Überblick über FeCoNiCrMn-Pulver

FeCoNiCrMn-Pulverdas oft als hochentropische Legierung (HEA) bezeichnet wird, stellt einen revolutionären Fortschritt in der Materialwissenschaft dar. Dieses Metallpulver ist für seine bemerkenswerten mechanischen, chemischen und thermischen Eigenschaften bekannt und wird in großem Umfang in Anwendungen eingesetzt, die Festigkeit, Korrosionsbeständigkeit und Vielseitigkeit erfordern. HEAs, zu denen auch FeCoNiCrMn gehört, haben aufgrund ihres einzigartigen Aufbaus aus mehreren Hauptelementen an Popularität gewonnen und unterscheiden sich damit von den herkömmlichen Legierungen, die von einem oder zwei Hauptelementen dominiert werden.

In diesem umfassenden Leitfaden werden wir uns eingehend mit FeCoNiCrMn-Pulver befassen und seine Zusammensetzung, Eigenschaften, Modelle und Anwendungen untersuchen. Wir gehen auch auf Vorteile, Einschränkungen und wichtige Lieferanten ein, damit Sie sich ein umfassendes Bild machen und fundierte Entscheidungen treffen können.

Was ist FeCoNiCrMn-Pulver?

FeCoNiCrMn-Pulver ist ein Pulver aus einer Fünfelementlegierung, die Eisen (Fe), Kobalt (Co), Nickel (Ni), Chrom (Cr) und Mangan (Mn) in nahezu gleichen Anteilen enthält. Diese ausgewogene Zusammensetzung bildet die Grundlage für seine hochentropischen Eigenschaften, die zu hervorragenden strukturellen und funktionellen Eigenschaften führen.

Wichtigste Highlights

- Hohe Festigkeit und Härte: Außergewöhnliche mechanische Eigenschaften aufgrund seiner einzigartigen atomaren Anordnung.

- Thermische Stabilität: Ideal für Hochtemperaturanwendungen.

- Korrosionsbeständigkeit: Beständig gegen Oxidation und chemische Zersetzung.

- Vielseitigkeit: Weit verbreitet in der additiven Fertigung, der Luft- und Raumfahrt und der biomedizinischen Industrie.

Zusammensetzung der FeCoNiCrMn-Pulver

Um zu verstehen, warum dieses Pulver so gut wirkt, muss man die Zusammensetzung kennen. Hier ist eine Aufschlüsselung:

| Element | Prozentsatz (typischer Bereich) | Rolle in Alloy |

|---|---|---|

| Eisen (Fe) | 19-23% | Verbessert die magnetischen Eigenschaften und die Zähigkeit. |

| Kobalt (Co) | 19-23% | Bietet Festigkeit und Wärmebeständigkeit. |

| Nickel (Ni) | 19-23% | Verbessert die Korrosionsbeständigkeit und Duktilität. |

| Chrom (Cr) | 19-23% | Bietet Korrosionsbeständigkeit und Härte. |

| Manganese (Mn) | 19-23% | Trägt zur Verarbeitbarkeit und zu den Verschleißschutzeigenschaften bei. |

Diese nahezu äquiatomische Verteilung minimiert die Verzerrung des Kristallgitters und führt zu einer hervorragenden Leistung unter schwierigen Bedingungen.

Eigenschaften von FeCoNiCrMn-Pulver

Die Eigenschaften des Materials machen es zu einer herausragenden Wahl für alle Branchen. Schauen wir uns diese Eigenschaften genauer an:

| Eigentum | Einzelheiten |

|---|---|

| Hohe Entropie | Einzigartige atomare Anordnung aufgrund der Gleichverteilung der Elemente. |

| Thermische Stabilität | Stabile Struktur und Leistung bei hohen Temperaturen (bis zu 1000°C und darüber hinaus). |

| Korrosionsbeständigkeit | Ausgezeichnete Beständigkeit gegen Oxidation und chemische Angriffe, auch in rauen Umgebungen. |

| Mechanische Festigkeit | Hohe Zugfestigkeit, Duktilität und Verschleißfestigkeit. |

| Magnetische Eigenschaften | Behält sein magnetisches Verhalten bei, was für Elektronik und Spezialmaschinen nützlich ist. |

Diese Eigenschaften gewährleisten, dass FeCoNiCrMn in anspruchsvollen Szenarien wie Düsentriebwerken, 3D-Druck und Meeresumgebungen eingesetzt werden kann.

Anwendungen von FeCoNiCrMn-Pulver

FeCoNiCrMn-Pulver ist in mehreren Hightech-Industrien unverzichtbar. Nachstehend finden Sie eine Anwendungsmatrix zur besseren Übersicht:

| Industrie | Anwendungen | Wichtigste Vorteile |

|---|---|---|

| Luft- und Raumfahrt | Triebwerkskomponenten, Turbinenschaufeln. | Hitzebeständigkeit und Festigkeit unter Belastung. |

| Additive Fertigung | 3D-Druck von komplexen Strukturen. | Vielseitigkeit und hochwertige Verarbeitung. |

| Biomedizinische | Chirurgische Instrumente, Implantate. | Biokompatibilität und Korrosionsbeständigkeit. |

| Marine | Schiffsteile, Unterwassermaschinen. | Korrosions- und Verschleißfestigkeit. |

| Energie | Kraftwerke, Kernreaktoren. | Stabilität bei hohen Temperaturen und hohem Druck. |

FeCoNiCrMn-Pulver Modelle

Um die verschiedenen Varianten und ihre spezifischen Anwendungen besser zu verstehen, wollen wir uns mit den einzelnen FeCoNiCrMn-Pulvermodellen befassen:

| Name des Modells | Beschreibung |

|---|---|

| FeCoNiCrMn-101 | Standardqualität für allgemeine additive Fertigung und Beschichtungen. |

| FeCoNiCrMn-202 | Verbesserte korrosionsbeständige Formulierung für den Einsatz in der Schifffahrt und in der Biomedizin. |

| FeCoNiCrMn-HT100 | Hochtemperaturvariante, die für die Luft- und Raumfahrt und die Energieerzeugung optimiert ist. |

| FeCoNiCrMn-WR | Das verschleißfeste Modell ist ideal für Industriemaschinen und Bergbauwerkzeuge. |

| FeCoNiCrMn-BM | Biokompatible Version, die speziell für medizinische Implantate und Instrumente entwickelt wurde. |

| FeCoNiCrMn-AM | Hochwertige Qualität für 3D-Druckanwendungen, die glattere Oberflächen und feinere Details gewährleistet. |

| FeCoNiCrMn-Plus | Hochwertige Legierungsmischung mit überlegener Zugfestigkeit und Duktilität für extreme Bedingungen. |

| FeCoNiCrMn-Ceramix | Hybridformulierung mit keramikähnlichen Eigenschaften für zusätzliche Härte und Verschleißfestigkeit. |

| FeCoNiCrMn-Light | Leichte Version für Anwendungen in der Luft- und Raumfahrt sowie in der Automobilindustrie, die ein hohes Verhältnis zwischen Festigkeit und Gewicht erfordern. |

| FeCoNiCrMn-Hybrid | Vielseitiges Modell, das auf Hybridanwendungen mit thermischen und korrosiven Herausforderungen zugeschnitten ist. |

Spezifikationen und Normen

Bei der Beschaffung von FeCoNiCrMn-Pulver ist es wichtig, die Spezifikationen zu kennen:

| Parameter | Range | Anmerkungen |

|---|---|---|

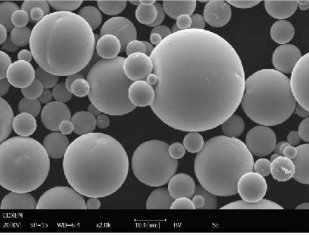

| Partikelgröße | 15-150 Mikrometer | Optimiert für 3D-Druck und Lasersintern. |

| Reinheit | ≥99.5% | Gewährleistet hohe Leistung und Zuverlässigkeit. |

| Dichte | 7,5-8,0 g/cm³ | Dies spiegelt seine hohe Entropie und Zusammensetzung wider. |

| Schmelzpunkt | ~1350°C | Bietet eine ausgezeichnete thermische Stabilität. |

| Einhaltung von Normen | ISO 9001, ASTM E-8 | Gewährleistet Qualität und Konsistenz über alle Chargen hinweg. |

Vorteile und Nachteile von FeCoNiCrMn-Pulver

Jedes Material hat seine Vor- und Nachteile, und FeCoNiCrMn-Pulver bildet da keine Ausnahme. Hier ist ein Vergleich:

| Vorteile | Benachteiligungen |

|---|---|

| Außergewöhnliche mechanische Eigenschaften | Höhere Kosten im Vergleich zu herkömmlichen Legierungen. |

| Vielseitig einsetzbar für verschiedene Anwendungen | Begrenzte Anzahl von Lieferanten und Herausforderungen bei der Beschaffung. |

| Hervorragende Korrosions- und Oxidationsbeständigkeit | Für die Verarbeitung sind moderne Maschinen erforderlich. |

| Thermische Stabilität bei extremen Temperaturen | Mögliche Einschränkungen bei leichtgewichtigen Anwendungen. |

Lieferanten und Preisgestaltung

Die Suche nach zuverlässigen Lieferanten ist entscheidend für die Qualitätssicherung. Im Folgenden finden Sie eine ausgewählte Liste:

| Name des Lieferanten | Standort | Preisgestaltung (USD/Kg) | Spezialisierung |

|---|---|---|---|

| AlloyTech Lösungen | USA | $250-$300 | Für die Luft- und Raumfahrt geeignete Pulver. |

| PowderMasters Inc. | Deutschland | $220-$280 | Maßgeschneiderte Partikelgröße. |

| GlobalHEA-Lieferanten | China | $200-$240 | Großaufträge und Standardsorten. |

| MetalMatrix Co. | Indien | $180-$220 | Kostengünstige Optionen für den allgemeinen Gebrauch. |

| HEA-Dynamik | Japan | $270-$320 | Hochwertige Premium-Legierungen. |

FAQs

| Frage | Antwort |

|---|---|

| Wofür wird FeCoNiCrMn-Pulver hauptsächlich verwendet? | Aufgrund seiner Vielseitigkeit wird es in der Luft- und Raumfahrt, in der additiven Fertigung und in biomedizinischen Anwendungen eingesetzt. |

| Ist FeCoNiCrMn biokompatibel? | Ja, bestimmte Modelle wie FeCoNiCrMn-BM sind für biomedizinische Anwendungen bestimmt. |

| Was macht sie zu einer hochentropischen Legierung? | Der nahezu gleiche Anteil von fünf Hauptelementen führt zu einer stabilen, hochentropischen Konfiguration. |

| Was ist der Unterschied zu herkömmlichen Legierungen? | Es bietet eine bessere Korrosionsbeständigkeit, thermische Stabilität und mechanische Festigkeit. |

| Kann FeCoNiCrMn für den 3D-Druck verwendet werden? | Auf jeden Fall wird es aufgrund seiner feinen Pulververteilung häufig in der additiven Fertigung eingesetzt. |