Genel Bakış FeCoNiCrMo-1 Toz

FeCoNiCrMo-1 tozu, olağanüstü mekanik özellikleri, korozyon direnci ve yapısal kararlılığı nedeniyle gelişmiş imalat ve malzeme biliminde ivme kazanan bir yüksek entropili alaşımdır (HEA). FeCoNiCrMo-1 gibi HEA'lar, bileşen elementlerinin neredeyse eşmolar oranlarıyla karakterize edilir ve onlara geleneksel alaşımlara kıyasla benzersiz özellikler kazandırır.

Bu toz neden önemli? Onu, tokluk, esneklik ve direncin bir kombinasyonunu sunan metal tozlarının süper kahramanı olarak düşünün. İster gelişmiş imalatı araştırıyor olun, ister aşırı koşullarda yapısal performansı iyileştirmek istiyor olun, FeCoNiCrMo-1 tozu sizin için doğru çözüm olabilir.

FeCoNiCrMo-1 Tozunun Bileşimi

FeCoNiCrMo-1 tozunun bileşimi, onu geleneksel metal alaşımlarından ayırır. Beş temel element - demir (Fe), kobalt (Co), nikel (Ni), krom (Cr) ve molibden (Mo) - yaklaşık eşit oranlarda karıştırılarak üstün performans sağlanır.

| Element | Bileşim (Yaklaşık %) | Alaşım'daki Rolü |

|---|---|---|

| Demir (Fe) | ~20% | Alaşım matrisini güçlendirir. |

| Kobalt (Co) | ~20% | Aşınma direncini artırır. |

| Nikel (Ni) | ~20% | Sünekliği ve tokluğu iyileştirir. |

| Krom (Cr) | ~20% | Korozyon direncini artırır. |

| Molibden (Mo) | ~20% | Mükemmel sertlik ve sürünme direnci sağlar. |

FeCoNiCrMo-1 Tozunun Özellikleri

FeCoNiCrMo-1 tozu, onu çeşitli uygulamalar için çok yönlü bir seçim haline getiren bir dizi özelliğe sahiptir:

- Olağanüstü Mukavemet ve Dayanıklılık: Çok elementli tasarımıyla toz, havacılık ve savunma uygulamaları için uygun, dikkate değer bir mukavemet-ağırlık oranına sahiptir.

- Korozyon Direnci: Krom ve molibden, yüksek derecede aşındırıcı ortamlara karşı direnç sağlar.

- Termal Kararlılık: Bileşimi, hem yüksek hem de düşük sıcaklıklarda kararlılık sağlar.

- Aşınma Direnci: Kobalt, zaman içinde mekanik aşınmaya karşı dayanma yeteneğini güçlendirir.

- Özelleştirilebilir Mikro yapı: 3D baskı ve diğer eklemeli imalat teknikleri için uygundur.

Uygulamaları FeCoNiCrMo-1 Toz

Etkileyici özellikleri sayesinde, FeCoNiCrMo-1 tozu çok sayıda endüstride kullanılmaktadır. İşte hızlı bir bakış:

| Endüstri | Uygulamalar |

|---|---|

| Havacılık ve Uzay | Türbin kanatları, yapısal bileşenler, ısı kalkanları |

| Otomotiv | Yüksek performanslı motor parçaları, aşınmaya dayanıklı dişliler |

| Tıbbi | Protezler, diş implantları, cerrahi aletler |

| Savunma | Zırh plakaları, füze bileşenleri |

| Enerji | Nükleer reaktör bileşenleri, açık deniz sondaj kuleleri |

| Katmanlı Üretim | Yüksek hassasiyet gerektiren 3D baskılı parçalar |

FeCoNiCrMo Bazlı Tozların Belirli Modelleri

İşte benzersiz özelliklere sahip bazı kayda değer FeCoNiCrMo bazlı toz modelleri:

1. FeCoNiCrMo-1 Standart

- Açıklama: Mukavemet, korozyon direnci ve termal kararlılığın dengesini sunan temel toz.

- En İyisi İçin: Genel endüstriyel uygulamalar ve araştırma amaçları.

2. FeCoNiCrMo-1 HTP

- Açıklama: Aşırı ısı koşullarında kullanım için optimize edilmiş yüksek sıcaklık performansı varyantı.

- En İyisi İçin: Havacılık ve enerji endüstrileri.

3. FeCoNiCrMo-1 XR

- Açıklama: Geliştirilmiş molibden içeriği sayesinde aşınma ve korozyona karşı ekstra dayanıklı.

- En İyisi İçin: Denizcilik ve açık deniz uygulamaları.

4. FeCoNiCrMo-1 Flex

- Açıklama: Mukavemetten ödün vermeden esneklik ve sünekliğe odaklanmıştır.

- En İyisi İçin: Tıbbi implantlar ve protezler.

5. FeCoNiCrMo-1 Nano

- Açıklama: Gelişmiş 3D baskı hassasiyeti için nano ölçekli toz parçacıkları.

- En İyisi İçin: Elektronik ve havacılıkta eklemeli imalat.

6. FeCoNiCrMo-1 AM

- Açıklama: Üstün yazdırılabilirlik sunan, özellikle eklemeli imalat için tasarlanmıştır.

- En İyisi İçin: Hızlı prototipleme.

7. FeCoNiCrMo-1 Ultra

- Açıklama: Ultra yüksek korozyon direnci özelliklerine sahiptir.

- En İyisi İçin: Kimyasal işleme ekipmanları.

8. FeCoNiCrMo-1 HP

- Açıklama: Geliştirilmiş aşınma direnci için artırılmış kobalt içeriğine sahip yüksek performanslı varyant.

- En İyisi İçin: Yüksek gerilimli mekanik bileşenler.

9. FeCoNiCrMo-1 Lite

- Açıklama: Azaltılmış yoğunluğa sahip hafif bir versiyon.

- En İyisi İçin: Havacılık ve otomotiv ağırlığına duyarlı bileşenler.

10. FeCoNiCrMo-1 Bio

- Açıklama: Tıbbi kullanım için tasarlanmış biyouyumlu toz.

- En İyisi İçin: Cerrahi implantlar ve diş uygulamaları.

Özellikleri FeCoNiCrMo-1 Toz

| Şartname | Detaylar |

|---|---|

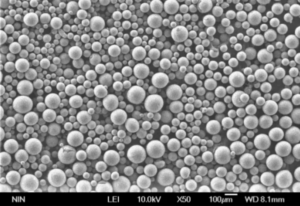

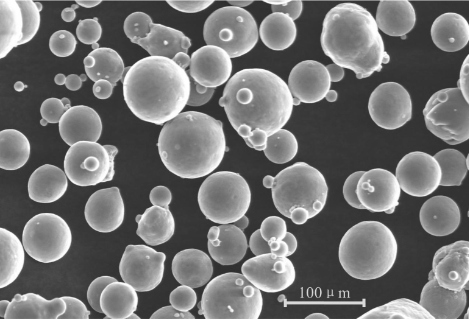

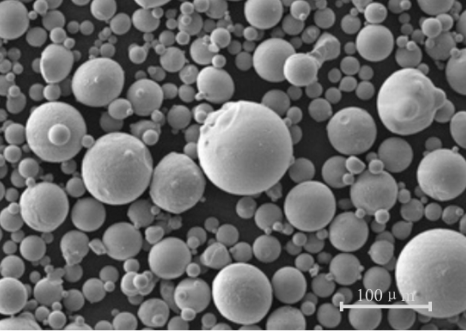

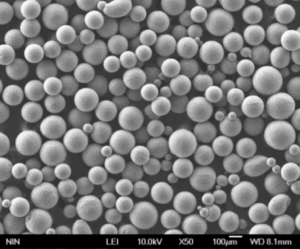

| Parçacık Boyutu | 10-45 μm (özelleştirilebilir) |

| Yoğunluk | ~7,8 g/cm³ |

| Erime Noktası | ~1300-1400°C |

| Sertlik | 300-400 HV |

| Standartlar | ASTM B212, ISO 9001 |

| Paketleme Seçenekleri | 1 kg, 5 kg, 10 kg |

Tedarikçiler ve Fiyatlandırma Bilgileri

| Tedarikçi | Bölge | Fiyat (USD/kg) | Notlar |

|---|---|---|---|

| Advanced Alloys Inc. | Kuzey Amerika | $150-$180 | Toplu indirimler sunar. |

| MetalWorks Co. | Avrupa | $140-$170 | Özel bileşimler mevcuttur. |

| Asia Alloys Pvt Ltd. | Asya-Pasifik | $120-$160 | Rekabetçi fiyatlandırma. |

| Global Metal Traders | Dünya çapında | $130-$175 | Dünya çapında hızlı sevkiyat. |

Avantajları ve Dezavantajları FeCoNiCrMo-1 Toz

| Avantajlar | Dezavantajlar |

|---|---|

| Olağanüstü korozyon ve aşınma direnci. | Geleneksel alaşımlara kıyasla daha yüksek başlangıç maliyeti. |

| Aşırı sıcaklıklarda mükemmel performans. | Bazı bölgelerde sınırlı bulunabilirlik. |

| Çoklu uygulamalar için çok yönlü. | İşleme için özel ekipman gerektirir. |

| Yüksek kararlılık ve dayanıklılık. | Çok elementli yapısı nedeniyle karmaşık geri dönüşüm süreci. |

SSS

| Soru | Cevap |

|---|---|

| FeCoNiCrMo-1 tozu ne için kullanılır? | Havacılık, otomotiv, tıp, enerji ve 3D baskı. |

| FeCoNiCrMo-1 çelikten nasıl daha iyidir? | Daha iyi korozyon direnci, aşınma direnci ve sıcaklık kararlılığı sunar. |

| 3D baskısı yapılabilir mi? | Evet, birçok model eklemeli imalat için optimize edilmiştir. |

| Pahalı mı? | Geleneksel alaşımlardan daha pahalıdır ancak üstün özellikler sunar. |

| Önde gelen tedarikçiler kimlerdir? | Advanced Alloys Inc., MetalWorks Co. ve Global Metal Traders. |