Titanhydrid (TiH₂)-Pulver ist ein vielseitiges und unverzichtbares Material, das in einer Reihe von Branchen wie der Luft- und Raumfahrt, der Automobilindustrie, der Metallurgie und sogar der Elektronik eingesetzt wird. Dieser Artikel erforscht jede Nuance von TiH₂-Pulvervon seiner Zusammensetzung bis hin zu den Anwendungen und allem, was dazwischen liegt. Ob Sie nun ein Fachmann auf diesem Gebiet sind oder einfach nur neugierig, lassen Sie uns in die faszinierende Welt des TiH₂-Pulvers eintauchen.

Überblick über TiH₂-Pulver

TiH₂-Pulver, auch bekannt als Titanhydridpulver, entsteht durch die Verbindung von Titan mit Wasserstoff. Das Material bietet einzigartige Eigenschaften wie ein hohes Verhältnis von Festigkeit zu Gewicht, Korrosionsbeständigkeit und ausgezeichnete Reaktivität, was es zu einem Favoriten in fortschrittlichen Fertigungsverfahren wie Pulvermetallurgie und 3D-Druck macht.

Wichtige Eigenschaften von TiH₂-Pulver

- Chemische Formel: TiH₂

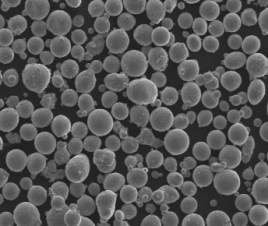

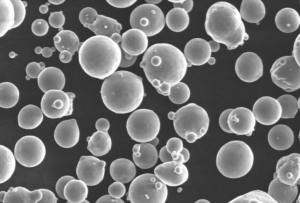

- Erscheinungsbild: Graues oder schwarzes Pulver

- Dichte: ~3,91 g/cm³

- Wasserstoffgehalt: Normalerweise etwa 4% nach Gewicht

- Thermische Stabilität: Zersetzt sich bei erhöhten Temperaturen zu Titan und Wasserstoff.

Zusammensetzung der TiH₂-Pulver

Das Verständnis der Zusammensetzung von TiH₂-Pulver ist entscheidend für die Auswahl der richtigen Sorte für Ihre Bedürfnisse. Die Reinheit und die Partikelgröße des Pulvers beeinflussen sein Verhalten in verschiedenen Anwendungen erheblich.

| Komponente | Typischer Inhalt (%) |

|---|---|

| Titan (Ti) | ≥ 96.0 |

| Hydrogen (H) | 3.8 – 4.5 |

| Sauerstoff (O) | ≤ 0.3 |

| Nitrogen (N) | ≤ 0.2 |

| Kohlenstoff (C) | ≤ 0.05 |

| Eisen (Fe) | ≤ 0.1 |

Eigenschaften von TiH₂-Pulver

Hohes Festigkeits-Gewichts-Verhältnis

Titanhydrid behält die charakteristische Eigenschaft von Titan bei - seine überragende Festigkeit bei gleichzeitig geringem Gewicht. Dies ist von unschätzbarem Wert für Anwendungen in der Luft- und Raumfahrt und in der Automobilindustrie, wo Gewichtseinsparungen entscheidend sind.

Zersetzungspotenzial

Bei hohen Temperaturen setzt TiH₂ Wasserstoff frei, was es zu einem einzigartigen Vorprodukt für Titanpulver beim Sintern und bei der additiven Fertigung macht.

Korrosionsbeständigkeit

TiH₂ ist von Natur aus resistent gegen viele korrosive Umgebungen und gewährleistet Langlebigkeit unter anspruchsvollen Bedingungen.

Anwendungen von TiH₂-Pulver

TiH₂-Pulver wird aufgrund seiner außergewöhnlichen Eigenschaften in verschiedenen Branchen eingesetzt.

| Anmeldung | Zweck |

|---|---|

| Pulvermetallurgie | Verbessert die Effizienz der Sinterung und senkt die Produktionskosten. |

| 3D-Druck | Bietet Präzision in der additiven Fertigung mit hervorragenden Materialeigenschaften. |

| Komponenten für die Luft- und Raumfahrt | Wird in leichten, hochfesten Teilen wie Flugzeugzellen und Triebwerksteilen verwendet. |

| Wasserstoff-Speichersysteme | Dient als Wasserstoffspeicher in modernen Energieanwendungen. |

| Metall-Matrix-Verbundwerkstoffe | Verbessert die Verschleißfestigkeit und die mechanische Festigkeit. |

| Schweißen und Löten | Dient als Quelle für Titan in Füllstoffen. |

Spezifikationen, Güteklassen und Normen

Um das richtige TiH₂-Pulver auszuwählen, müssen Sie die Spezifikationen und Qualitäten kennen, die für Ihr Projekt relevant sind.

| Klasse | Partikelgröße (µm) | Wasserstoffgehalt (%) | Anmeldung |

|---|---|---|---|

| TiH₂-10 | ≤ 10 | 4.0 | 3D-Druck, Mikroelektronik |

| TiH₂-20 | ≤ 20 | 3.8 | Pulvermetallurgie |

| TiH₂-45 | ≤ 45 | 4.2 | Anwendungen für allgemeine Zwecke |

| TiH₂-UltraPure | ≤ 10 | 4.5 | Hohe Anforderungen an die Reinheit |

Top-Modelle der TiH₂-Pulver

Im Folgenden werden einige der beliebten TiH₂-Pulvermodelle, die auf unterschiedliche Anwendungen zugeschnitten sind, näher vorgestellt:

- TiH₂-Microfine

- Beschreibung: Ultrafeines Pulver mit Partikelgrößen unter 5 Mikron.

- Anwendungen: Ideal für die additive Fertigung und hochpräzise Teile.

- TiH₂-Industriell

- Beschreibung: Kostengünstiges Pulver in Standardqualität.

- Anwendungen: Allgemeine Verwendung beim Schweißen, Löten und bei Metallverbundwerkstoffen.

- TiH₂-Hochrein

- Beschreibung: Hochreines Pulver mit strengen Qualitätskontrollen.

- Anwendungen: Luft- und Raumfahrt und medizinische Geräte.

- TiH₂-3DP

- Beschreibung: Speziell für den 3D-Druck entwickelt, mit optimierter Fließfähigkeit.

- Anwendungen: Additive Fertigung und Prototyping.

- TiH₂-Standard

- Beschreibung: Vielseitiges Pulver für zahlreiche Branchen.

- Anwendungen: Pulvermetallurgie und Verbundwerkstoffe.

- TiH₂-Energie

- Beschreibung: Wasserstoffhaltige Formulierung für die Energiespeicherung.

- Anwendungen: Wasserstoff-Brennstoffzellen und Energiesysteme.

- TiH₂-Plus

- Beschreibung: Verbesserte Einheitlichkeit der Partikelgröße.

- Anwendungen: Fortgeschrittene Sintertechniken.

- TiH₂-Nano

- Beschreibung: Nanoskalige Pulver für die Spitzenforschung.

- Anwendungen: Nanotechnologie und Spezialbeschichtungen.

- TiH₂-medizinisch

- Beschreibung: Erfüllt die Normen für Biokompatibilität.

- Anwendungen: Medizinische Implantate und chirurgische Instrumente.

- TiH₂-HighDensity

- Beschreibung: Optimiert für hochdichtes Sintern.

- Anwendungen: Luft- und Raumfahrt und Verteidigung.

Lieferanten und Preisangaben

| Anbieter | Preisspanne ($/kg) | Region | Besondere Merkmale |

|---|---|---|---|

| Fortgeschrittene Materialien Inc. | 50 – 100 | USA | Anpassbare Partikelgrößen und -zusammensetzungen |

| TitanMetalle Co. | 45 – 90 | Europa | Hochreine Sorten für die Luft- und Raumfahrt |

| SinoPowder Ltd. | 30 – 70 | Asien | Wettbewerbsfähige Preise für Großaufträge |

Vergleich von Vorteilen und Beschränkungen

| Aspekt | Vorteile | Beschränkungen |

|---|---|---|

| Stärke | Hohes Festigkeits-Gewichts-Verhältnis | Spröde unter bestimmten Bedingungen |

| Wasserstoffspeicher | Ausgezeichneter Wasserstoffträger | Erfordert kontrollierte Zersetzung |

| Kosten | Erschwinglich im Vergleich zu Titanpulver | Kostenanstieg bei hochreinen Sorten |

FAQ

| Frage | Antwort |

|---|---|

| Wofür wird TiH₂-Pulver verwendet? | TiH₂-Pulver wird in der Pulvermetallurgie, beim 3D-Druck und bei der Wasserstoffspeicherung verwendet. |

| Wie wird TiH₂-Pulver hergestellt? | Es wird durch Reaktion von Titan mit Wasserstoff unter kontrollierten Bedingungen hergestellt. |

| Kann TiH₂-Pulver in der Luft- und Raumfahrt verwendet werden? | Ja, es ist ideal für leichte, stabile Komponenten für die Luft- und Raumfahrt. |

| Was ist die typische Partikelgröße? | Die Partikelgröße reicht je nach Sorte von Nanometern bis zu 45 Mikrometern. |