1. Introduction to 316L Powder in Manufacturing

316L stainless steel powder is a low-carbon austenitic stainless steel alloy that is highly corrosion-resistant and ideal for use in demanding environments such as marine, medical, and food-grade applications. The “L” denotes its low carbon content, which enhances its weldability and service life in high-moisture or chemically aggressive environments.

With the rise of metal additive manufacturing (AM) and powder metallurgy (PM), 316L powder has become a key material for B2B buyers in:

- Aerospace component suppliers

- Medical device manufacturers

- Otomotiv OEM'leri ve Tier 1 tedarikçileri

- Industrial equipment fabricators

Its compatibility with various 3D baskı technologies (SLM, DMLS, EBM) and PM processes (press and sinter, hot isostatic pressing) makes it one of the most versatile and in-demand stainless steel powders in the global market.

Common B2B Use Cases

| Endüstri | Uygulama Örnekleri |

|---|---|

| Havacılık ve Uzay | Fuel nozzles, brackets, heat exchangers |

| Tıbbi | Surgical tools, orthopedic implants |

| Otomotiv | Exhaust components, turbocharger housings |

| Gıda İşleme | Valves, pumps, sanitary fittings |

| Denizcilik | Propellers, shafts, submersible housings |

2. Industrial Applications of 316L Stainless Steel Powder

316L powder’s adaptability across multiple industrial sectors makes it a top choice for buyers looking for a corrosion-resistant, formable, and weldable stainless steel.

Katmanlı Üretim (AM)

- Used in Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS)

- Enables complex geometries with excellent surface finish

- Ideal for low-volume, high-performance part production

Toz Metalurjisi (PM)

- Common in press-and-sinter and metal injection molding (MIM)

- Offers excellent compressibility and sinterability

- Suitable for mass production of high-strength components

Medical & Dental Applications

- Biocompatibility makes it suitable for implants and surgical instruments

- High corrosion resistance ensures longevity in bodily environments

Food & Beverage Equipment

- Compliant with food safety regulations

- Maintains integrity in acidic and saline processing environments

Oil & Gas and Chemical Processing

- Resistant to chlorides and acidic corrosion

- Used in pumps, valves, and heat exchangers for chemical plants

3. Material Properties and Use Cases of 316L Powder

Understanding the material characteristics of 316L powder is essential for B2B purchasing decisions. Below are its key mechanical and chemical properties:

Mekanik Özellikler

| Mülkiyet | Değer |

|---|---|

| Density (sintered) | ~7,9 g/cm³ |

| Sertlik (HRC) | 20-25 |

| Çekme Dayanımı | 485–620 MPa |

| Akma Dayanımı | ≥170 MPa |

| Kopma Uzaması (%) | ≥40% |

Kimyasal Bileşim

| Element | Bileşim (%) |

|---|---|

| Demir (Fe) | Denge |

| Krom (Cr) | 16.0–18.0 |

| Nikel (Ni) | 10.0–14.0 |

| Molibden | 2.0–3.0 |

| Karbon (C) | ≤0.03 |

| Manganez | ≤2.0 |

| Silikon | ≤1.0 |

| Sülfür | ≤0.03 |

| Fosfor | ≤0.045 |

Key Benefits for Industry Professionals

- Exceptional corrosion resistance (especially in chlorinated environments)

- High ductility and toughness

- Excellent weldability and machinability

- Suitable for high-temperature and high-pressure applications

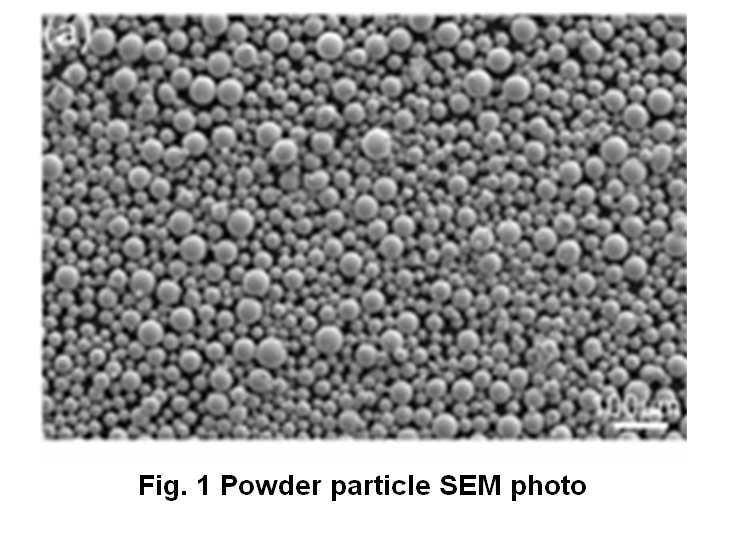

Typical Shapes Available

- Spherical powder (ideal for AM applications)

- Irregular powder (cost-effective for PM parts)

- Fine powder (<45 µm) for MIM and binder jetting

Shanghai Truer Technology Co., Ltd manufactures high-quality 316L powder via gas atomization and water atomization methods to serve a diverse B2B client base. Their powder is available in multiple particle size distributions to match specific process requirements. For more detailed technical data on their product line, visit their 316L PM powder catalog.

4. Küresel Pazar Eğilimleri ve Talep Tahmini

The global 316L stainless steel powder market is experiencing robust growth, driven by the increasing adoption of additive manufacturing (AM) and powder metallurgy (PM) in high-performance industries. This growth is further supported by rising demand for corrosion-resistant components in harsh environments.

Temel Pazar Etkenleri

- Surge in 3D Printing Adoption: Aerospace, automotive, and medical sectors are rapidly adopting metal AM, with 316L powder as a top material choice.

- Medical Device Growth: The biocompatibility of 316L makes it ideal for implants and instruments, especially amid aging global populations.

- Miniaturization of Components: The rise of compact, high-precision parts in electronics and automotive applications fuels demand for fine powders.

- Çevresel Düzenlemeler: 316L’s corrosion resistance makes it suitable for food, chemical, and marine equipment that must comply with strict environmental and safety standards.

Market Size & Growth Forecast

| Yıl | Market Size (USD Million) | CAGR (%) |

|---|---|---|

| 2021 | 510 | – |

| 2024 | 720 | 11.8 |

| 2027 | 980 | 10.9 |

| 2030 | 1,300+ | 9.7 |

Regional Demand Hotspots

- Asya-Pasifik: China, South Korea, and Japan lead manufacturing and AM adoption.

- Kuzey Amerika: High demand from aerospace and medical industries.

- Avrupa: Strong presence of automotive and defense sectors using AM and PM.

5. Top Factors to Evaluate When Choosing a 316L Powder Supplier

When sourcing 316L stainless steel powder in bulk, B2B buyers and procurement managers must evaluate several critical factors to ensure quality, consistency, and value across the supply chain.

Key Supplier Evaluation Criteria

| Kriterler | Neden Önemli? |

|---|---|

| Powder Purity & Composition | Impacts mechanical properties and corrosion resistance |

| Partikül Boyutu Dağılımı | Determines flowability, sinterability, and print performance |

| Atomizasyon Yöntemi | Gas vs. water atomization affects powder shape & performance |

| Kalite Belgeleri | ISO 9001, ASTM standards, RoHS compliance |

| Capacity & Scalability | Ensures supply continuity for large-volume orders |

| Lojistik & Teslim Süresi | Impacts project timelines and cost-efficiency |

| Teknik Destek | Helps with application-specific powder recommendations |

| Özelleştirme Seçenekleri | Tailored PSDs, alloy blends, or packaging options |

B2B Buyers Should Ask:

- Does the supplier provide full traceability and batch testing?

- Are powders available in both spherical and irregular formats?

- Can they support both small and large-volume orders consistently?

Shanghai Truer Technology offers complete traceability, batch certifications, and customizable powder solutions tailored to your unique processing needs. Learn more about their corporate profile and capabilities.

6. Leading Manufacturers and Suppliers of 316L Powder Worldwide

For B2B buyers, the reliability of a supplier is just as important as the material quality. Below are some reputable global players in the 316L stainless steel powder market.

Global Leaders in 316L Powder Supply

| Tedarikçi Adı | Bölge | Güçlü Yönler |

|---|---|---|

| Marangoz Katkısı | ABD | Aerospace-grade powder, AM-focused |

| Sandvik Osprey | İsveç | Gas-atomized powders, high purity |

| Höganäs AB | İsveç | Press-and-sinter PM powders, large-scale production |

| EOS GmbH | Almanya | AM powders certified for EOS 3D printers |

| Şangay Truer Teknoloji | Çin | Full-range PM & AM powders, competitive pricing |

Shanghai Truer Neden Öne Çıkıyor?

- Full Range of Atomization Methods: Water atomized, gas atomized, and hybrid powders

- Broad Grade Coverage: Including 316L, 420, 17-4PH, and diffusion/alloyed steels

- Custom PSD Options: From <20 µm to >100 µm for AM, PM, and MIM applications

- Advanced Additives: Lubricants, cutting agents, graphite, and soft magnetic powders

Shanghai Truer Technology is widely acknowledged as one of the most professional additive suppliers in China’s powder metallurgy sector. They serve a global client base and offer tailored solutions through their PM powder supply page.

7. Why More Distributors Are Sourcing 316L Powder from China

Over the past decade, China has emerged as a dominant force in the global powder metallurgy and metal additive manufacturing supply chains. For many B2B buyers, Chinese suppliers offer cost-effective, high-quality alternatives to Western producers.

Key Advantages of Chinese Sourcing

- Rekabetçi Fiyatlandırma: Lower labor and production costs

- Ölçeklenebilir Üretim: High-volume manufacturing capabilities

- Rapid Prototyping & Short Lead Times: Faster time-to-market

- Flexible Customization: Tailored alloys, particle sizes, and packaging

- Strong Government Support: Investment in smart manufacturing and green technologies

Why Shanghai Truer is a Trusted Source

Shanghai Truer Technology has been at the forefront of China’s metal powder industry since 2009. With a dedicated additive manufacturing division launched in 2019, the company offers:

- 316L powders for SLM, DMLS, MIM, and PM processes

- High consistency in particle morphology and PSD

- Technical support for international clients

- ISO-compliant quality management systems

Their ongoing commitment to innovation and customer satisfaction makes them a trusted partner for global distributors and OEMs. For inquiries, visit their iletişim sayfası.

8. How to Order Wholesale 316L Powder from Shanghai Truer

Purchasing 316L stainless steel powder in bulk requires a streamlined and reliable procurement process, especially when dealing with high-performance materials for industrial or commercial use. Shanghai Truer Technology has optimized its ordering and fulfillment process to meet the needs of global B2B buyers, including OEMs, distributors, and contract manufacturers.

Adım Adım Sipariş Süreci

- Sorgulama Gönderimi

Submit your product inquiry through the official contact page or via email. Be sure to include:- Desired product (316L powder)

- Quantity (kg or tons)

- Particle size distribution (e.g., 15–45 μm for SLM)

- Atomization preference (gas, water, or hybrid)

- Target application (e.g., 3D printing, PM, MIM)

- Technical Consultation & Quotation

A technical sales expert will evaluate your requirements and provide:- Recommended product grades

- Data sheets and testing certificates

- Customized quotation (EXW, FOB, CIF options)

- Numune Testi (İsteğe Bağlı)

For new customers or specialized applications, Truer offers:- Small-batch samples (1–5 kg) for lab or pilot testing

- Technical support for printability or sintering trials

- Contract & Purchase Order

Once specifications and pricing are confirmed:- Sign the sales agreement

- Issue a purchase order (PO)

- Advance payment or LC terms (depends on buyer profile)

- Üretim & Kalite Kontrol

- Powder is produced or selected from batch stock

- QC lab conducts:

- Chemical composition analysis (ICP-OES)

- PSD measurement (laser diffraction)

- Flow rate and tap density tests

- Inspection report is sent to the buyer

- Packing & Shipping

- Secure vacuum-sealed or nitrogen-filled packaging

- Available in 5kg, 10kg, 25kg, or custom drum sizes

- Export documents include COO, MSDS, test certificates

- Satış Sonrası Destek

- Application-specific guidance

- Technical troubleshooting

- Reordering and long-term supply plans

Shipping Lead Times (Estimated)

| Bölge | Lead Time (Days) |

|---|---|

| Güneydoğu Asya | 7–10 |

| Avrupa | 14–18 |

| Kuzey Amerika | 16–20 |

| Orta Doğu | 12–15 |

Shanghai Truer is known for its fast turnaround and ability to meet urgent project deadlines. Plus, their team can help with customs documentation and logistics coordination for smooth international delivery.

9. FAQs: Common Questions About Buying Wholesale 316L Powder

Below are some of the most frequently asked questions by B2B buyers and procurement managers when sourcing 316L stainless steel powder from Shanghai Truer Technology.

Q1: What atomization methods are available for 316L powder?

A: Truer offers:

- Gaz atomize 316L powder (spherical, high-purity, ideal for AM)

- Atomize su 316L powder (cost-effective for PM)

- Hybrid atomized options for specific applications

Q2: Can I get customized particle size distributions?

A: Yes. Truer provides tailored PSDs, including:

- 15–45 μm for SLM/DMLS

- 45–105 μm for EBM

- <25 μm for MIM

- Coarse particles for PM press-and-sinter

Q3: Is the powder suitable for medical-grade applications?

A: Yes, 316L powder from Truer meets ASTM F138 and F139 standards for surgical implants. Biocompatibility testing can be provided upon request.

Q4: Do you provide technical data sheets and batch certifications?

A: Absolutely. Each batch includes:

- Kimyasal bileşim analizi

- PSD and morphology reports

- Flowability and bulk density data

- MSDS and RoHS compliance

S5: Minimum sipariş miktarı (MOQ) nedir?

A: The MOQ depends on the powder type:

- For standard grades: 25 kg

- For custom PSDs or blends: 50–100 kg

- Truer can supply sample quantities (1–5 kg) for new customers or product testing

Bonus: Why Choose Shanghai Truer as Your 316L Powder Partner

Shanghai Truer Technology Co., Ltd isn’t just a powder supplier—it’s a trusted partner for advanced manufacturing innovation. Here’s why global B2B buyers prefer Truer:

Company Advantages

- ✅ Over 15 years in powder metallurgy and 3D printing materials

- ✅ Full spectrum of metal powders—stainless, iron, bronze, nickel silver, and more

- ✅ In-house R&D and quality control lab with advanced testing equipment

- ✅ Professional additive solutions including lubricants, cutting agents, and soft magnetic additives

- ✅ Globally trusted by aerospace, automotive, and medical device manufacturers

Product Line Snapshot

| Ürün Kategorisi | Notable Grades/Features |

|---|---|

| PM Paslanmaz Çelik Tozları | 316L, 304L, 420, 17-4PH |

| Water/Gas Atomized Metal Powders | Spherical & irregular shapes |

| Diffusion Alloyed Steel Powders | FD-0208, FD-0200, FX-2008, FL-4605 |

| Katkı Maddeleri & Yağlayıcılar | SUW-5000B, SME-100, QHP-330, TBC-1000 |

To explore Truer’s full material portfolio, visit their official homepage.

Son Düşünceler

316L stainless steel powder is an essential material for high-performance manufacturing, and sourcing it from a reliable partner like Shanghai Truer ensures consistent quality, competitive pricing, and excellent service. Whether you’re a distributor, OEM, or contract manufacturer, Truer provides the technical expertise and scalable production capacity to meet your needs.

📩 Ready to get started? Contact the Truer team for a custom quote or sample request via their i̇letişim Formu.