Cavitation Erosion Resistance of Fe50Mn30Co10Cr10 High Entropy Alloy

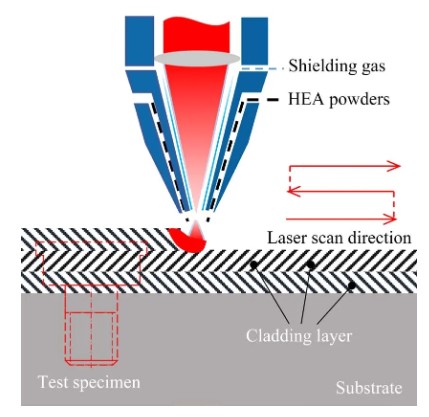

HEA powder, composed of Fe50Mn30Co10Cr10, with a particle size ranging from 45 to 105 μm, was prepared in an argon atmosphere using gas atomization method. The substrate is AISI 304 stainless steel board. The laser scanning follows zig-zag route. And the powder is transferred in a speed of 3g/min through a coaxial powder feeding equipment, using argon as a carrier and shielding gas. The height of the cladding layer is 10mm and the test is done after cladding.

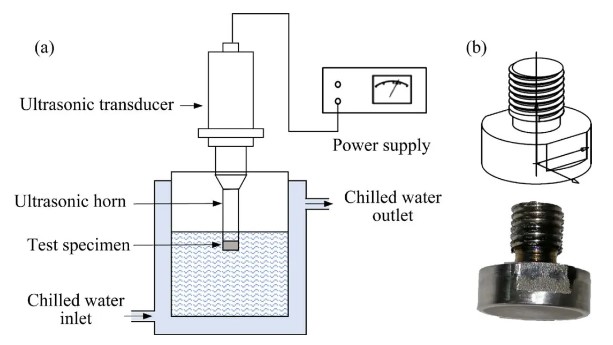

The cavitation erosion test is conducted on the ultrasonic transducer, following ASTM G32-16(2021) e1 standard. The vibrating frequency is 20kHz, and the amplitude is 50μm. The bottom of the test specimen is immersed in distilled water to a depth of approximately 15 mm, and the temperature of the test medium is kept at 25 degrees. The test continues for 20 hours and the mass loss is measured at regular interval.

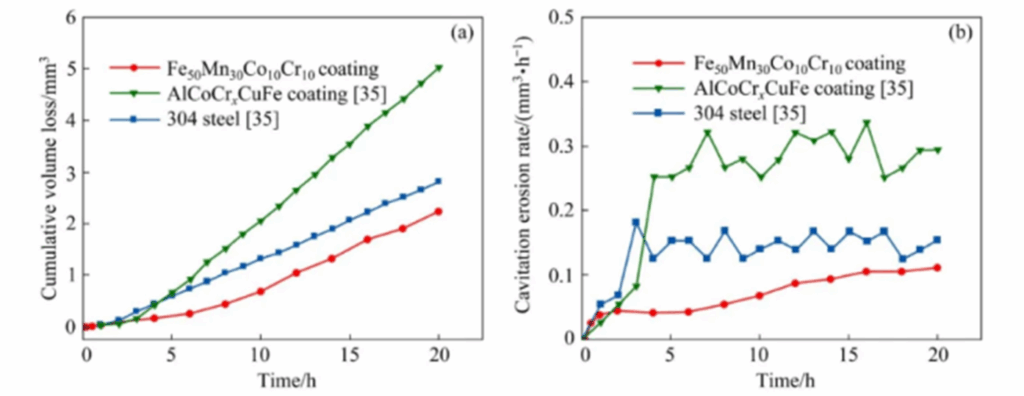

The cavitation process of the Fe50Mn30Co10Cr10 coating is divided into three stages: the incubation period, the acceleration period and the stabilization period. Compared with AISI 304 stainless steel and AlCoCrCuFe coatings, Fe50Mn30Co10Cr10 coating has a longer incubation period, a lower rate of cavitation corrosion, and no obvious acceleration period. After vibrating for 20 hours, its cumulative volume loss ratio is 55% less than that of AlCoCrCuFe coating.

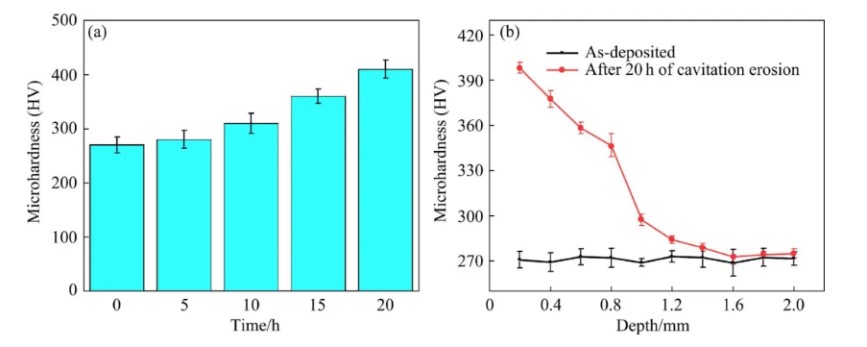

The Fe50Mn30Co10Cr10 coating prepared by laser melting deposition after a 20-hour cavitation corrosion test, the microhardness increases from HV 270 to HV 410. EBSD analysis suggest that, the The HCP ε phase aggregates and grows during the corrosion process, forming large grains embedded in the basis composed of FCC γ phase.

Micro-hardness

XPS analysis suggests, a stable layer of Fe2O3, Mn2O3, Co2O3 and Cr2O3 oxides is formed on the surface of the coating after corrosion. These oxides increase the hardness of the surface of the coating, delay the detachment, therefore enhance the resistance to the cavitation corrosion.

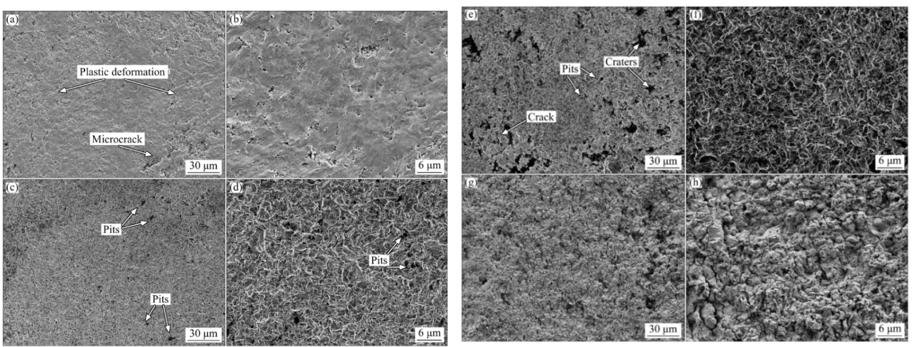

SEM Photo (testing time increase from a to h)

SEM observation showcases that, in the early stage of cavitation corrosion, shallow wrinkles and local plastic deformation appear on the surface of the coating, followed by the formation of microcracks and pitting corrosion. As the testing time increases, the number and size of the pitting corrosion increase, leading to the extensive detachment.