Pó de TiCO pó de carboneto de titânio, ou TiC, é um material essencial em vários setores devido à sua excepcional dureza, resistência ao desgaste e estabilidade em altas temperaturas. Seja no setor aeroespacial, automotivo ou de ferramentas de corte, o pó de TiC desempenha um papel fundamental na melhoria do desempenho e da durabilidade. Este guia abrangente se aprofundará em todos os aspectos do pó de TiC - sua composição, características, aplicações, vantagens e especificações - ao mesmo tempo em que explora modelos específicos disponíveis no mercado. Você também encontrará comparações detalhadas e perguntas frequentes para entender melhor o pó de TiC e sua importância em diferentes setores.

Visão geral do pó de TiC

O pó de carbeto de titânio (TiC) é um tipo de pó cerâmico com dureza e resistência excepcionais ao desgaste e à corrosão. Como um dos materiais mais duros conhecidos, o TiC é frequentemente usado em aplicações de alto desempenho, como ferramentas de corte, abrasivos, revestimentos e como aditivo em compostos de matriz metálica. Suas propriedades o tornam ideal para ambientes expostos a condições extremas, como altas temperaturas, alto desgaste e ambientes corrosivos.

O pó de TiC é frequentemente sintetizado por meio de vários processos químicos, geralmente usando tetracloreto de titânio (TiCl4) e fontes de carbono em altas temperaturas. O pó de TiC resultante pode ser personalizado para diferentes aplicações industriais com base em fatores como tamanho de partícula, pureza e composição.

Principais características do pó de TiC

- Dureza: O TiC é conhecido por sua extrema dureza, superando a de muitos outros materiais. Ele ocupa a posição 9 na escala Mohs de dureza, o que o torna adequado para ferramentas de corte, abrasivos e revestimentos.

- Estabilidade térmica: O pó de TiC pode suportar altas temperaturas, mantendo sua integridade estrutural mesmo sob calor extremo, o que o torna um material ideal para aplicações de alta temperatura, como motores a jato.

- Resistência ao desgaste: Devido à sua dureza, o pó de TiC é altamente resistente à abrasão e ao desgaste. Isso o torna uma excelente opção para uso em maquinário pesado, mineração e componentes automotivos.

- Resistência à corrosão: O TiC apresenta excelente resistência à corrosão, principalmente em ambientes de alta temperatura e quimicamente agressivos, garantindo a longevidade de peças e componentes.

- Condutividade elétrica: O TiC também é um bom condutor de eletricidade, o que o torna valioso em contatos elétricos, resistores e outras aplicações eletrônicas.

Composição de Pó de TiC

O pó de carbeto de titânio é composto principalmente de dois elementos: titânio (Ti) e carbono (C). A composição exata do pó pode variar de acordo com o método de produção, mas a proporção de Ti para C permanece relativamente constante em 1:1. Aqui está um detalhamento do que compõe o pó de TiC:

| Elemento | Símbolo | Porcentagem por peso | Função na composição |

|---|---|---|---|

| Titânio | Ti | ~50% | Proporciona dureza e estabilidade térmica |

| Carbono | C | ~50% | Contribui para a alta dureza e resistência ao desgaste |

Além desses dois elementos primários, o pó de TiC também pode conter traços de outros elementos, como oxigênio, nitrogênio ou impurezas metálicas, dependendo do processo de síntese.

Tipos de pó de TiC e modelos específicos

O pó de TiC é fornecido em vários tipos e graus, cada um otimizado para diferentes aplicações industriais. Essas variações dependem de fatores como tamanho da partícula, pureza e propriedades específicas, como resistência ao desgaste ou condutividade elétrica.

Aqui estão dez modelos populares de pó de TiC e seus recursos específicos:

| Modelo de pó de TiC | Descrição | Tamanho da partícula (μm) | Pureza (%) | Formulários |

|---|---|---|---|---|

| Pó de TiC padrão | Pó de TiC para uso geral com propriedades balanceadas | 10-50 | 99 | Ferramentas de corte, revestimentos resistentes ao desgaste |

| Pó de TiC ultrafino | Pó com tamanho de partícula menor para revestimentos de alto desempenho | 1-5 | 99.5 | Nanorrevestimentos, materiais abrasivos |

| Pó revestido de TiC | Revestimento em pó de TiC com outros materiais para maior resistência ao desgaste | 5-25 | 99.8 | Ferramentas industriais, aplicações de retificação |

| Pó de TiC de alta pureza | Pó de TiC ultrapuro com o mínimo de impurezas | 10-30 | 99.9 | Ambientes aeroespaciais, militares e de alta temperatura |

| Nano pó de carboneto de titânio | Partículas de TiC nanométricas com propriedades aprimoradas | <1 | 99 | Eletrônicos, fabricação avançada |

| Pó composto de TiC-Metal | Pó composto que combina TiC com metais para aumentar a resistência | 20-40 | 97 | Compostos de matriz metálica, peças automotivas |

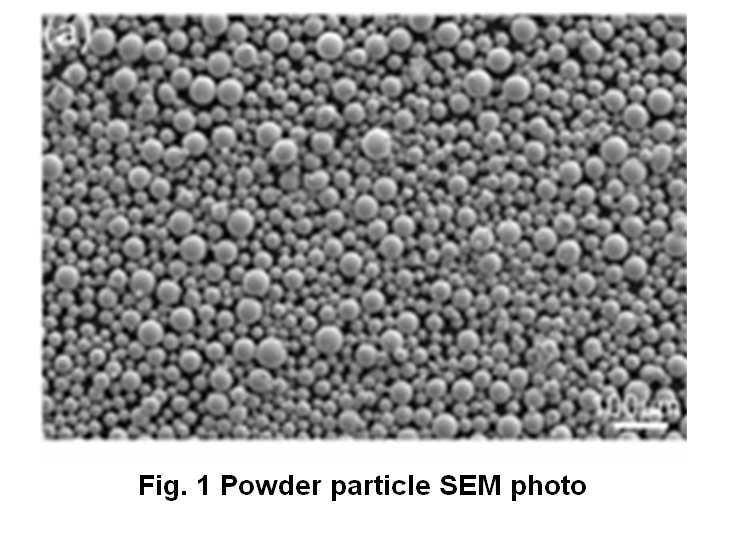

| Pó esférico de TiC | Pó de TiC em formato esférico para melhor fluidez e sinterização | 15-45 | 99.5 | Impressão 3D, metalurgia do pó |

| TiC para pó de revestimento duro | Projetado para revestimentos resistentes ao desgaste em máquinas pesadas | 30-60 | 98 | Mineração, construção, maquinário |

| Pó composto à base de TiC | Pó combinado com outros materiais cerâmicos para maior resistência | 10-50 | 98.5 | Revestimentos de alto desempenho, aplicações militares |

| Pó de carbonitreto de titânio (TiCN) | TiC combinado com nitrogênio para maior resistência ao desgaste e à corrosão | 20-50 | 99 | Ferramentas de corte, indústrias de abrasivos |

Aplicações do pó de TiC

O pó de TiC é usado em uma ampla gama de setores devido à sua notável dureza e durabilidade. Abaixo estão algumas das principais aplicações do pó de TiC, categorizadas por setor:

Aplicações industriais

| Setor | Formulários |

|---|---|

| Aeroespacial | Revestimentos de alto desempenho, componentes de motores, proteções térmicas |

| Automotivo | Pastilhas de freio, revestimentos resistentes ao desgaste para motores e engrenagens |

| Mineração | Ferramentas de corte, brocas, materiais de revestimento duro |

| Metalurgia | Ferramentas de usinagem CNC, ferramentas de corte, insertos e materiais abrasivos |

| Eletrônicos | Revestimentos condutores, contatos elétricos, resistores |

| Energia | Componentes de alta temperatura para usinas de energia, pás de turbinas e reatores |

Aplicações médicas e de biotecnologia

| Aplicativo | Detalhes |

|---|---|

| Implantes médicos | Revestimentos à base de TiC para melhorar a resistência ao desgaste de implantes ortopédicos |

| Biocompatibilidade | Devido à natureza inerte do TiC, ele pode ser usado em aplicações médicas de longo prazo |

Especificações, tamanhos e classes de Pó de TiC

Ao selecionar o pó de TiC, é importante considerar especificações como tamanho da partícula, grau e pureza. Aqui está uma visão geral das principais especificações e tamanhos disponíveis:

| Especificação | Descrição | Faixa |

|---|---|---|

| Tamanho da partícula | Tamanho das partículas de pó | 1-100 μm |

| Pureza | A quantidade de impurezas no pó de TiC | 97%-99.9% |

| Densidade | Massa por unidade de volume do pó | 4,9-5,1 g/cm³ |

| Dureza | A capacidade do pó de TiC de resistir à indentação | 9 na escala Mohs |

| Ponto de fusão | Temperatura na qual o pó de TiC derrete | 3,300°C |

| Grau | A classificação da qualidade com base na pureza e no tamanho | Alto, Médio, Baixo |

Informações sobre fornecedores e preços de TiC Powder

O pó de TiC está disponível em vários fornecedores, cada um oferecendo diferentes graus, tamanhos e preços. Veja a seguir uma breve visão geral dos fornecedores de pó de TiC e as faixas de preços típicas:

| Fornecedor | Grau | Faixa de preço | Formulários |

|---|---|---|---|

| Sigma-Aldrich | Alta pureza | $500-$1500 por kg | Pesquisa, aplicativos de alto desempenho |

| H.C. Starck | Pureza média | $300-$700 por kg | Revestimentos industriais, compostos de matriz metálica |

| Elementos americanos | Baixa pureza | $200-$500 por kg | Uso industrial a granel, abrasivos |

| Materiais avançados | Ultrafino | $1000-$3000 por kg | Nanorrevestimentos, fabricação avançada |

| Indústria Treibacher | Nota padrão | $250-$600 por kg | Ferramentas de corte, materiais de revestimento duro |

Prós e contras do pó de TiC

Como qualquer material, o pó de TiC tem seus pontos fortes e fracos. Vamos detalhar as vantagens e limitações do uso do pó de TiC em várias aplicações.

| Prós | Contras |

|---|---|

| Dureza e resistência ao desgaste excepcionais | Caro em comparação com outros materiais |

| Alta estabilidade térmica para temperaturas extremas | Pode ser difícil de processar em formas complexas |

| Resistência à corrosão em ambientes agressivos | Pode exigir equipamentos especializados para manuseio e síntese |

| Pode ser usado em vários setores | Flexibilidade limitada em termos de aplicação para determinados projetos |

perguntas frequentes

| Pergunta | Resposta |

|---|---|

| Qual é o ponto de fusão do pó de TiC? | O pó de TiC tem um ponto de fusão de aproximadamente 3.300°C. |

| O pó de TiC é usado na impressão 3D? | Sim, o pó esférico de TiC é usado com frequência em processos de impressão 3D. |

| Como o TiC se compara ao carbeto de tungstênio? | O TiC é geralmente mais duro, porém mais frágil que o carbeto de tungstênio, o que o torna mais adequado para revestimentos e aplicações resistentes ao desgaste. |

| Quais são as principais vantagens do pó de TiC em aplicações industriais? | As principais vantagens incluem sua dureza, resistência ao desgaste e estabilidade térmica, tornando-o ideal para ambientes de trabalho pesado. |

| O pó de TiC pode ser usado em aplicações aeroespaciais? | Sim, o pó de TiC é amplamente utilizado em aplicações aeroespaciais devido à sua resistência a altas temperaturas e durabilidade. |

Conclusão

O pó de TiC é um material incrivelmente versátil usado em vários setores, de aeroespacial a mineração e automotivo. Com sua notável dureza, resistência ao desgaste e estabilidade térmica, o pó de TiC é crucial para criar componentes de alto desempenho que podem suportar condições extremas.