1. Introduction: Why High-Speed Steel Powder Matters in Manufacturing

High-speed steel (HSS) powder is a foundational material in precision manufacturing, toolmaking, and additive manufacturing processes. Its superior hardness, wear resistance, toughness, and ability to retain cutting-edge properties at high temperatures make it indispensable in metalworking and engineering industries.

Die wichtigsten Vorteile für B2B-Käufer:

- High Thermal Resistance: Ideal for high-speed machining tools.

- Hervorragende Abnutzungsbeständigkeit: Increases component life in harsh environments.

- Powder Metallurgy Compatibility: Enables complex shapes and near-net-shape components.

Why It’s Relevant to Wholesale Buyers and OEMs:

- Kosteneffizienz: Powder metallurgy allows for reduced waste and energy use.

- Skalierbarkeit: Ideal for mass production of cutting tools, dies, and automotive parts.

- Personalisierung: Tailored compositions available for industry-specific needs.

Companies sourcing high-speed steel powder are increasingly seeking reliable suppliers who can meet technical standards, ensure consistent quality, and offer scalable solutions for OEM and industrial applications.

2. Applications of HSS Powder in Industrial Sectors

High-speed steel powder plays a critical role in a variety of industries where strength, heat resistance, and precision are non-negotiable.

Major Industries Using HSS Powder:

| Industrie | Anwendungen |

|---|---|

| Automobilindustrie | Camshafts, gears, valve seats, fuel injectors |

| Werkzeug & Matrize | Drills, milling cutters, taps, cold-forming tools |

| Luft- und Raumfahrt | Turbine blades, structural fasteners, engine components |

| Öl & Gas | Schneidwerkzeuge, verschleißfeste Teile |

| Additive Fertigung | High-performance 3D printed tools and dies |

B2B Use Cases:

- Tool Manufacturers: Need high wear resistance, precision, and temperature resilience.

- OEMs: Demand bulk quantities with consistent metallurgical properties.

- Vertriebspartner: Seek reliable sourcing for regional resale.

For a wide range of PM powder applications, including HSS, Shanghai Truer offers customizable grades and technical support.

3. Types of High-Speed Steel Powders and Their Properties

High-speed steel powders are classified based on their chemical composition and hardening characteristics. Each type caters to specific industrial needs.

Common Grades of HSS Powder:

| Klasse | Zusammensetzung | Eigenschaften | Anwendungsfall |

|---|---|---|---|

| M2 | Fe-C-Mo-W-V | General purpose, good wear resistance | Metal cutting tools |

| M42 | Fe-Co-Mo-W-Cr-V | High red hardness, cobalt enriched | Aerospace, high-speed tools |

| T15 | Fe-W-Cr-V | Tungsten-based, high hardness | Precision cutting tools |

| PM T15 | Powder-metallurgy variant | Erhöhte Zähigkeit | Complex tool shapes |

Powder Manufacturing Methods:

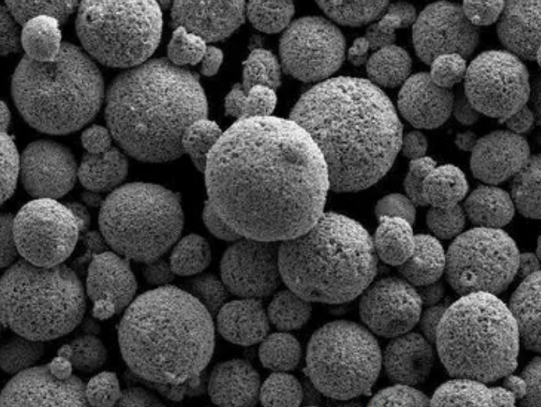

- Gaszerstäubung: Produces spherical powders with high purity and flowability.

- Wasserzerstäubung: More cost-effective, slightly irregular shapes.

- Spray Conversion or Mechanical Alloying: Used for specific advanced grades.

Why Powder Metallurgy HSS Is Preferred:

✔ Allows near-net shaping

✔ Reduces machining costs

✔ Enhances microstructure uniformity

✔ Enables reuse and recyclability

Shanghai Truer Technology offers a wide selection of PM stainless steel and HSS powders in both water and gas atomized forms. Visit the Über uns page to learn more about our metallurgy expertise and innovation.

4. Global Market Trends and Growth in HSS Powder Demand

The global demand for high-speed steel (HSS) powder is on a sharp incline, driven by the rise of precision manufacturing, electrification of vehicles, and advancements in additive manufacturing technologies. For B2B buyers, understanding these trends is crucial for strategic sourcing and long-term procurement planning.

Wichtige Markttreiber:

- Increased Demand for Precision Tools

As industries like aerospace, automotive, and electronics become more reliant on high-precision machining, the demand for wear-resistant and heat-resistant materials like HSS grows. - Additive Manufacturing Boom

The shift toward 3D-Druck and metal additive manufacturing has spurred demand for spherical, high-purity HSS powders. - Asia-Pacific as a Manufacturing Hub

Countries like China, India, and South Korea are emerging as key players due to lower production costs and advanced PM capabilities.

Market Growth Statistics:

| Region | Marktanteil (%) | Key Growth Factors |

|---|---|---|

| Asien-Pazifik | 42% | Cost-effective production, industrial expansion |

| Nord-Amerika | 25% | Innovation-led demand, aerospace sector |

| Europa | 20% | Automotive and tooling exports |

| Rest of the World | 13% | Emerging industries and infrastructure |

Wholesale buyers and tool manufacturers are turning to powder metallurgy as a scalable, sustainable production method. The trend is clear: demand for PM-Pulver like HSS is moving rapidly toward high-volume, high-performance solutions.

5. Choosing the Right HSS Powder Supplier: Key Considerations

When sourcing high-speed steel powder in bulk, the quality of your supplier directly impacts your production outcomes. Below are essential factors to consider for wholesale buyers, OEMs, and distributors.

Key Selection Criteria:

| Faktor | Bedeutung | Was zu beachten ist |

|---|---|---|

| Purity & Particle Size | ⚙️ Critical | Consistency and tight tolerances |

| Produktionsverfahren | ⚒️ High | Gas atomized for high-end applications |

| Personalisierung | 📐 Very Important | Ability to tailor compositions |

| Zertifizierungen | 📄 Essential | ISO, REACH, RoHS compliance |

| Lieferkapazität | 🚛 Vital | Ability to handle large, recurring orders |

| Technische Unterstützung | 🧪 Valuable | Guidance on use, performance tuning |

Zu vermeidende rote Fahnen:

- Inconsistent batch quality

- Fehlende Dokumentation oder Rückverfolgbarkeit

- Limited powder grades or customization

- No local support or after-sales service

A trusted supplier like Shanghai Truer Technologie not only meets these criteria but also helps clients optimize material usage and cost-efficiency with technical guidance and tailored solutions.

6. Top 5 High-Speed Steel Powder Suppliers in Asia

Asia is home to some of the most advanced powder metallurgy manufacturers. Here are five key suppliers known for their quality, scale, and innovation in high-speed steel powder.

Top Asian HSS Powder Suppliers:

| Unternehmen | Land | Stärken | Wichtige Produkte |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | China | Wide range of PM grades, strong R&D | HSS, PM steel, stainless steel powders |

| Daido-Stahl | Japan | High-end tool steels | M2, M42, T15 |

| Hitachi Metalle | Japan | Cobalt-rich HSS powders | M42, PM high-performance HSS |

| Powdertech | Indien | Competitive pricing, bulk capacity | M2, M35 |

| POSCO Powder Materials | Südkorea | OEM-focused, advanced atomization | Gas atomized HSS powders |

Shanghai Truer Technologie stands out with its combination of:

- 15+ years in powder metallurgy

- Integrated 3D printing powders and equipment solutions

- Specialization in both water and gas atomized HSS and stainless steel powders

- Proven supply chain serving toolmakers, OEMs, and additive manufacturers

Sie können kontakt zu Shanghai Truer directly to request a sample, get technical specifications, or discuss your custom powder needs.

7. Why More OEMs Are Turning to Chinese HSS Powder Sources

China has become a strategic sourcing destination for OEMs and industrial buyers seeking high-performance metal powders at competitive prices. The combination of advanced manufacturing capabilities, raw material availability, and cost advantages makes Chinese suppliers extremely attractive.

Key Advantages of Sourcing from China:

- Niedrigere Produktionskosten: Economies of scale and local raw materials reduce overall pricing.

- Technology Integration: Suppliers like Truer offer in-house R&D and customization.

- Global Logistics Infrastructure: Fast lead times and export-ready capabilities.

- Hochwertige Standards: ISO-certified facilities and rigorous QC.

Risk Mitigation Tips for B2B Buyers:

- Partner with established suppliers with export experience

- Insist on batch testing and material traceability

- Start with small batch orders to evaluate quality and service

With a growing list of international clients, Shanghai Truer has become a go-to partner for OEMs worldwide. Explore their full product range on the official site.

8. Why Choose Shanghai Truer Technology as Your HSS Powder Supplier

When it comes to sourcing high-speed steel powder for industrial or additive manufacturing applications, Shanghai Truer Technology Co., Ltd. stands out as a trusted, innovative, and technically advanced partner for B2B buyers, OEMs, and distributors.

Überblick über das Unternehmen

Shanghai Truer Technology Co, Ltd. was established in 2009 and entered the additive manufacturing market in 2019. Today, it is one of the most respected powder metallurgy (PM) solutions providers in China. The company integrates 3D printing powder manufacturing equipment, customized powder production, and technical services to support engineering and industrial applications.

Why Truer is a Preferred Partner:

✅ Umfassendes Produktportfolio

Truer manufactures a wide range of PM powders including:

- PM HSS powders (M2, M42, T15, etc.)

- PM stainless steels (gas & water atomized)

- Prealloyed, hybrid, infiltrated steels

- Soft magnetic materials, cutting agents, lubricants

✅ Flexible Production Methods

- Gas atomization for high-purity, spherical HSS powders

- Water atomization for cost-effective bulk supply

- Combined atomization for unique performance blends

✅ Technical Expertise & Support

- R&D-backed powder customization

- Metallurgical consultation and additive manufacturing support

- Tailored solutions for toolmakers, automotive OEMs, and AM manufacturers

✅ Global Supply Chain Ready

- Proven track record with international buyers

- Export-compliant logistics and documentation

- Responsive communication in English and other languages

✅ Innovation & Sustainability

Truer is committed to sustainable metallurgy and cost-efficient powder production, which aligns with modern OEM and distributor goals.

Ready to explore your sourcing options? Learn more about Truer’s mission and capabilities on the Über uns seite.

9. How to Order Wholesale HSS Powder from Truer

Truer makes the bulk ordering process convenient for B2B buyers, whether you’re a tooling manufacturer, a distributor, or an additive manufacturer.

Step-by-Step Guide to Placing a Wholesale Order:

| Schritt | Beschreibung |

|---|---|

| 1. Submit Inquiry | Verwenden Sie die Kontakt form to request a quote or sample. Provide details about quantity, grade, and specifications. |

| 2. Technische Konsultation | Truer’s engineering team will assess your needs and recommend the right powder composition or atomization method. |

| 3. Sample Approval (Optional) | For large orders, sample batches can be provided for validation. |

| 4. Confirm Order and Payment | Once terms are agreed, payment and logistics arrangements are finalized. |

| 5. Production and Delivery | Orders are manufactured and packed in compliance with international shipping and safety standards. |

| 6. After-Sales Support | Truer offers ongoing technical support and repeat order facilitation. |

Available Packaging Options:

- 10kg, 25kg, 50kg sealed containers

- Anti-oxidation and moisture-proof packaging

- Custom labeling for OEMs and resellers

Payment & Shipping Methods:

- Payment: T/T, L/C, secure escrow options

- Versand: CIF, FOB, EXW via air or sea freight

For more technical information or to browse powder options, visit Truer’s PM-Pulver Produktseite.

10. FAQs: Buying High-Speed Steel Powder in Bulk

Q1: What HSS powder grades does Truer offer?

Truer provides a wide range of high-speed steel powders including M2, M35, M42, T15, and customized prealloyed grades suitable for both PM and additive manufacturing.

Q2: What is the typical lead time for bulk orders?

Lead times typically range from 2 to 4 weeks for standard grades. Custom compositions may take 4 to 6 weeks depending on the complexity and volume.

Q3: Can I request a custom composition?

Yes, Truer’s R&D team can formulate custom powder blends based on your required mechanical, thermal, or magnetic properties.

Q4: What industries does Truer serve?

Truer supplies to:

- Automobil-OEMs

- Tool and die manufacturers

- Aerospace components makers

- Industrial equipment producers

- Metal 3D printing and additive manufacturing firms

Q5: Does Truer offer international shipping?

Yes, Truer ships globally and supports all major Incoterms (CIF, FOB, EXW). Logistics support includes documentation and customs clearance assistance.

Final Call to Action:

If you’re a B2B buyer, distributor, or OEM looking for a trusted source of high-speed steel powder with technical depth, global reach, and unmatched customizability — Shanghai Truer Technology is your go-to partner.

✅ Request a quote

✅ Ask for a technical consultation

✅ Explore custom powder solutions