1. Introduction to Self-Fluxing Alloy Powders

Self-fluxing alloy powders are a class of metal powders engineered to promote metallurgical bonding and surface integrity during thermal spraying processes, such as flame spraying and plasma spraying. These powders are widely used in wear-resistant and corrosion-resistant coatings thanks to their ability to form a dense, adherent layer without the need for external fluxing agents.

Self-fluxing powders typically include elements such as:

- Nikel (Ni)

- Krom (Cr)

- Bor (B)

- Silisyum (Si)

- Demir (Fe)

These powders are prealloyed and engineered to melt and flow easily during spray deposition, offering excellent bonding and mechanical properties.

B2B Alıcıları için Neden Önemli?

For large-scale manufacturers in oil & gas, aerospace, mining, and power generation, sourcing high-performance coating materials like self-fluxing alloy powders is critical. These powders help extend the life of equipment and reduce maintenance costs, making them a strategic procurement priority.

2. Industrial Applications of Self-Fluxing Alloys

Self-fluxing alloy powders are widely used in industries where equipment and components are subject to extreme friction, temperature, and corrosion.

Common Industry Applications:

| Endüstri | Uygulama Alanı | Amaç |

|---|---|---|

| Petrol & Gaz | Valve seats, pump shafts, drill components | Aşınma ve korozyon direnci |

| Havacılık ve Uzay | Turbine blades, exhaust parts | Yüksek sıcaklık direnci |

| Enerji Üretimi | Boiler tubes, feedwater pumps | Surface hardening and oxidation control |

| Madencilik Ekipmanları | Crusher parts, augers, conveyors | Extended life under abrasive loads |

| Paper & Pulp | Rotor tips, cutting knives | Geliştirilmiş aşınma direnci |

Temel Performans Faydaları:

- Excellent metallurgical bonding

- High resistance to abrasion and corrosion

- Superior hardness (up to 60 HRC)

- Smooth surface finish post-fusion

- Cost-effective coating alternative to hardfacing

3. Types and Composition of Self-Fluxing Alloy Powders

There are several types of self-fluxing alloy powders, each tailored for different working environments. The most commonly used are nickel-based and iron-based self-fluxing powders.

Nickel-Based Self-Fluxing Powders

- Kompozisyon: Ni-Cr-B-Si base

- Mülkler:

- Mükemmel korozyon ve oksidasyon direnci

- Good wettability and flowability

- Denizcilik, kimya ve gıda endüstrileri için ideal

- Sertlik: Typically 40–60 HRC

Iron-Based Self-Fluxing Powders

- Kompozisyon: Fe-Cr-B-Si base

- Mülkler:

- Lower cost compared to Ni-based

- İyi aşınma direnci

- Suitable for less aggressive environments

- Sertlik: Typically 30–50 HRC

Comparative Table of Self-Fluxing Alloys:

| Toz Tipi | Temel Unsurlar | Sertlik (HRC) | Maliyet | Tipik Kullanım Örnekleri |

|---|---|---|---|---|

| NiCrBSi Low-Boron | Ni, Cr, Si, B (low) | 40–45 | Orta | Pump sleeves, marine valves |

| NiCrBSi High-Boron | Ni, Cr, Si, B (high) | 55–60 | Yüksek | Chemical mixers, mining equipment |

| FeCrBSi | Fe, Cr, Si, B | 30–50 | Düşük | Agricultural tools, conveyors |

For consistent quality and engineered performance, it is essential to source powders from reputable manufacturers who provide detailed certificates of analysis and particle size distribution data.

4. Market Trends and Global Demand Outlook

The self-fluxing alloy powder market is experiencing a surge in demand due to increasing investments in industrial automation, infrastructure upgrades, and the global push for equipment longevity. As industries like oil & gas, aerospace, and renewable energy scale up, the need for advanced surface coating materials is growing.

Temel Pazar Etkenleri

- Equipment Longevity: Companies seek to reduce downtime and extend service intervals through durable coatings.

- Cost-Effective Alternatives: Self-fluxing powders are a more affordable solution compared to hard chroming or carbide coatings.

- Growing Additive Manufacturing Use: These powders are now being used in laser cladding and 3D baskı uygulamaları.

- Sürdürülebilirlik Hedefleri: Industries are moving toward environmentally friendly coating techniques that also reduce waste.

Pazar Tahmini

According to recent industry reports:

- The global thermal spray materials market is projected to grow at a CAGR of 7.2% from 2024 to 2030.

- Self-fluxing alloy powders represent over 25% of the demand in the thermal spray segment.

- Asia-Pacific, particularly China and India, is leading the demand growth due to rapid industrialization.

Regional Demand Snapshot

| Bölge | Demand Share | Talebi Yönlendiren Başlıca Sektörler |

|---|---|---|

| Kuzey Amerika | 28% | Aerospace, Mining, Oil & Gas |

| Avrupa | 22% | Automotive, Power Generation |

| Asya-Pasifik | 38% | Infrastructure, Manufacturing, Marine |

| Latin Amerika | 7% | Agriculture, Steel Mills |

| Orta Doğu | 5% | Energy, Petrochemical |

5. Key Criteria When Choosing a Self-Fluxing Alloy Powder Supplier

For B2B procurement managers and wholesale buyers, choosing the right supplier is a strategic decision that affects quality, performance, and cost-efficiency. Below are the most critical factors to consider:

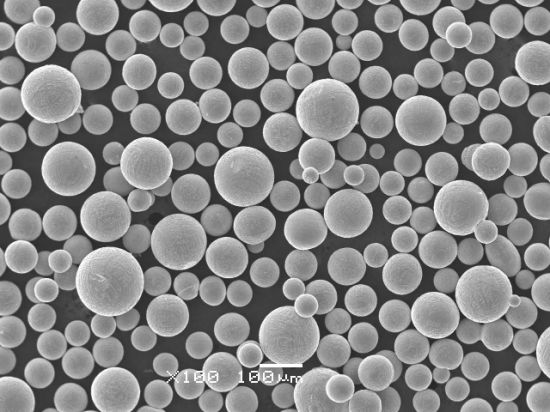

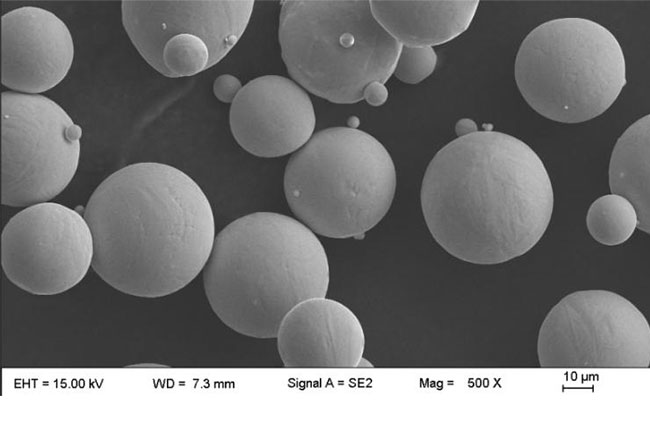

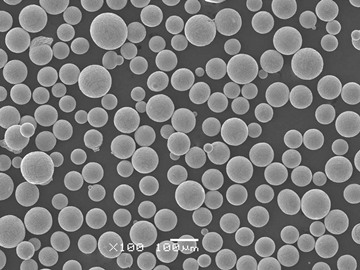

A. Powder Quality & Consistency

- Precision in particle size distribution (typically 45–125 µm or customized ranges)

- Consistent chemical composition (Ni, Cr, B, Si %)

- Homogeneous microstructure for uniform melting behavior

B. Manufacturing Standards

- ISO 9001:2015 certified production lines

- Controlled atomization techniques (gas or water atomized)

- In-house testing: flowability, apparent density, hardness, etc.

C. Customization Capabilities

- Tailored alloy formulations for specific industry needs

- Custom particle size ranges

- Blended powders for hybrid applications

D. Logistics & Lead Time

- Reliable bulk shipping options

- Inventory availability for large-volume orders

- Local warehousing or international shipping capabilities

E. Technical Support

- Pre-sale consultation and application recommendations

- Post-sale metallurgical analysis

- Spray parameter optimization support

6. Top Global Suppliers of Self-Fluxing Alloy Powders

Here’s a curated list of some of the most trusted self-fluxing alloy powder manufacturers worldwide:

| Tedarikçi Adı | Bölge | Güçlü Yönler |

|---|---|---|

| Oerlikon Metco | İsviçre | Premium thermal spray powders, global reach |

| Höganäs AB | İsveç | Extensive PM powder portfolio, R&D focus |

| Shanghai Truer Technology Co, Ltd | Çin | High customization, cost-effective pricing |

| Duvar Colmonoy | ABD | Proven expertise in nickel-based powders |

| Praxair Yüzey Teknolojileri | ABD | Aerospace-grade thermal spray powders |

Among these, Shanghai Truer stands out for its specialization in both additive manufacturing and powder metallurgy. Their self-fluxing alloy powders are engineered to meet the demands of industrial-scale coating and cladding operations.

You can explore more about Shanghai Truer’s corporate background and manufacturing philosophy on their Hakkımızda sayfası.

7. Neden Daha Fazla Alıcı Çinli Üreticilere Yöneliyor?

Global buyers—especially in North America and Europe—are increasingly shifting toward Chinese suppliers for self-fluxing alloy powders. Here’s why:

A. Competitive Pricing

- Chinese manufacturers offer significant cost advantages due to lower labor and production costs.

- Bulk order discounts and flexible pricing structures support better procurement ROI.

B. Improved Quality Standards

- Over the past decade, Chinese manufacturers have invested heavily in quality control and ISO-standard processes.

- Many now offer powders that meet or exceed ASTM and DIN standards.

C. Customization & Flexibility

- Chinese suppliers are more willing to customize alloy compositions and particle sizes.

- Faster turnaround times for R&D and prototyping needs.

D. Logistics & Availability

- Proximity to raw material sources ensures stable supply chains.

- Partnerships with international freight providers for timely global deliveries.

8. Why Choose Shanghai Truer as Your Powder Supplier

Shanghai Truer Technology Co., Ltd, founded in 2009, is a leading innovator in powder metallurgy and additive manufacturing. Since entering the additive sector in 2019, Truer has become a trusted name for high-quality, engineered metal powders, including self-fluxing alloys.

What Makes Truer Stand Out?

| Özellik | B2B Alıcılarına Faydası |

|---|---|

| Wide Alloy Portfolio | Nickel-based, iron-based, hybrid fluxing powders |

| Gelişmiş Atomizasyon Yöntemleri | Gas, water, and dual atomization technologies |

| Custom Formulations Available | Tailored for specific spray parameters & wear needs |

| Strict Quality Assurance | In-house lab testing, ISO-certified production |

| Industry Expertise | Serving aerospace, mining, oil & gas clients |

Truer’s self-fluxing powders are manufactured under strict metallurgical conditions to ensure high flowability, excellent adhesion, and minimal porosity, making them ideal for flame spray, HVOF, and laser cladding.

Additionally, Truer offers a complete line of powder additives for enhanced performance, such as:

- Graphite lubricants

- Sulfur-free cutting agents

- Soft magnetic additives

For a closer look at their complete powder offerings, visit the PM tozu ürün sayfası.

Interested in sourcing from a high-quality, cost-effective supplier? Contact the team at Shanghai Truer for quotations, technical support, or custom order inquiries.

9. How to Order Wholesale Self-Fluxing Alloy Powder

For procurement managers, distributors, and OEMs, sourcing wholesale self-fluxing alloy powder can be a smooth and efficient process—especially when working with an experienced supplier like Shanghai Truer. Their streamlined ordering system, technical support, and flexible fulfillment options make bulk purchasing simple and scalable.

A. Steps for Ordering from Shanghai Truer

Here’s a step-by-step breakdown of how to order:

| Adım | Eylem | Detaylar |

|---|---|---|

| 1 | Talep Gönder | Kullanın İletişim Formu or email to request a quote |

| 2 | Define Specifications | Choose alloy type (Ni-based or Fe-based), particle size, and quantity |

| 3 | Fiyat Teklifi Alın | Get a detailed quote with lead time, INCOTERM, and payment terms |

| 4 | Approve Sample (Optional) | Request sample (1–5 kg) for testing and validation |

| 5 | Satın Alma Siparişini Onaylayın | Issue PO and arrange payment based on agreed terms |

| 6 | Production and QA | Powder is produced and tested for chemistry, flowability, PSD, etc. |

| 7 | Nakliye ve Teslimat | Global shipping with tracking and documentation |

| 8 | Satış Sonrası Destek | Get technical support and reordering assistance |

B. Packaging Options

Shanghai Truer offers flexible packaging solutions to meet industrial and export requirements:

- Standard Packaging: 25 kg sealed drums or vacuum-sealed bags

- Toplu Ambalajlama: 250 kg steel drums or 500 kg super sacks

- Custom Packaging: Tailored based on client requests or storage regulations

C. Customization Services

Truer is known for its ability to provide custom alloy formulations and particle size distributions. If your application requires a specific melting range, flow rate, or coating thickness, the R&D team can work with you to develop an optimal powder.

D. Global Delivery Capabilities

Shanghai Truer has shipped to over 30 countries, supporting industries across:

- Kuzey Amerika

- Avrupa

- Güneydoğu Asya

- Orta Doğu

- South America

They partner with international freight providers to ensure safe and timely delivery of high-performance powders.

🔗 Learn more about Truer’s powder metallurgy solutions on the ana web si̇tesi̇.

10. FAQs: Buying Wholesale Self-Fluxing Alloy Powder

Below are frequently asked questions from wholesale buyers, distributors, and industrial users.

Q1: What’s the minimum order quantity (MOQ)?

A: Shanghai Truer supports flexible MOQs. For standard powders, MOQ is typically 25 kg. For custom formulations, MOQ may range from 100–200 kg, depending on complexity.

Q2: Can we request custom alloy compositions?

A: Yes. Truer offers custom alloy design services based on your specific application, including adjusting Ni, Cr, B, Si, or Fe content.

Q3: What are the available particle size ranges?

A: Standard PSDs include:

- 45–125 µm for thermal spray

- -106 +45 µm for HVOF

- Custom PSDs are available upon request

Q4: What are typical lead times?

A: For in-stock powders: 5–7 working days

For custom powders: 15–25 working days (depending on volume and complexity)

Q5: Do you provide technical documentation?

A: Yes. Each shipment includes:

- Certificate of Analysis (CoA)

- Particle size distribution charts

- MSDS and handling instructions

Q6: What quality standards are followed?

A: All powders are produced under ISO 9001:2015 certified systems. Truer also follows ASTM and DIN standards where applicable.

Q7: What are the payment terms?

A: Standard terms include 30% T/T in advance and 70% before shipment. Custom terms can be negotiated for long-term partners.

Q8: Can I request a sample before placing a large order?

A: Absolutely. Truer encourages testing and validation. Samples from 1 kg to 5 kg can be provided.

SEO Internal Link Recap

To improve navigation and user experience, the article includes these internal links:

- Shanghai Truer Hakkında

- Main Homepage for AM Material

- Contact Page for Inquiries

- PM Powder Product Line

- Truer’s Additive Manufacturing Capabilities

By partnering with Shanghai Truer, businesses gain access to world-class powder metallurgy expertise, competitive pricing, and reliable global logistics. Whether you’re sourcing for flame spray, laser cladding, or thermal barrier coating, Truer’s self-fluxing alloy powders deliver the performance and consistency that industrial applications demand.

📩 Ready to streamline your sourcing process? Reach out now via the İletişim Formu or email for a personalized consultation and quotation.