VIGA (Vacuum Inert Gas Atomization) machines have become pivotal in the production of high-quality metal powders. These machines are widely used in various industries, including aerospace, medical, and automotive, thanks to their ability to produce fine and uniform metal powders. In this detailed guide, we will explore every aspect of Máquinas VIGA, from their overview to specific metal powder models, their applications, and much more. Get ready for an in-depth look at the world of VIGA machines!

Overview of VIGA Machines

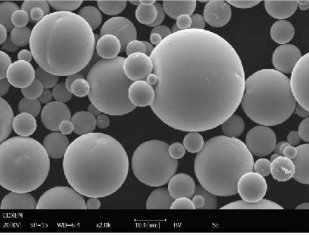

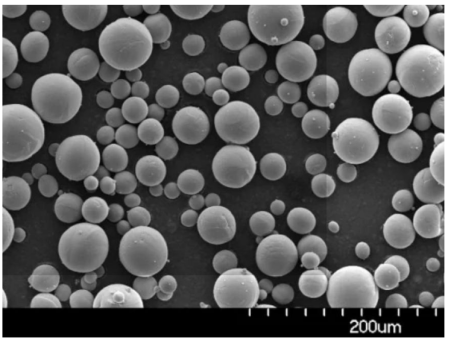

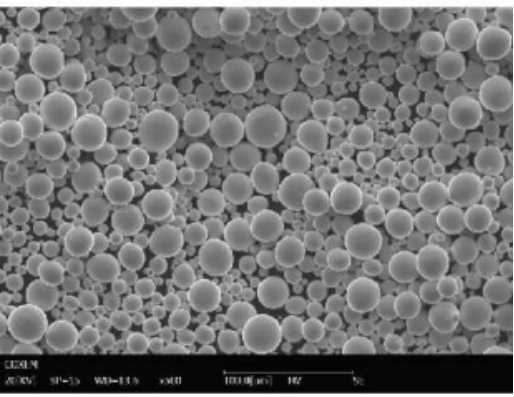

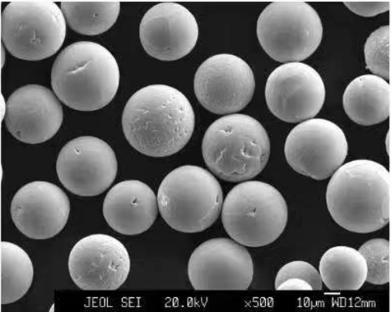

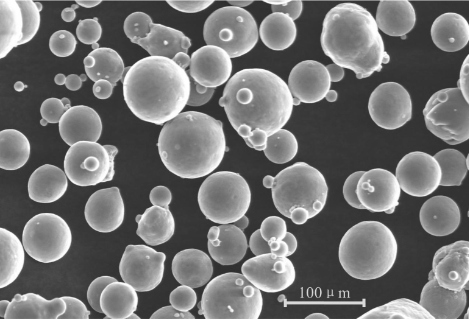

Vacuum Inert Gas Atomization (VIGA) is a method used to produce metal powders by atomizing molten metal in a controlled environment. The process involves melting metal in a vacuum and then atomizing it using an inert gas like argon or nitrogen. This results in high-purity metal powders with excellent properties, making them suitable for various advanced manufacturing processes.

Key Details of VIGA Machines

- Proceso: Melting and atomization in vacuum/inert gas environment

- Output: High-purity, spherical metal powders

- Aplicaciones: Additive manufacturing, metallurgy, powder metallurgy, coating technologies

Types of Metal Powders Produced by VIGA Machines

The versatility of VIGA machines allows them to produce a wide range of metal powders. Below is a list of specific metal powder models produced using VIGA technology, along with detailed descriptions.

1. Stainless Steel Powder (316L)

Descripción: Stainless steel 316L powder is known for its excellent corrosion resistance and mechanical properties. It is widely used in the medical and aerospace industries.

Caracteristicas:

- Composición: Iron, chromium, nickel, molybdenum

- Propiedades: High corrosion resistance, good mechanical strength

2. Titanium Alloy Powder (Ti-6Al-4V)

Descripción: Ti-6Al-4V is the most commonly used titanium alloy powder, known for its high strength-to-weight ratio and excellent biocompatibility.

Caracteristicas:

- Composición: Titanium, aluminum, vanadium

- Propiedades: High strength, lightweight, biocompatible

3. Inconel Powder (Inconel 718)

Descripción: Inconel 718 powder is a nickel-chromium alloy with excellent high-temperature strength and corrosion resistance, ideal for aerospace applications.

Caracteristicas:

- Composición: Nickel, chromium, iron, niobium

- Propiedades: High-temperature stability, corrosion resistance

4. Aluminum Alloy Powder (AlSi10Mg)

Descripción: AlSi10Mg powder is an aluminum-silicon-magnesium alloy with good thermal conductivity and lightweight properties, making it suitable for automotive and aerospace applications.

Caracteristicas:

- Composición: Aluminum, silicon, magnesium

- Propiedades: Lightweight, good thermal conductivity

5. Cobalt-Chrome Alloy Powder (CoCrMo)

Descripción: CoCrMo alloy powder is known for its excellent wear resistance and biocompatibility, widely used in medical implants.

Caracteristicas:

- Composición: Cobalt, chromium, molybdenum

- Propiedades: Alta resistencia al desgaste, biocompatibilidad

6. Copper Alloy Powder (CuCrZr)

Descripción: CuCrZr powder is a copper-chromium-zirconium alloy with excellent electrical and thermal conductivity, suitable for electrical and thermal applications.

Caracteristicas:

- Composición: Copper, chromium, zirconium

- Propiedades: High conductivity, good mechanical strength

7. Maraging Steel Powder (18Ni300)

Descripción: Maraging steel 18Ni300 powder is known for its high strength and toughness, commonly used in tooling and aerospace industries.

Caracteristicas:

- Composición: Iron, nickel, cobalt, molybdenum

- Propiedades: Alta resistencia, tenacidad

8. Tool Steel Powder (H13)

Descripción: H13 tool steel powder is renowned for its high hardness and heat resistance, making it suitable for tooling and mold making.

Caracteristicas:

- Composición: Iron, chromium, molybdenum, vanadium

- Propiedades: High hardness, heat resistance

9. Nickel Alloy Powder (NiCr8020)

Descripción: NiCr8020 powder is a nickel-chromium alloy with excellent oxidation resistance and high-temperature stability, used in heating elements and industrial furnaces.

Caracteristicas:

- Composición: Nickel, chromium

- Propiedades: Oxidation resistance, high-temperature stability

10. Tungsten Carbide Powder (WC-Co)

Descripción: Tungsten carbide powder is known for its extreme hardness and wear resistance, widely used in cutting tools and wear-resistant coatings.

Caracteristicas:

- Composición: Tungsten carbide, cobalt

- Propiedades: Extreme hardness, wear resistance

Composition and Characteristics of VIGA Metal Powders

Below is a table summarizing the composition and characteristics of the metal powders produced by Máquinas VIGA.

| Polvo metálico | Composición | Propiedades |

|---|---|---|

| Acero inoxidable 316L | Iron, chromium, nickel, molybdenum | High corrosion resistance, mechanical strength |

| Ti-6Al-4V | Titanium, aluminum, vanadium | High strength, lightweight, biocompatible |

| Inconel 718 | Nickel, chromium, iron, niobium | Estabilidad a altas temperaturas, resistencia a la corrosión |

| AlSi10Mg | Aluminio, silicio, magnesio | Ligero, buena conductividad térmica |

| CoCrMo | Cobalt, chromium, molybdenum | Alta resistencia al desgaste, biocompatibilidad |

| CuCrZr | Copper, chromium, zirconium | High conductivity, good mechanical strength |

| 18Ni300 | Iron, nickel, cobalt, molybdenum | Alta resistencia, tenacidad |

| H13 | Iron, chromium, molybdenum, vanadium | High hardness, heat resistance |

| NiCr8020 | Nickel, chromium | Oxidation resistance, high-temperature stability |

| WC-Co | Tungsten carbide, cobalt | Dureza extrema, resistencia al desgaste |

Applications of VIGA Metal Powders

The metal powders produced by VIGA machines have a wide range of applications across various industries. The following table highlights some of these applications.

| Industria | Aplicaciones | Metal Powders Used |

|---|---|---|

| Aeroespacial | Componentes del motor, piezas estructurales | Ti-6Al-4V, Inconel 718, AlSi10Mg |

| Médico | Implantes, prótesis | Stainless Steel 316L, CoCrMo, Ti-6Al-4V |

| Automotor | Lightweight parts, thermal management | AlSi10Mg, CuCrZr |

| Herramientas | Moldes, herramientas de corte | H13, WC-Co, 18Ni300 |

| Eléctrico | Conductive components, thermal management | CuCrZr, NiCr8020 |

| Industrial | Heating elements, wear-resistant coatings | NiCr8020, WC-Co |

Especificaciones, tamaños, calidades y normas

The following table provides specifications, sizes, grades, and standards for some commonly produced metal powders by VIGA machines.

| Polvo metálico | Tamaños (µm) | Grado | Normas |

|---|---|---|---|

| Acero inoxidable 316L | 10-45 | AISI 316L | ASTM F138, ISO 5832-1 |

| Ti-6Al-4V | 15-45 | 5º curso | ASTM F136, ISO 5832-3 |

| Inconel 718 | 15-53 | AMS 5662 | ASTM B637 |

| AlSi10Mg | 20-63 | AlSi10Mg | EN AC-43400, ISO 3522 |

| CoCrMo | 10-45 | ASTM F75 | ASTM F75, ISO 5832-4 |

| CuCrZr | 20-63 | CuCrZr | ASTM B505, DIN 17670 |

| 18Ni300 | 10-53 | Maraging Steel 300 | AMS 6521 |

| H13 | 15-45 | H13 | ASTM A681 |

| NiCr8020 | 20-63 | NiCr8020 | ASTM B163, DIN 17742 |

| WC-Co | 10-45 | WC-Co | ISO 3327 |

Proveedores y precios

Here is a table listing some of the suppliers and approximate pricing details for various metal powders produced by VIGA machines.

| Polvo metálico | Proveedor | Precio (per kg) | Notas |

|---|---|---|---|

| Acero inoxidable 316L | Tecnología Carpenter | $50 – $70 | Bulk discounts available |

| Ti-6Al-4V | AP&C | $200 – $250 | Premium quality, aerospace grade |

| Inconel 718 | Tecnologías de superficie Praxair | $150 – $200 | Aplicaciones de alta temperatura |

| AlSi10Mg | ECKART | $30 – $50 | Common in additive manufacturing |

| CoCrMo | Arcam AB | $300 – $350 | Medical implant grade |

| CuCrZr | Aditivos GKN | $40 – $60 | Alta conductividad |

| 18Ni300 | Höganäs AB | $80 – $100 | High strength, tooling applications |

| H13 | Tecnología Carpenter | $70 – $90 | Heat resistant tooling |

| NiCr8020 | Oerlikon Metco | $100 – $130 | Industrial furnaces |

| WC-Co | Kennametal | $250 – $300 | Extreme hardness, cutting tools |

Comparing Pros and Cons of VIGA Metal Powders

The following table compares the pros and cons of various metal powders produced by VIGA machines.

| Polvo metálico | Ventajas | Limitaciones |

|---|---|---|

| Acero inoxidable 316L | Excellent corrosion resistance, mechanical strength | Higher cost compared to regular steel |

| Ti-6Al-4V | Elevada relación resistencia/peso, biocompatibilidad | Caro, difícil de mecanizar |

| Inconel 718 | High-temperature strength, corrosion resistance | Caro, maquinabilidad limitada |

| AlSi10Mg | Ligero, buenas propiedades térmicas | Menor resistencia en comparación con otras aleaciones |

| CoCrMo | Resistencia al desgaste, biocompatibilidad | Caro, disponibilidad limitada |

| CuCrZr | Excelente conductividad eléctrica y térmica | Menor resistencia mecánica |

| 18Ni300 | Alta resistencia, tenacidad | Expensive, requires special handling |

| H13 | High hardness, heat resistance | Prone to cracking |

| NiCr8020 | Oxidation resistance, high-temperature stability | Caro, disponibilidad limitada |

| WC-Co | Dureza extrema, resistencia al desgaste | Very expensive, brittleness |

Preguntas más frecuentes

What is the VIGA process?

The VIGA process involves melting metal in a vacuum and atomizing it using inert gas to produce fine metal powders.

Which industries use VIGA metal powders?

Industries like aerospace, medical, automotive, tooling, and electrical use VIGA metal powders.

What are the advantages of using VIGA metal powders?

VIGA metal powders offer high purity, uniform particle size, and excellent properties suitable for advanced manufacturing processes.

How do VIGA machines compare to other atomization methods?

VIGA machines provide better control over powder quality and purity compared to other methods like water atomization or gas atomization.

Are VIGA metal powders expensive?

The cost of VIGA metal powders can be higher due to the advanced technology and high-quality output, but the benefits often outweigh the costs.

What are some common metal powders produced by VIGA machines?

Common powders include stainless steel 316L, Ti-6Al-4V, Inconel 718, AlSi10Mg, CoCrMo, CuCrZr, 18Ni300, H13, NiCr8020, and WC-Co.

Conclusión

Máquinas VIGA represent a pinnacle in the field of metal powder production, providing high-quality materials for a wide range of industries. Their ability to produce powders with precise control over composition and particle size makes them indispensable in modern manufacturing. Whether it’s aerospace components, medical implants, or industrial tools, the versatility and reliability of VIGA-produced powders ensure they remain a critical resource in advanced material applications.