1. Introduction: Why Aluminum Oxide Powder Is Vital for Industrial Buyers

Aluminum oxide powder (Al₂O₃), commonly referred to as alumina, is a crucial industrial material used across a wide range of sectors including metallurgy, ceramics, electronics, and abrasive manufacturing. Its high hardness, thermal stability, and resistance to wear and corrosion make it ideal for use in both traditional and advanced manufacturing environments.

For B2B buyers such as wholesale distributors, industrial manufacturers, and material engineers, aluminum oxide powder is a foundational material that supports core operational processes. Whether it’s for surface finishing or high-performance ceramic production, choosing the right grade and supplier of aluminum oxide can significantly impact product quality and production efficiency.

Key Attributes of Aluminum Oxide Powder for B2B Use:

| Propriedade | Industrial Benefit |

|---|---|

| High hardness (Mohs 9) | Ideal for abrasives and wear-resistant parts |

| High melting point (2072°C) | Adequado para aplicações de alta temperatura |

| Quimicamente inerte | Compatible with a wide range of industrial processes |

| Electrical insulation | Used in electronic components and insulators |

| Abrasion resistance | Extends lifespan of components in heavy machinery |

2. Key Applications in Manufacturing and Engineering

Aluminum oxide powder is used extensively across industries that require materials with high strength, chemical resistance, and thermal stability. Below is a breakdown of its most common B2B applications:

A. Abrasives and Surface Finishing

- Sandblasting media for surface cleaning

- Grinding wheels and cutting discs

- Lapping and polishing compounds

B. Refractory Materials

- Used in the production of kiln linings

- Crucibles and refractory bricks for steel and glass industries

C. Ceramics and Electronics

- Substrates for semiconductors and integrated circuits

- Spark plug insulation and dielectric layers

D. Metal Matrix Composites

- Reinforcement in aluminum-based composites

- Improves wear resistance in automotive parts

E. Paints, Coatings, and Polymers

- Used as a filler to improve hardness and UV resistance

- Enhances thermal and chemical stability of coatings

F. Medical and Dental Applications

- Orthopedic implants and dental prosthetics

- Bone graft substitutes

3. Types of Aluminum Oxide Powders for B2B Buyers

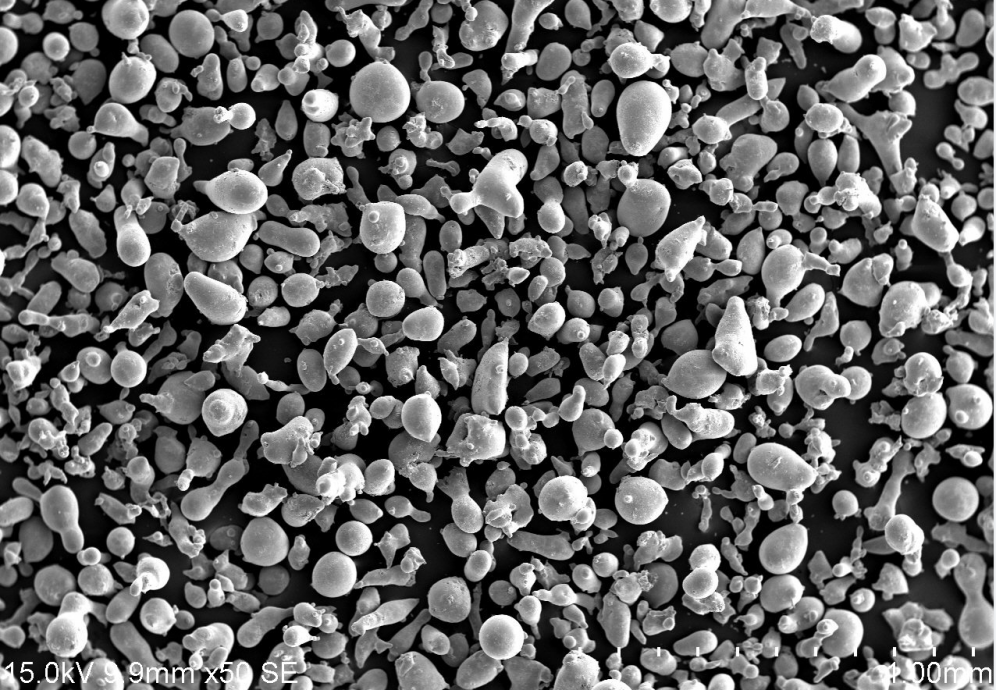

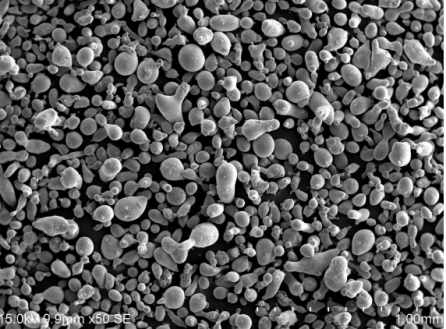

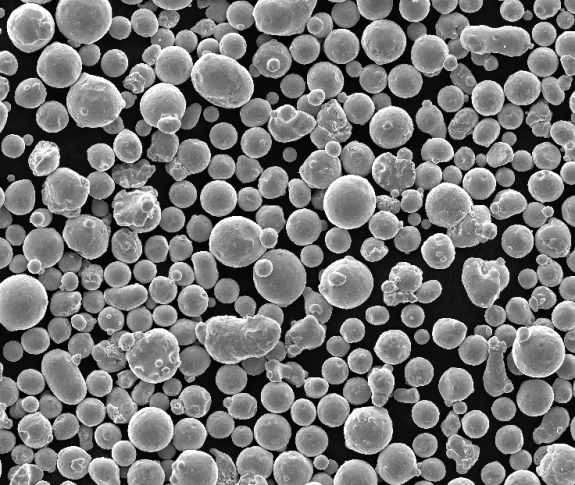

Selecting the right type of aluminum oxide powder is essential for achieving the desired performance in industrial applications. Depending on the method of production and intended use, aluminum oxide powders can vary in particle size, purity, and morphology.

Classification by Purity

| Tipo | Nível de pureza | Casos de Uso Típicos |

|---|---|---|

| Technical Grade | 90-95% | Abrasives, refractories |

| High Purity (99.5% – 99.99%) | Electronics, ceramics, medical components | |

| Ultra-High Purity (99.999%) | Semiconductor & optical applications |

Classification by Crystal Structure

- Alpha (α) Alumina: Most stable form; used in ceramics and abrasives

- Gamma (γ) Alumina: High surface area; ideal for catalysts

- Delta, Theta Alumina: Intermediate phases used in specialized applications

Classification by Particle Size

| Tamanho da malha | Área de aplicação |

|---|---|

| Coarse (>120 mesh) | Sandblasting, lapping media |

| Fine (325 mesh) | Polishing compounds, ceramics |

| Nano (<100 nm) | High-tech coatings, precision polishing |

For buyers looking to procure high-quality aluminum oxide powder for various industrial applications, it’s critical to match the grade and type with the application requirements. Shanghai Truer Technology offers a range of advanced powder metallurgy materials, including custom formulations that meet the needs of additive manufacturing, surface finishing, and ceramics. Visit their catálogo de produtos to explore available options.

4. Market Trends Driving Bulk Demand for Aluminum Oxide

Wholesale buyers and distributors are increasingly investing in aluminum oxide powder due to rising demand across multiple high-growth industries. From renewable energy to electric vehicles and advanced electronics, aluminum oxide plays a crucial role as a raw material with strategic importance.

Global Market Overview

According to industry reports, the global aluminum oxide market is expected to surpass USD 10 billion by 2027, growing at a CAGR of 5.6%. This growth is primarily driven by:

- Increased demand for high-performance ceramics

- Expansion of the semiconductor and electronics industries

- Rising consumption in the abrasives and coatings sector

- Growth of additive manufacturing and powder metallurgy applications

Key Industry Demand Drivers

| Industry Segment | Demand Driver |

|---|---|

| Ceramics & Electronics | Miniaturization of electronic devices |

| Automotivo | Lightweight components and wear-resistant parts |

| Aeroespacial | High-temperature materials for jet engines |

| Energia renovável | Insulation materials in solar and wind turbines |

| Manufatura Aditiva | Precision-engineered powders for impressao 3D |

Regulatory & ESG Trends

- Increased focus on sustainable sourcing and environmentally-friendly production processes

- Preference for ISO-certified suppliers and REACH-compliant materials

- Emphasis on traceable supply chains and ethical sourcing

As these trends continue, B2B buyers will need to align themselves with suppliers who not only offer high-quality aluminum oxide powder but also meet global compliance and sustainability standards.

5. How to Choose a Reliable Aluminum Oxide Powder Supplier

Choosing the right supplier is vital for ensuring consistent quality, reliable delivery, and optimal performance in your manufacturing processes. Here are the key factors B2B buyers should evaluate when selecting an aluminum oxide powder supplier:

A. Product Quality & Specifications

- Purity levels aligned with application needs (e.g., 99.5%+ for electronics)

- Particle size distribution and morphology

- Availability of technical datasheets and certificates of analysis (COA)

B. Capacidades de produção

- In-house manufacturing vs. third-party sourcing

- Control over atomization and crystallization processes

- Customization options for unique industrial needs

C. Compliance & Certifications

- ISO 9001:2015 certified production facilities

- RoHS, REACH, and other international regulatory compliance

- Material safety data sheets (MSDS) availability

D. Logistics & Supply Chain

- Global distribution network with consistent lead times

- Bulk packaging options (bags, drums, IBCs)

- Technical support and after-sales service

E. Customer References & Reputation

- Years in business and industry endorsements

- Reviews from other industrial buyers and distributors

- Case studies of successful B2B collaborations

💡 For example, Shanghai Truer Technology Co., Ltd. is a trusted name in the powder metallurgy industry, boasting over a decade of experience and a strong reputation for delivering high-quality 3D printing and PM powders. Their modern facilities and R&D-driven approach make them a reliable partner for industrial buyers worldwide.

6. Top 5 Global Suppliers of Aluminum Oxide Powder

For B2B buyers looking to source aluminum oxide in bulk quantities, the following companies represent some of the most established and reputable suppliers globally:

| Nome do fornecedor | Região | Principais pontos fortes |

|---|---|---|

| Almatis GmbH | Alemanha | High-purity alumina, global distribution |

| Saint-Gobain Ceramics | França | Advanced ceramics and refractory materials |

| Sumitomo Chemical Co., Ltd. | Japão | Ultra-pure alumina for semiconductors |

| Huber Engineered Materials | EUA | Technical-grade alumina for industrial use |

| Shanghai Truer Technology | China | Custom PM powders, 3D printing integration |

Por que a Shanghai Truer se destaca:

- Offers both standard and custom aluminum oxide powders for different industrial applications

- Advanced equipment for gas and water atomization processes

- Dedicated R&D team for continuous innovation

- Professional support for additive manufacturing and PM applications

Shanghai Truer is particularly well-positioned to serve international buyers looking for tailored solutions in aluminum oxide and other powder metallurgy materials. Their commitment to technical excellence, customer service, and global logistics support makes them a competitive player in the global B2B market.

7. Why More Distributors Are Sourcing Aluminum Oxide from China

Over the past decade, China has emerged as a dominant force in the global aluminum oxide powder market. A combination of advanced manufacturing capabilities, competitive pricing, and vast raw material availability has made Chinese suppliers highly attractive to B2B buyers, including distributors, e-commerce sellers, and industrial manufacturers.

Principais vantagens do sourcing da China

| Vantagens | Descrição |

|---|---|

| Eficiência de custo | Lower labor and production costs without sacrificing quality |

| Alta capacidade de produção | Ability to handle large-volume, high-frequency orders |

| Wide Variety of Grades | From technical to ultra-high purity alumina powders |

| Innovation in Powder Metallurgy | Advanced R&D in atomization and crystal engineering |

| Export-Ready Infrastructure | Efficient logistics and global shipping capabilities |

Market Evidence

- China accounts for over 45% of the global aluminum oxide production capacity.

- Continuous investment in smart manufacturing and automation.

- Increasing number of Chinese suppliers obtaining ISO and REACH certifications.

What to Watch Out For

While sourcing from China offers many benefits, due diligence is essential. Buyers should:

- Request detailed specification sheets and third-party test reports.

- Verify supplier credentials and export capabilities.

- Choose suppliers with multilingual support and international trade experience.

🔗 One reliable example is Shanghai Truer Technology Co., Ltd., which has built a reputable brand by combining high-quality powder metallurgy products with dependable international service. Their expertise in both traditional PM and advanced 3D printing powders ensures a wide application scope for global customers.

8. Why Choose Shanghai Truer Technology as Your Supplier

If you’re sourcing aluminum oxide powder for industrial or commercial purposes, Shanghai Truer Technology Co., Ltd. offers a compelling value proposition for B2B buyers worldwide.

Company Snapshot

- Estabelecido: 2009

- Additive Manufacturing Division Launched: 2019

- Headquarters: Xangai, China

- 网站: am-material.com

为何 Truer 脱颖而出

Portfólio abrangente de produtos

Shanghai Truer provides a complete range of aluminum oxide and PM powders, including:

- Water atomized, gas atomized, and combined atomization powders

- Grades suitable for both PM and additive manufacturing

- Custom formulations for niche industrial applications

✔ Technical Excellence

- In-house R&D team focused on material innovation

- Advanced production lines with strict quality control

- Real-time technical support for formulation and application guidance

confiado pelos líderes do setor

- Recognized as one of the most professional additive suppliers in China’s PM industry

- Long-term partnerships with OEMs, distributors, and research institutions

- Offers specialty additives like graphite lubricants, soft magnetic powders, and cutting agents

✔ End-to-End B2B Support

- Bulk ordering capabilities with flexible MOQs

- Secure packaging and international logistics

- Dedicated contact team for global buyers

Whether you’re a wholesaler, distributor, or end-user manufacturer, Shanghai Truer’s aluminum oxide powder solutions are tailored to meet your technical and commercial needs.

9. FAQs: Buying Wholesale Aluminum Oxide Powder for Industrial Use

Q1: What is the minimum order quantity (MOQ) for wholesale aluminum oxide powder?

A: The MOQ typically starts at 25 kg for standard grades, but custom quantities can be arranged depending on your application and logistical needs. Contact a equipa de vendas da Shanghai Truer for specific MOQ details.

Q2: Can I request a custom particle size or purity level?

A: Yes, Shanghai Truer offers tailored solutions, including custom particle size distribution, surface treatments, and purity levels up to 99.99%, depending on your application (abrasives, ceramics, electronics, etc.).

Q3: Are technical data sheets (TDS) and COAs provided?

A: Absolutely. Each batch comes with a Certificate of Analysis (COA) and Technical Data Sheet (TDS) to ensure traceability and quality assurance. These documents are essential for industrial and regulatory compliance.

Q4: What packaging options are available for bulk orders?

A: Standard packaging includes 25kg bags, 500kg super sacks, or custom containers. Vacuum-sealed and moisture-proof options are also available based on storage requirements.

Q5: Is international shipping available?

A: Yes. Shanghai Truer has a robust international logistics network and can ship globally via air or sea freight. All shipments include proper documentation for customs clearance and import compliance.

Q6: What grades of aluminum oxide does Shanghai Truer stock?

A: Truer stocks a variety of grades, including high-purity alpha alumina for electronics and technical ceramics, as well as technical grade powders for abrasives and refractories. You can check available inventory on their Página do pó PM.

Q7: How do I place an order?

A: Orders can be placed directly via the company’s website or through their formulário de contato. A sales representative will follow up promptly with pricing, lead times, and shipping options.

Q8: Does Shanghai Truer offer samples for testing?

A: Yes, sample orders are available for qualified industrial buyers and R&D departments. This allows you to test the powder’s compatibility with your existing processes.

Q9: Can aluminum oxide powder be used in additive manufacturing?

A: Yes. Truer supplies aluminum oxide powders suitable for selective laser sintering (SLS) and other 3D printing applications. Their materials are engineered for high flowability, purity, and thermal stability.

Final Note:

If you’re ready to elevate your supply chain with a dependable aluminum oxide powder partner, explore the full capabilities and product offerings available at Shanghai Truer Technology. From technical-grade abrasives to ultra-pure electronic ceramics, they support diverse industry requirements with precision and professionalism.