に関する包括的なガイドへようこそ。 電極誘導溶解不活性ガス (EIMIG)は、高品質の金属粉末の製造に用いられる高度な技術である。材料技術者であれ、研究者であれ、あるいは単に高度な冶金プロセスについて興味があるだけであれ、この記事はEIMIGについて詳しく理解することを目的としています。この記事では、EIMIGのメカニズム、具体的な金属粉末のモデル、そして様々な用途についてご紹介します。それでは始めましょう!

電極誘導溶解不活性ガスの概要

電極誘導溶解不活性ガス(EIMIG)は、不活性ガス環境下で電極間に発生する電気アークを利用して金属を溶解する最先端の冶金プロセスです。この方法は、航空宇宙から生体医工学に至るまで、幅広い産業で不可欠な高純度金属粉末の製造に特に有利である。

EIMIGの特徴

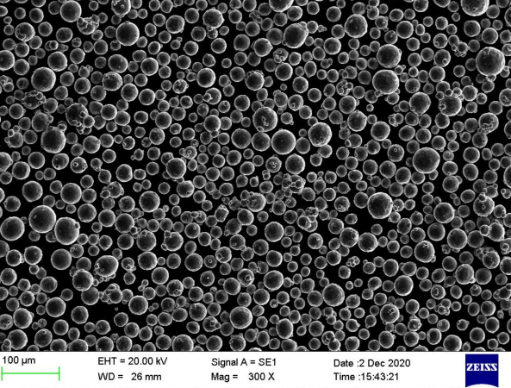

EIMIGの特長は、優れた純度と制御された粒子径を持つ金属粉末を製造する能力にあります。アルゴンやヘリウムなどの不活性ガス雰囲気を使用することで、酸化やコンタミネーションを最小限に抑え、高品質の金属粉末の製造を保証します。また、このプロセスは汎用性が高く、さまざまな金属や合金の溶解が可能です。

EIMIGのコア・コンポーネント

- 電極:通常、グラファイトまたはタングステン製で、溶解に必要な電気アークを発生させる。

- 不活性ガス環境:酸化を防ぐため、アルゴンまたはヘリウムが一般的に使用される。

- 誘導加熱システム:溶融プロセスを維持するために必要なエネルギーを供給する。

- るつぼ:金属が溶けて冷えて粉末状になるのを保持する。

EIMIGが製造する金属粉末の種類

EIMIGは様々な用途に適したユニークな特性を持つ様々な金属粉末を製造することができます。具体的な10種類のモデルをご紹介します:

1.チタン合金 (Ti-6Al-4V)

構成:チタン、アルミニウム、バナジウム

プロパティ:高い強度対重量比、優れた耐食性

用途:航空宇宙部品、医療用インプラント

2.ニッケル超合金(インコネル718)

構成:ニッケル、クロム、鉄、ニオブ

プロパティ:高温耐性、優れた機械的特性

用途:タービンブレード、ジェットエンジン

3.ステンレススチール(316L)

構成:鉄、クロム、ニッケル、モリブデン

プロパティ:高耐食性、良好な成形性

用途:バイオ医療機器、食品加工機器

4.コバルトクロム合金(Co-Cr-Mo)

構成:コバルト、クロム、モリブデン

プロパティ:高い耐摩耗性、生体適合性

用途:歯科インプラント、整形外科インプラント

5.アルミニウム合金 (AlSi10Mg)

構成:アルミニウム、シリコン、マグネシウム

プロパティ:軽量、良好な熱伝導性

用途:自動車部品、航空宇宙構造物

6.銅合金(CuNi2SiCr)

構成:銅、ニッケル、シリコン、クロム

プロパティ:高い導電性、良好な機械的強度

用途:電気コネクター、熱交換器

7.工具鋼(H13)

構成:鉄、クロム、モリブデン、バナジウム

プロパティ:高靭性、優れた耐熱性

用途:ダイカスト用金型、押出金型

8.マルエージング鋼 (18Ni300)

構成:鉄、ニッケル、コバルト、モリブデン

プロパティ:高強度、高靭性

用途:航空宇宙部品、工具

9.炭化タングステン(WC-Co)

構成:タングステン、コバルト

プロパティ:非常に硬く、高い耐摩耗性

用途:切削工具、鉱山機械

10.ジルコニウム合金 (Zr702)

構成:ジルコニウム、ハフニウム、鉄

プロパティ:優れた耐食性、優れた機械的特性

用途:原子炉、化学処理装置

の特徴 電極誘導溶解不活性ガス

EIMIGは、金属粉末を製造するための魅力的な選択肢となるいくつかの重要な特性で知られている。

純度

不活性ガス環境はコンタミネーションを大幅に低減し、その結果、高純度レベルの金属粉が得られる。

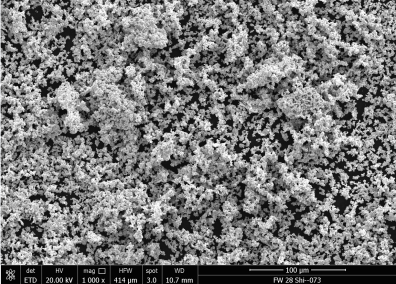

粒子径コントロール

EIMIGは粒度分布の精密な制御を可能にし、これは特定の粉体特性を必要とする用途にとって極めて重要である。

汎用性

このプロセスはさまざまな金属や合金に適応できるため、多様な産業用途に適している。

効率性

EIMIGはエネルギー効率の高いプロセスであり、廃棄物を最小限に抑えながら高収率の金属粉末を生産することができる。

電極誘導溶解不活性ガスの用途

EIMIGが製造する金属粉末は、その優れた特性により、様々なハイテク産業で使用されている。

航空宇宙産業

Ti-6Al-4Vのような高強度軽量合金は、性能と信頼性が最も重要な航空機部品にとって極めて重要です。

バイオメディカル・エンジニアリング

Co-Cr-Moのような生体適合材料は、医療用インプラントや機器に使用され、患者の安全性と有効性を保証している。

自動車部門

AlSi10Mgのようなアルミニウム合金は、軽量化と燃費向上のために自動車部品に使用されている。

エレクトロニクス

高い導電率を持つ銅合金は、コネクターやその他の電子部品に不可欠です。

金型と製造

工具鋼と炭化タングステン粉末は、さまざまな製造工程で耐久性のある金型や切削工具を作るために使用される。

EIMIG金属粉末の詳細仕様

特性と特徴

| 金属粉 | 密度 (g/cm³) | 融点 (°C) | 硬度(HV) | 引張強さ (MPa) | 伸び(%) |

|---|---|---|---|---|---|

| Ti-6Al-4V | 4.43 | 1660 | 349 | 895 | 10 |

| Inconel 718 | 8.19 | 1350 | 330 | 1240 | 12 |

| 316Lステンレス鋼 | 7.99 | 1375 | 217 | 620 | 40 |

| コバルト-クロム-モリブデン | 8.29 | 1330 | 450 | 900 | 8 |

| AlSi10Mg | 2.68 | 570 | 85 | 310 | 7 |

| CuNi2SiCr | 8.78 | 1083 | 100 | 450 | 20 |

| H13工具鋼 | 7.80 | 1427 | 750 | 1450 | 12 |

| 18Ni300マルエージング鋼 | 8.00 | 1413 | 340 | 2000 | 10 |

| WC-コ | 15.60 | 2870 | 1600 | – | – |

| Zr702 | 6.50 | 1855 | 250 | 550 | 30 |

アプリケーションと用途

| 金属粉 | 主な用途 | その他の用途 |

|---|---|---|

| Ti-6Al-4V | 航空宇宙部品、医療用インプラント | スポーツ用品、船舶用 |

| Inconel 718 | タービンブレード、ジェットエンジン | 原子炉、宇宙船 |

| 316Lステンレス鋼 | バイオ医療機器、食品加工 | 化学処理、海洋用途 |

| コバルト-クロム-モリブデン | 歯科インプラント、整形外科インプラント | 時計部品、産業用ベアリング |

| AlSi10Mg | 自動車部品、航空宇宙構造物 | 家電製品、自転車 |

| CuNi2SiCr | 電気コネクター、熱交換器 | マリン・アプリケーション、コイン |

| H13工具鋼 | ダイカスト用金型、押出金型 | 射出成形用金型、鍛造用金型 |

| 18Ni300マルエージング鋼 | 航空宇宙部品、工具 | 高性能ギア、シャフト |

| WC-コ | 切削工具、鉱山機械 | 耐摩耗部品、穴あけ工具 |

| Zr702 | 原子炉、化学処理 | 医療機器、航空宇宙部品 |

仕様、サイズ、等級、規格

| 金属粉 | グレード | サイズ範囲 (µm) | スタンダード |

|---|---|---|---|

| Ti-6Al-4V | グレード5 | 15-45 | ASTM B348 |

| Inconel 718 | UNS N07718 | 15-53 | AMS 5662 |

| 316Lステンレス鋼 | 316L | 10-45 | ASTM F138 |

| コバルト-クロム-モリブデン | ASTM F75 | 20-63 | ISO 5832-4 |

| AlSi10Mg | – | 15-45 | DIN EN 1706 |

| CuNi2SiCr | – | 20-50 | ASTM B422 |

| H13工具鋼 | H13 | 20-63 | ASTM A681 |

| 18Ni300マルエージング鋼 | 18Ni300 | 10-45 | AMS 6514 |

| WC-コ | 1-20 | ISO 4499-1 | |

| Zr702 | R60702 | 15-45 | ASTM B551 |

サプライヤーと価格詳細

| サプライヤー | 金属粉 | 価格(kgあたり) | 空室状況 |

|---|---|---|---|

| アドバンスド・パウダーズ社 | Ti-6Al-4V | $150 | 在庫あり |

| 特殊金属株式会社 | Inconel 718 | $200 | 在庫限り |

| メディカル・マテリアル合同会社 | 316Lステンレス鋼 | $120 | 在庫あり |

| バイオメタル社 | コバルト-クロム-モリブデン | $180 | 要事前予約 |

| ライトメタルズ | AlSi10Mg | $100 | 在庫あり |

| エレクトリカルアロイ社 | CuNi2SiCr | $160 | 在庫あり |

| ツール・スチール・サプライ | H13工具鋼 | $140 | 在庫限り |

| 高強度金属 | 18Ni300マルエージング鋼 | $220 | 在庫あり |

| ハードメタル・グループ | WC-コ | $300 | 要事前予約 |

| ニュークリアマテリアルズ社 | Zr702 | $250 | 在庫あり |

長所と短所、利点と限界を比較する

| 金属粉 | メリット | 制限事項 |

|---|---|---|

| Ti-6Al-4V | 高強度、軽量、耐食性 | 高価、機械加工が難しい |

| Inconel 718 | 優れた高温特性 | 高コスト、複雑な処理 |

| 316Lステンレス鋼 | 耐食性、生体適合性 | 他の合金に比べて強度が低い |

| コバルト-クロム-モリブデン | 高い耐摩耗性、生体適合性 | 脆さ、高価 |

| AlSi10Mg | 軽量、優れた熱特性 | 合金鋼に比べて強度が低い |

| CuNi2SiCr | 高い導電性、耐食性 | 高価、機械的強度に限界がある |

| H13工具鋼 | 高靭性、耐熱性 | 応力下で割れやすい |

| 18Ni300マルエージング鋼 | 高強度、優れた靭性 | 高価で複雑な熱処理が必要 |

| WC-コ | 非常に硬く、高い耐摩耗性 | 脆さ、高コスト |

| Zr702 | 優れた耐食性、優れた機械的特性 | 高コスト、限られた利用可能性 |

よくある質問

何なのか? 電極誘導溶解不活性ガス (EIMIG)?

EIMIGは、不活性ガス雰囲気中で電極間の電気アークを利用して金属を溶解し、高純度の金属粉末を製造するプロセスである。

EIMIGで不活性ガスを使用する理由は?

アルゴンやヘリウムのような不活性ガスは、溶解プロセス中の酸化や汚染を防ぎ、高品質の金属粉末を確保します。

EIMIGを使用して溶融できる金属は何ですか?

EIMIGは汎用性が高く、チタン、ニッケル、ステンレス鋼、コバルトクロムなど、さまざまな金属や合金を溶かすことができる。

EIMIG金属粉末の用途は?

EIMIG金属粉末は、その優れた特性により、航空宇宙、生体医工学、自動車、電子機器、工具産業で使用されています。

EIMIGはどのように粒子径を制御しているのか?

EIMIGのプロセスパラメーターは、粒度分布を制御するために細かく調整することができ、最終製品の一貫性と精度を保証する。

EIMIGの金属粉末は高価ですか?

EIMIG金属粉末のコストは、金属の種類と純度によって異なるが、プロセスの高度な性質のため、一般的に高くなる傾向がある。

EIMIGの主なメリットは何ですか?

EIMIGは、高純度、精密な粒度制御、金属種類の多様性、効率的な生産を提供し、特殊な金属粉末の生産に非常に有益です。

EIMIGは他の溶融技術とどう違うのですか?

EIMIGは不活性ガス雰囲気と誘導加熱を使用しており、コンタミネーションを低減し、溶解プロセスを正確に制御できるため、従来のアーク溶解のような他の技術とは一線を画している。

EIMIGは大規模生産に使えるか?

そう、EIMIGは工業生産用にスケールアップできるので、小規模な研究にも大規模な製造にも適している。

EIMIG金属粉末の主要サプライヤーは?

主要サプライヤーには、Advanced Powders Inc.、Specialty Metals Co.、Medical Materials LLC、BioMetals Corp.などがあり、用途に応じた様々な金属粉末を提供している。

結論

電極誘導溶解不活性ガス(EIMIG)は、金属粉末製造において比類のない純度と精度を提供する、冶金分野における変革的技術です。その用途は重要な産業分野に及び、厳しい環境下でも高い性能と信頼性を保証します。航空宇宙部品、生物医学機器、高性能工具など、EIMIGはイノベーションの限界を押し広げるために必要な先端材料を提供します。