1. Introduction: Why Phosphorus-Alloyed Powder Matters in PM

Phosphorus-alloyed powders play a critical role in powder metallurgy (PM) formulations due to their ability to enhance sintering activity, improve mechanical strength, and reduce production costs. These powders are especially valuable in automotive, machinery, and tool manufacturing industries looking for high-performance materials that are cost-effective and easy to process.

Key Benefits of Phosphorus-Alloyed Powders Include:

- Enhanced sintering densification

- Improved wear and fatigue resistance

- Cost-effective alloying alternative

- Better dimensional control

- Increased green strength

Phosphorus additives are commonly alloyed with iron-based powders to form grades like FD-0208 and SBF2218, which are widely used in manufacturing sintered structural parts and gears.

2. Industrial Applications of Phosphorus-Alloyed Powders

Phosphorus-alloyed powders are used across multiple sectors, especially where high wear resistance and strength are required. Below are the primary industries and application segments:

| Industrie | Anmeldung | Benefits of Phosphorus Alloys |

|---|---|---|

| Automobilindustrie | Transmission parts, synchronizer hubs, oil pump gears | Hohe Festigkeit, Ermüdungsbeständigkeit |

| Werkzeugbau | Cutting tools, bushings, bearings | Hervorragende Verschleißfestigkeit |

| Baumaschinen | Load-bearing components | Dimensional stability, cost-efficiency |

| Unterhaltungselektronik | Precision gears, sintered metal cases | Improved compaction, fine detail |

| Luft- und Raumfahrt | Non-critical structural parts | Lightweight, stable under stress |

Phosphorus enhances the bonding between iron particles during sintering, improving the final mechanical properties. For example, FD-0208 is an iron-phosphorus powder alloy that exhibits excellent wear resistance and is ideal for high-load automotive components.

Common Use Cases:

- Sintered oil-impregnated bearings

- Structural sintered components

- High-load bushings

- Sintered gears and cams

3. Types of Phosphorus-Alloyed PM Powders and Properties

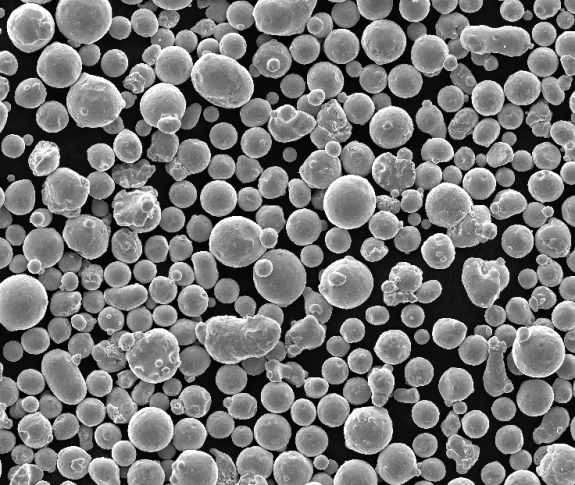

Phosphorus-alloyed powders come in several variations depending on the base metal, phosphorus content, and processing method. Below is a breakdown of commonly used types and their characteristics:

| Pulver Typ | Zusammensetzung | Produktionsverfahren | Typische Anwendungen |

|---|---|---|---|

| FD-0208 | Fe + ~0.8% P | Diffusionslegiert | Strukturteile, Zahnräder |

| SBF2218 | Fe + Cu + P | Prealloyed | High-load sintered parts |

| FC-0208 | Fe + Cu + P | Hybrid Alloy | Automotive synchronizers |

| FN-5000 | Fe + Ni + P | Diffusionslegiert | Shock-resisting parts |

| Specialized CuSn-P | Bronze + P | Diffusionslegiert | Diamond tools, bearings |

Key Properties of Phosphorus-Alloyed Powders:

- Hohe Härte: Phosphorus increases the hardness of sintered parts, making them suitable for wear-heavy applications.

- Verbesserte grüne Stärke: Better compaction and handling before sintering.

- Enhanced Sintering Response: Promotes solid-state diffusion during sintering.

- Kosteneffizienz: Reduces reliance on more expensive alloying elements like nickel or molybdenum.

Shanghai Truer Technology offers a diverse portfolio of phosphorus-alloyed powders, including FD-0208 and SBF2218, produced through advanced diffusion and prealloying techniques. These powders are engineered to meet stringent industry standards for mechanical performance and consistency. Explore our phosphorus-alloyed powder lineup.

4. Market Trends and Global Demand for PM Phosphorus Alloys

The global market for phosphorus-alloyed powders is experiencing steady growth, driven by the expansion of the automotive and industrial machinery sectors. As manufacturers continue to shift toward cost-effective and high-performance materials, phosphorus-alloyed PM powders are becoming increasingly favored.

Wichtige Markttreiber:

- Automobil-Leichtbau: Automakers are increasingly using PM parts for weight reduction without compromising strength.

- Optimierung der Kosten: Phosphorus-alloyed powders offer a more affordable alternative to high-alloy formulations.

- Sustainability Trends: PM manufacturing is more energy-efficient and generates less waste, aligning with global sustainability goals.

- Rise in Electric Vehicles (EVs): More EV components are being produced using sintered PM parts for efficiency and durability.

Regional Demand Overview:

| Region | Market Insights |

|---|---|

| Nord-Amerika | Strong demand from automotive and industrial equipment manufacturers |

| Europa | Increasing use in lightweight, high-strength parts for energy-efficient designs |

| Asien-Pazifik | Rapid industrialization and large-scale automotive production |

| Lateinamerika | Growing interest in cost-effective sintered components |

Growth Forecast:

According to market research reports, the global powder metallurgy market is projected to reach USD 12.5 billion by 2030, with phosphorus-alloyed powders expected to represent a significant share due to their affordability and mechanical performance.

5. Key Considerations When Selecting a Phosphorus-Alloyed Powder Supplier

Choosing the right supplier for phosphorus-alloyed PM powders is critical for manufacturers who need consistency, material integrity, and logistical reliability. Here are the top factors B2B buyers should evaluate:

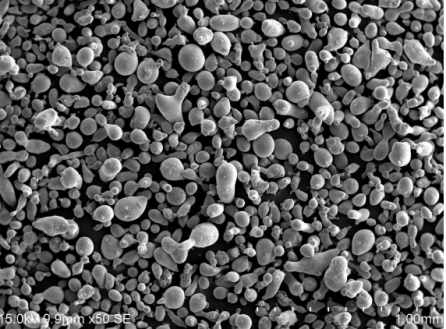

1. Powder Quality and Purity

- Konsistente Partikelgrößenverteilung

- Low oxygen and impurity levels

- High flowability and compressibility

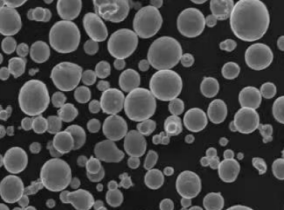

2. Production Method and Technology

- Water atomization, diffusion alloying, or prealloying

- In-house quality control and material testing

- R&D capabilities for custom formulations

3. Compliance and Certification

- ISO 9001, IATF 16949 certifications

- REACH and RoHS compliance

- Material data sheets and MSDS availability

4. Lead Times and Logistics

- Just-in-time (JIT) delivery capabilities

- Global shipping support

- Scalability and inventory availability

5. Technische Unterstützung

- Technische Beratung

- Custom alloy design

- Troubleshooting and after-sales service

💡 Tip for Buyers: Request a sample batch and technical data sheets before placing large-scale orders.

Shanghai Truer Technology stands out as a full-service supplier of phosphorus-alloyed powders, offering diffusion alloyed grades like FD-0208, hybrid alloys like FC-0208, and prealloyed options like SBF2218—all backed by over a decade of metallurgy experience. Learn more about Shanghai Truer’s background and expertise.

6. Top 5 Global Suppliers for Phosphorus-Alloyed PM Powders

For B2B procurement, it’s essential to identify reliable and well-established powder suppliers. Below is a curated list of top global suppliers known for their phosphorus-alloyed PM powder capabilities:

| Name des Lieferanten | Hauptsitz | Notable Products | Zentrale Stärken |

|---|---|---|---|

| Shanghai Truer Technologie | China | FD-0208, FC-0208, SBF2218 | Wide catalog, custom formulations, export-ready |

| Hoganas AB | Schweden | Distaloy HP, Astaloy CrA | Global footprint, automotive-grade certifications |

| GKN Hoeganaes | USA | Ancorsteel™ alloys | Advanced atomization, R&D-backed solutions |

| Rio Tinto Metall-Pulver | Kanada | ATOMET series | Large-scale production, sustainable sourcing |

| JFE Steel Corporation | Japan | Fe-P and Fe-Cu-P powders | High-purity powders for precision applications |

Why Shanghai Truer Technology?

- Over 15 years of powder metallurgy manufacturing experience

- State-of-the-art production lines for diffusion and prealloyed powders

- Exported to 30+ countries

- Responsive support for custom orders and technical queries

Shanghai Truer is recognized as one of China’s most professional additive suppliers in the PM industry, with a strong commitment to innovation, quality, and customer satisfaction. Contact Shanghai Truer for partnership opportunities.

7. Why More Buyers Are Turning to Chinese Phosphorus-Alloyed Powder Sources

In recent years, global manufacturers and distributors have increasingly chosen Chinese suppliers for phosphorus-alloyed PM powders. This shift is driven by several strategic advantages that Chinese manufacturers—especially industry veterans like Shanghai Truer Technology—bring to the table.

Key Competitive Advantages of Chinese Suppliers:

| Vorteil | Beschreibung |

|---|---|

| Kosteneffizienz | Lower raw material and labor costs result in highly competitive pricing. |

| Produktionskapazität | High-volume output supports large-scale orders and consistent availability. |

| Technologische Fortschritte | State-of-the-art atomization, diffusion, and hybrid production lines. |

| Flexibilität bei der Anpassung | Ability to develop niche grades and modified formulations on demand. |

| Export-Ready Logistics | Established global shipping channels and compliance with international standards. |

Strategic Value for Distributors and OEMs:

- Kürzere Vorlaufzeiten: Many Chinese suppliers have optimized logistics and warehousing to enable fast delivery.

- Local Sourcing Hubs: Distributors can establish regional warehouses to better serve local OEMs.

- Private Labeling & Branding: Custom packaging and labeling services support B2B marketing and resale.

Shanghai Truer Technology exemplifies these advantages by offering a full-service experience—from R&D to logistics—for its phosphorus-alloyed powders. The company’s strong presence in both domestic and international markets underscores its reliability and scale.

🧭 For buyers looking to diversify their supply chain or reduce procurement costs, Shanghai Truer’s PM powder catalog offers an ideal starting point.

8. Warum Sie Shanghai Truer Technology als Ihren PM-Pulver-Partner wählen sollten

Shanghai Truer Technology Co., Ltd, founded in 2009, has become one of China’s most reliable and professional providers of powder metallurgy materials and additive manufacturing solutions.

Was zeichnet Truer aus?

| Merkmal | Nutzen für B2B-Einkäufer |

|---|---|

| Diverse Powder Range | Phosphorus-alloyed, iron-copper, nickel steel, stainless, and more. |

| Fortschrittliche Fertigung | Water, gas, and combined atomization; diffusion and hybrid alloying. |

| Technisches Fachwissen | In-house metallurgists and engineers support custom formulation needs. |

| Sicherung der Qualität | Strict testing for particle size, purity, compressibility, and flow rate. |

| Globale Exporterfahrung | Serving clients in Europe, North America, Southeast Asia, and beyond. |

Example Grades Offered by Shanghai Truer:

- FD-0208: Iron-phosphorus alloy with excellent wear resistance

- SBF2218: Prealloyed iron-copper-phosphorus for high-load applications

- FC-0208: Hybrid alloy with excellent green strength and sinterability

- FN-5000: Iron-nickel-phosphorus alloy for impact-resistant parts

Additive Solutions Beyond Metal Powders:

In addition to PM base powders, Truer also supplies a comprehensive range of additives:

- Schmiermittel: Lube-W, SUW-5000B, SUW-8000

- Schneidmittel: Mangansulfid, SME-100 (schwefelfrei), TD-8 (Verbundwerkstoff)

- Soft magnetic additives: QH-150, QHP-330

- Graphite grades: TBC-400, TBC-1000

🔗 Visit our homepage to explore our full solution portfolio

Truer’s commitment to innovation, product quality, and customer satisfaction makes it the supplier of choice for hundreds of global enterprises and emerging manufacturers alike.

9. FAQs: Common Questions About Buying Phosphorus-Alloyed Powders in Bulk

Q1: What grade of phosphorus-alloyed powder is best for automotive sintered parts?

A: FD-0208 and SBF2218 are ideal due to their high strength, wear resistance, and excellent sinterability. These grades are commonly used in gears, hubs, and bushings.

Q2: How is phosphorus added to PM powders?

A: Phosphorus is typically introduced via diffusion alloying or prealloying techniques. Shanghai Truer uses advanced diffusion methods to ensure consistent phosphorus dispersion.

Q3: What are the minimum order quantities (MOQs) for wholesale orders?

A: Shanghai Truer offers flexible MOQs depending on the powder type and customer requirements. For most standard grades, MOQ starts at 500 kg.

Q4: Can Truer provide custom formulations?

A: Yes, Truer’s R&D team works closely with clients to develop custom alloy compositions for specific mechanical or manufacturing requirements.

Q5: How do I request a quote or technical data sheet?

A: You can request a quote or technical documentation directly via the kontaktseite. A technical sales representative will respond within 24 hours.

Q6: Are Truer’s powders compliant with international standards?

A: Yes, all PM powders are produced in accordance with international standards (ASTM, ISO, MPIF) and come with full documentation.

Q7: What is the typical lead time for international orders?

A: Lead times vary by region and order volume but usually range from 2–4 weeks. Truer offers expedited shipping options for urgent orders.

By leveraging Shanghai Truer Technology’s rich portfolio of phosphorus-alloyed powders, global buyers and manufacturers can optimize their product performance, reduce costs, and streamline their supply chains.

🔍 Ready to boost your PM production with high-performance phosphorus-alloyed powders? Contact our team today for samples, pricing, and technical guidance.