أصبحت ماكينات التفتيت بالغاز الخامل بالتفريغ محورية في إنتاج مساحيق المعادن عالية الجودة. وتستخدم هذه الماكينات على نطاق واسع في مختلف الصناعات، بما في ذلك صناعة الطيران والطب والسيارات، بفضل قدرتها على إنتاج مساحيق معدنية دقيقة وموحدة. في هذا الدليل المفصل، سنستكشف في هذا الدليل المفصل كل جانب من جوانب ماكينات VIGAمن النظرة العامة إلى نماذج المساحيق المعدنية المحددة وتطبيقاتها وغير ذلك الكثير. استعد لإلقاء نظرة متعمقة على عالم ماكينات VIGA!

نظرة عامة على ماكينات VIGA

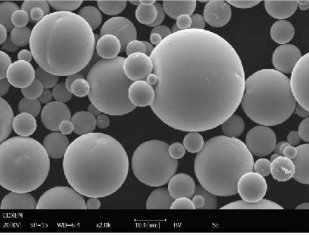

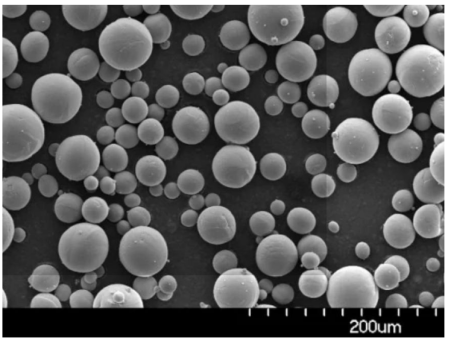

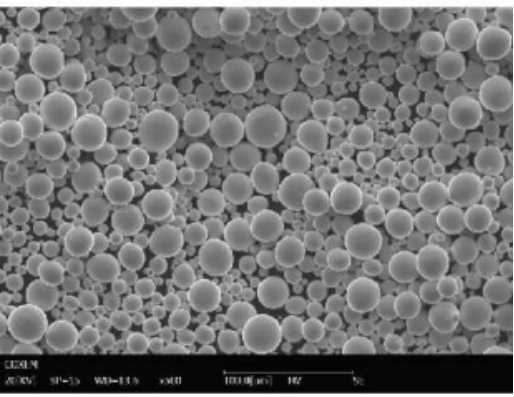

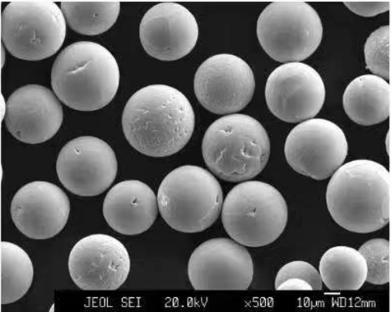

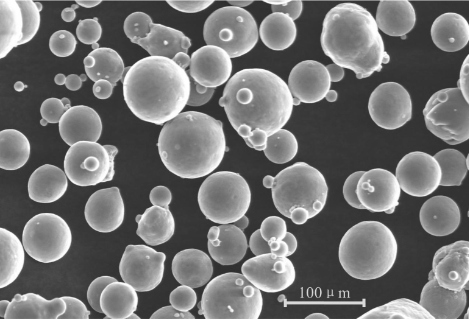

ترذيذ الغاز الخامل بالتفريغ (VIGA) هي طريقة تستخدم لإنتاج مساحيق المعادن عن طريق ترذيذ المعدن المنصهر في بيئة محكومة. تتضمن العملية صهر المعدن في الفراغ ثم تفتيته باستخدام غاز خامل مثل الأرجون أو النيتروجين. وينتج عن ذلك مساحيق معدنية عالية النقاء بخصائص ممتازة، مما يجعلها مناسبة لمختلف عمليات التصنيع المتقدمة.

التفاصيل الرئيسية لماكينات VIGA

- العملية: الذوبان والانصهار في بيئة الفراغ/الغاز الخامل

- المخرجات: مساحيق معدنية كروية عالية النقاء

- التطبيقات: التصنيع الإضافي، علم المعادن، علم المعادن، مسحوق المعادن، تقنيات الطلاء

أنواع المساحيق المعدنية التي تنتجها ماكينات VIGA

تتيح تعدد استخدامات ماكينات VIGA إنتاج مجموعة واسعة من مساحيق المعادن. فيما يلي قائمة بنماذج محددة من المساحيق المعدنية التي يتم إنتاجها باستخدام تقنية VIGA، إلى جانب وصف تفصيلي.

1. مسحوق الفولاذ المقاوم للصدأ (316L)

الوصف: يشتهر مسحوق الفولاذ المقاوم للصدأ 316L بمقاومته الممتازة للتآكل وخصائصه الميكانيكية. ويستخدم على نطاق واسع في الصناعات الطبية والفضائية.

صفات:

- التركيب: الحديد والكروم والنيكل والنيكل والموليبدينوم

- الخصائص: مقاومة عالية للتآكل، قوة ميكانيكية جيدة

2. مسحوق سبائك التيتانيوم (Ti-6Al-4V)

الوصف: Ti-6Al-4V هو مسحوق سبائك التيتانيوم الأكثر استخدامًا، والمعروف بنسبة قوته العالية إلى وزنه وتوافقه الحيوي الممتاز.

صفات:

- التركيب: التيتانيوم والألومنيوم والفاناديوم

- الخصائص: قوة عالية وخفيفة الوزن ومتوافقة حيوياً

3. مسحوق الإينكونيل (Inconel 718)

الوصف: مسحوق Inconel 718 عبارة عن سبيكة من النيكل والكروم ذات قوة ممتازة في درجات الحرارة العالية ومقاومة للتآكل، وهي مثالية للتطبيقات الفضائية.

صفات:

- التركيب: النيكل والكروم والحديد والنيوبيوم والنيوبيوم والنيكل والكروم والحديد والنيوبيوم

- الخصائص: ثبات في درجات الحرارة العالية، ومقاومة التآكل

4. مسحوق سبائك الألومنيوم (AlSi10Mg)

الوصف: مسحوق AlSi10Mg عبارة عن سبيكة ألومنيوم-سيليكون-مغنيسيوم ذات توصيل حراري جيد وخصائص خفيفة الوزن، مما يجعلها مناسبة لتطبيقات السيارات والفضاء.

صفات:

- التركيب: الألومنيوم والسيليكون والمغنيسيوم

- الخصائص: خفيف الوزن وموصلية حرارية جيدة

5. مسحوق سبائك الكوبالت والكروم (CoCrMo)

الوصف: يشتهر مسحوق سبيكة CoCrMo بمقاومته الممتازة للتآكل وتوافقه الحيوي، ويستخدم على نطاق واسع في الغرسات الطبية.

صفات:

- التركيب: الكوبالت، والكروم، والموليبدينوم

- الخصائص: مقاومة عالية للتآكل، والتوافق الحيوي

6. مسحوق سبائك النحاس (CuCrZr)

الوصف: مسحوق CuCrZr عبارة عن سبيكة من النحاس والكروم والزركونيوم ذات توصيل كهربائي وحراري ممتاز، ومناسبة للتطبيقات الكهربائية والحرارية.

صفات:

- التركيب: النحاس والكروم والزركونيوم والزركونيوم

- الخصائص: موصلية عالية، قوة ميكانيكية جيدة

7. مسحوق الفولاذ المسحوق (18Ni300)

الوصف: يُعرف مسحوق الفولاذ الصلب 18Ni300 الصلب الصلب الصلب 18Ni300 بقوته وصلابته العالية، ويستخدم عادةً في صناعات الأدوات وصناعات الطيران.

صفات:

- التركيب: الحديد، والنيكل، والكوبالت، والموليبدينوم

- الخصائص: قوة وصلابة عالية

8. مسحوق فولاذ الأدوات (H13)

الوصف: يشتهر مسحوق فولاذ الأدوات H13 بصلابته العالية ومقاومته للحرارة، مما يجعله مناسبًا لصناعة الأدوات والقوالب.

صفات:

- التركيب: الحديد والكروم والموليبدينوم والموليبدينوم والفاناديوم

- الخصائص: صلابة عالية، مقاومة للحرارة

9. مسحوق سبائك النيكل (NiCr8020)

الوصف: مسحوق NiCr8020 عبارة عن سبيكة نيكل-كروم ذات مقاومة ممتازة للأكسدة وثبات في درجات الحرارة العالية، وتستخدم في عناصر التسخين والأفران الصناعية.

صفات:

- التركيب: النيكل، الكروم

- الخصائص: مقاومة الأكسدة، ثبات في درجات الحرارة العالية

10. مسحوق كربيد التنغستن (WC-Co)

الوصف: يشتهر مسحوق كربيد التنجستن بصلابته الشديدة ومقاومته للتآكل، ويستخدم على نطاق واسع في أدوات القطع والطلاءات المقاومة للتآكل.

صفات:

- التركيب: كربيد التنغستن والكوبالت

- الخصائص: الصلابة الشديدة، ومقاومة التآكل

تركيبة مساحيق VIGA المعدنية وخصائصها

فيما يلي جدول يلخص تركيبة وخصائص المساحيق المعدنية التي تنتجها ماكينات VIGA.

| المسحوق المعدني | التركيب | الخصائص |

|---|---|---|

| فولاذ مقاوم للصدأ 316L | الحديد، والكروم، والنيكل، والنيكل، والموليبدينوم | مقاومة عالية للتآكل، وقوة ميكانيكية عالية |

| Ti-6Al-4V | التيتانيوم والألومنيوم والفاناديوم | متانة عالية وخفيفة الوزن ومتوافقة حيوياً |

| انكونيل 718 | النيكل والكروم والحديد والنيوبيوم والنيوبيوم والنيكل والكروم والحديد والنيوبيوم | ثبات في درجات الحرارة العالية ومقاومة التآكل |

| AlSi10 ملغ | الألومنيوم والسيليكون والمغنيسيوم | خفيف الوزن وموصلية حرارية جيدة |

| CoCrMo | الكوبالت، والكروم، والموليبدينوم | مقاومة عالية للتآكل، وتوافق حيوي |

| CuCrZr | نحاس، كروم، زركونيوم، نحاس، كروم، زركونيوم | موصلية عالية، قوة ميكانيكية جيدة |

| 18ni300 | الحديد، والنيكل، والكوبالت، والموليبدينوم | قوة وصلابة وصلابة عالية |

| H13 | الحديد والكروم والموليبدينوم والموليبدينوم والفاناديوم | صلابة عالية، مقاومة للحرارة |

| NiCr8020 | نيكل، كروم | مقاومة الأكسدة، والثبات في درجات الحرارة العالية |

| WC-Co | كربيد التنجستن والكوبالت | صلابة فائقة، مقاومة للتآكل |

تطبيقات مساحيق VIGA المعدنية

المساحيق المعدنية التي تنتجها ماكينات VIGA لها مجموعة واسعة من التطبيقات في مختلف الصناعات. يسلط الجدول التالي الضوء على بعض هذه التطبيقات.

| الصناعة | التطبيقات | المساحيق المعدنية المستخدمة |

|---|---|---|

| الفضاء | مكونات المحرك، الأجزاء الهيكلية | Ti-6Al-4V، Ti-6Al-4V، Inconel 718، AlSi10Mg |

| الطبية | الغرسات والأطراف الصناعية | الفولاذ المقاوم للصدأ 316L، CoCrMo، Ti-6Al-4V |

| السيارات | أجزاء خفيفة الوزن، إدارة حرارية | AlSi10Mg، CuCrZr، AlSi10Mg، CuCrZr |

| الأدوات | القوالب وأدوات القطع | H13، WC-Co، 18Ni300 |

| كهربائي | المكونات الموصلة والإدارة الحرارية | CuCrCrZr، NiCr8020 |

| صناعي | عناصر التسخين، والطلاءات المقاومة للتآكل | NiCr8020، WC-Co، NiCr8020، WC-Co |

المواصفات والأحجام والدرجات والمعايير

يقدم الجدول التالي المواصفات والأحجام والدرجات والمعايير لبعض مساحيق المعادن التي يتم إنتاجها عادةً بواسطة ماكينات VIGA.

| المسحوق المعدني | نطاق الحجم (ميكرومتر) | الصف | المعايير |

|---|---|---|---|

| فولاذ مقاوم للصدأ 316L | 10-45 | AISI 316L | معيار النجم F138، ISO 5832-1 |

| Ti-6Al-4V | 15-45 | الصف الخامس | معيار الفلكي الفلكي F136، ISO 5832-3 |

| انكونيل 718 | 15-53 | AMS 5662 | ASTM B637 |

| AlSi10 ملغ | 20-63 | AlSi10 ملغ | EN AC-43400، ISO 3522، ISO 3522 |

| CoCrMo | 10-45 | ASTM F75 | astm f75، ISO 5832-4 |

| CuCrZr | 20-63 | CuCrZr | أستم B505، دين 17670، دين 17670 |

| 18ni300 | 10-53 | فولاذ مارينجنيت 300 | AMS 6521 |

| H13 | 15-45 | H13 | ASTM A681 |

| NiCr8020 | 20-63 | NiCr8020 | أستم B163, DIN 17742 |

| WC-Co | 10-45 | WC-Co | آيزو 3327 |

تفاصيل الموردين والأسعار

فيما يلي جدول يسرد بعض الموردين وتفاصيل الأسعار التقريبية لمختلف المساحيق المعدنية التي تنتجها ماكينات VIGA.

| المسحوق المعدني | المورد | السعر (لكل كيلوغرام) | الملاحظات |

|---|---|---|---|

| فولاذ مقاوم للصدأ 316L | تكنولوجيا النجار | $50 – $70 | خصومات بالجملة متاحة |

| Ti-6Al-4V | AP&C | $200 – $250 | جودة ممتازة، من الدرجة الممتازة في مجال الطيران |

| انكونيل 718 | براكسير للتقنيات السطحية | $150 – $200 | تطبيقات درجات الحرارة العالية |

| AlSi10 ملغ | إيكارت | $30 – $50 | شائع في التصنيع المضاف |

| CoCrMo | أركام إيه بي | $300 – $350 | درجة الزرع الطبي |

| CuCrZr | مضافات GKN | $40 – $60 | موصلية عالية |

| 18ni300 | هوغاناس إيه بي | $80 – $100 | قوة عالية، وتطبيقات الأدوات |

| H13 | تكنولوجيا النجار | $70 – $90 | أدوات مقاومة للحرارة |

| NiCr8020 | أورليكون ميتكو | $100 – $130 | الأفران الصناعية |

| WC-Co | كيناميتال | $250 – $300 | الصلابة الشديدة، أدوات القطع |

مقارنة إيجابيات وسلبيات مساحيق VIGA المعدنية

يقارن الجدول التالي إيجابيات وسلبيات المساحيق المعدنية المختلفة التي تنتجها ماكينات VIGA.

| المسحوق المعدني | مزايا | محددات |

|---|---|---|

| فولاذ مقاوم للصدأ 316L | مقاومة ممتازة للتآكل، وقوة ميكانيكية | تكلفة أعلى مقارنة بالفولاذ العادي |

| Ti-6Al-4V | نسبة عالية من القوة إلى الوزن، والتوافق الحيوي | باهظة الثمن وصعبة التشغيل الآلي |

| انكونيل 718 | مقاومة درجات الحرارة العالية، ومقاومة التآكل | باهظة الثمن، وقابلية التشغيل الآلي المحدودة |

| AlSi10 ملغ | خفة الوزن وخصائص حرارية جيدة | قوة أقل مقارنة بالسبائك الأخرى |

| CoCrMo | مقاومة التآكل، والتوافق الحيوي | باهظة الثمن ومحدودية التوفر |

| CuCrZr | توصيل كهربائي وحراري ممتاز | قوة ميكانيكية أقل |

| 18ni300 | قوة وصلابة وصلابة عالية | باهظة الثمن، تتطلب معالجة خاصة |

| H13 | صلابة عالية، مقاومة للحرارة | عرضة للتشقق |

| NiCr8020 | مقاومة الأكسدة، والثبات في درجات الحرارة العالية | باهظة الثمن ومحدودية التوفر |

| WC-Co | صلابة فائقة، مقاومة للتآكل | باهظة الثمن للغاية، هشاشة |

التعليمات

ما هي عملية VIGA؟

تنطوي عملية VIGA على صهر المعدن في الفراغ وتفتيته باستخدام غاز خامل لإنتاج مساحيق معدنية دقيقة.

ما هي الصناعات التي تستخدم مساحيق المعادن VIGA؟

تستخدم صناعات مثل الفضاء والطبية والطبية والسيارات والأدوات والكهربائية مساحيق VIGA المعدنية.

ما هي مزايا استخدام مساحيق VIGA المعدنية؟

توفر المساحيق المعدنية VIGA درجة نقاء عالية وحجم جسيمات موحد وخصائص ممتازة مناسبة لعمليات التصنيع المتقدمة.

كيف تقارن ماكينات VIGA بطرق الانحلال الأخرى؟

توفر ماكينات VIGA تحكمًا أفضل في جودة المسحوق ونقاوته مقارنة بالطرق الأخرى مثل الانحلال المائي أو الانحلال الغازي.

هل مساحيق VIGA المعدنية باهظة الثمن؟

يمكن أن تكون تكلفة مساحيق المعادن VIGA أعلى بسبب التكنولوجيا المتقدمة والإنتاج عالي الجودة، ولكن الفوائد غالبًا ما تفوق التكاليف.

ما هي بعض المساحيق المعدنية الشائعة التي تنتجها ماكينات VIGA؟

تتضمن المساحيق الشائعة الفولاذ المقاوم للصدأ 316L، وTi-6Al-4V، وInconel 718، وAlSi10Mg، وCoCrMo، وCuCrZr، و18Ni300، وH13، وNiCr8020، وWC-Co.

خاتمة

ماكينات VIGA تمثل قمة في مجال إنتاج المساحيق المعدنية، حيث توفر مواد عالية الجودة لمجموعة واسعة من الصناعات. إن قدرتها على إنتاج مساحيق ذات تحكم دقيق في التركيب وحجم الجسيمات يجعلها لا غنى عنها في التصنيع الحديث. وسواء كان الأمر يتعلق بمكونات الطيران أو الغرسات الطبية أو الأدوات الصناعية، فإن تعدد استخدامات المساحيق التي تنتجها VIGA وموثوقيتها يضمنان بقاءها موردًا مهمًا في تطبيقات المواد المتقدمة.