1. Introduction: Why WC-Co Powder Matters in Advanced Manufacturing

WC-Co powder, a composite of tungsten carbide (WC) and cobalt (Co), is one of the most crucial hard materials used in modern industrial manufacturing. It is widely known for its exceptional hardness, high wear resistance, and toughness, making it an ideal material for cutting tools, wear-resistant components, and additive manufacturing.

Why WC-Co Powder is Important for B2B Buyers:

- High-Performance Machining: Used in CNC cutting tools and inserts.

- Additive Manufacturing Applications: Especially valuable in binder jetting and laser-based impressao 3D.

- Powder Metallurgy (PM) Compatibility: Perfect for sintered components with complex geometries.

| Recurso | Descrição |

|---|---|

| Composição | Tungsten carbide (WC) + Cobalt (Co) |

| Dureza | Up to 1800 HV |

| Densidade | ~14.5 g/cm³ |

| Formulários | Cutting tools, wear parts, AM, PM |

| Tipos de pó | Agglomerated, Spherical, Angular |

| Morfologia | Water atomized or gas atomized |

For enterprises involved in tooling, mining, aerospace, or advanced manufacturing, sourcing high-purity, consistent WC-Co powder is a key operational requirement.

2. Key Industrial Applications of WC-Co Powder

WC-Co powder is used across multiple B2B industries due to its mechanical and thermal excellence. Here’s a breakdown of the primary sectors:

2.1. Cutting Tool Manufacturing

- CNC Inserts & End Mills: WC-Co is used to manufacture high-speed cutting tools.

- Drills & Reamers: Robust enough to handle high-stress applications in hard metals.

2.2. Mining & Construction

- Drill Bits & Rock Tools: WC-Co’s toughness ensures prolonged life under abrasive conditions.

- Wear Plates & Liners: Ideal for high-impact, high-friction environments.

2.3. Additive Manufacturing (3D Printing)

- Binder Jetting & SLS: WC-Co powders are increasingly used in 3D-printed wear parts.

- Tooling Inserts for Molds: Rapid prototyping and small batch production.

2.4. Powder Metallurgy Components

- Sintered Bearings & Bushings: Enhanced wear resistance in mechanical parts.

- Valve Seats, Nozzles: Used in oil & gas and fluid handling applications.

| Setor | Aplicativo | WC-Co Benefit |

|---|---|---|

| Aeroespacial | Turbine engine parts | Resistência ao calor |

| Automotivo | Brake pad tooling | Resistência ao desgaste |

| Mineração | Drill bits, cutters | Shock tolerance |

| Ferramentas | Inserts, dies | Extrema dureza |

Industrial buyers, distributors, and procurement managers must understand these applications to align material capabilities with end-use performance specs.

3. Types of WC-Co Powders and Their Properties

Different WC-Co powders are engineered depending on the cobalt content, grain size, and manufacturing process. Here’s an overview:

3.1. By Grain Size

- Fine Grain (0.5–1.0 µm): Best for wear parts and high-precision tools.

- Medium Grain (1–2 µm): Standard for cutting tools.

- Coarse Grain (>2 µm): Used in mining applications for impact resistance.

3.2. By Cobalt Content

- Low Co (3–6%): High hardness, lower toughness — ideal for finishing tools.

- Medium Co (6–10%): Balance of toughness and hardness.

- High Co (10–20%): Higher toughness — suitable for mining and impact applications.

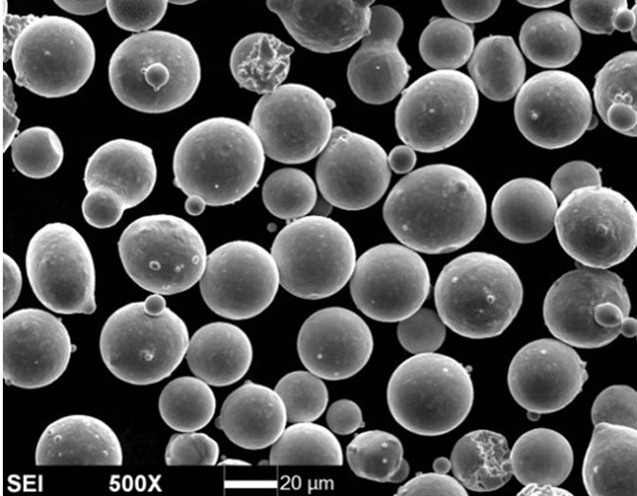

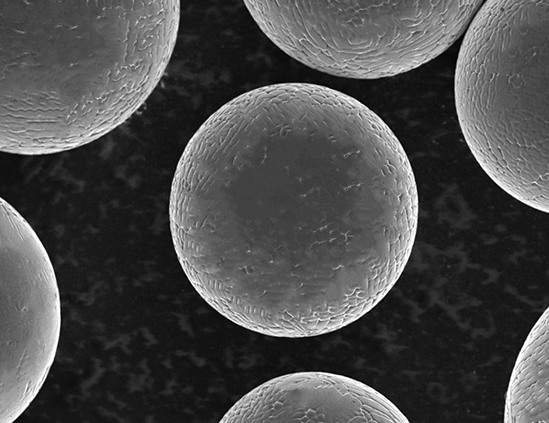

3.3. By Powder Morphology

- Agglomerated & Sintered Powders: High flowability for thermal spraying and AM.

- Spherical Powders: Uniform packing density, ideal for binder jetting.

- Angular Powders: Better mechanical interlocking for pressing.

| Tipo | Tamanho do grão | Co % | Caso de uso |

|---|---|---|---|

| WC-6Co | 1 µm | 6% | CNC inserts |

| WC-10Co | 2 µm | 10% | Brocas |

| WC-12Co | 3 µm | 12% | Mining tools |

| WC-4Co | 0.8 µm | 4% | Mold inserts |

If you’re sourcing WC-Co powders for precision applications, selecting the right combination of grain size, cobalt content, and morphology is essential. For more information on available powder types and specifications, visit our WC-Co powder product page.

4. Market Trends & Global Demand for WC-Co Powder

In the past decade, the global WC-Co powder market has seen sustained growth, driven by increasing demand from industries like aerospace, automotive, oil & gas, and additive manufacturing. For B2B buyers, understanding these trends is key to making smart procurement decisions.

4.1. Market Size & Growth Rate

- 2023 Market Size: USD 1.2 billion

- CAGR (2024–2030): ~6.8%

- Top Growth Sectors: Additive manufacturing, tool-making, mining

4.2. Factors Driving Demand

- Expansion in Additive Manufacturing: WC-Co is increasingly used in binder jetting and laser powder bed fusion (LPBF) due to its excellent mechanical properties.

- Tooling Industry Boom: The global resurgence in industrial production has driven up demand for carbide tools.

- Focus on Wear Resistance: Many industries are upgrading to WC-Co components for longer lifecycle and reduced maintenance.

4.3. Regional Demand Insights

| Região | Principais indústrias | Demanda do mercado |

|---|---|---|

| Ásia-Pacífico | Automotivo, Manufatura | Alta |

| América do Norte | Aeroespacial, petróleo e gás | Medium-High |

| Europa | Precision Tools, AM | Médio |

| Oriente Médio | Mining, Oil Drilling | Crescendo |

For B2B procurement teams, this means increased lead times and fluctuating prices. It’s essential to lock in reliable supply chains and consider domestic and international sourcing strategies to stay competitive.

5. How to Choose the Right WC-Co Powder Supplier

Choosing the right WC-Co supplier is crucial for manufacturers, distributors, and wholesalers dealing in hard metals or powder metallurgy. Here are the key evaluation factors:

5.1. Technical Specifications

- Purity & Composition Consistency: Ensure stable WC and Co ratios for each batch.

- Distribuição de tamanho de partícula (PSD): Uniform PSD ensures predictable sintering and AM results.

- Flowability & Morphology: Essential for additive manufacturing and thermal spraying.

5.2. Production Capabilities

- Atomization Methods Available: Gas atomized and water atomized powders offer different performance traits.

- Batch Traceability: Important for quality assurance and regulatory compliance.

- On-Time Delivery & Logistics: Especially for global supply chains.

5.3. Support Services

- Technical Consultation: Ability to provide engineering support and custom solutions.

- Customization Options: Tailored grain sizes, Co content, additives.

- Post-Sales Support: Troubleshooting, reordering, and documentation.

| Critérios | Why It’s Important |

|---|---|

| Qualidade consistente | Reduces tool failure and downtime |

| Preços competitivos | Improves margins for resellers and OEMs |

| Suporte técnico | Enables optimization of applications |

✅ Pro Tip: Always request a Certificate of Analysis (CoA) and third-party test reports before confirming bulk orders. Some suppliers, like Shanghai Truer Technology, offer comprehensive technical documentation and in-house R&D testing.

6. Top WC-Co Powder Suppliers in Asia and Globally

The WC-Co powder supply landscape includes several key players across Asia, North America, and Europe. Here’s a snapshot of the top-tier providers known for quality and consistency:

6.1. Asia-Based Suppliers

| Empresa | País | Principais pontos fortes |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Wide product range, custom alloys, PM & AM powders |

| Grupo de Carbeto Cimentado de Zhuzhou | China | Legacy player, tooling industry focus |

| Sumitomo Electric Hardmetal | Japão | High-end carbide grades, precision tool focus |

6.2. Europe & North America

| Empresa | País | Focus |

|---|---|---|

| H.C. Starck Tungsten | Alemanha | Ultra-pure WC powders |

| Kennametal | EUA | Tooling and wear parts |

| Tungstênio de Buffalo | EUA | Custom powder solutions |

Shanghai Truer Technology has emerged as a trusted supplier offering a complete range of powder metallurgy and additive manufacturing powders. Since 2019, Truer has expanded its WC-Co powder offerings, including agglomerated, spherical, and angular options designed for sintering and 3D printing.

Truer is also recognized for its additive innovations such as:

- Hybrid atomization (gas + water)

- Custom Co content and grain sizes

- Advanced lubricants and additives for PM

To learn more about the company’s history and capabilities, visit the Sobre nós página.

7. Why More Distributors Are Turning to Chinese Manufacturers

In recent years, global distributors and industrial wholesalers have increasingly shifted their sourcing of WC-Co powder to Chinese manufacturers. This shift is fueled by a strategic combination of cost-efficiency, scalable production, and technological advancement.

7.1. Competitive Pricing Without Compromising Quality

- Lower Production Costs: China maintains lower operational and labor costs, allowing manufacturers to offer globally competitive prices.

- Economias de escala: With high-volume production facilities, Chinese suppliers can fulfill bulk orders faster and at reduced per-unit costs.

7.2. Technological Advancements in Powder Production

- Adoption of Atomization Technologies: Many Chinese manufacturers now employ advanced gas and water atomization technologies that rival Western counterparts.

- Improved Quality Control: Certification to ISO and ASTM standards ensures global compatibility.

7.3. Customization and Flexibility

- Tailored Compositions: Chinese producers often offer customized WC-Co formulations for specific industrial applications.

- Flexible MOQ (Minimum Order Quantity): Adaptable to both large distributors and smaller e-commerce buyers.

| Výhody získavania z Číny | Descrição |

|---|---|

| Menor custo por kg | Ideal for bulk procurement |

| Prazos de entrega rápidos | Efficient logistics & shipping |

| Custom powder grades | Engineered to application needs |

| Strong technical support | R&D backed customization |

One of the leading Chinese manufacturers benefiting from this trend is Shanghai Truer Technology Co., Ltd, which offers customizable WC-Co powder solutions to meet diverse B2B needs in tooling, 3D printing, and powder metallurgy.

8. Why Choose Shanghai Truer Technology as Your WC-Co Supplier

As a recognized leader in the Chinese powder metallurgy industry, Shanghai Truer Technology stands out for its commitment to quality, innovation, and customer-centric service.

8.1. Comprehensive Product Offering

Truer offers a wide range of PM and AM powders, including:

- WC-Co Grades: With 4–20% cobalt content, tailored for mining, tooling, and additive manufacturing.

- Water & Gas Atomized Powders: Suitable for sintering, thermal spraying, and binder jetting.

- PM Additives & Lubricants: Including SUW-8000 and SME-100 for enhanced pressing and cutting performance.

8.2. Custom Engineering Solutions

Truer’s R&D team collaborates directly with clients to develop custom powder formulations, ensuring optimal performance in:

- High-wear environments

- Precision CNC machining

- Binder jetting and LPBF 3D printing

8.3. Certifications and Quality Assurance

- ISO-certified production processes

- Batch-level traceability

- In-house and third-party material testing

8.4. Global Export Capabilities

- Multilingual Support: English, Chinese, and more.

- Efficient Logistics: Strong partnerships with international freight carriers.

- Responsive Service: Fast quotes and tailored sample programs.

| Recurso | Benefício para os compradores |

|---|---|

| Custom powder grades | Meet specific project requirements |

| Fast sample turnaround | Accelerate product development |

| Extensive inventory | Shorten lead times |

| Technical consultations | Improve application performance |

To explore Truer’s full product catalog of WC-Co and other PM powders, visit the Produtos de metalurgia do pó página.

9. FAQs: Buying WC-Co Powder in Bulk for Industrial Use

Q1: What cobalt content should I choose for my application?

A: For high hardness and moderate toughness (e.g., cutting tools), 6–10% Co is ideal. For impact-resistant applications like mining, opt for 12% or higher Co content.

Q2: What’s the typical MOQ for wholesale orders?

A: Shanghai Truer offers flexible MOQs for B2B clients, starting from 25kg for sampling and scaling up to tons for mass production.

Q3: Can I get customized WC-Co powder for 3D printing?

A: Yes, Truer provides spherical WC-Co powders with fine PSD and high purity for binder jetting and LPBF printing.

Q4: What shipping methods are available for international orders?

A: Truer offers international air and sea freight options, with customs documentation and export support included.

Q5: How can I request a quote or technical consultation?

A: You can easily reach out through the Contate-Nos page for pricing, samples, or technical info.

By leveraging Shanghai Truer Technology’s capabilities, global distributors, tool manufacturers, and AM startups can ensure consistent supply, competitive pricing, and top-tier quality for their WC-Co powder needs. For more information about Truer’s full range of metallurgy solutions, visit AM-Material.com.