1. Einführung in FX-2000-Pulver und seine industrielle Bedeutung

FX-2000-Pulver ist ein Hochleistungs-Hybridstahlpulver, das in der Pulvermetallurgie (PM) und der additiven Fertigung (AM) weit verbreitet ist. Als diffusionslegiertes, vorgemischtes Pulver wurde FX-2000 für Anwendungen entwickelt, die eine hervorragende Festigkeit, Verschleißfestigkeit und Bearbeitbarkeit erfordern. Es ist besonders vorteilhaft für Automobilkomponenten, Zahnradherstellung und Strukturteile, die robuste und wiederholbare mechanische Eigenschaften erfordern.

Warum FX-2000 in der industriellen Fertigung wichtig ist:

- Hohes Leistungs-Kosten-Verhältnis: Bietet nahezu verarbeitete Eigenschaften bei geringeren Verarbeitungskosten.

- Ausgezeichnete Anpassungsfähigkeit: Geeignet für verschiedene Sintertechniken und Mischungsanforderungen.

- Konsistenz in der Massenproduktion: Gewährleistet Dimensionsstabilität und mechanische Festigkeit bei der Herstellung von Großserienteilen.

In der aktuellen Fertigungslandschaft, in der Präzision, Kosteneffizienz und Materialleistung von entscheidender Bedeutung sind, hat sich FX-2000 sowohl für Erstausrüster als auch für Tier-1-Zulieferer zu einer bevorzugten Lösung entwickelt.

2. Anwendungen von FX-2000 in der Pulvermetallurgie und der additiven Fertigung

FX-2000-Pulver kann in zahlreichen Branchen eingesetzt werden, die auf hochfeste, wärmebehandelbare PM-Teile angewiesen sind. Aufgrund seiner hybriden, niedrig legierten Formulierung eignet es sich besonders für Sinterteile mit komplexen Formen und Leistungsanforderungen.

Die wichtigsten Anwendungen von FX-2000-Pulver:

| Industrie | Anwendungsbeispiele | Leistungsanforderungen |

|---|---|---|

| Automobilindustrie | Nockenwellenräder, Synchronisationsnaben, Zahnräder | Hohe Ermüdungsfestigkeit, Verschleißfestigkeit |

| Industrielle Maschinen | Buchsen, Lager, Wellen | Formbeständigkeit, mechanische Haltbarkeit |

| Werkzeuge und Hardware | Präzisionszahnräder, Einsätze, Befestigungselemente | Enge Toleranzen, Bearbeitbarkeit |

| Luft- und Raumfahrt | Strukturelle Halterungen, Gehäuse | Geringes Gewicht, strukturelle Integrität |

Vorteile für die Additive Fertigung:

- Gleichmäßiges Gefüge: Gewährleistet eine gleichbleibende Qualität der Teile.

- Hohe Grünfestigkeit: Ideal für komplexe Formen vor der Sinterung.

- Ausgezeichnete Kompressibilität: Verbessert die Dichte und Festigkeit der Teile.

FX-2000 ist außerdem mit verschiedenen Schmierstoffsystemen und Additiven kompatibel, einschließlich moderner Schmierstoffe wie SUW-8000 und Graphitoptionen wie TBC-400, was seine Vielseitigkeit in kritischen Anwendungen erhöht.

3. Wichtige Eigenschaften und Leistungsmerkmale von FX-2000

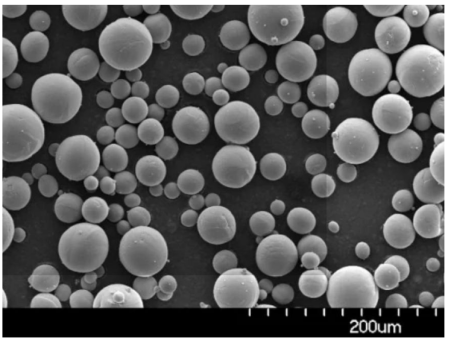

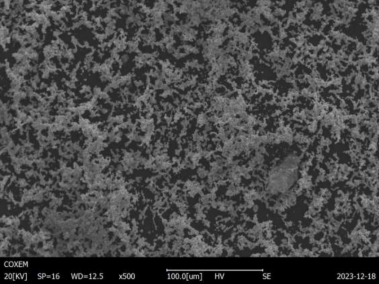

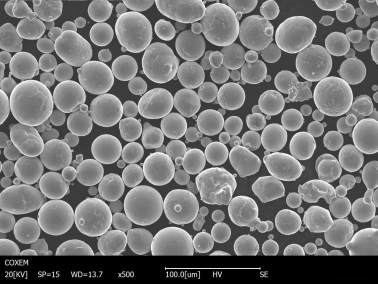

Die Leistung des FX-2000-Pulvers wird durch seine einzigartige hybride, niedrig legierte Zusammensetzung und optimierte Partikelstruktur bestimmt. Es wird durch fortschrittliche Misch- und Diffusionslegierungsverfahren hergestellt und bietet ein ausgewogenes Verhältnis von mechanischer Festigkeit, Kompressibilität und Sinterfähigkeit.

Technische Daten des FX-2000-Pulvers:

| Eigentum | Typischer Wertebereich |

|---|---|

| Partikelgrößenverteilung | 0-150 µm (anpassbar) |

| Scheinbare Dichte | 2.8-3,0 g/cm³ |

| Durchflussmenge (Halle, 50g) | <30 s |

| Grün Dichte (verdichtet) | 6.6-7,1 g/cm³ |

| Gesintert Dichte | 7.0-7,4 g/cm³ |

| Zugfestigkeit (MPa) | Bis zu 900 MPa |

| Härte (HRB) | 80-95 |

Vorteile von FX-2000 in der PM-Produktion:

- ✅ Hohe Maßhaltigkeit nach dem Sintern

- ✅ Ausgezeichnete Härtbarkeit für wärmebehandelte Bauteile

- ✅ Hervorragende Verschleiß- und Ermüdungsfestigkeit

- ✅ Gute Bearbeitbarkeit mit Schneidmitteln wie SME-100

FX-2000 ist in verschiedenen kundenspezifischen Mischungen erhältlich und kann mit den proprietären Additivlösungen von Truer optimiert werden, um anwendungsspezifische Anforderungen zu erfüllen. Truer's Geschäftsbereich Pulvermetallurgie bietet maßgeschneiderte materialtechnische Unterstützung für OEMs und Zulieferer.

4. Aktuelle Marktnachfrage und Trends für Hochleistungs-PM-Pulver

Der FX-2000-Pulvermarkt erfährt ein starkes Wachstum, das durch die zunehmende Einführung der Pulvermetallurgie (PM) und der additiven Fertigung von Metallen (AM) in der Automobilindustrie, der Luft- und Raumfahrt und der Industrie vorangetrieben wird. Da die Hersteller versuchen, die Kosten zu senken und gleichzeitig die Leistung der Teile zu verbessern, steigt die Nachfrage nach hochentwickelten niedrig legierten Pulvern wie FX-2000 weiter an.

Wichtige Markttrends, die die Nachfrage nach FX-2000 antreiben:

- Leichtbauinitiativen in der Automobilindustrie: Die Erstausrüster gehen zu hochfesten, leichten PM-Teilen über, um die Kraftstoffeffizienz zu verbessern und die Emissionsvorschriften zu erfüllen.

- Aufschwung der grünen Produktion: Die niedrige Ausschussrate und der energieeffiziente Sinterprozess von FX-2000 stehen im Einklang mit den Zielen der Nachhaltigkeit.

- Erweiterung von Metal AM: Zunehmende Verwendung von Metallpulvern in 3D-DruckfX-2000 bietet eine kostengünstige Alternative zu hochlegierten Pulvern.

- Anpassungsnachfrage: Die Abnehmer suchen nach maßgeschneiderten Pulverformulierungen, die mit bestimmten Sinterbedingungen und Schmiermitteln kompatibel sind.

Marktprognose (2024-2028):

| Region | CAGR % | Wachstumstreibende Schlüsselsektoren |

|---|---|---|

| Asien-Pazifik | 7.4% | Automobilindustrie, Industriemaschinen |

| Nord-Amerika | 6.2% | Luft- und Raumfahrt, Verteidigung, Werkzeugbau |

| Europa | 5.9% | Automobilindustrie, Erneuerbare Energien |

| Naher Osten/Afrika | 4.5% | Öl & Gas, Schwermaschinen |

Da sich der globale PM-Markt weiter entwickelt, wird die Nachfrage nach zuverlässigen, skalierbaren und hochreinen Pulverquellen wie FX-2000 weiter zunehmen. Daher ist die Auswahl des Lieferanten wichtiger denn je.

5. Wie man einen zuverlässigen FX-2000-Pulverlieferanten auswählt

Die Wahl des richtigen FX-2000-Pulverlieferanten ist entscheidend für die Gewährleistung einer gleichbleibenden Teilequalität, die Verringerung von Produktionsausfällen und die Aufrechterhaltung wettbewerbsfähiger Preise. Für B2B-Einkäufer, insbesondere für diejenigen, die mit engen Produktionsplänen arbeiten, ist eine vertrauensvolle Lieferantenbeziehung ein strategischer Vorteil.

Zu berücksichtigende Schlüsselfaktoren:

- Produktionskapazitäten

- Kann der Lieferant eine Großserienproduktion durchführen?

- Bieten sie sowohl Standard- als auch kundenspezifische Mischungen an?

- Sicherung der Qualität

- ISO-Zertifizierungen (z. B. ISO 9001)

- Interne Tests für Partikelgröße, Fließgeschwindigkeit und Dichte

- Technische Unterstützung

- Bieten sie Hilfestellung bei der Auswahl des Pulvers, beim Mischen und Sintern?

- Können sie kompatible Schmiermittel und Additive empfehlen?

- Zuverlässigkeit der Lieferkette

- Erfolgsbilanz bei pünktlicher Lieferung

- Stabile Beschaffung von Rohstoffen

- After-Sales-Unterstützung

- Fähigkeit zur Fehlerbehebung bei Mängeln oder Unstimmigkeiten

- Bereitschaft zur Anpassung der Formulierungen auf der Grundlage von Rückmeldungen

Vergleichs-Checkliste für die Bewertung von Anbietern:

| Kriterien für die Bewertung | Shanghai Truer | Andere Lieferanten |

|---|---|---|

| ISO-zertifiziertes QA-System | ✅ | Variiert |

| Unterstützung für kundenspezifische Formulierungen | ✅ | ❌ / Begrenzt |

| Pünktliche Lieferung >98% | ✅ | ❌ / Ungewiss |

| Stabilität der Lieferkette | ✅ | ❌ |

| Additives Fachwissen | ✅ | ❌ |

Die Kombination aus materialwissenschaftlichem Know-how, additiven Lösungen und stabiler Logistik macht Shanghai Truer zu einem bevorzugten Lieferanten für Kunden, die ihre Produktion ohne Qualitätseinbußen skalieren wollen.

6. Die besten FX-2000-Pulverlieferanten in Asien

Asien ist die Heimat einiger der fortschrittlichsten und kosteneffizientesten Pulvermetallurgieanbieter der Welt. Die folgenden Anbieter von FX-2000-Pulver sind für ihre technische Innovation, Qualitätskontrolle und Zuverlässigkeit bekannt.

Führende FX-2000-Lieferanten in Asien:

| Name des Unternehmens | Land | Zentrale Stärken |

|---|---|---|

| Shanghai Truer Technology Co, Ltd. | China | Fortschrittliche PM-Zusatzstoffsysteme, kundenspezifische Formulierungen |

| ABC Powder Corp. | Südkorea | PM-Teile in Automobilqualität |

| Nippon PM Industries | Japan | Hochpräzise PM-Pulver |

| Bharat Metall-Pulver | Indien | Wettbewerbsfähige Preise, hohe Stückzahlen |

| Formet PM Technologien | Taiwan | Starke Forschung und Entwicklung, lokale Unterstützung |

Warum Shanghai Truer sich auszeichnet:

- über 10 Jahre PM-Erfahrung

- ✅ Start der Abteilung für additive Fertigung im Jahr 2019

- ✅ Bietet hybride niedrig legierte Pulver wie FX-2000

- ✅ Liefert diffusionslegierte, gas- und wasserzerstäubte Pulver

- ✅ Komplette Additivpalette: Schmiermittel (SUW-8000), Schneidmittel (SME-100), Graphit (TBC-400)

Um mehr über Truer’s Fähigkeiten und Firmenhintergrund zu erfahren, besuchen Sie die offizielle Über uns Seite.

Shanghai Truer ist nicht nur ein Lieferant, sondern ein strategischer Partner für Hersteller, die das volle Potenzial der Pulvermetallurgie ausschöpfen wollen.

7. Warum immer mehr Käufer zu chinesischen FX-2000-Pulverherstellern wechseln

In den letzten Jahren hat eine wachsende Zahl von B2B-Einkäufern, darunter Erstausrüster, Tier-1-Zulieferer und Hersteller von Metallteilen, begonnen, FX-2000 und andere pulvermetallurgische Materialien von chinesischen Herstellern zu beziehen. Diese Verlagerung ist weitgehend auf die verbesserte Qualität der chinesischen Produktion, wettbewerbsfähige Preise und die Möglichkeit, maßgeschneiderte Formulierungen in großem Umfang anzubieten, zurückzuführen.

Hauptgründe, warum B2B-Einkäufer chinesische Lieferanten wählen:

- Kosteneffizienz ohne Kompromisse bei der Qualität

Chinesische Hersteller bieten dank optimierter Produktionslinien, niedrigerer Arbeitskosten und der Verfügbarkeit von Rohstoffen Pulver zu wettbewerbsfähigen Preisen an. - Fortgeschrittene Fertigungskapazitäten

Führende Anbieter wie Shanghai Truer verwenden Gaszerstäubung, Wasserzerstäubung und hybride Verfahren zur Herstellung von Pulvern, die internationale Standards erfüllen oder übertreffen. - Anpassung und technische Unterstützung

Chinesische Anbieter bieten oft flexiblere Anpassungsdienste an, einschließlich der Beimischung von speziellen Schmiermitteln (z. B. SUW-8000) oder Graphitsystemen (TBC-400) in die Pulvermischung. - Schnellerer Turnaround und skalierbares Angebot

Dank starker Logistiknetze und großer Produktionskapazitäten können chinesische Zulieferer enge Fristen für Großaufträge einhalten.

Zeugnis des Käufers:

"Wir sind für unseren Bedarf an FX-2000-Pulver zu Shanghai Truer gewechselt und konnten die Materialkosten um 12 % senken, während wir die Leistung der Teile beibehalten - und in einigen Fällen sogar verbessern - konnten. Der technische Support und die Liefertreue waren hervorragend."

- Beschaffungsmanager, Tier-1 Automobilzulieferer

Angesichts des sich verschärfenden globalen Wettbewerbs ist die Beschaffung aus China nicht mehr nur ein kostensparender Schritt, sondern ein strategischer Vorteil für Hersteller, die sowohl auf Leistung als auch auf Gewinnspannen Wert legen.

8. Warum sollten Sie Shanghai Truer Technology Co. als Ihren FX-2000-Lieferanten wählen?

Die Shanghai Truer Technology Co., Ltd. hat sich schnell einen Namen als zuverlässiger Marktführer in der Pulvermetallurgiebranche gemacht. Seit der Gründung seiner Abteilung für additive Fertigung im Jahr 2019 ist Truer zu einem wichtigen Partner für FX-2000-Pulverkäufer in Asien, Europa und Nordamerika geworden.

Highlights des Unternehmens:

- 🌍 Gegründet im Jahr 2009; Start der Abteilung Additive im Jahr 2019

- 🧪 Bietet umfassende PM-Pulverlösungen, einschließlich hybrider niedrig legierter Stähle wie FX-2000

- ⚙️ Verwendet fortschrittliche Zerstäubungsmethoden: Gas, Wasser und Hybrid

- 🔧 Internes Fachwissen über PM-Zusatzstoffe: SUW-8000, SME-100, QH-150, TBC-400

- 📦 Flexibles MOQ und globale Versandoptionen

- 📞 Engagierte technische Unterstützung bei der Optimierung der Formulierung

FX-2000 Powder Eigenschaften von Truer:

| Merkmal | Nutzen für den Käufer |

|---|---|

| Hybride niedrig legierte Zusammensetzung | Hohe Festigkeit, gute Bearbeitbarkeit |

| Diffusionslegiert | Konsistente Leistung der Teile |

| Kompatibel mit Zusatzstoffen | Schmiermittel & Graphit für präzise Abstimmung |

| Anpassbare Mischungen | Maßgeschneidert für Ihre Sinterumgebung |

| Wettbewerbsfähige Preise | Ideal für die Großserienproduktion |

Um die gesamte Palette der verfügbaren PM-Pulver zu entdecken, besuchen Sie Truer's PM-Pulver Produktseite.

Egal, ob Sie in der Automobilindustrie, im industriellen Werkzeugbau oder im Maschinenbau tätig sind, Truer bietet Ihnen sowohl das Produkt als auch die Partnerschaft, um Sie bei der effizienten und sicheren Skalierung zu unterstützen.

9. FAQ: Häufige Fragen zum Kauf von FX-2000-Pulver im Großhandel

Q1: Was ist die Mindestbestellmenge (MOQ) für FX-2000 Pulver von Shanghai Truer?

A: Das MOQ beginnt in der Regel bei 100 kg, aber für F&E- oder Pilotproduktionsprojekte sind flexible Vereinbarungen möglich.

F2: Kann Shanghai Truer die Formulierung des FX-2000 anpassen?

A: Ja, Truer bietet maßgeschneiderte Mischungen mit kompatiblen Additiven (z. B. SUW-8000, SME-100, TBC-400) an, die Ihren spezifischen Anwendungsanforderungen entsprechen.

F3: Was ist die typische Vorlaufzeit für Großhandelsaufträge?

A: Die Standardvorlaufzeit für die meisten Bestellungen beträgt 2 bis 3 Wochen, wobei je nach Lagerbestand und Lieferort auch eine beschleunigte Lieferung möglich ist.

F4: Ist während der Test- und Integrationsphase technische Unterstützung verfügbar?

A: Unbedingt. Truer bietet spezielle technische Unterstützung bei der Auswahl des Pulvers, der Verdichtungsparameter und der Optimierung des Sinterprozesses.

F5: Wo kann ich Unternehmenszertifizierungen und Qualitätskontrollprotokolle einsehen?

A: Mehr über die Fähigkeiten und Zertifizierungen von Truer erfahren Sie auf der Website Über uns Seite.

F6: Wie kann ich eine Großhandelsbestellung aufgeben oder ein Muster anfordern?

A: Sie können ein Angebot einholen oder Muster anfordern über die Kontakt Seite. Ein Vertriebsingenieur wird innerhalb von 24 Stunden antworten.

Sind Sie bereit, Hochleistungs-FX-2000-Pulver zu beziehen?

Die Shanghai Truer Technology Co., Ltd. ist Ihr zuverlässiger Partner für die Beschaffung von hochwertigem FX-2000-Pulver in großem Maßstab. Ganz gleich, ob Sie Standardformulierungen oder kundenspezifische Mischungen mit fortschrittlichen Additiven benötigen, Truer liefert Leistung, Präzision und Partnerschaft.

👉 Entdecken Sie unsere gesamte Produktpalette auf der PM-Pulver-Seite

📩 Kontaktieren Sie uns direkt über unser Kontakt Seite

📦 Fordern Sie noch heute ein Angebot oder ein Muster an und erleben Sie den Truer-Vorteil.

🔗 Zusammenfassung der internen Ankerlinks

| Ankertext | Ziel-URL |

|---|---|

| Geschäftsbereich Pulvermetallurgie | https://am-material.com/pm-powder/ |

| Über uns Seite | https://am-material.com/about/ |

| PM-Pulver Produktseite | https://am-material.com/pm-powder/ |

| Kontakt Seite | https://am-material.com/contact-us/ |

| vollständige Produktpalette | https://am-material.com/pm-powder/ |