Introduction: Why Mar-M247 Powder Is Critical in High-Performance Industries

Mar-M247 is a nickel-based superalloy powder widely used in high-temperature, high-stress environments where superior mechanical strength, corrosion resistance, and thermal stability are essential. Developed initially for aerospace applications, this alloy is now indispensable across various industries that require parts to perform under extreme conditions.

What Makes Mar-M247 Powder Unique?

- Hohe Kriechstromfestigkeit

- Excellent castability

- Outstanding oxidation and corrosion resistance

- Superior fatigue strength at elevated temperatures

These attributes make Mar-M247 a go-to material for turbine engine components, aerospace brackets, and other complex parts manufactured via additive manufacturing (AM) or conventional powder metallurgy (PM).

B2B Significance of Mar-M247

For OEMs, aerospace contractors, and turbine manufacturers, sourcing high-quality Mar-M247 powder is not just a technical requirement—it’s a business-critical process that directly affects product reliability and compliance with industry standards.

Applications of Mar-M247 in Aerospace and Gas Turbine Manufacturing

Mar-M247 powder is specifically engineered for applications where parts must withstand high temperatures, thermal cycling, and mechanical stress. Its capabilities make it ideal for the following uses:

1. Aerospace Applications

| Komponente | Funktion | Reason for Using Mar-M247 |

|---|---|---|

| Turbine blades | Convert heat to mechanical energy | High creep and fatigue resistance |

| Combustor liners | Contain high-pressure combustion gases | Ausgezeichnete Oxidationsbeständigkeit |

| Nozzle guide vanes | Direct gas flow in turbines | Dimensional stability at high temperatures |

| Aerospace brackets & mounts | Structural stabilization | Strength-to-weight ratio advantage |

2. Industrial & Power Generation Turbines

- Gas turbines: Mar-M247 is used for hot-section components due to its high thermal fatigue strength.

- Heat exchangers: The alloy resists oxidation, making it suitable for corrosive and high-temperature environments.

3. Additive Fertigung (3D-Druck)

Mar-M247 powder is increasingly used in metal 3D-Druck technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM) for:

- Rapid prototyping of turbine components

- Lightweight structural elements for aerospace

- Complex geometries that are difficult to cast or forge

Key Properties and Use Cases of Mar-M247 Powder

Mar-M247 is a precipitation-hardenable nickel-based alloy designed to perform in extreme conditions. Its chemical composition includes chromium, cobalt, aluminum, titanium, tantalum, and hafnium, which contribute to its high-performance characteristics.

Chemische Zusammensetzung (typisch)

| Element | Inhalt (%) |

|---|---|

| Nickel (Ni) | Waage |

| Chrom (Cr) | 8.0 - 10.0 |

| Kobalt (Co) | 9.0 – 10.5 |

| Aluminium (Al) | 5.3 – 6.3 |

| Titan (Ti) | 0.7 – 1.1 |

| Tantal (Ta) | 3.0 – 4.2 |

| Hafnium (Hf) | 1.2 – 1.6 |

| Kohlenstoff (C) | ≤ 0.15 |

| Bor (B) | ≤ 0.015 |

| Zirkonium (Zr) | ≤ 0.10 |

Key Mechanical Properties

- Tensile Strength: > 1,100 MPa

- Creep Rupture Strength: Excellent up to 980°C

- Hardness (HRC): ~40–45 after heat treatment

- Die Dichte: 8.8–9.0 g/cm³

Summary of Use Cases

| Industrie | Komponente | Benefit of Mar-M247 |

|---|---|---|

| Luft- und Raumfahrt | Turbine blades, seals | High thermal fatigue & creep strength |

| Stromerzeugung | Gas turbines, liners | Oxidationsbeständigkeit |

| Additive Fertigung | Custom aerospace parts | Precision and performance |

| Verteidigung | Jet engine components | Durability under combat conditions |

For businesses sourcing Mar-M247, it’s critical to ensure powder quality, consistency, and traceability. That’s where trusted suppliers like Shanghai Truer Technology come into play.

🔗 Learn more about Truer’s PM and AM powder capabilities on the PM-Pulver-Seite.

Global Market Trends and Demand for Mar-M247 Powder

The global demand for high-temperature superalloy powders like Mar-M247 has surged in recent years due to the rapid expansion of aerospace, defense, and energy sectors. With the growth of additive manufacturing (AM) and powder metallurgy (PM) technologies, Mar-M247 has become a cornerstone material for manufacturers aiming to produce complex, high-performance parts.

Haupttreiber des Marktwachstums

1. Aerospace Industry Expansion

- Commercial Aviation: Demand for fuel-efficient engines is driving the need for high-temperature alloys like Mar-M247.

- Space Exploration: Reusable rocket engines and satellite components require materials that can withstand extreme conditions.

- Military Aviation: Advanced jet engines require materials with superior creep and fatigue resistance.

2. Additive Manufacturing Adoption

- Metal 3D printing is now widely used for producing turbine blades and other high-stress components.

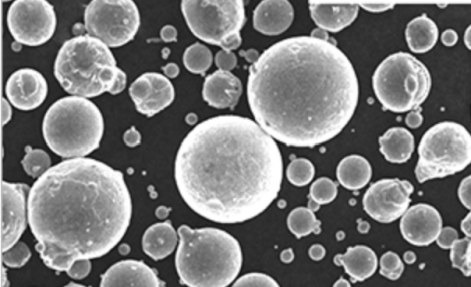

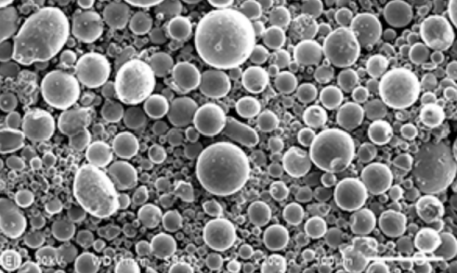

- Mar-M247 powder is favored for its flowability, spherical morphology, and high-temperature stability.

3. Sustainability and Energy Efficiency

- Gas turbines in power plants are being redesigned for higher efficiency, requiring materials like Mar-M247 that can operate at elevated temperatures for longer service lives.

Market Size & Forecast

| Jahr | Global Market for Nickel-Based Superalloy Powders (USD Billion) |

|---|---|

| 2022 | 1.15 |

| 2023 | 1.34 |

| 2024 | 1.52 (estimated) |

| 2027 | 2.10+ (projected) |

Growth is particularly strong in Asia-Pacific due to increased investments in aerospace and defense manufacturing.

How to Choose a Reliable Mar-M247 Powder Supplier

Selecting the right supplier is crucial for OEMs, distributors, and contractors who require consistency, traceability, and performance. Here’s how to evaluate a Mar-M247 supplier from a B2B perspective.

Wichtige Bewertungskriterien

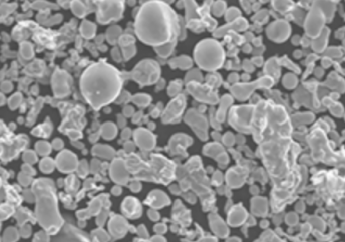

1. Powder Quality & Particle Morphology

- Sphärizität: Critical for 3D printing / AM applications.

- Partikelgrößenverteilung (PSD): Consistency affects flowability and build quality.

- Reinheit: Low oxygen and carbon content minimize the risk of oxidation and cracking.

2. Production Method & Traceability

- Gaszerstäubung: Preferred method for AM-grade Mar-M247 due to its high sphericity and low contamination.

- Batch Certification: Ensure full traceability and compliance with aerospace standards (e.g., AMS, ASTM).

3. Logistics & Global Availability

- Evaluate the supplier’s ability to ship globally with minimal lead time.

- Check for local warehousing or partnerships to reduce logistics costs.

4. Technical Support & Documentation

- Suppliers should offer:

- Technical datasheets

- MSDS certifications

- Custom particle size options

- R&D collaboration for new applications

5. Industry Certifications

- Look for ISO 9001, AS9100, or NADCAP certifications that validate quality management practices.

Checkliste zur Lieferantenbewertung

| Kriterien | Bedeutung | Supplier Y/N |

|---|---|---|

| Gaszerstäubungsprozess | Hoch | ✅ |

| Aerospace Certifications | Hoch | ✅ |

| Custom PSD Options | Mittel | ✅ |

| Globale Schifffahrt und Logistik | Hoch | ✅ |

| R&D Collaboration Support | Mittel | ✅ |

Top 5 Global Suppliers of Mar-M247 Powder

1. Shanghai Truer Technology Co, Ltd (China)

Website: Visit Truer’s official website

Shanghai Truer is a leading Chinese manufacturer specializing in additive manufacturing powders and PM solutions. With over a decade of experience, Truer offers high-quality Mar-M247 powder produced via gas atomization, suitable for aerospace and turbine applications.

Die wichtigsten Vorteile:

- Competitive pricing for bulk/wholesale orders

- Custom particle size distributions

- Excellent customer service and fast global shipping

- Full traceability and quality certifications

- Extensive portfolio of PM and AM powders

🔗 Learn more about Truer’s history and capabilities on their Über uns Seite.

2. Praxair Surface Technologies (USA)

A major player in the industrial gas and powder metallurgy sectors, Praxair (now part of Linde) supplies high-purity Mar-M247 powder for AM and PM applications.

Stärken:

- Advanced gas atomization facilities

- Strong aerospace client base

- High consistency in PSD and morphology

3. Höganäs AB (Sweden)

Höganäs is a globally recognized powder metallurgy company offering specialty alloys, including Mar-M247, for advanced manufacturing sectors.

Stärken:

- Extensive R&D capabilities

- Strong EU and North American distribution networks

- Technical support for AM clients

4. Carpenter Additive (USA)

Carpenter Technology provides high-performance powders for AM with a focus on aerospace and medical alloys.

Stärken:

- Expertise in nickel-based superalloys

- Strict quality control and batch-to-batch consistency

- Dedicated AM division

5. Aubert & Duval (France)

Aubert & Duval, part of the Eramet Group, is a key European producer of high-performance alloys for aerospace, including Mar-M247.

Stärken:

- Strong presence in global defense aerospace sectors

- High-quality powder and ingot production

- Aerospace-certified supply chain

Why More Buyers Are Turning to Chinese Producers for Mar-M247

With global supply chain disruptions and rising costs from Western suppliers, many B2B buyers are exploring alternative sources for high-quality superalloy powders.

Vorteile der Beschaffung aus China

| Faktor | Nutzen Sie |

|---|---|

| Preisliche Wettbewerbsfähigkeit | Lower costs for high-volume orders |

| Fortschrittliche Fertigung | State-of-the-art atomization technology |

| Vertikale Integration | From powder production to packaging |

| Personalisierung | Flexible PSD and additive options |

| Growing Export Ecosystem | Efficient logistics and compliance |

Warum Shanghai Truer Technology sich abhebt

- Gegründet im Jahr 2009 with a dedicated AM division since 2019

- Bietet sowohl PM and AM powders, including Mar-M247

- Entwicklung kundenspezifischer Legierungen und R&D partnerships

- Full technical support and export documentation

- Proven track record in supplying to global B2B clients

🔗 Ready to get started? Visit Truer’s Kontakt Seite um ein Angebot oder Muster anzufordern.

How to Order Wholesale Mar-M247 Powder from Shanghai Truer

For B2B buyers, aerospace manufacturers, and 3D printing service providers, ordering Mar-M247 powder in bulk requires a supplier that offers not only high-quality materials but also a seamless and efficient procurement process. Shanghai Truer Technology Co., Ltd offers a streamlined ordering system designed specifically for wholesale and industrial clients.

Schritt-für-Schritt-Bestellprozess

Step 1: Product Inquiry

- Besuchen Sie die offizielle Website and navigate to the PM-Pulver oder Kontakt seite.

- Fill out the inquiry form with details such as:

- Erforderliche Menge

- Particle size distribution (e.g., 15–45 µm for AM, 45–105 µm for PM)

- Application (e.g., aerospace casting, AM, turbine components)

- Required certifications (e.g., ISO 9001, material test reports)

Schritt 2: Technische Konsultation (fakultativ)

- Truer’s technical team will assist you with:

- Selecting the correct PSD based on application

- Customizing alloy composition if needed

- Providing datasheets and relevant documentation

Step 3: Quotation & Sample Provision

- Receive a competitive quote based on quantity and shipping destination.

- Request a free sample (for qualifying B2B clients) to test consistency, morphology, and flowability.

Step 4: Order Confirmation

- Sign a purchase agreement or confirm a PO (Purchase Order).

- Provide shipping and billing details.

Step 5: Production & Quality Check

- Truer prepares your order under strict QC protocols:

- Gas atomization or blended powder process

- Sieve analysis and morphology verification

- Batch traceability and lot number assignment

- Packaged in moisture-proof, anti-contamination containers.

Step 6: Global Shipping & Delivery

- Truer supports:

- Air freight for urgent orders

- Seefracht for cost-effective bulk shipping

- Incoterms: FOB, CIF, EXW available

- All necessary documentation (MSDS, COO, RoHS, etc.) provided.

Supported Order Sizes

| Art der Bestellung | Quantity Range | Target Buyers |

|---|---|---|

| Trial Order | 5 – 20 kg | R&D labs, small AM startups |

| Mid-size Order | 50 – 500 kg | Aerospace part makers, 3D printing firms |

| Bulk Wholesale Order | 1,000+ kg | OEMs, turbine manufacturers, distributors |

🔗 Ready to place an order? Go to the Kontakt Seite um loszulegen.

FAQs: Common Questions About Buying Wholesale Mar-M247 Powder

1. What is the minimum order quantity (MOQ) for Mar-M247 powder?

- MOQ depends on the application and particle size:

- AM-grade powder: mindestens 5 kg

- PM-grade powder: mindestens 20 kg

- Customized MOQ available for long-term contracts

2. What particle size distributions are available?

- Standard options include:

- 15–45 µm: SLM, EBM, DMLS 3D printing

- 45–105 µm: Press and sinter PM applications

- Custom sieving available upon request

3. Is Mar-M247 powder certified for aerospace applications?

- Yes. Shanghai Truer provides full documentation including:

- Material Test Reports (MTRs)

- Analysezertifikat (COA)

- ISO 9001 Quality Management Certificate

4. Can I request a sample before placing a bulk order?

- Absolutely. Samples (typically 200–500g) are available for testing.

- Some restrictions may apply based on region or shipping regulations.

5. How is the powder packaged for export?

- Standard packaging:

- Vacuum-sealed aluminum foil bags (1–5 kg)

- Steel drums with inert gas purge (25–50 kg)

- All packages are moisture-resistant and contamination-proof.

6. What payment terms are available?

- Flexible options based on order size and client history:

- T/T (Telegraphic Transfer)

- L/C (Letter of Credit)

- Partial advance + balance on delivery

7. Does Truer offer custom alloy development?

- Yes. Truer’s R&D team can support:

- Alloy tweaking

- Hybrid powder mixtures

- Additive package integration (e.g., lubricants, sintering aids)

8. Can I become a distributor of Truer’s metal powders?

- Truer welcomes partnerships with:

- Regional distributors

- 3D-Druck-Dienstleister

- Aerospace component suppliers

- Contact the sales team to discuss distribution agreements.

🔗 Learn more about Truer’s powder range on the PM-Pulver-Seite

Summary of Internal Anchor Links Used

| Ankertext | Linked URL |

|---|---|

| PM-Pulver-Seite | https://am-material.com/pm-powder/ |

| Über uns Seite | https://am-material.com/about/ |

| Kontakt Seite | https://am-material.com/contact-us/ |

| Visit Truer’s official website | https://am-material.com/ |

| Learn more about Truer’s history | https://am-material.com/about/ |

This completes the comprehensive B2B guide to sourcing Mar-M247 powder for high-performance applications. By selecting Shanghai Truer Technology Co., Ltd as your supplier, you’re partnering with a trusted leader in the Chinese powder metallurgy and additive manufacturing industry—backed by over 14 years of expertise, advanced production capabilities, and a client-first approach.

🔗 For quotes, samples, or technical support, kontaktieren Sie das Truer-Team noch heute.