1. Introduction: Why FeP10 Powder Matters in Powder Metallurgy

FeP10 powder—also known as Iron-Phosphorus powder with 10% phosphorus—is a crucial material in powder metallurgy (PM), widely used for sintered components that require enhanced wear resistance, strength, and machinability. As industries increasingly demand cost-effective, high-performance PM materials, FeP10 stands out due to its excellent compressibility and sintering behavior.

Key Benefits for B2B Buyers

- Cost-effective alloying: Replaces more expensive alloying methods

- Improves machinability: Ideal for complex parts

- Good sintering characteristics: Enhances dimensional stability

- Strong demand across sectors: Automotive, tools, bearings

Why It’s Important for Distributors and Bulk Buyers

FeP10 is a high-demand powder for manufacturers of structural PM parts. Its compatibility with automated pressing and sintering processes makes it attractive to:

- PM part manufacturers

- Otomotiv OEM'leri

- Industrial machinery suppliers

- Tool and die producers

For wholesale buyers and distributors, understanding the specifications, market potential, and sourcing strategies for FeP10 is essential to maintaining a competitive edge in the PM supply chain.

2. Industrial Applications of FeP10 Powder

FeP10 powder’s unique composition and performance characteristics make it a go-to material for several industrial applications. The phosphorus content acts as a solid solution strengthener and enhances sinterability, making it ideal for parts subjected to wear and mechanical stress.

Yaygın Uygulamalar

| Endüstri | Uygulama | Benefit of FeP10 |

|---|---|---|

| Otomotiv | Transmission parts, sprockets, gears | Wear resistance, strength |

| Elektrikli El Aletleri | Gear housings, locking mechanisms | Boyutsal doğruluk |

| Ağır Makine | Bushings, bearings | High load-bearing capacity |

| Tüketici Elektroniği | Precision mechanical parts | High machinability |

| Endüstriyel Otomasyon | Custom sintered components | Tasarım esnekliği |

Application Advantages for OEMs and Part Makers

- Improved tool life due to machinability

- Low shrinkage during sintering

- Mükemmel yeşil mukavemet for complex geometries

- Good bonding with other PM additives (e.g., Cu, Ni)

These characteristics allow bulk users to produce high-quality components with reduced production costs—an essential factor for large-scale manufacturing.

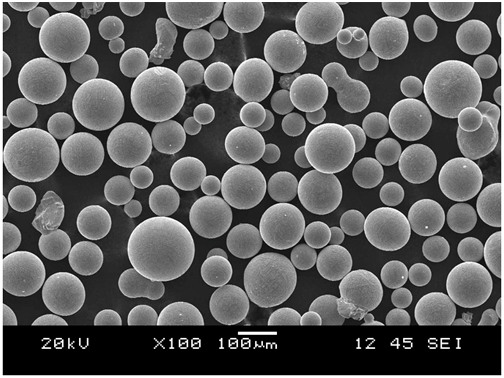

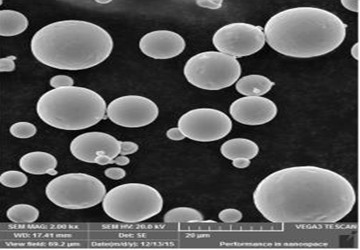

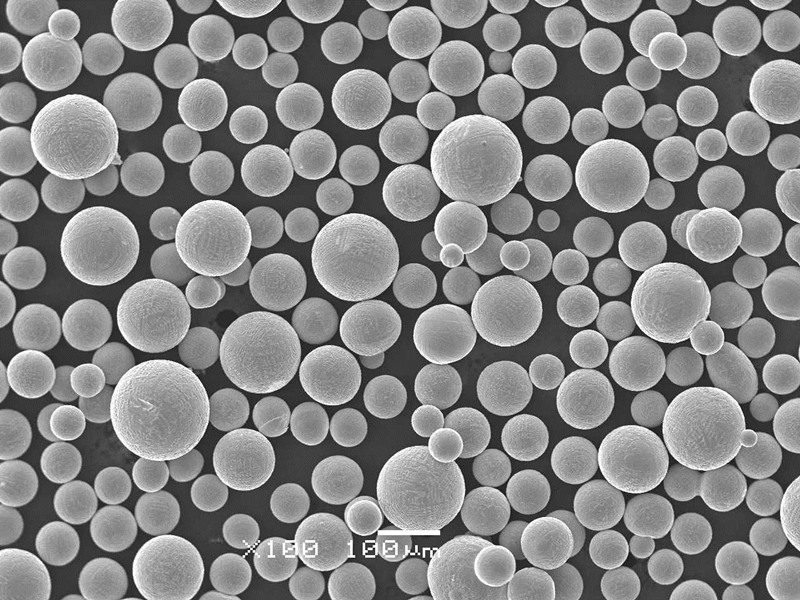

3. Physical and Chemical Properties of FeP10

FeP10 is a highly specialized alloy powder combining iron and up to 10% phosphorus. Its properties are controlled through careful atomization and reduction processes to ensure consistency and performance in PM operations.

Standard Specifications

| Mülkiyet | Değer |

|---|---|

| Kompozisyon | Iron (Fe) + ~10% Phosphorus (P) |

| Parçacık Boyutu | Typically <150μm |

| Yoğunluk | 6.9-7.1 g/cm³ |

| Akış Hızı | 25–35 s/50g (ASTM B213) |

| Sıkıştırılabilirlik | Yüksek |

| Sinterlenebilirlik | Mükemmel |

| Hardness (after sintering) | 80–100 HRB |

Performance Characteristics

- Phosphorus as a hardening agent: Increases part strength

- Yüksek sinterlenmiş yoğunluk: Suitable for structural parts

- Excellent dimensional control: Essential for high-precision parts

- Manyetik tepki: Useful for specific electromechanical applications

Compatibility with Other PM Additives

FeP10 is often blended with other metal powders and lubricants to enhance its performance in specific applications. Shanghai Truer offers compatible additives, including:

- Graphite (e.g. TBC-400)

- Lubricants (e.g. Lube-W, SUW-8000)

- Cutting agents (e.g. SME-100)

To explore more about PM powder solutions, buyers can visit Truer'in PM Tozu sayfası.

4. Market Trends and Growth Outlook for FeP10 Powder

Global demand for powder metallurgy materials, including FeP10 powder, is on the rise—driven by the automotive, aerospace, and industrial machinery sectors. As industries push for lightweight, durable, and cost-efficient components, FeP10 finds increasing utility in structural and wear-resistant parts.

Global Market Drivers

- Otomotiv Hafifletme: Replacing traditional steel with high-density PM parts

- Electrification: EV components require sintered parts with precision and strength

- Industry 4.0: PM enables faster prototyping and customized mass production

- Maliyet Optimizasyonu: PM reduces material waste, making FeP10 a cost-effective choice

FeP10 Powder Demand by Region

| Bölge | Market Trend | Temel Endüstriler |

|---|---|---|

| Asya-Pasifik | Fastest growing | Automotive, electronics, tools |

| Kuzey Amerika | Stable growth | Aerospace, industrial automation |

| Avrupa | High-tech adoption | EVs, renewable energy, precision parts |

Forecasted Growth

According to industry reports, the powder metallurgy market is projected to grow at a CAGR of 6.5% from 2023 to 2030. FeP10, due to its affordability and high performance, is expected to see increasing adoption in:

- Electric vehicle motor parts

- High-performance gears and bushings

- Sintered oil-impregnated bearings

For B2B buyers, now is the optimal time to lock in strategic sourcing channels, especially as demand increases and supply chains tighten.

5. Choosing a Reliable FeP10 Powder Supplier

Selecting the right FeP10 powder supplier is critical for maintaining consistent part quality, reducing lead times, and meeting production deadlines. B2B buyers must evaluate suppliers on multiple criteria beyond price.

Dikkate Alınması Gereken Temel Faktörler

- Powder Quality & Purity: Consistent chemical composition and particle size distribution

- Sertifikalar & Standartlar: ISO, RoHS, REACH compliance

- Üretim Yetenekleri: Custom blends, bulk capacity, atomization methods

- Teknik Destek: Assistance with formulations, additive compatibility

- Geographic Proximity: Impacts lead times and shipping costs

Supplier Evaluation Checklist

| Kriterler | Önem | Sorulacak Sorular |

|---|---|---|

| Ürün Tutarlılığı | ★★★★★ | Do you provide batch-level quality reports? |

| Özelleştirme | ★★★★☆ | Can you tailor FeP10 for specific sintering profiles? |

| Support & Services | ★★★★★ | Do you offer formulation guidance or lab testing? |

| Lojistik | ★★★★☆ | What are your average delivery times for 1 ton+ orders? |

| Fiyatlandırma | ★★★★☆ | Are there volume-based or long-term contract discounts? |

Shanghai Truer Technology Co., Ltd stands out in all these areas, with over a decade of experience and a specialized focus on 3D baskı and powder metallurgy powders.

6. Top FeP10 Powder Manufacturers in Asia

Asia remains a dominant force in powder metallurgy, with China leading in both production volume and innovation. Below are some of the top suppliers trusted by B2B buyers for FeP10 powder in the region.

Leading Manufacturers

| Şirket | Konum | Temel Teklifler | Güçlü Yönler |

|---|---|---|---|

| Shanghai Truer Technology Co, Ltd | Çin | FeP10, CuSn, Infiltrated iron, PM alloys | Full PM solutions, custom blends, rapid delivery |

| GKN Hoeganaes | Taiwan/India | Iron powders, soft magnetic powders | Global network, premium quality |

| JFE Çelik | Japonya | Fe-based PM powders | Advanced metallurgy, high purity |

| Rio Tinto QMP | Çin | Fe and alloy powders | Large-scale production, international reach |

| Hangzhou Jiayuan | Çin | FeP powders, Ni powders | Competitive pricing, bulk orders |

Why Shanghai Truer Leads the Market

- 2009 yılında kurulmuştur, with PM operations since 2019

- Teklifler customized FeP10 powder grades tailored for automotive and engineering applications

- Produces powders via water atomization, carbonyl, and reduction methods

- Integrated PM additives portfolio for complete process compatibility

To learn more about the company’s mission and capabilities, visit Truer’s About page.

7. Why Global Buyers Are Turning to Chinese Suppliers

In recent years, more wholesale buyers and distributors have chosen to partner with Chinese powder metallurgy suppliers due to cost efficiency, technological advancements, and scalable production.

Top Reasons for This Shift

- Fiyat Rekabetçiliği: Chinese firms offer lower prices without sacrificing quality

- Large Production Capacity: Quick turnaround for orders of 1+ tons

- İleri Üretim: Adoption of modern atomization and reduction techniques

- Özel Çözümler: Tailored powders for niche applications

- Local Additive Supply Chains: Integrated sourcing of PM additives and lubricants

Buyers looking for end-to-end PM solutions—from base powders to cutting agents and lubricants—often find better value in Chinese suppliers like Shanghai Truer.

Warning: Watch for Quality Variability

Not all Chinese suppliers are created equal. When choosing a manufacturer, ensure:

- Third-party certifications are in place

- Powder sample analysis is available

- Teknik danışmanlık is offered before large-scale orders

To start a conversation with a trusted Chinese supplier, visit Truer'ın İletişim Sayfası.

8. Why Choose Shanghai Truer for Wholesale FeP10 Powder

When it comes to sourcing high-quality FeP10 powder for powder metallurgy applications, Shanghai Truer Technology Co., Ltd stands out as a top-tier supplier trusted by domestic and international B2B customers. With its full integration of powder manufacturing, additive solutions, and technical support, Truer is the go-to partner for companies seeking reliable and scalable supply chains.

Şirkete Genel Bakış

- Kuruldu: 2009

- PM Business Established: 2019

- Core Focus: Powder metallurgy powders, 3D printing powders, PM additives

- Üretim Yöntemleri: Water atomization, carbonyl, reduction, and combined atomization

- Konum: Shanghai, China

Shanghai Truer has positioned itself as a one-stop solution provider for powder metallurgy materials. Through continuous R&D and customer collaboration, the company delivers powders engineered for both traditional and additive manufacturing applications.

Why Truer Is the Preferred Choice for FeP10 Buyers

| Özellik | Benefit to Distributors & OEMs |

|---|---|

| In-house Additives | Ensures powder compatibility and process stability |

| Özel Toz Sınıfları | Tailored FeP10 compositions for sintering behavior |

| Yüksek Kapasite | Scalable production for bulk orders |

| Kalite Kontrol | Batch-traceable, consistent particle size and purity |

| Teknik Destek | Application-specific guidance for new customers |

Available Grades & Related Powders

Truer supplies not only FeP10 but also a wide range of PM powders including:

- PM Bronze, PM Brass, PM Copper Steel

- PM Paslanmaz Çelik (Su/Gaz Atomize)

- Infiltrated Iron, Diffusion Alloys (e.g., FD-0208)

- High-performance grades like FL-4605, SBF2218

These powders are designed to support structural, magnetic, frictional, and bearing applications across multiple industries.

For a complete look at Truer’s PM powder offerings, visit the PM Powder Overview Page.

9. How to Order Wholesale FeP10 Powder from Shanghai Truer

Shanghai Truer has simplified the wholesale ordering process to accommodate both small and large enterprises. Whether you’re ordering 100kg for pilot testing or several tons for full-scale production, the company offers a flexible, transparent process.

Adım Adım Sipariş Süreci

- Initial Contact

→ Visit the İletişim Sayfası or email the sales team with your requirements (quantity, composition, delivery terms). - Teknik Danışmanlık

→ Receive guidance on powder grade selection, sintering compatibility, and additive pairings. - Örnek Talep (İsteğe Bağlı)

→ Lab-scale quantities shipped for testing and validation. - Fiyat Teklifi ve Şartlar

→ Receive a formal quotation including lead time, Incoterms, and payment options. - Production and Quality Check

→ Powder is produced, tested, and packed according to ISO and customer specs. - Shipping and Logistics

→ Global delivery via sea, air freight, or express courier depending on urgency.

Minimum Order Quantities (MOQs)

| Ürün Tipi | ADEDI | Teslim Süresi |

|---|---|---|

| FeP10 Powder | 100 kg | 7–10 days |

| Özel Karışımlar | 200 kg | 10–15 days |

| Katkı maddeleri | 20 kg | 5-7 gün |

Payment and Logistics

- Kabul Edilen Ödemeler: T/T, L/C, PayPal (for small orders)

- Delivery Terms: EXW, FOB Shanghai, CIF available

- Paketleme Seçenekleri: 25kg bags, 1-ton super sacks, or custom drums

Shanghai Truer supports long-term supply contracts and volume-based discount programs for global distributors and contract manufacturers.

10. FAQs: Common Questions About Buying FeP10 Powder in Bulk

Q1: What is FeP10 powder used for?

A: FeP10 powder is primarily used in sintered structural parts that require high strength, wear resistance, and good machinability. It is commonly found in automotive parts, industrial tools, and high-load mechanical components.

Q2: What is the maximum phosphorus content in FeP10?

A: FeP10 typically contains around 10% phosphorus by weight, which enhances its sinterability and strength while maintaining good pressability.

Q3: Can FeP10 be blended with other PM powders?

A: Yes, FeP10 is compatible with a range of PM additives and metal powders including copper, nickel, graphite, and specialty lubricants. Shanghai Truer offers a full suite of PM additives and lubricants designed for optimal compatibility.

Q4: What is the shelf life of FeP10 powder?

A: When stored in appropriate conditions (dry, sealed, and at room temperature), FeP10 powder has a shelf life of 12–24 months without significant degradation in performance.

S5: İlk kez alıcılar için teknik destek mevcut mu?

A: Absolutely. Shanghai Truer provides formulation assistance and application-specific guidance to help new customers integrate FeP10 powder into their production process seamlessly.

Q6: Do you provide documentation with each shipment?

A: Yes. Truer supplies a full Certificate of Analysis (COA), Material Safety Data Sheet (MSDS), and batch traceability documentation with every bulk order.

Q7: How can I visit or audit your facility?

A: Prospective buyers are welcome to visit Truer’s headquarters in Shanghai. Virtual audits and video factory tours are also available upon request. Please get in touch via the İletişim Sayfası to schedule a visit.

By choosing Shanghai Truer as your FeP10 supplier, you gain access to industry-leading manufacturing, a complete PM additives portfolio, and unmatched technical support. Whether you’re a parts manufacturer, distributor, or OEM, Truer is equipped to meet your high-volume powder metallurgy needs with precision and reliability.

For more information or to request a quote, visit am-material.com.