VIGA (Vacuum Inert Gas Atomization)装置は、高品質の金属粉末を製造する上で極めて重要な役割を担っています。これらのマシンは、微細で均一な金属粉末を製造する能力により、航空宇宙、医療、自動車を含む様々な産業で広く使用されています。この詳細なガイドでは、金属粉製造のあらゆる側面についてご紹介します。 VIGAマシンその概要から、具体的な金属粉末モデル、用途、その他もろもろ。VIGAマシンの世界をより深くご覧ください!

VIGAマシンの概要

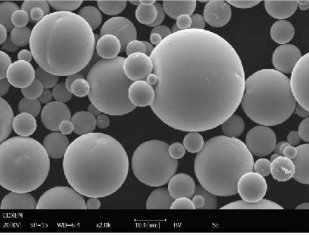

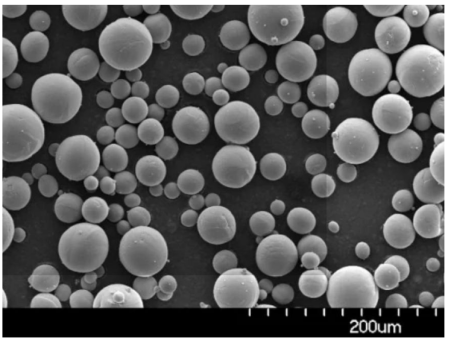

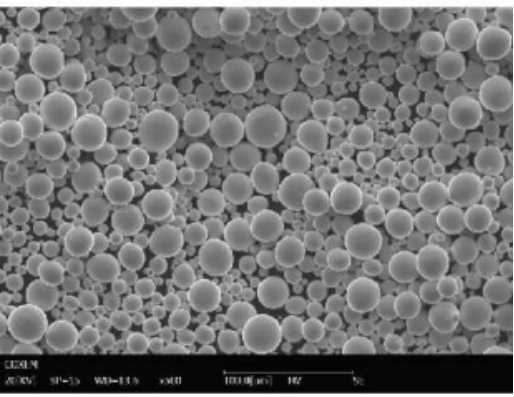

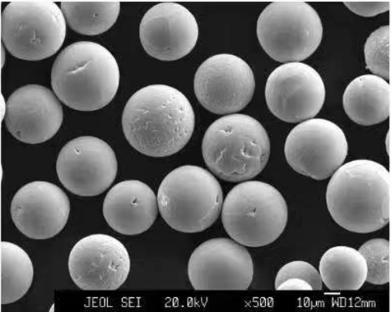

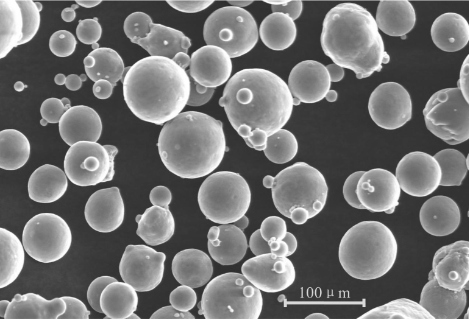

真空不活性ガスアトマイゼーション(VIGA)は、制御された環境で溶融金属をアトマイズすることにより金属粉末を製造する方法である。真空中で金属を溶かし、アルゴンや窒素などの不活性ガスを用いてアトマイズする。その結果、優れた特性を持つ高純度の金属粉が得られ、様々な先端製造プロセスに適している。

VIGAマシンズの主な詳細

- プロセス:真空/不活性ガス環境での溶解と微粒化

- 出力:高純度球状金属粉

- 用途:積層造形、冶金、粉末冶金、コーティング技術

VIGAマシンが製造する金属粉末の種類

VIGAマシンの多用途性により、幅広い金属粉末の生産が可能です。以下は、VIGA技術を使用して製造された金属粉末の具体的なモデルのリストと詳細な説明です。

1.ステンレススチール粉(316L)

説明:ステンレス鋼316L粉末は、その優れた耐食性と機械的特性で知られています。それは広く、医療や航空宇宙産業で使用されています。

特徴:

- 構成:鉄、クロム、ニッケル、モリブデン

- プロパティ:高耐食性、優れた機械的強度

2.チタン合金粉末 (Ti-6Al-4V)

説明:Ti-6Al-4Vは最も一般的に使用されるチタン合金粉末で、高い強度対重量比と優れた生体適合性で知られています。

特徴:

- 構成:チタン、アルミニウム、バナジウム

- プロパティ:高強度、軽量、生体適合性

3.インコネル粉末(インコネル718)

説明:インコネル718粉末は、高温強度と耐食性に優れたニッケルクロム合金で、航空宇宙用途に最適です。

特徴:

- 構成:ニッケル、クロム、鉄、ニオブ

- プロパティ:高温安定性、耐食性

4.アルミニウム合金粉末 (AlSi10Mg)

説明:AlSi10Mg粉末はアルミニウム-シリコン-マグネシウム合金で、熱伝導性が良く軽量であるため、自動車や航空宇宙用途に適している。

特徴:

- 構成:アルミニウム、シリコン、マグネシウム

- プロパティ:軽量、良好な熱伝導性

5.コバルトクロム合金粉(CoCrMo)

説明:CoCrMo合金粉末は、優れた耐摩耗性と生体適合性で知られ、医療用インプラントに広く使用されている。

特徴:

- 構成:コバルト、クロム、モリブデン

- プロパティ:高い耐摩耗性、生体適合性

6.銅合金粉 (CuCrZr)

説明:CuCrZr粉末は、電気および熱伝導性に優れた銅-クロム-ジルコニウム合金で、電気および熱用途に適しています。

特徴:

- 構成:銅、クロム、ジルコニウム

- プロパティ:高い導電性、優れた機械的強度

7.マルエージング鋼粉(18Ni300)

説明:マルエージング鋼18Ni300粉末は、その高い強度と靭性で知られており、一般的に工具や航空宇宙産業で使用されています。

特徴:

- 構成:鉄、ニッケル、コバルト、モリブデン

- プロパティ:高強度、高靭性

8.工具鋼粉(H13)

説明:H13工具鋼粉末は、高い硬度と耐熱性で有名で、金型製作に適しています。

特徴:

- 構成:鉄、クロム、モリブデン、バナジウム

- プロパティ:高硬度、耐熱性

9.ニッケル合金粉末 (NiCr8020)

説明:NiCr8020粉末は、耐酸化性と高温安定性に優れたニッケルクロム合金で、発熱体や工業炉に使用されています。

特徴:

- 構成:ニッケル、クロム

- プロパティ:耐酸化性、高温安定性

10.炭化タングステン粉(WC-Co)

説明:炭化タングステン粉末は、その非常に高い硬度と耐摩耗性で知られており、切削工具や耐摩耗性コーティングに広く使用されています。

特徴:

- 構成:タングステンカーバイド、コバルト

- プロパティ:超硬度、耐摩耗性

VIGA金属粉末の組成と特性

以下の表は、ヴォルフガングが製造した金属粉末の組成と特徴をまとめたものである。 VIGAマシン.

| 金属粉 | 構成 | プロパティ |

|---|---|---|

| ステンレススチール316L | 鉄、クロム、ニッケル、モリブデン | 高耐食性、機械的強度 |

| Ti-6Al-4V | チタン、アルミニウム、バナジウム | 高強度、軽量、生体適合性 |

| Inconel 718 | ニッケル、クロム、鉄、ニオブ | 高温安定性、耐食性 |

| AlSi10Mg | アルミニウム、シリコン、マグネシウム | 軽量、良好な熱伝導性 |

| CoCrMo | コバルト、クロム、モリブデン | 高い耐摩耗性、生体適合性 |

| CuCrZr | 銅、クロム、ジルコニウム | 高い導電性、優れた機械的強度 |

| 18Ni300 | 鉄、ニッケル、コバルト、モリブデン | 高い強度と靭性 |

| H13 | 鉄、クロム、モリブデン、バナジウム | 高硬度、耐熱性 |

| NiCr8020 | ニッケル、クロム | 耐酸化性、高温安定性 |

| WC-コ | 炭化タングステン、コバルト | 極めて高い硬度、耐摩耗性 |

VIGA金属粉末の用途

VIGA機で製造される金属粉末は、様々な産業分野で幅広い用途に使用されています。以下の表は、これらの用途の一部をハイライトしたものです。

| 産業 | 用途 | 使用金属粉 |

|---|---|---|

| 航空宇宙 | エンジン部品、構造部品 | Ti-6Al-4V、インコネル718、AlSi10Mg |

| メディカル | インプラント、補綴 | ステンレス鋼316L、CoCrMo、Ti-6Al-4V |

| 自動車 | 軽量部品、熱管理 | AlSi10Mg, CuCrZr |

| 工具 | 金型、切削工具 | H13、WC-Co、18Ni300 |

| 電気 | 導電性部品、熱管理 | CuCrZr、NiCr8020 |

| インダストリアル | 発熱体、耐摩耗コーティング | NiCr8020、WC-Co |

仕様、サイズ、等級、規格

以下の表は、VIGAマシンで一般的に製造される金属粉末の仕様、サイズ、グレード、規格を示したものです。

| 金属粉 | サイズ範囲 (μm) | グレード | 規格 |

|---|---|---|---|

| ステンレススチール316L | 10-45 | AISI 316L | ASTM F138、ISO 5832-1 |

| Ti-6Al-4V | 15-45 | グレード5 | アストマ F136、ISO 5832-3 |

| Inconel 718 | 15-53 | AMS 5662 | ASTM B637 |

| AlSi10Mg | 20-63 | AlSi10Mg | EN AC-43400、ISO 3522 |

| CoCrMo | 10-45 | ASTM F75 | ASTM F75、ISO 5832-4 |

| CuCrZr | 20-63 | CuCrZr | アストムB505、ディン17670 |

| 18Ni300 | 10-53 | マレージング・スチール300 | AMS 6521 |

| H13 | 15-45 | H13 | ASTM A681 |

| NiCr8020 | 20-63 | NiCr8020 | アストムB163、ディン17742 |

| WC-コ | 10-45 | WC-コ | ISO 3327 |

サプライヤーと価格詳細

以下は、VIGAマシンで生産される様々な金属粉末のサプライヤーとおおよその価格詳細の一覧表です。

| 金属粉 | サプライヤー | 価格 (kgあたり) | 備考 |

|---|---|---|---|

| ステンレススチール316L | カーペンター・テクノロジー | $50 – $70 | 一括割引あり |

| Ti-6Al-4V | AP&C | $200 – $250 | プレミアム品質、航空宇宙グレード |

| Inconel 718 | プラクセア・サーフェス・テクノロジー | $150 – $200 | 高温アプリケーション |

| AlSi10Mg | エックカート | $30 – $50 | 一般的な積層造形 |

| CoCrMo | アルカムAB | $300 – $350 | 医療用インプラントグレード |

| CuCrZr | GKNアディティブ | $40 – $60 | 高い導電性 |

| 18Ni300 | ヘガネスAB | $80 – $100 | 高強度、工具用途 |

| H13 | カーペンター・テクノロジー | $70 – $90 | 耐熱工具 |

| NiCr8020 | エリコン・メトコ | $100 – $130 | 工業炉 |

| WC-コ | ケナメタル | $250 – $300 | 極限の硬度、切削工具 |

VIGAメタルパウダーの長所と短所を比較する

以下の表は、VIGAマシンで製造される様々な金属粉末の長所と短所を比較したものです。

| 金属粉 | メリット | 制限事項 |

|---|---|---|

| ステンレススチール316L | 優れた耐食性、機械的強度 | 一般的なスチールに比べ高コスト |

| Ti-6Al-4V | 高い強度対重量比、生体適合性 | 高価、機械加工が難しい |

| Inconel 718 | 高温強度、耐食性 | 高価、加工性に限界がある |

| AlSi10Mg | 軽量、優れた熱特性 | 他の合金に比べて強度が低い |

| CoCrMo | 耐摩耗性、生体適合性 | 高価、入手可能なものが限られる |

| CuCrZr | 優れた電気伝導性と熱伝導性 | 機械的強度の低下 |

| 18Ni300 | 高い強度と靭性 | 高価、特別な取り扱いが必要 |

| H13 | 高硬度、耐熱性 | 割れやすい |

| NiCr8020 | 耐酸化性、高温安定性 | 高価、入手可能なものが限られる |

| WC-コ | 極めて高い硬度、耐摩耗性 | 非常に高価、脆い |

よくある質問

VIGAのプロセスとは?

VIGAプロセスでは、真空中で金属を溶解し、不活性ガスで噴霧化して微細な金属粉末を製造する。

VIGAの金属粉末はどのような産業で使用されていますか?

航空宇宙、医療、自動車、工具、電気などの産業でVIGA金属粉が使用されています。

VIGA金属粉末を使用する利点は何ですか?

VIGA金属粉末は、高純度、均一な粒子径、高度な製造工程に適した優れた特性を提供します。

VIGAマシンは他の噴霧方式と比べてどうですか?

VIGA機は、水アトマイズやガスアトマイズのような他の方法と比較して、粉体の品質と純度をよりよく制御することができます。

VIGAの金属粉末は高価ですか?

VIGA金属粉末のコストは、高度な技術と高品質の出力により高くなることがありますが、多くの場合、利点はコストを上回ります。

VIGAマシンで製造される一般的な金属粉末にはどのようなものがありますか?

一般的な粉末には、ステンレス鋼316L、Ti-6Al-4V、インコネル718、AlSi10Mg、CoCrMo、CuCrZr、18Ni300、H13、NiCr8020、WC-Coなどがある。

結論

VIGAマシン は、金属粉末製造の分野における最高峰であり、幅広い産業に高品質の材料を提供している。組成と粒子径を正確に制御して粉末を製造するその能力は、現代の製造業に欠かせないものとなっている。航空宇宙部品、医療用インプラント、産業用工具のいずれにおいても、VIGAが製造するパウダーの汎用性と信頼性は、先端材料アプリケーションにおける重要なリソースであり続けることを保証します。