52907 QA.

Results: Sphericity 0.97; O reduced from 0.11→0.06 wt%; Hall flow 16.8 s/50 g; LPBF density ≥99.5%; leak-tight thin walls achieved with 18% fewer recoater defects; first‑pass yield +15%.

Case Study 2: DED of Spherical W for Radiation Shielding with Binder‑Jet Hybrid Cores (2024)

Background: A med‑tech OEM sought complex tungsten shielding geometries with dense outer skins.

Solution: Produced spherical W (45–90 μm) by RF plasma; printed binder‑jet cores, then DED over‑clad for dense outer layers; stress relief and HIP performed.

Results: Final density 99.6% (outer layer); dimensional shrink variation −30% vs BJ-only; shielding performance +12% vs spec; cycle time −22% relative to full DED builds.

Expert Opinions

- Prof. Rajiv Asthana, Professor of Materials Science, University of Wisconsin–Stout

Viewpoint: “For tungsten powder in AM, oxygen and satellite control are decisive—flow and densification hinge on both, not just PSD.” Source: Academic publications and conference proceedings. - Dr. John Slotwinski, Materials Research Engineer, NIST

Viewpoint: “Digital material passports tied to ISO/ASTM 52907 characterization are improving cross‑site reproducibility for high‑Z powders like tungsten.” Source: NIST AM workshops https://www.nist.gov/ - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Viewpoint: “2025 round‑robin efforts are connecting powder metrics to LPBF defect maps in refractory systems, accelerating qualification of spherical tungsten powder.” Source: ASTM AM CoE https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Powder characterization for AM

https://www.iso.org/standard/78974.html - ASTM B212/B213/B703 (density/flow) and ASTM E1019 (O/N/H)

https://www.astm.org/ - NIST AM‑Bench: Public datasets for validating AM processes

https://www.nist.gov/ambench - HSE ATEX/DSEAR: Safe handling of reactive/dense metal powders

https://www.hse.gov.uk/fireandexplosion/atex.htm - Senvol Database: Compare machines/materials, including tungsten powders

https://senvol.com/database - Open-source/engineering tools: Thermo‑Calc (phase predictions), pySLM (scan strategy), AdditiveFOAM (thermal/porosity modeling), ImageJ (morphology analysis)

Last updated: 2025-08-27

Changelog: Added targeted FAQs, 2025 KPI table for tungsten powder routes, two recent case studies, expert viewpoints, and a curated tools/resources list with standards links.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major energy/cost breakthroughs in RF plasma lines, or new LPBF parameter sets for tungsten are released by OEMs.