モリブデン金属粉 は、様々な産業で用途が拡大している重要な材料である。このガイドでは、モリブデン金属粉末の概要、特性、製造方法、用途、サプライヤーなどについて詳しく説明しています。

モリブデン金属粉末の概要

モリブデンは銀白色の遷移金属で、記号はMo、原子番号は42。純金属の形態では、モリブデンは高い強度、硬度、熱伝導性、耐食性を持っています。

モリブデン金属粉末は、様々な方法で微粉末状に製造された純粋なモリブデン金属またはモリブデン合金の小粒子を指す。

ここでは、モリブデン金属粉の主要な詳細をまとめたクイックリファレンス表を示します:

| パラメータ | 詳細 |

|---|---|

| 化学式 | Mo |

| 原子番号 | 42 |

| 原子量 | 95.95 g/mol |

| 密度 | 10.22 g/cm3 |

| 融点 | 2622°C |

| カラー | シルバーホワイト |

| 一般的なパウダーの種類 | 純モリブデン、モリブデン合金 |

| 粒子径 | 1-100ミクロン |

| 主要物件 | 高強度、熱伝導性、耐食性、潤滑性 |

| 主な用途 | 冶金、化学、触媒、コーティング、エレクトロニクス |

モリブデン金属粉末は、さまざまな産業におけるさまざまな高温用途での使用に適した、いくつかの有益な特性を備えています。

特性 モリブデン金属粉

モリブデン金属粉末は、化学的、物理的、電気的、機械的特性のユニークな組み合わせを持っています。ここでは、モリブデン粉末の主な特性のいくつかを紹介します:

高融点

モリブデンの融点は2622℃と非常に高く、ほとんどの市販金属よりも高い。このため、モリブデン粉末は1000℃を超える高温の使用条件下でも強度を維持し、変形に耐えることができます。

熱伝導率

モリブデンの熱伝導率は138W/m・Kで、電極や発熱体などの用途で効率的な熱伝達を可能にします。これにより、耐熱衝撃性が向上する。

耐食性

モリブデン粉末は、高温下でも酸、塩、還元性雰囲気に対して優れた耐食性を示します。表面に保護酸化物層が形成されます。

高強度

モリブデンは200~300MPaの高い引張強度を持つ。これは、コンポーネントに優れた耐クリープ性と構造的完全性を与えます。

潤滑性

モリブデンパウダーは、特定の用途で固体潤滑を提供し、摩擦と摩耗を低減します。潤滑性は高温で増加する。

電気伝導率

モリブデンの電気抵抗率は5.5μΩ・cmであり、電極、接点、発熱体として有用である。

このユニークな特性の組み合わせにより、モリブデン金属粉末は厳しい環境下での特殊な高温用途に適しています。適切な粉末特性は、これらの特性を活用するのに役立ちます。

モリブデン金属粉末の製造方法

モリブデン金属粉末は、金属モリブデンの粒径を小さくして微粉末にする様々な技術によって製造することができる:

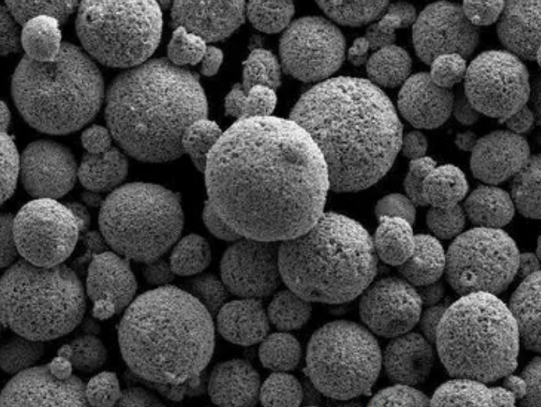

機械加工

モリブデンの塊はボールミルやスタンプミルで粉砕され、粉末になります。制御された粉砕は1ミクロンまでの微粉を生産する。

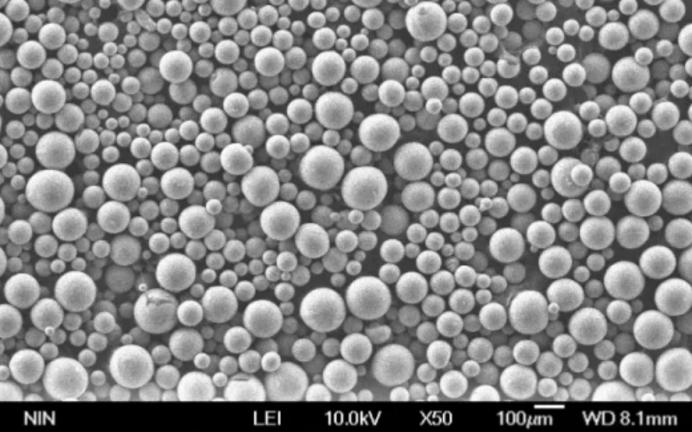

ガス噴霧

溶融したモリブデンを不活性ガスジェットで霧状にして小さな液滴にし、固化させて微細な球状粉末にします。最大100ミクロンの粉末が製造可能です。

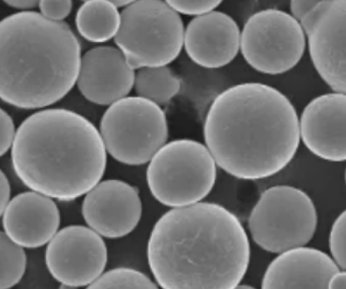

プラズマ球状化

不規則なモリブデン粉末を再溶解し、プラズマトーチで球状化することで、流動性の良い球状粉末を作る。

化学物質削減

酸化モリブデンのようなモリブデン化合物を水素ガスを用いて化学的に還元し、純粋な金属粉末を得る。

電解

モリブデン酸塩水溶液を電気分解し、モリブデン粉末を陰極に析出させる。

製造工程のパラメータを適切に制御することで、用途に適した粒度、形状、純度、微細構造をカスタマイズ可能なモリブデン粉が得られる。

種類 モリブデン金属粉

モリブデン金属粉末は、組成と用途の要件に応じてさまざまなタイプがあります:

| パウダータイプ | 説明 |

|---|---|

| 純モリブデン | 不純物の少ないモリブデンを99%以上含有 |

| モリブデン合金 | ランタン、チタン、タングステン、ニオブなど他の金属との合金。 |

| 酸化物コーティング | 薄い酸化皮膜による耐食性 |

| 潤滑コーティング | グラファイト、二硫化モリブデン、二硫化タングステンなどの潤滑剤でコーティング。 |

| 焼結助剤コーティング | 粉末成形体の焼結を促進するニッケルコーティング付き |

純粋なモリブデン粉末は、最適な高温性能を提供します。カリウム、シリコン、ホウ素などの合金添加により、機械加工性と焼結性が向上します。コーティングは、特定の用途向けに粉末特性を調整します。

粒度分布

モリブデン粉末は、メッシュサイズによって分類された異なる粒度分布で入手可能です:

| パウダーグレード | 粒子径(ミクロン) |

|---|---|

| ウルトラファイン | 1-10 |

| サブミクロン | 1-20 |

| ファイン | 10-30 |

| ミディアム | 30-75 |

| 粗目 | 75-150 |

超微粉やサブミクロンの粉末は、より高い焼結密度と均一な微細構造を提供する。しかし、発熱性がある。粗い粉末は、工業的な取り扱いに適した流動性を提供します。適切な粒子径は、最終的な部品の要件に基づいて選択されます。

モリブデン粉末の特徴

モリブデン粉末は、その性能を決定する様々な属性によって特徴付けられている:

| パラメータ | 意義 |

|---|---|

| 粒子サイズ | 焼結密度、収縮、微細構造、表面積に影響する。 |

| 粒子形状 | 球状で流動性が良い |

| 純度 | 高純度が高温での挙動を最適化 |

| 見かけ密度 | ネットシェイプ加工のコンプライアンスに影響 |

| 比表面積 | 焼結速度論と緻密化の決定 |

| 焼結活動 | 気孔のない微細構造に緻密化する能力 |

| 酸素含有量 | 低酸素は延性と導電性を向上させる |

パウダーの特性は、パウダー製造の段階で特定の用途のニーズに合わせて調整される。

モリブデン金属粉末の用途

モリブデン金属粉末は、さまざまな産業分野のさまざまな高温用途で使用されている:

自動車部品

- ピストンズ

- エンジンバルブ

- ノズル部品

電気接点

- リレー

- スイッチ

加熱エレメント

- 高温炉

- 窯

溶接製品

- 溶接棒

- ワイヤー用フラックス

化学装置

- 原子炉容器

- 熱交換器

エレクトロニクス

- 導電性ペースト

- セラミックのメタライゼーション

コーティング

- 溶射コーティング

- 耐食コーティング

複合材料

- 援軍

- マイクロ波吸収体

触媒

- 水素化分解触媒

- 水素化分解触媒

モリブデン粉末は、高温強度、導電性、耐食性、その他の利点をこれらの用途の部品に与えます。

モリブデン粉末のグローバルサプライヤー

モリブデン金属粉末の主な世界的サプライヤーには以下のようなものがある:

| 会社概要 | 所在地 |

|---|---|

| H.C.スタルク | ドイツ |

| モリメット | チリ |

| JDC-モリ | 中国 |

| エクスプロイター モリブデン | 中国 |

| 山東広川モリブデン | 中国 |

| 江蘇豊豊タングステン;モリブデン | 中国 |

これらの企業は、組成、粒子径、形状、粉末特性などの面で、様々な用途向けにカスタマイズされたモリブデン粉末を提供することができる。

モリブデンパウダーの価格

モリブデン粉末の価格は様々な要因に左右される:

- 純度:高純度(99.9%)の粉末は、低純度グレードよりも高価である。

- 粒子サイズ:超微粉やサブミクロンの粉末は、粗粉に比べてコストが高い。

- 構成:合金粉末やコーティングされた粉末は、純粋なモリブデンよりも高価である。

- 数量:スケールメリットにより、大量注文の場合は価格が下がる。

- サプライヤー:価格は世界のサプライヤーによって異なる。

一般的な価格帯:

| パウダーグレード | 価格帯 |

|---|---|

| 純モリブデン | kgあたり30~50ドル |

| 合金粉末 | kgあたり50~100ドル |

| 超微粉 | kgあたり80-150ドル |

特定の要件に基づく正確な価格見積もりについては、サプライヤーにお問い合わせください。

モリブデン粉末の部品加工

モリブデン粉末は、さまざまな技術を使って部品に加工することができる:

プレスと焼結

プレス機で成形し、真空焼結する。これが最も一般的な方法である。

金属射出成形(MIM)

バインダーと混合して原料にし、金型に注入して複雑な形状を作る。

付加製造

レーザーまたは電子ビーム粉末床溶融法を用いたモリブデン部品の3Dプリント。

溶射

モリブデン粉を使ったスプレーコーティング。

| プロセス | メリット | デメリット |

|---|---|---|

| プレスと焼結 | シンプル、低コスト | 限られた複雑さ、機械加工が必要 |

| 金属射出成形(MIM) | 複雑な形状、ネットシェイプ | 多段階プロセス、バインダー除去 |

| 付加製造 | カスタムデザイン、短納期 | 高い設備コスト、サイズの制限 |

| 溶射 | 低設備コスト、大型部品 | 多孔質コーティング、ライン・オブ・サイト・プロセス |

最適な粉末冶金プロセスは、部品のサイズ、形状、数量、特性に基づいて選択されます。

設置、操作、メンテナンス

モリブデン粉末を取り扱う際には、適切な設置、運転、保守の慣行に従わなければならない:

- 酸化を防ぐため、粉末の取り扱い時には不活性ガス用手袋を使用する。モリブデンは高温の空気中で容易に酸化する。

- 湿気がこもらないように、パウダーは密閉して乾燥した状態で保管してください。湿気はパウダーを発火させます。

- 火花や着火源から離れた換気の良い場所で粉末を取り扱うこと。微粉末のモリブデンは引火性がある。

- 地域の環境規制に従って廃棄する。モリブデンが環境中に放出されると危険性がある。

- 安全な取り扱い、処理、メンテナンスのための標準作業手順を作成する。要員にトレーニングを提供する。

- 漏れがないか、シールが損傷していないか、粉体移送ラインが詰まっていないか、定期的に装置を点検してください。予防メンテナンスを実施する。

- リスクを最小限に抑えるため、労働安全衛生団体が推奨する慣行に従うこと。

粉体の品質、装置の寿命、作業の安全性を最適化するためには、適切な取り扱いが不可欠です。

信頼できるモリブデン粉末サプライヤーの選択

ここでは、適切なモリブデン粉末サプライヤーを選択するためのいくつかのヒントを示します:

経験

- 特にモリブデン粉末の製造に長年の経験を持つ、実績のある会社を探すこと。

技術力

- サプライヤーが、様々な技術を使ってカスタマイズされた特性を持つ粉体を製造する専門知識を持っていることを確認する。

品質システム

- ISO 9001のような品質規格の認定を受け、厳格な品質管理を実践しているサプライヤーを選びましょう。

研究開発能力

- 粉体製造プロセスを継続的に改善するための研究開発に投資しているサプライヤーを優先する。

カスタマーサービス

- 顧客のニーズを理解し、個別のサービスを提供することに重点を置いた、迅速な対応をしてくれるサプライヤーを選びましょう。

物流インフラ

- 世界中にタイムリーに配送するために、倉庫や輸送能力を持つサプライヤーを選ぶ。

価格

- コストと品質の最適なバランスを取るために、候補となったサプライヤーの価格見積もりを比較する。

経験豊富で信頼できるモリブデン粉末メーカーを選ぶことで、特定の要件に合わせた高品質の粉末を安定的に供給することができます。

長所と短所 モリブデン金属粉

モリブデンパウダーには、いくつかの利点があるが、いくつかの限界もある:

長所

- 優れた高温強度

- 高い熱伝導性

- 強い耐食性

- 優れた耐摩耗性

- 高い導電性

- 低熱膨張

- ネットシェイプの製造可能性

短所

- 比較的高いコスト

- 焼結体では機械加工性が低い

- 高温で酸化しやすい

- 形状によっては溶接性が制限される

- 低温での脆性挙動

熱サイクルを伴う1000℃以上の温度で安定した性能を必要とする用途では、モリブデン粉末はコストが高いにもかかわらず、独自の能力を発揮します。

よくある質問

Q: モリブデン金属粉末は何に使われるのですか?

A: モリブデン粉末の主な用途は、冶金、化学、コーティング、エレクトロニクス、溶接、自動車部品、発熱体、その他の高温用途です。

Q: モリブデンパウダーは特別な取り扱いが必要ですか?

A: はい、モリブデン粉末は細かく砕くと引火性があります。また、高温で容易に酸化します。適切な不活性雰囲気での取り扱いと保管が必要です。

Q: モリブデンパウダーは有毒ですか?

A: モリブデンの毒性は低いが、モリブデン粉末は長期間の暴露により、眼や呼吸器への刺激などの健康被害をもたらす可能性がある。十分な安全対策が必要です。

Q:モリブデン粉末はどのような方法で成形できますか?

A: 粉末加工の主な方法は、プレス・焼結、金属射出成形、積層造形、溶射です。部品の大きさ、形状、要件に応じて方法を選択します。

Q: モリブデン粉末は焼結助剤を必要としますか?

A: プレス・アンド・シンター加工では、モリブデン粉末に少量のニッケルや鉄を添加して焼結を促進することが多い。その他の焼結助剤も緻密化を助けます。

結論

モリブデン金属粉末は、高温、熱サイクル、腐食環境など、他の材料では不十分な特殊用途に適した汎用性の高い高性能材料です。モリブデン粉末の生産と加工の継続的な進歩は、より多くの産業でその利用を拡大しています。モリブデン粉の適切な取り扱いと加工により、モリブデン粉から製造される部品は、厳しい使用条件下でも卓越した性能を発揮します。

Additional FAQs: Molybdenum Metal Powder

1) What particle size distributions are preferred for different processes using molybdenum metal powder?

- Press-and-sinter: 5–30 µm for good green density and sinterability.

- MIM: 1–20 µm (often D50 ≈ 5–10 µm) for high surface area and densification.

- LPBF/SLM: 15–45 µm spherical, high flowability; EBM: 45–106 µm.

- Thermal spray: 15–63 µm for HVOF/APS coatings.

2) How critical is oxygen content in Mo powder and what are typical targets?

- Very critical: oxygen increases brittleness and lowers conductivity. Typical specs: O ≤ 0.10–0.20 wt% for PM/sintering; O ≤ 0.05–0.10 wt% for AM and high-conductivity uses. Manage O/N/H via inert packaging and limited exposure.

3) Can molybdenum metal powder be additively manufactured without cracking?

- Yes, with spherical, low-oxygen powder, elevated plate preheat, optimized hatch/scan strategies, and post-build HIP. Thin walls may need slower scan or contour remelts to mitigate residual stresses.

4) What sintering atmospheres are recommended for Mo powder?

- High vacuum (≤10⁻³ mbar) or dry hydrogen to reduce oxides and promote densification. Dew point control (≤–40°C) is important in H₂ to avoid re-oxidation.

5) Which alloying or dopant additions are common and why?

- La₂O₃ or K–Si–B dopants improve recrystallization resistance and creep. Ni/Fe act as sintering aids for press-and-sinter. TiC or WC can be added for wear-resistant composites in coatings.

2025 Industry Trends: Molybdenum Metal Powder

- AM penetration: More LPBF/EBM qualifications for high-temperature tooling, radiation shields, and furnace hardware.

- Inline QA: Powder genealogy with O/N/H tracking and PSD/shape analytics mandated by more OEMs.

- Sustainability: Recycling of off-spec and revert Mo streams increases; environmental product declarations (EPDs) requested for large coating programs.

- Price dynamics: Moderation in Mo oxide prices stabilizes powder pricing; demand growth tied to energy, chemicals, and semiconductor equipment.

- Coating performance: Hybrid carbide–Mo powders gain share for slurry/erosion environments in mining and pulp & paper.

2025 Molybdenum Powder Market Snapshot (Indicative)

| メートル | 2023 | 2024 | 2025 YTD (Aug) | 備考 |

|---|---|---|---|---|

| Global Mo powder demand (kt) | ~93 | ~98 | ~103 | Energy/chemicals + AM |

| AM-grade spherical Mo price (USD/kg) | 70–110 | 68–105 | 65–100 | Stabilizing raw material |

| Typical O spec for AM-grade (wt%) | ≤0.10 | ≤0.08 | ≤0.07 | Better atomization/handling |

| Share of spherical gas-atomized Mo in AM (%) | ~60 | ~64 | ~68 | Flowability requirements |

| HIP usage for AM Mo components (%) | ~48 | ~53 | ~58 | Fatigue/thermal shock |

| Lots with digital genealogy (%) | ~46 | ~58 | ~72 | Traceability adoption |

Sources:

- ASTM/ISO powder and AM standards: https://www.astm.org, https://www.iso.org

- MPIF powder metallurgy guides: https://www.mpif.org

- USGS commodity summaries for Mo: https://www.usgs.gov

- NIST AM-Bench and metrology: https://www.nist.gov/ambench

Latest Research Cases

Case Study 1: LPBF Molybdenum Heat Shields for Semiconductor Furnaces (2025)

Background: A semiconductor equipment OEM needed dense, low-contamination Mo heat shields with complex cooling features.

Solution: Used spherical Mo powder (D50 ~32 µm, O=0.07 wt%); 200°C baseplate preheat; optimized hatch; post-build HIP + vacuum anneal.

Results: Relative density ≥99.6%; thermal conductivity within 95% of wrought baseline; deformation reduced 30% during thermal cycling; lead time cut from 12 to 5 weeks.

Case Study 2: HVOF Molybdenum-Based Wear Coatings for Slurry Valves (2024)

Background: A mining customer reported rapid erosion-corrosion of valve seats.

Solution: HVOF-sprayed Mo + WC composite powder (15–45 µm); controlled oxygen in spray gas; sealed porosity with post-spray heat treatment.

Results: Erosion rate reduced 38% vs. Cr-based coating; down-time interval extended by 8 months; coating porosity <1.5% (image analysis).

Expert Opinions

- Prof. Gerhard Dehm, Director, Max-Planck-Institut für Eisenforschung

- “Interstitial control and oxide reduction in molybdenum powders are pivotal to achieving ductility and high thermal conductivity in consolidated parts.”

- Dr. Alan Lawley, Emeritus Professor, Drexel University (Powder Metallurgy)

- “For press-and-sinter Mo, particle size and sintering atmosphere dominate densification kinetics—dew point discipline in hydrogen is often the difference between success and failure.”

- Dr. Brandon A. Lane, Additive Manufacturing Metrologist, NIST

- “Powder spreadability and humidity history correlate strongly with lack-of-fusion defects in refractory metals like molybdenum; inline monitoring is becoming standard.”

Practical Tools and Resources

- ASTM B387 (Mo and Mo-alloy products), ASTM B331/B821 (PM characterization), ASTM E1019/E1409/E1447 for O/N/H analysis: https://www.astm.org

- ISO 4491 (reduction of metal oxides), ISO/ASTM 52907 (AM feedstock requirements), ISO 10204 (Mo powder specifications context): https://www.iso.org

- MPIF Standards and design guides for refractory PM: https://www.mpif.org

- USGS Molybdenum Commodity Summary for market data: https://www.usgs.gov

- NIST AM-Bench datasets and metrology resources: https://www.nist.gov/ambench

- Senvol Database for AM material–machine mappings: https://senvol.com

- OEM technical libraries (Plansee, H.C. Starck) for Mo processing datasheets

Last updated: 2025-08-25

Changelog: Added 5 targeted FAQs; introduced a 2025 market snapshot table with indicative metrics and sources; provided two recent case studies; included expert viewpoints; compiled practical standards and resources

Next review date & triggers: 2026-02-01 or earlier if ASTM/ISO/MPIF standards update, significant Mo price volatility (>10%), or major OEMs publish new AM qualifications for molybdenum components