1. Einführung: Was ist SMF5030-Pulver und warum es für PM wichtig ist

SMF5030-Pulver ist ein spezielles vorlegiertes pulvermetallurgisches (PM) Material, das in der Herstellung von Strukturen und mechanischen Komponenten weit verbreitet ist. Es gehört zur Familie der hochleistungsfähigen Sinterstahlpulver, die speziell entwickelt wurden, um eine überlegene Festigkeit, Maßhaltigkeit und Bearbeitbarkeit für verschiedene industrielle Anwendungen zu bieten.

In der B2B-Welt, in der Kosteneffizienz, Leistung und Zuverlässigkeit von entscheidender Bedeutung sind, hat sich der SMF5030 als erste Wahl erwiesen:

- Automobilhersteller

- Lieferanten von Werkzeugen und Formen

- Hersteller von Industrieanlagen

- OEM-Lieferanten und Auftragshersteller

Aufgrund seiner chemischen Zusammensetzung und seiner Legierungselemente eignet es sich hervorragend für Sinter-, Schmiede- und Bearbeitungsvorgänge, die in großen Produktionsumgebungen erforderlich sind.

Hauptmerkmale von SMF5030 Powder:

| Eigentum | Beschreibung |

|---|---|

| Pulver Typ | Vorlegierter pulvermetallurgischer Stahl |

| Zusammensetzung der Legierung | Fe-Ni-Mo-Cu-Basis (typisch) |

| Sintertemperatur | 1120°C – 1150°C |

| Dichtebereich | 6.8 – 7,2 g/cm³ (wie gesintert) |

| Methode der Anwendung | Pressen und Sintern |

| Merkmale der Stärke | Hohe Zug- und Ermüdungsfestigkeit |

| Bearbeitbarkeit | Gut mit minimaler Nachbearbeitung |

SMF5030-Pulver ist bekannt für sein hervorragendes Gleichgewicht zwischen Festigkeit und Verarbeitbarkeit, wodurch es sich für anspruchsvolle mechanische Teile eignet.

2. Industrielle Anwendungen von SMF5030-Pulver

SMF5030-Pulver wird aufgrund seiner robusten mechanischen Eigenschaften und der einfachen Verarbeitung in zahlreichen Branchen eingesetzt. Nachfolgend sind die wichtigsten Anwendungen aufgeführt, bei denen dieses Pulver glänzt:

Automobilkomponenten

- Zahnräder und Ritzel: SMF5030’s hohe Zugfestigkeit und Verschleißfestigkeit machen es ideal für Teile der Kraftübertragung.

- Komponenten der Nockenwelle: Wird in Baugruppen verwendet, die Ermüdungsfestigkeit und Maßgenauigkeit erfordern.

- Pleuelstangen: Sorgt für die erforderliche Festigkeit und Ausdauer bei dynamischen Belastungen.

Industrielle Maschinen

- Hydraulische Systemteile: Hohe Dichte und minimale Porosität gewährleisten Auslaufsicherheit.

- Lager und Buchsen: Hervorragende Verschleißfestigkeit verlängert die Lebensdauer.

- Klammern und Halterungen: Bietet strukturelle Integrität und Schwingungsdämpfung.

Elektrowerkzeuge und Ausrüstung

- Rotierende Wellen: Ausgewogene Dichte und Zähigkeit verbessern die Konsistenz der Rotation.

- Kupplungen: Hohe Schlagzähigkeit und Ermüdungsfestigkeit.

Zusammenfassung der Anträge nach Branchen:

| Industrie | Gemeinsame Teile mit SMF5030 |

|---|---|

| Automobilindustrie | Zahnräder, Kettenräder, Pleuelstangen, Nockenwellenteile |

| Industrielle Ausrüstung | Lager, Buchsen, hydraulisch kolben |

| Werkzeuge & Maschinen | Wellen, Kupplungen, Strukturkonsolen |

3. Materialeigenschaften und Leistungsmerkmale

Für Ingenieure, Beschaffungsmanager und Produktdesigner ist es wichtig, die Kerneigenschaften von SMF5030-Pulver zu verstehen. Die Formulierung des Pulvers ermöglicht es, strenge Leistungsanforderungen in anspruchsvollen Anwendungen zu erfüllen.

Mechanische Eigenschaften (typische Werte)

| Eigentum | Wert (wie gesintert) |

|---|---|

| Zugfestigkeit | 600-700 MPa |

| Streckgrenze | 450-550 MPa |

| Dehnung | 2-4% |

| Härte | 90-100 HRB |

| Aufprallenergie | 15-20 J |

Thermische und Verarbeitungseigenschaften

- Sinter-Verhalten: Geringer Verzug beim Sintern, daher ideal für Präzisionsteile.

- Wärmeleitfähigkeit: Mäßige thermische Belastung ermöglicht den Einsatz in beheizten Umgebungen.

- Abmessungstoleranz: Hohe Wiederholbarkeit in der Massenproduktion.

Vorteile für B2B-Einkäufer und -Ingenieure

- Near-Net-Shape-Fähigkeit: Verringert den Ausschuss und die Bearbeitungskosten.

- Zuverlässige Lieferkette: Erhältlich bei globalen und chinesischen Anbietern.

- Anpassungsfähigkeit: Die Zusammensetzung der Legierung kann auf spezifische Anforderungen zugeschnitten werden.

Ausführlichere Spezifikationen und Pulversorten finden Sie in unserer PM-Pulver Produktseite.

4. Wachsende Marktnachfrage nach SMF5030 in der Fertigung

Die Nachfrage nach SMF5030-Pulver ist in den letzten Jahren sprunghaft angestiegen, angetrieben durch den weltweiten Trend zu leichten, leistungsstarken und kostengünstigen Fertigungskomponenten. Da Branchen wie die Automobilindustrie, die Luft- und Raumfahrt und der Maschinenbau die Pulvermetallurgie (PM) aus Gründen der Nachhaltigkeit und Effizienz nutzen, hat sich SMF5030 zu einem Grundstoff in der B2B-Lieferkette entwickelt.

Schlüsselfaktoren für die Nachfrage:

- Automobil-Elektrifizierung: Mit der zunehmenden Verbreitung von Elektrofahrzeugen steigt auch die Nachfrage nach leichten, hochfesten Komponenten.

- Massenanpassung: Die Fähigkeit des SMF5030, endkonturnahe Formen herzustellen, unterstützt die flexible Fertigung.

- Ziele der Nachhaltigkeit: Die PM-Fertigung mit SMF5030 reduziert den Materialabfall und den Energieverbrauch.

- Kosteneffizienz: Geringerer Materialverlust und geringere Bearbeitungskosten im Vergleich zum herkömmlichen Gießen oder Schmieden.

Marktwachstumsprognosen

| Region | CAGR (2024-2029) | Wachstumstreibende Schlüsselindustrien |

|---|---|---|

| Asien-Pazifik | 8.5% | Automobilindustrie, Baugewerbe, allgemeine Maschinen |

| Nord-Amerika | 6.8% | Luft- und Raumfahrt, Verteidigung, Werkzeugbau |

| Europa | 5.9% | Automobilindustrie, Industrierobotik |

Der asiatisch-pazifische Raum, insbesondere China, ist aufgrund von Fortschritten bei den PM-Produktionstechnologien, einer günstigen Regierungspolitik und einem robusten Produktionssystem führend in diesem Bereich.

5. Die Wahl des richtigen SMF5030-Pulverlieferanten

Für B2B-Einkäufer ist die Auswahl des richtigen SMF5030-Lieferanten von entscheidender Bedeutung, um Konsistenz, Kosteneffizienz und anwendungsreife Leistung zu gewährleisten. Hier sind die Schlüsselfaktoren, die bei der Bewertung von Lieferanten zu berücksichtigen sind:

Bewertungskriterien für SMF5030-Lieferanten

- Pulverqualität & Konsistenz

- Überprüfen Sie die ISO-Zertifizierung und die Rückverfolgbarkeit der Prozesse.

- Gewährleistung einer strengen Kontrolle der Partikelgrößenverteilung und des Legierungsgehalts.

- Produktionskapazität & Vorlaufzeit

- Können sie Ihre Mengenanforderungen ohne Verzögerungen erfüllen?

- Suchen Sie nach Lieferanten mit skalierbaren Fertigungsmöglichkeiten.

- Technische Unterstützung & Anpassung

- Bieten sie R&D-Unterstützung an?

- Können sie die Legierungszusammensetzung auf Ihre Anwendung abstimmen?

- Globale Logistik & Einhaltung der Vorschriften

- Haben sie Erfahrung mit internationalen Versand- und Zolldokumenten?

- Entsprechen sie REACH, RoHS und anderen globalen Standards?

- Kundendienst

- Technische Unterstützung vor Ort

- Rückverfolgbarkeit der Chargen und Lösung von Qualitätsproblemen

Lieferantenvergleichstabelle

| Name des Lieferanten | Stärken | Beschränkungen |

|---|---|---|

| Shanghai Truer Technologie | Hohe Anpassungsfähigkeit, ISO-zertifiziert, schnelle Lieferung | Begrenzte Präsenz in Nordamerika |

| Hoganas AB | Globale Reichweite, hervorragende F&E-Unterstützung | Höhere Preise |

| GKN Pulvermetallurgie | Starke OEM-Beziehungen | Begrenzte Flexibilität für kleine Käufer |

| Rio Tinto Metall-Pulver | Groß angelegte Lieferkette | Weniger Fokus auf individuelle Noten |

Brauchen Sie Hilfe bei der Auswahl des richtigen Anbieters? Erfahren Sie mehr über unser unternehmen und Produktionsmöglichkeiten um zu sehen, warum wir das Vertrauen von Einkäufern weltweit genießen.

6. Die wichtigsten globalen und chinesischen Lieferanten von SMF5030-Pulver

Wenn Sie SMF5030-Pulver in loser Schüttung beschaffen möchten, finden Sie hier eine Liste der leistungsstärksten Lieferanten weltweit und in China:

Globale Zulieferer

- Höganäs AB (Schweden)

- Branchenführer mit einer breiten PM-Produktpalette.

- Erweiterte technische Unterstützung und F&E-Labors.

- GKN Powder Metallurgy (Deutschland/USA)

- Bietet SMF5030-Varianten im Rahmen seiner Sinterstahllinie an.

- Starke Präsenz im Automobil- und Luftfahrtsektor.

- Rio Tinto Metallpulver (Kanada)

- Hochreine PM-Pulver auf Eisenbasis.

- Fokus auf Nachhaltigkeit und Großaufträge.

Chinesische Lieferanten

- Shanghai Truer Technology Co. Ltd.

- Gegründet im Jahr 2009truer hat sich auf hochwertige PM-Pulver und die Entwicklung kundenspezifischer Legierungen spezialisiert.

- Angebote SMF5030 und andere niedrig legierte Hybridpulver wie FL-4605, FN-0205 und FD-0208.

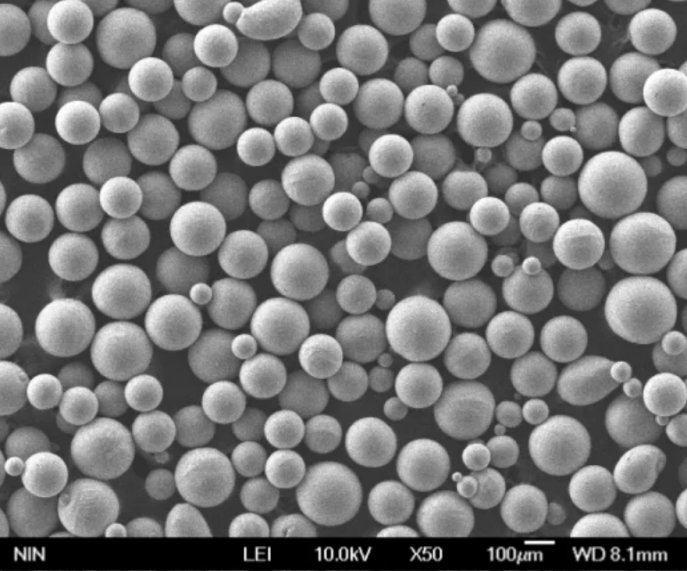

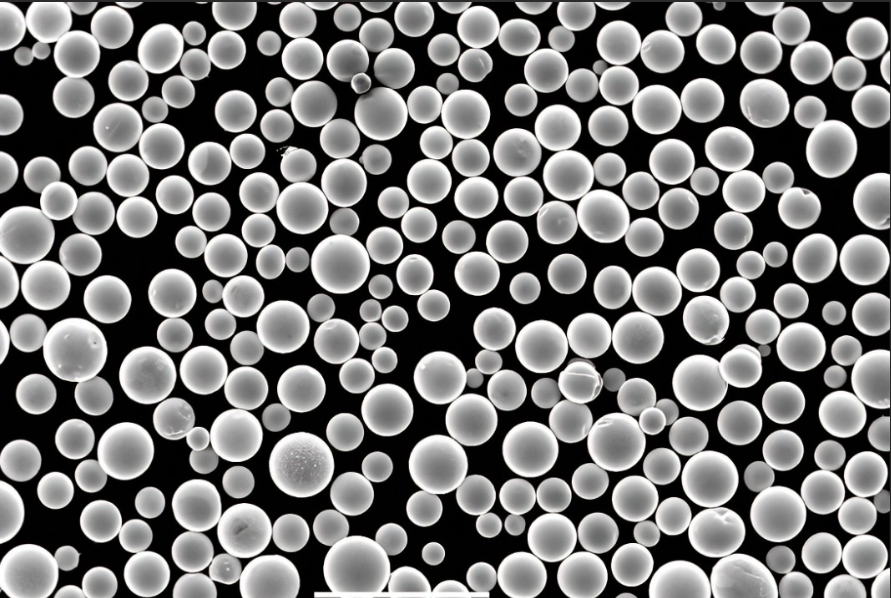

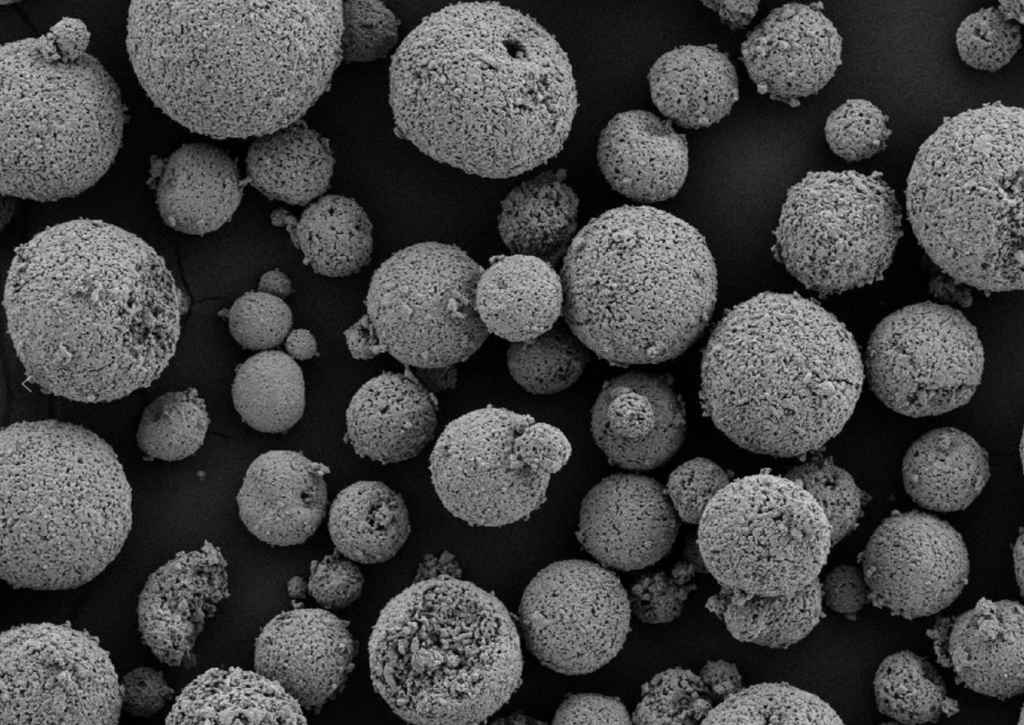

- Die Fähigkeiten umfassen wasserzerstäubung, Gaszerstäubung und kombinierte Verfahren.

- Liefert auch Zusatzstoffe, Schmiermittel und weichmagnetische Materialien.

- CNPC-Pulver-Gruppe

- Bietet eine breite Palette von PM-Pulvern, einschließlich SMF-Alternativen.

- Schwerpunkt auf inländischen Automobil- und Werkzeugbaukunden.

- Jinhu Metallurgie

- Produziert Eisen- und Stahlpulver in Standardqualität.

- Geeignet für großvolumige, preissensible Aufträge.

Für Käufer, die auf Flexibilität, Leistung und technischen Support Wert legen, Shanghai Truer Technologie zeichnet sich als zuverlässiger Partner mit einer umfassenden PM-Lösung aus.

7. Warum mehr B2B-Einkäufer bei chinesischen Herstellern einkaufen

China hat sich schnell zu einem globalen Zentrum für pulvermetallurgische Werkstoffe entwickelt und bietet wettbewerbsfähige Preise, fortschrittliche Produktionstechnologien und kürzere Lieferzeiten. B2B-Einkäufer, insbesondere in den USA, Europa und Südostasien, entscheiden sich zunehmend für chinesische Lieferanten von SMF5030-Pulver, weil:

Vorteile der Beschaffung aus China:

- Niedrigere Materialkosten: Wettbewerbsfähige Preise ohne Kompromisse bei der Qualität.

- Skalierbare Produktion: Die Fähigkeit, sowohl kleine als auch große Aufträge zu erfüllen.

- Personalisierung: Flexible Prozesse ermöglichen maßgeschneiderte Pulvermischungen.

- Fortschrittliche Fertigung: Die Verwendung von Wasser-/Gas-/Kombo-Zerstäubungsmethoden gewährleistet eine hohe Pulverqualität.

- Starke logistische Infrastruktur: Effiziente Hafensysteme und Erfahrung im Export.

Fallstudie: Der Exporterfolg von Truer

Shanghai Truer Technology hat PM-Pulver in über 20 Länder exportiert und seinen Kunden geholfen, die Kosten um bis zu 25 % zu senken und gleichzeitig die mechanischen Eigenschaften der Endprodukte zu verbessern. Ihr Engagement für Qualität und kontinuierliche Innovation hat sie zu einer führenden Wahl für internationale Käufer gemacht, die zuverlässige SMF5030-Lieferanten suchen.

Um Ihre Großbestellung zu besprechen oder ein Angebot anzufordern, kontaktieren Sie uns hier.

8. Warum sollten Sie Shanghai Truer Technology als Ihren SMF5030-Lieferanten wählen?

Wenn es um die Beschaffung von hochleistungsfähigem SMF5030-Pulver für industrielle Anwendungen geht, zeichnet sich Shanghai Truer Technology Co., Ltd. als einer der vertrauenswürdigsten und kompetentesten Lieferanten in der chinesischen Pulvermetallurgie (PM) aus. Mit mehr als einem Jahrzehnt Erfahrung in PM-Materialien und additiver Fertigung bietet Truer eine Kombination aus technischem Know-how, Produktionskapazität und kundenorientiertem Service, die das Unternehmen zu einem bevorzugten Partner für B2B-Käufer weltweit macht.

Die wichtigsten Vorteile der Zusammenarbeit mit Truer:

| Nutzen Sie | Beschreibung |

|---|---|

| 1. Fortgeschrittene Fertigungsmethoden | Wasserzerstäubung, Gaszerstäubung und hybride Verfahren für eine bessere Pulverkontrolle |

| 2. Vielfältige PM-Produktpalette | SMF5030, FL-4605, FN-0205, FD-0208 und eine breite Palette an kundenspezifischen Legierungen |

| 3. Abteilung Integrierte Additive | Eigene Produktion von Schmiermitteln (Lube-W, SUW-5000B), Graphit (TBC-400) und Schneidmitteln (TD-8) |

| 4. Erfahrung im Export | Belieferung der globalen Märkte in den Bereichen Automobil, Werkzeuge und allgemeiner Maschinenbau |

| 5. R&D und Anpassung | Maßgeschneiderte Unterstützung bei der Legierungsentwicklung und Materialprüfung |

| 6. Konkurrenzfähige Preisgestaltung | Direktpreise ab Werk ohne Kompromisse bei der Qualität |

Zertifizierungen und Qualitätssicherung:

- ISO9001:2015 zertifiziert

- Strenge Chargenprüfung und Rückverfolgbarkeit der Qualität

- Einhaltung der internationalen Normen (RoHS, REACH)

Truer's Specialized SMF5030 Pulverfähigkeiten:

- Individuelle Partikelgrößenverteilung

- Hohe Grünfestigkeit und Sinterdichte

- Hervorragende Kompressibilität für Hochleistungswerkzeuge

Entdecken Sie das gesamte Angebot an SMF5030 und anderen Hochleistungs-PM-Materialien auf Truer's PM-Pulver Produktseite.

9. Bestellung von Großhandelspulver SMF5030 bei Truer

Die Bestellung bei Shanghai Truer Technology ist einfach und effizient und wurde zur Unterstützung von B2B-Beschaffungsteams, OEMs und Händlern entwickelt. Ob Sie eine wiederkehrende Bestellung aufgeben oder eine neue Produktlinie testen, Truer bietet skalierbare Lösungen mit umfassender technischer und logistischer Unterstützung.

Schritt-für-Schritt-Bestellverfahren:

- Erste Anfrage

- Kontaktieren Sie Truer über die offizielles Kontakt-Formular oder per E-Mail, um Ihre Anforderungen zu besprechen.

- Geben Sie Spezifikationen an, wie zum Beispiel:

- Gewünschter Pulvertyp (z. B. SMF5030)

- Partikelgrößenbereich

- Menge (MOQ und Großmenge)

- Zeitplan für die Lieferung

- Technische Bestätigungen

- Das technische Team von Truer bestätigt die Produktübereinstimmung oder bietet eine kundenspezifische Formulierung an.

- Auf Anfrage können Muster zur Bewertung versandt werden.

- Angebot und Bedingungen

- Sie erhalten ein detailliertes Angebot:

- FOB/CIF-Preise

- Vorlaufzeit

- Verpackungsoptionen

- Zahlungsbedingungen (T/T, LC, etc.)

- Sie erhalten ein detailliertes Angebot:

- Produktion und Qualitätsprüfung

- Das Pulver wird unter strenger Qualitätskontrolle hergestellt.

- Die Batch-Testberichte werden dem Kunden mitgeteilt.

- Versand und Lieferung

- Truer kümmert sich um die gesamte Logistik, einschließlich Exportdokumentation und Zoll.

- Optionaler Expressversand oder Seefracht je nach Wunsch des Käufers.

- After-Sales-Unterstützung

- Technische Unterstützung bei der Anwendungsintegration.

- Laufende Leistungsüberwachung und Unterstützung bei Nachbestellungen.

Bestell-Tipps für neue Käufer:

- Fordern Sie für jede Charge ein COA (Certificate of Analysis) an.

- Fragen Sie nach Mehrwertdiensten wie Pulvermischung oder Integration von Zusatzstoffen.

- Ziehen Sie Großbestellungen in Betracht, um Kosten für Versand und Stückpreis zu sparen.

Brauchen Sie Hilfe bei Ihrer ersten Bestellung? Besuchen Sie unser kontaktseite um noch heute mit einem Beschaffungsspezialisten zu sprechen.

10. FAQs: SMF5030-Pulver als Bulkware kaufen

Nachfolgend finden Sie einige der am häufigsten gestellten Fragen von B2B-Einkäufern, Ingenieuren und Beschaffungsmanagern zu SMF5030-Pulver.

❓ Wie hoch ist die Mindestbestellmenge (MOQ) für SMF5030-Pulver?

- Das typische MOQ beträgt 100 kg, aber Truer bietet flexible Bedingungen für neue Kunden und F&E-Projekte.

kann ich eine kundenspezifische Legierungsvariante von SMF5030 erhalten?

- Ja, Truer bietet maßgeschneiderte Legierungszusammensetzungen an, um bestimmte Anforderungen an Sinterung, Festigkeit oder Bearbeitbarkeit zu erfüllen.

❓ Welche Verpackungsmöglichkeiten gibt es?

- Die Standardverpackung umfasst 25-kg-Säcke oder 1-Tonnen-Säcke mit Vakuumversiegelung und Feuchtigkeitsschutz.

❓ Wie lange dauert es, bis ich eine Bestellung erhalte?

- Die Vorlaufzeit beträgt in der Regel 10-15 Werktage, je nach Auftragsvolumen und individuellen Anforderungen.

❓ Gibt es technische Unterstützung für die Entwicklung von Teilen?

- Unbedingt. Das F&E-Team von Truer unterstützt Sie bei der Auswahl des Pulvers, dem Anwendungsdesign und der Leistungsprüfung.

❓ Stehen Proben für Tests zur Verfügung?

- Ja, Truer stellt auf Anfrage Mustersendungen in kleinen Mengen zur Bewertung zur Verfügung.

❓ Ist SMF5030 für die additive Fertigung geeignet?

- Truer wird in erster Linie für PM-Press- und Sinterverfahren verwendet, bietet aber auch AM-kompatible Pulver an. Erfahren Sie mehr über ihre 3D-Druckfähigkeiten auf der Über uns Seite.

Letzte Erkenntnis: Partnerschaft mit Truer für zuverlässige SMF5030-Versorgung

Ob Sie ein globaler Händler, ein Automobil-OEM oder ein Hersteller von Industriekomponenten sind, die Beschaffung von qualitativ hochwertigem SMF5030-Pulver ist für die Gewährleistung von Leistung und Rentabilität unerlässlich. Shanghai Truer Technology Co., Ltd liefert nicht nur Material, sondern eine komplette Lösung.

Mit einer breiten Palette an PM-Pulvern, integrierter Unterstützung für Additive und globaler Logistikerfahrung ist Truer Ihr One-Stop-Partner für den Erfolg in der Pulvermetallurgie.

✅ ISO-zertifizierte Produktion

✅ Entwicklung kundenspezifischer Legierungen

✅ Umfassende technische Unterstützung

✅ Lieferung in großen Mengen zu wettbewerbsfähigen Preisen

🔗 Sind Sie bereit für den nächsten Schritt auf Ihrer Beschaffungsreise? Entdecken Sie unser vollständiges Produktkatalog oder Kontakt für ein individuelles Angebot noch heute.