316 paslanmaz çelik toz havacılıktan biyomedikale kadar çeşitli sektörlerde kullanılan özel bir malzemedir. Bu kılavuz, bileşimi, özellikleri, uygulamaları, kaliteleri, teknik özellikleri, fiyatlandırması, artıları/eksileri ve daha fazlası dahil olmak üzere 316 paslanmaz çelik tozu hakkında ayrıntılı bir genel bakış sağlar.

316 Paslanmaz Çelik Tozunun Bileşimi

316 paslanmaz çelik tozunun elementel bileşimi şöyledir:

| Element | Ağırlık % |

|---|---|

| Demir (Fe) | Denge |

| Krom (Cr) | 16-18% |

| Nikel (Ni) | 10-14% |

| Molibden (Mo) | 2-3% |

| Manganez (Mn) | <%2 |

| Silisyum (Si) | <1% |

| Fosfor (P) | <0.045% |

| Kükürt (S) | <%0.03 |

| Karbon (C) | <%0.08 |

| Azot (N) | <%0.1 |

Yüksek krom ve nikel içeriği 316 paslanmaza korozyon direnci kazandırır. Molibden bu özelliği daha da geliştirir. Toz bileşimi, %0,08'den daha az karbon içeren 316/316L sınıfı için ASTM spesifikasyonlarına uygundur.

Özelliklere ve Karakteristiklere Genel Bakış

316 paslanmaz çelik tozu, olağanüstü bir özellik kombinasyonu sunar:

| Mülkiyet | Önem |

|---|---|

| Mükemmel korozyon direnci | Çeşitli kimyasal maruziyetlere karşı dayanıklılık |

| Olağanüstü güç | Yüksek mukavemetli parçalar halinde sinterlenebilir |

| Biyo-uyumluluk | Tıbbi cihazlarda/implantlarda kullanım için güvenli |

| Isı direnci | Yüksek sıcaklıklarda gücünü ve kararlılığını korur |

| Kaynaklanabilirlik | Bu tozdan yapılan bileşenleri kaynaştırmak kolaydır |

| İşlenebilirlik | Sinterlenmiş / + mumlanmış parçalar işlenebilir, delinebilir, diş açılabilir vb |

| Manyetizma | Nikel içeriği nedeniyle hafif manyetik |

Bu özellikler, çok çeşitli uygulama ve sektörlerde kullanıma olanak sağlar.

Arızaları önlemek için ~0,3-0,5 mm'lik minimum duvar kalınlığı 316 Paslanmaz Çelik Tozu

316 paslanmaz çelik tozunun bazı tipik uygulamaları şunlardır:

| Endüstri | Uygulamalar |

|---|---|

| Havacılık ve Uzay | Motor bileşenleri, bağlantı parçaları, bağlantı elemanları |

| Otomotiv | Vanalar, toz metal parçalar |

| Kimyasal işleme | Pompalar, vanalar, tanklar, borular |

| Petrol ve gaz | Kuyu başları, manifoldlar, kuyu içi aletler |

| Biyomedikal | İmplantlar, cerrahi aletler, cihazlar |

| 3D baskı | Havacılık ve otomotiv prototipleri |

Korozyon direnci, mukavemeti ve üretimdeki çok yönlülüğü 316 paslanmazın zorlu mekanik ve yapısal uygulamalar için kullanışlı olmasını sağlar. Biyouyumluluk özelliği tıbbi kullanımlara da olanak sağlar.

316 Paslanmaz Çelik Tozunun Kaliteleri ve Özellikleri

316 paslanmaz çelik tozu standart kalitelerde mevcuttur:

| Sınıf | ASTM Spesifikasyonu | Notlar |

|---|---|---|

| 316 | ASTM A240, A276, A479 | Standart molibden taşıyan kalite |

| 316L | ASTM A240, A276, A479 | Düşük karbonlu varyant, daha iyi kaynak |

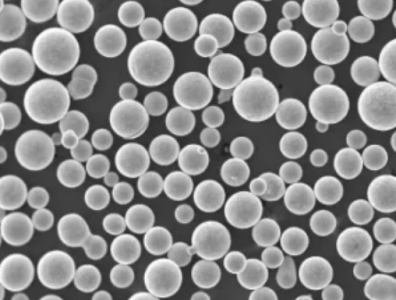

Popüler boyut dağılımları:

| Mesh Aralığı | Mikron Aralığı |

|---|---|

| -140+325 ağ | 44-104 mikron |

| -325 ağ | <44 mikron |

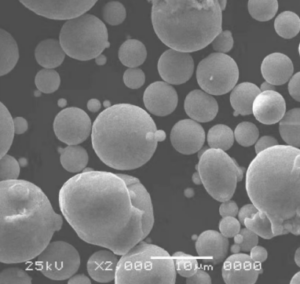

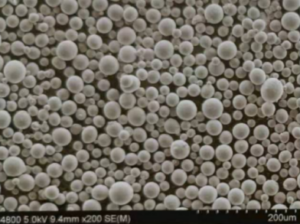

Hem gaz atomize hem de su atomize tozlar yaygındır. Özel parçacık boyutu dağılımları mevcuttur.

316 Paslanmaz Çelik Tozu için Fiyatlandırma

| Distribütör | Kg Başına Fiyat |

|---|---|

| Atlantic Equipment Engineers | $25 – $60 |

| Sandvik Osprey | $45 – $150 |

| Marangoz Toz Ürünleri | $40 – $100 |

| Höganäs | $30 – $80 |

| Kymera Uluslararası | $35 – $90 |

Fiyatlar sipariş edilen miktara, boyut dağılımına, üretim yöntemine (gaz ve su atomizasyonu), tedarikçi koşullarına ve konuma göre değişir.

Artıları ve Eksileri 316 Paslanmaz Çelik Tozu

| Artıları | Eksiler |

|---|---|

| Mükemmel korozyon direnci | Karbon çeliği tozuna göre pahalı |

| Yüksek mukavemet/ağırlık oranı | Sinterleme sırasında yüzey oksidasyonu oluşabilir |

| Çok ince partiküller elde edilebilir | Sinterleme sırasında iyi havalandırma/atmosfer kontrolü gerekir |

| Özel alaşım kaliteleri mevcuttur | Demir tozuna kıyasla yeşil parçalar halinde sıkıştırılması daha zordur |

| Küresel tedarikçi yelpazesi |

Özelliklerin maliyetlerden daha ağır bastığı kritik uygulamalar için 316 paslanmaz toz performans sunar.

Sıkça Sorulan Sorular

S: Lazer sinterleme AM için en iyi partikül boyutu 316L tozu hangisidir?

A: Genellikle 45 mikrondan (-325 mesh) daha azı tercih edilir, 35 mikronun altındaki D90 idealdir.

S: 316L paslanmaz çelik tozu için tipik kılavuz çekme yoğunluğu nedir?

A: Atomizasyon yöntemine ve partikül boyutu dağılımına bağlı olarak 4,0 ila 4,8 g/cc arasında.

S: Paslanmaz çelik tozu sinterlemeden sonra tekrar kullanılabilir mi?

A: Evet, kontaminasyonu önlemek için uygun şekilde kullanılırsa kullanılmayan büyük boy toz kurtarılabilir ve yeniden kullanım için elenebilir.

S: 316L tozu vakumda veya inert atmosferlerde sinterleme gerektirir mi?

A: Yüzey oksidasyon etkilerini önlemek için sinterleme sırasında vakum veya argon/azot atmosferi önerilir.

Sonuç

316/316L paslanmaz çelik tozu, korozyon direnci, mukavemeti ve üretimdeki çok yönlülüğü ile biyomedikal implantlardan havacılık ve uzay bileşenlerine kadar birçok uygulamada tercih edilen bir malzemedir. Detaylı bileşimini, özelliklerini, teknik özelliklerini ve sinterleme hususlarını anlamak, mühendislerin bu malzemenin avantajlarından yararlanmasını sağlar.