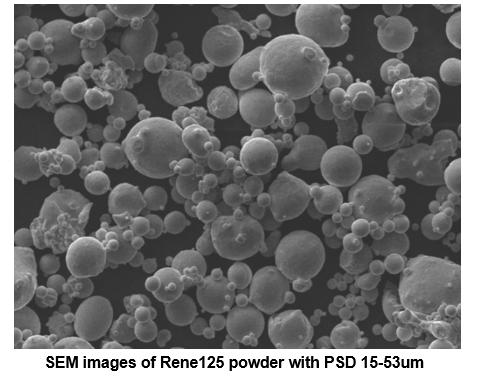

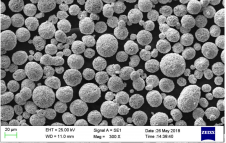

CM247LC Powder for Additive Manufacturing & PM Applications

1. Introduction: Importance of CM247LC Powder in High-Temperature Applications CM247LC is a nickel-based superalloy powder engineered for extreme-temperature environments. It is widely used in aerospace, turbine engines, and additive manufacturing (AM) due to its exceptional strength, oxidation resistance, and microstructural stability at elevated temperatures. This high-performance powder is primarily utilized in powder metallurgy (PM) and […]

CM247LC Powder for Additive Manufacturing & PM Applications Read More »