What Is T15 Powder and Why It Matters in Industry

T15 powder, also known as AISI T15 or high-speed tool steel powder, is a cobalt-bearing, high-alloy steel, designed for extreme wear resistance and high red hardness. It is widely used in the manufacturing of high-performance cutting tools, dies, and components that operate under high thermal and mechanical stress.

Overview of T15 Powder Composition

| Elemento | Conteúdo típico (%) |

|---|---|

| Carbono (C) | 1.50 |

| Tungstênio (W) | 12.00 |

| Vanádio (V) | 5.00 |

| Cromo (Cr) | 4.00 |

| Molibdênio (Mo) | 1.25 |

| Cobalto (Co) | 5.00 |

This composition makes T15 powder ideal for tooling applications that require high hot hardness and wear resistance.

Importance in Powder Metallurgy and Additive Manufacturing

T15 powder is increasingly used in:

- Advanced Powder Metallurgy (PM) parts

- Additive Manufacturing (AM) for high-speed cutting tools

- Moldagem por injeção de metal (MIM)

- Near-net shape manufacturing of wear-resistant components

T15’s performance in these applications makes it a high-demand material for industries such as aerospace, automotive, and precision tooling.

Applications of T15 Powder in Tooling and Manufacturing

T15 powder is highly valued in sectors where tool longevity and performance are critical. The powder form allows manufacturers to produce complex shapes and customized geometries without compromising material integrity.

Principais Áreas de Aplicação

- CNC Tooling: Drill bits, milling cutters, reamers, and taps

- Die Manufacturing: Cold heading dies, extrusion dies, and forging dies

- Componentes de metalurgia do pó: Wear parts in high-temperature environments

- Manufatura Aditiva: Custom cutting tools via laser powder bed fusion (LPBF) and electron beam melting (EBM)

Benefits for Industrial Buyers

- Extended tool life and reduced downtime

- Enhanced productivity in high-speed operations

- Superior performance under high thermal stress

- Cost efficiency through reduced replacement frequency

Compatibility with Manufacturing Technologies

| Tecnologia | Compatibility Level |

|---|---|

| MIM (moldagem por injeção de metal) | Alta |

| LPBF (Laser Powder Bed Fusion) | Alta |

| HIP (Hot Isostatic Pressing) | Médio |

| Conventional PM Sintering | Moderado |

Key Properties and Use Cases of T15 Powder

T15 tool steel powder’s mechanical and thermal properties are the foundation of its industrial demand.

Mechanical and Thermal Properties

| Propriedade | Valor |

|---|---|

| Dureza (HRC) | Up to 67 |

| Red Hardness | Excelente |

| Resistência ao desgaste | Excelente |

| Robustez | Bom |

| Resistência ao calor | Up to 600°C operating temperature |

| Usinabilidade | Moderado |

Use Cases in B2B Context

- Tool Manufacturers: For producing industrial-grade cutting tools

- OEMs automotivos: For high-performance engine and transmission components

- Aerospace Suppliers: For wear-resistant tooling in turbine manufacturing

- Mold and Die Shops: For cold work and hot work dies requiring extreme toughness

Why B2B Buyers Prefer T15 Powder

- Customization: Powder form allows for tailored compositions and particle sizes.

- Scalability: Suitable for both small-batch prototyping and large-scale production.

- Supply Chain Efficiency: Lower scrap rates and material waste.

For more details on how T15 powder fits into your manufacturing setup, visit our T15 powder product page.

Global Market Trends and Growth Potential of T15 Powder

The global market for high-speed tool steel powders like T15 is experiencing sustained growth, driven by the demand for precision tooling in advanced manufacturing sectors. From aerospace to automotive and energy, industries are increasingly adopting powder metallurgy and additive manufacturing technologies – both of which favor high-performance materials like T15 powder.

Market Size & Growth Forecast

| Ano | Global T15 Powder Market Size (USD Million) |

|---|---|

| 2021 | 320 |

| 2023 | 370 |

| 2025 (projetado) | 460 |

| 2028 (projetado) | 600+ |

Key Trends Driving the Market

- Shift to Additive Manufacturing (AM): The growth of impressao 3D for tooling applications is accelerating demand for T15 in powder form.

- Rising Demand from Aerospace & Automotive: Lightweight, high-performance tools are essential for modern production lines.

- Preference for Near-Net Shape Manufacturing: Reduces machining time and waste, making powder-based manufacturing more cost-effective.

- Material Customization: T15 is often tailored in particle size, morphology, and pre-alloyed forms to meet specific industrial needs.

Regional Demand Analysis

| Região | Growth Driver |

|---|---|

| América do Norte | Aerospace and defense tooling |

| Europa | Automotive and precision engineering |

| Ásia-Pacífico | Large-scale industrial manufacturing and tool production |

| China | Expansion of domestic AM and PM industries |

As the market continues to grow, suppliers offering consistent quality, flexible customization, and fast delivery will become increasingly important to B2B buyers.

How to Choose a Reliable T15 Powder Supplier

Wholesale buyers, distributors, and manufacturing professionals must evaluate several critical factors before partnering with a T15 powder supplier. Selecting the right partner can significantly impact product performance, timelines, and costs.

Key Criteria for Supplier Evaluation

- Material Consistency & Purity

- High cobalt and vanadium content

- Free from harmful contaminants (e.g., sulfur, phosphorus)

- Distribuição consistente do tamanho das partículas

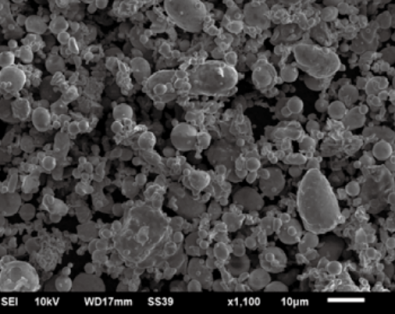

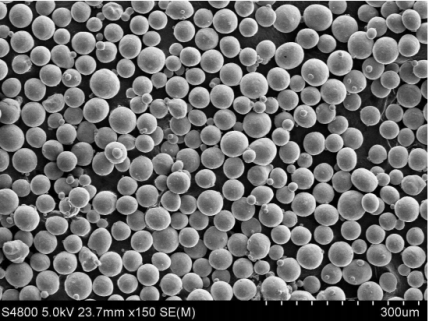

- Método de fabricação

- Gas Atomization: Ideal for additive manufacturing

- Water Atomization: Cost-effective for powder metallurgy

- Combined Atomization: Balanced solution for cost and quality

- Suporte técnico e personalização

- Custom alloy formulation

- Tailored particle size (e.g., <15 μm for LPBF, <45 μm for MIM)

- Application-specific consulting

- Certifications & Quality Assurance

- ISO 9001, ISO 14001, and RoHS compliance

- Batch traceability and third-party testing reports

Checklist for B2B Buyers

| Requisito | Por que é importante |

|---|---|

| Particle morphology inspection | Ensures flowability in AM |

| Pre-alloyed vs. blended | Influences mechanical performance |

| Embalagem e logística | Prevents oxidation and contamination |

| MOQ flexibility | Supports both prototyping and mass production |

For wholesale buyers looking to source high-quality T15 powder, these factors are essential to ensure long-term supply chain reliability and product quality.

Top T15 Powder Suppliers Globally and in China

When it comes to sourcing T15 tool steel powder, B2B buyers have a range of options. However, not all suppliers offer the same level of consistency, customization, and technical support.

Principais fornecedores globais

- Höganäs AB (Suécia)

- Large-scale producer of metal powders for PM

- Offers gas-atomized high-speed steel powders

- Carpenter Additive (USA)

- Specializes in additive manufacturing powders

- Advanced gas atomization capabilities

- Sandvik Osprey (UK)

- Supplies pre-alloyed tool steel powders for AM

- Strong quality control and technical documentation

- Erasteel (France)

- Offers ASP® grades including T15 equivalent

- Known for ultra-clean powder metallurgy steels

Principais Fornecedores Chineses

| Fornecedor | Pontos fortes |

|---|---|

| Shanghai Truer Technology Co., Ltd | Broad product range, advanced atomization methods, custom alloy solutions |

| Pó CNPC | Offers both water and gas atomized powders |

| Foshan Powtech | Specializes in high-speed steel powders for MIM and PM |

Ymhlith y rhain, Shanghai Truer Technology Co., Ltd stands out with its extensive experience in both powder manufacturing and additive manufacturing support services. Established in 2009 and entering the AM space in 2019, Truer provides a one-stop solution from powder production to application consulting.

To learn more about Truer’s company background and technical capabilities, visit the Página sobre nós.

Why More Buyers Are Switching to Chinese T15 Powder Sources

Over the last decade, the Chinese powder metallurgy industry has rapidly matured, offering high-quality metal powders that rival global brands — but at significantly more competitive prices. This shift is especially relevant to wholesale buyers and industrial manufacturers sourcing T15 powder.

Competitive Advantages of Chinese Suppliers

- Lower Price per Kilogram

- Cost-effective without compromising quality

- Ideal for large-volume buyers and distributors

- Flexible Customization

- Tailored particle size distribution and morphology

- Custom alloy compositions to meet national or proprietary specs

- Agile Production & Shorter Lead Times

- Rapid batch production and responsive fulfillment

- Located closer to emerging Asian and Middle Eastern markets

- Serviços integrados

- Many suppliers offer both powder and equipment (e.g., atomization machinery)

Case for Shanghai Truer Technology

Shanghai Truer not only offers a wide range of PM and AM powders, including T15, but also:

- Provides technical consultation to help clients optimize tooling design

- Delivers batch-specific testing data with every shipment

- Supports both water and gas atomization, as well as hybrid techniques

Their focus on quality assurance, customization, and B2B service makes them an ideal strategic partner for companies looking to streamline their supply chain.

Explore Truer’s full product range and manufacturing capabilities on the main product page.

Why Choose Shanghai Truer Technology as Your T15 Powder Partner

Shanghai Truer Technology Co., Ltd is a trusted name in China’s powder metallurgy and additive manufacturing industry. Since its founding in 2009, the company has evolved into a comprehensive supplier of high-quality metal powders and atomization technology solutions. For businesses sourcing T15 powder in bulk, Truer offers a powerful combination of quality, customization, and technical expertise.

Core Strengths of Truer in T15 Powder Supply

| Recurso | Vantagens |

|---|---|

| Multiple Atomization Methods | Offers gas, water, and combined atomization to meet diverse T15 powder requirements |

| Full Range of High-Speed Steels | Supplies hybrid, diffusion alloyed, and pre-alloyed steel powders including T15 |

| Custom Particle Size Distribution | Tailored to specific AM/PM technologies (e.g., <15μm for LPBF, <45μm for MIM) |

| Application Support | Engineering support for tooling, sintering optimization, and AM integration |

| Robust Quality Control | ISO-certified production, batch QA testing, and material traceability |

Exclusive T15 Powder Offerings from Truer

Shanghai Truer provides T15 powder with the following industrial-grade specifications:

- Pureza: ≥ 99.5%

- Particle Size Options:

- 0–15μm for LPBF

- 15–45μm for MIM and PM

- 45–100μm for hot isostatic pressing (HIP)

- Morfologia: Spherical and highly flowable (gas atomized)

- Embalagem: Vacuum-sealed, anti-oxidation packaging for export

These characteristics ensure excellent performance in both additive and traditional powder metallurgy applications.

Additional Value-Added Services

- R&D Collaboration: Truer partners with clients on custom alloy development and prototyping.

- Bulk Order Discounts: Competitive pricing for wholesale buyers and OEMs.

- Fast Global Shipping: Efficient logistics to Asia, Europe, and the Americas.

- Lubrificantes e aditivos: Truer also supplies lubricants (e.g., Lube-W, SUW-5000B) and sintering additives specifically formulated for PM applications.

For a complete overview of Truer’s additive manufacturing solutions and powder metallurgy products, visit their página inicial.

How to Order Wholesale T15 Powder from Shanghai Truer

Ordering wholesale T15 powder from Shanghai Truer is a straightforward, B2B-optimized process designed to ensure quality assurance, smooth logistics, and tailored service for enterprise buyers.

Processo de pedido por atacado passo a passo

- Envio de Consulta

- Contact Truer’s sales team via the Automotivo, máquinas industriais or email with your specifications.

- Include details such as quantity, particle size, atomization method (gas or water), and intended use (AM or PM).

- Quotation & Sample Provision

- Receive official quotation, lead time, and logistics estimate.

- Request a sample batch for testing and validation.

- Cadarnhad Archeb

- Confirm technical specifications and place a purchase order (PO).

- Payment terms can be negotiated (T/T, L/C, etc.).

- Produção e garantia de qualidade

- Powder is manufactured with batch-specific traceability, purity testing, and morphology analysis.

- QA reports and MSDS documents are provided.

- Packaging & Delivery

- Vacuum-sealed, moisture-free packaging in 10kg–25kg containers.

- Shipping via sea, air, or express courier depending on urgency.

- Suporte pós-venda

- Application guidance, technical support, and re-order assistance provided by Truer’s engineering team.

B2B Buyer Support

- Flexibilidade de MOQ: Small trial batches supported for R&D

- Customized Alloys: Modify cobalt, vanadium, or tungsten content to meet unique tooling needs

- OEM/ODM Services: Private label packaging available for distributors

For faster processing, you can directly submit your requirements through Truer’s official formulário de contato.

FAQs: Wholesale Buying of T15 Powder

Below are some frequently asked questions by B2B buyers considering T15 powder for industrial and additive manufacturing use.

Q1: What is the minimum order quantity (MOQ) for T15 powder?

A: Truer supports flexible MOQs starting from 10kg for trial batches and R&D purposes. For production quantities, pricing tiers begin at 100kg.

Q2: What atomization methods are available for T15 powder?

A: Truer offers gas atomized, water atomized, and combined atomization. Gas atomized T15 is recommended for additive manufacturing due to its high sphericity and flowability.

Q3: Can I request a custom composition or particle size?

A: Yes. Truer specializes in custom alloying and sizing. This is especially useful for clients with proprietary tooling requirements or unique AM platform needs.

Q4: How is T15 powder packaged for international shipping?

A: Powders are vacuum-sealed in anti-oxidation foil bags, placed in sealed steel drums or PE containers. Each shipment includes a material certification and testing documentation.

Q5: Does Truer provide technical support for tooling applications?

A: Absolutely. Truer’s engineers assist clients with application-specific consultation, including AM parameter optimization, sintering profiles, and tool design recommendations.

By sourcing T15 powder from Shanghai Truer Technology, you’re partnering with one of China’s most advanced powder metallurgy solution providers. Whether you’re producing cutting tools via LPBF or sintered PM components, Truer offers unmatched quality, customization, and support for industrial buyers.

To get started with your custom T15 powder solution, explore Truer’s full product range on the Escolher o fornecedor certo de pó FX-2000 é essencial para garantir a qualidade consistente das peças, reduzir o tempo de inatividade da produção e manter preços competitivos. Para compradores B2B, especialmente aqueles que operam em cronogramas de produção apertados, um relacionamento confiável com o fornecedor é um ativo estratégico..