1. Introduction to Selective Laser Melting (SLM) Powder

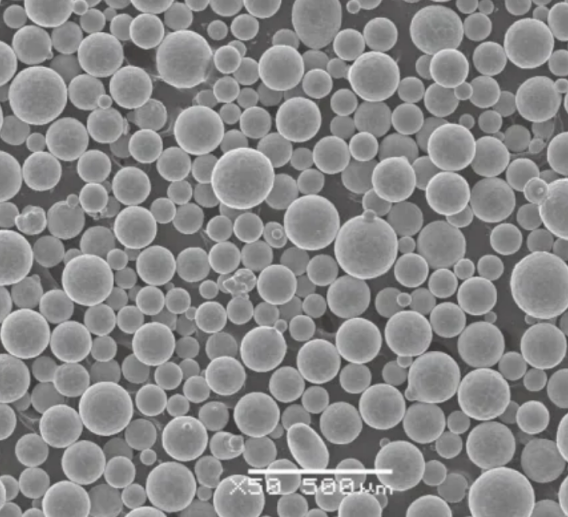

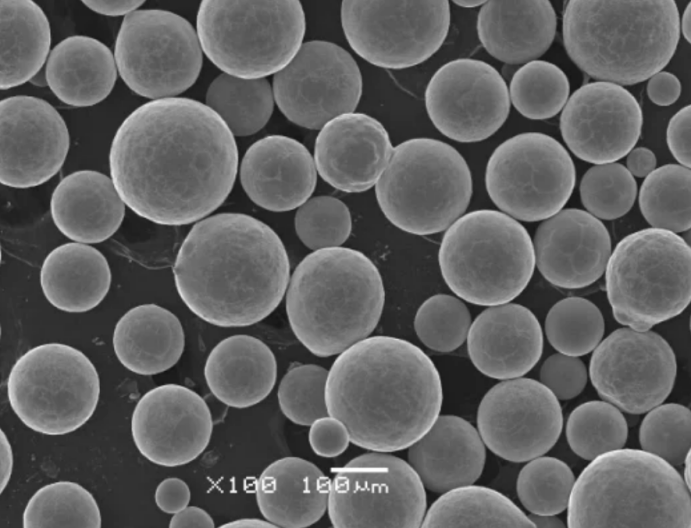

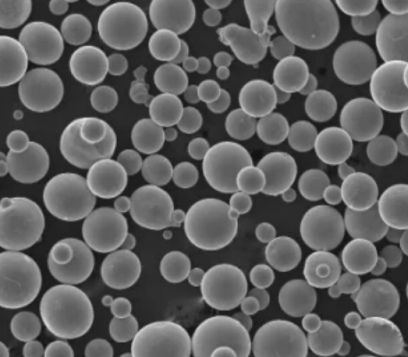

Selective Laser Melting (SLM) is a cutting-edge additive manufacturing (AM) process that uses high-energy lasers to fuse fine metal powders into dense, complex, and high-performance metal parts layer by layer. The quality, consistency, and composition of metal powders used in SLM directly influence the performance of the final product, making SLM powders a critical component in the metal 3D-Druck supply chain.

SLM powders are characterized by:

- High Sphericity: Ensures uniform powder flow and layer deposition.

- Controlled Particle Size Distribution (PSD): Typically ranges from 15–45 μm for optimal laser absorption.

- High Purity & Low Oxygen Content: Enhances mechanical properties and prevents porosity.

- Ausgezeichnete Fließfähigkeit: Vital for consistent layering and part quality.

For B2B buyers, especially those in aerospace, automotive, medical, and industrial tooling, sourcing high-quality SLM powders is essential for reliable and repeatable production.

Wichtige B2B-Schlüsselwörter:

SLM metal powder supplier, 3D printing powder for additive manufacturing, selective laser melting powder wholesale, metal AM powder distributor, SLM powder manufacturer

2. Industrial Applications of SLM Powder

SLM powders serve a wide array of high-precision, performance-critical applications across various industries. Below is a breakdown of how different industries leverage SLM powders:

A. Aerospace Industry

- Manufacture of lightweight, high-strength components (e.g., turbine blades, brackets, heat exchangers)

- Materials: Ti-6Al-4V, Inconel 718, Aluminum AlSi10Mg

B. Medical Sector

- Custom orthopedic implants (hip and knee replacements)

- Dental prosthetics and surgical tools

- Materials: Titanium alloys, CoCrMo

C. Automotive Industry

- Lightweight structural parts for racing and electric vehicles

- Prototyping of complex geometries

- Materials: Stainless steels, aluminum alloys

D. Tooling and Molds

- Conformal cooling channels in injection molds

- Wear-resistant tooling for die-casting

- Materials: Maraging steel, H13 tool steel

E. Energy Sector

- Heat exchangers, fuel nozzles, and combustion components

- Materials: Nickel-based superalloys

Industry-Specific Benefits of SLM Powder:

- Hohes Festigkeits-Gewichts-Verhältnis

- Customization for complex geometries

- Geringerer Materialabfall

- Faster lead times vs. traditional manufacturing

3. Types of Metal Powders Used in Selective Laser Melting

SLM requires metal powders with precisely tuned properties to ensure optimal printing performance. Below are the most commonly used powder types for SLM, along with their characteristics.

| Pulver Typ | Typische Anwendungen | Wichtige Eigenschaften |

|---|---|---|

| Titan-Legierungen | Luft- und Raumfahrt, Medizin | Hohe Festigkeit, Korrosionsbeständigkeit |

| Rostfreie Stähle | Automotive, tooling, medical | Korrosionsbeständigkeit, Duktilität |

| Aluminium-Legierungen | Automobilindustrie, Luft- und Raumfahrt | Leichtes Gewicht, gute Wärmeleitfähigkeit |

| Nickel-Legierungen | Luft- und Raumfahrt, Energie | Hochtemperaturbeständigkeit |

| Kobalt-Chrom (CoCr) | Medizinisch, zahnmedizinisch | Biokompatibilität, Verschleißfestigkeit |

| Werkzeugstähle | Injection molds, dies | High hardness, thermal fatigue resistance |

Shanghai Truer Technology Co., Ltd offers a broad spectrum of SLM-compatible metal powders, including:

- PM stainless steel (gas atomized and water atomized variants)

- PM nickel steel, PM copper steel, and PM infiltrated steels

- Custom grades like FX-1005, FX-2008, FD-0208, FN-5000, and more

These powders are produced using advanced atomization methods such as:

- Gaszerstäubung: Produces highly spherical particles with low oxygen content.

- Wasserzerstäubung: Cost-effective method for certain alloy types.

- Hybride Zerstäubung: Combines benefits of gas and water atomization for superior flow and density.

🔗 Erfahren Sie mehr über our available PM and SLM powders from Shanghai Truer.

4. Market Demand and Growth Trends in SLM Powder

The global selective laser melting (SLM) powder market is experiencing exponential growth, largely driven by the expanding adoption of metal additive manufacturing in high-performance industries. According to industry reports, the global metal AM powder market is expected to exceed USD 3.5 billion by 2028, with SLM powders accounting for a significant share.

Wichtige Markttreiber:

- Increased adoption in aerospace and defense, where lightweight and high-strength parts are essential.

- Expansion of medical and dental 3D printing, especially for patient-specific implants.

- Automotive industry’s shift to electric vehicles, demanding advanced manufacturing for lighter components.

- Government funding and R&D programs in Europe, China, and the U.S. supporting additive manufacturing.

Market Trends:

| Trend | Beschreibung |

|---|---|

| Material Diversification | Rising demand for multi-metal and alloy SLM powders |

| Personalisierung | Custom powder blends tailored for specific AM applications |

| Nachhaltigkeit | Emphasis on recyclable and low-waste powders |

| Expansion im asiatisch-pazifischen Raum | Surge in production and exports from China, Japan, and South Korea |

🌍 For international buyers and distributors, sourcing SLM powders from high-growth markets like China offers a competitive edge in both price and innovation.

5. How to Choose a Reliable SLM Powder Supplier

When selecting a wholesale supplier or manufacturer for SLM powders, it’s critical for B2B buyers to evaluate several key criteria. The right supplier ensures not only consistent powder quality but also technical support, reliability, and scalable supply.

Key Factors to Evaluate:

| Faktor | Warum es wichtig ist |

|---|---|

| Powder Quality Certification | Look for ISO 9001, ASTM, or other relevant standards |

| Produktionsverfahren | Gas atomized powders tend to offer better flowability and sphericity |

| Partikelgrößenverteilung (PSD) | Consistency in PSD affects layer thickness and print resolution |

| Logistik & Vorlaufzeit | Faster shipping and local warehousing reduce downtime |

| Technische Unterstützung | On-demand consultations for material compatibility and performance |

| Konsistenz der Chargen | Essential for repeat production and quality assurance |

Red Flags to Watch For:

- Inconsistent PSD data

- Lack of material traceability

- No in-house R&D or testing facilities

- Limited product range or customization options

Shanghai Truer Technology Co., Ltd stands out as a trusted supplier for global B2B clients, offering not only a wide range of high-performance powders but also end-to-end services from formulation to technical support.

6. Top SLM Powder Manufacturers in Asia-Pacific

The Asia-Pacific region has emerged as a global hub for SLM powder manufacturing, driven by strong industrial infrastructure, cost-effective production, and government-backed AM initiatives. Below are some of the top suppliers to consider:

| Name des Unternehmens | Land | Wichtige Angebote | Stärken |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | PM stainless steel, hybrid low-alloy powders, gas/water atomized SLM powder | Broad product range, R&D support, global exports |

| EOS Materials Asia | Singapur | Proprietary EOS metal powders | Deep integration with EOS 3D printers |

| AP&C (GE-Zusatzstoff) | Japan | Titanium and nickel superalloys | High-purity powders for aerospace |

| Sandvik Fischadler | China/Schweden | gaszerstäubte Pulver | High-performance tooling and medical materials |

| CNPC-Pulver | China | Stainless steel, nickel-based powders | Large production capacity, competitive pricing |

🔗 Looking to partner with a trusted Asian supplier? Contact Shanghai Truer today to explore bulk purchasing options.

7. Why More Buyers Are Sourcing SLM Powder from China

China’s rapid advancements in additive manufacturing technology, combined with its scale of production and cost advantages, have made it a preferred sourcing destination for SLM powders among global buyers.

Advantages of Chinese Sourcing:

- Kosteneffizienz: Lower production and labor costs translate to more competitive pricing.

- Technologischer Fortschritt: Chinese manufacturers increasingly adopt high-end gas atomization and hybrid atomization technologies.

- Entwicklung kundenspezifischer Legierungen: Many suppliers offer tailor-made solutions for specific industries and applications.

- Skalierbare Produktion: Ability to handle high-volume orders for OEMs and large distributors.

- Local Raw Material Access: Lower material procurement costs contribute to overall affordability.

Shanghai Truer exemplifies these benefits by offering:

- Full traceability and batch consistency

- Strategic shipping logistics for international clients

- Proprietary PM powder blends like FX1005, SUW-8000, and FN-5000

- Advanced hybrid atomization techniques for improved powder performance

8. Warum Shanghai Truer Technology Co. wählen?

Since 2009, Shanghai Truer Technology Co., Ltd has been a pioneer in powder metallurgy and additive manufacturing in China. With a dedicated additive manufacturing division launched in 2019, Truer has since become one of the most respected names in the B2B metal powder sector.

Was Truer auszeichnet:

- Umfassendes Produktportfolio: Over 20 SLM-compatible PM powder types including PM bronze, nickel silver, PM infiltrated steel, and stainless steel.

- Fortschrittliche Fertigung: Gas atomized, water atomized, and hybrid atomized powder production lines.

- Custom Solutions for B2B Clients: Tailored powder blends like SBF2218, TBC-400 graphite, and TD-8 cutting agents.

- Globale Reichweite: Export-ready logistics and multilingual support for international buyers.

- Trusted by Industry: Recognized across China’s PM industry for innovation and reliability.

Featured Products for SLM Buyers:

| Produkt-Code | Beschreibung | Zerstäubungsmethode | Anmeldung |

|---|---|---|---|

| FX-1005 | Hybrid low-alloy steel powder | Water/Gas Hybrid | Automotive, tooling |

| FN-5000 | Iron-nickel alloy powder | Zerstäubtes Gas | Aerospace, structural parts |

| FD-0208 | Diffusionslegierter Stahl | Zerstäubtes Wasser | Allgemeines Ingenieurwesen |

| PM 4200 | Hybrid low-alloy | Zerstäubtes Gas | Complex 3D printed tooling |

✅ Visit Truer’s official site to browse the full catalog or request a sample.

9. How to Order Wholesale SLM Powder from Shanghai Truer

For B2B buyers, especially OEMs, distributors, or additive manufacturing service providers, sourcing SLM powder from a reliable manufacturer like Shanghai Truer Technology Co., Ltd is a streamlined and scalable process. Here’s a step-by-step breakdown of how to place a wholesale order:

Schritt-für-Schritt-Bestellprozess

| Schritt | Beschreibung |

|---|---|

| 1. Product Selection | Browse through available SLM powders, including stainless steel, nickel alloys, tool steels, and custom blends like FX-2008, FN-5000. You can view the complete powder portfolio here. |

| 2. Request a Quote | Submit a wholesale inquiry through the Kontakt-Formular, specifying required volumes, grades, and particle size distribution (PSD). |

| 3. Technical Consultation | Truer’s technical team will recommend the best-fit powder based on your application (e.g., aerospace, tooling, or medical). |

| 4. Sample Evaluation | For large-volume clients, sample batches can be shipped for prototyping and testing before finalizing the order. |

| 5. Contract & Payment | Upon agreement, Truer provides a formal quote, MOQ, lead time, and payment terms. |

| 6. Production & Quality Control | Powders are produced and inspected under strict quality standards (ISO, ASTM). COA and PSD reports are provided with each batch. |

| 7. Global Shipping | Truer offers international logistics services, including sea freight, air freight, and support for local warehousing if needed. |

Order Customization Options

- Custom alloy formulations

- Specific PSDs (e.g., 15–45 µm, 20–63 µm)

- Surface treatments and coating options

- Metal powder additives (e.g., graphite TBC-1000, soft magnetic QHP-330)

📦 Whether you’re a regional distributor or a global OEM, Truer is equipped to handle both small-batch prototyping and full-scale production orders.

10. FAQs: Buying SLM Powder for Additive Manufacturing

Q1: What is the minimum order quantity (MOQ) for wholesale buyers?

A: MOQ depends on the type of powder and customization required. For standard grades like FD-0208 or PM stainless steel, MOQ typically starts at 25 kg. For custom formulations, higher MOQs may apply.

Q2: Can Truer provide gas atomized powders for aerospace or medical applications?

A: Yes. Truer produces high-purity gas atomized powders suitable for aerospace, energy, and medical sectors. All batches come with chemical analysis and PSD certification.

Q3: How does Truer ensure powder quality and consistency?

A: Truer implements strict quality control using advanced particle size analyzers, sphericity measurement tools, oxygen/nitrogen analyzers, and batch traceability systems. Each shipment includes a Certificate of Analysis (COA).

Q4: Is international shipping available?

A: Absolutely. Truer ships globally and has experience handling logistics for clients in North America, Europe, Southeast Asia, and the Middle East. Export documentation and customs support are included.

Q5: Can I request a sample before placing a bulk order?

A: Yes. For qualified B2B customers, Truer offers sample evaluation programs. You may request samples of standard or custom powders for testing and 3D print trials.

Q6: How do I know which powder grade fits my application?

A: Truer’s technical engineers will work with you to understand your application and recommend the most suitable powder composition, PSD, and atomization type.

💬 Still have questions? Visit our Über uns Seite to learn more about our expertise and service capabilities.

Final Considerations: Partnering with a Trusted SLM Powder Supplier

Choosing the right SLM powder supplier is a strategic decision for any additive manufacturing business. From product quality and consistency to logistics and support, Shanghai Truer Technology Co., Ltd offers a comprehensive solution for your metal powder needs.

Why Truer Should Be Your Preferred Sourcing Partner:

- ✔️ Over 15 years in metallurgy and powder production

- ✔️ Full line of PM and SLM-compatible powders

- ✔️ Customization for alloy, PSD, and additive needs

- ✔️ Competitive pricing for wholesale buyers

- ✔️ End-to-end support with samples, logistics, and technical consulting

Whether you’re a metal AM service provider, an OEM in aerospace or automotive, or a distributor looking to expand your powder portfolio, Truer provides the reliability, quality, and flexibility you need in a fast-evolving industry.

🔗 Ready to get started? Contact Shanghai Truer today to request a quote or receive a free consultation with our powder experts.

Zusammenfassung der internen Ankerlinks

| Ankertext | Reiseziel |

|---|---|

| our available PM and SLM powders | https://am-material.com/pm-powder/ |

| Contact Shanghai Truer today | https://am-material.com/contact-us/ |

| official site | https://am-material.com/ |

| Über uns Seite | https://am-material.com/about/ |

| complete powder portfolio here | https://am-material.com/pm-powder/ |

This comprehensive blog post has been optimized to attract B2B buyers, distributors, and additive manufacturing professionals searching for high-quality selective laser melting powders. By leveraging Shanghai Truer Technology Co., Ltd as your sourcing partner, you gain access to world-class products, technical expertise, and scalable supply solutions.